Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Framo Ballast Operation Manual

Cargado por

spamalstublieft1832Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Framo Ballast Operation Manual

Cargado por

spamalstublieft1832Copyright:

Formatos disponibles

Framo Submerged Ballast Pumps

No. 1000-0199-4

Rev. A 27Oct09

Operation manual

SB200 SB300 SB400 SB600

Framo Submerged Ballast Pumps OPERATION MANUAL

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 2 of 13 27Oct09/AGAa

CONTENTS

1 2 GENERAL DESCRIPTION ................................ ................................ ............................. 2 OPERATING INFORMATION................................ ................................ ......................... 5

2.1 Ballasting / deballasting ................................................................................ 5 2.2 Cofferdam control ......................................................................................... 8

3 4 MAINTENANCE INFORMATION ................................ ................................ .................. 11 TROUBLE SHOOTING ................................ ................................ ................................ 11

Reference to associated instructions 1000-0109-4: Interchange of pump control valve 1375-0027-4: Service manual for Speed Torque Controller (STC)

1 GENERAL DESCRIPTION

The Framo hydraulically driven submerged ballast pump consists of five main parts: - Pump casing/ air separator - Pump head - Pipe stack - Top plate/Control valves - Evacuation system Figures in this procedure are made general for all types of submerged ballast pumps. For further information, see drawings for the actual ballast pump.

Pump casing / Air Separator

The pump casing is bolted to a foundation. Air entering the pump through the suction line will be separated in the air separator and removed by the evacuation system.

Pump head

The pump head includes the hydraulic motor, impeller and sealing arrangement. A cofferdam completely segregates the hydraulic oil from the ballast water. The cofferdam is filled with water/glycol.

Pipe stack

The pipe stack consists of a hydraulic section and an arrangement with pipe and cable for the evacuation system. Supports on the pipe stack prevent horizontal movement and allow for vertical expansion.

Top plate/ Control valves

The pipe stack penetrates the top plate. A sealing arrangement between top plate and pipe stack allows the pipe stack to expand. The pump control valve STC(Speed Torque Controller) and evacuation control unit and header tank is located at the top plate.

Framo Submerged Ballast Pumps OPERATION MANUAL

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 3 of 13 27Oct09/AGAa

Fig. 1

Framo Submerged Ballast Pumps OPERATION MANUAL Evacuation system

The evacuation system starts if it is air in the pump casing. The system is automatically activated by the level switch (conductive type with intrinsically safe circuit [EExia]). If there is air in the pump casing the level switch will be dry. Then the ejector will start evacuation the pump casing and suction piping (priming on). When the water level again reaches the level switch, the ejector will stop. Illuminated lamp on the pump control panel indicates that the evacuation system is in operation. In this running mode, reduce pump capacity to obtain an improved suction performance. Note! The evacuation system is only activated when pump control is switched on.

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 4 of 13 27Oct09/AGAa

Fig. 2

The evacuating capacity for the air driven ejector is given in fig. 3.

Vacuum (mwc)

Priming with 7 bar air supply pressure to ejector

-8 -6

S

0 B4

0 60 0/

0 0/3 20 B S

With an air supply pressure of 7 bar to the ejector, the air consumption will be;

For SB200 and SB300 pumps: 1.1 Nm /min (18 Nl/sec) 3 For SB400 and SB600 pumps: 2.9 Nm /min (49 Nl/sec) 3 3 (Nm = normal m )

3

-4 -2

Volume 1 m3

20

40 60 80 Time (seconds)

100

120

140

Fig. 3 Curve indicating vacuum in a 1 m 3 volume (suction line) versus priming time.

Framo Submerged Ballast Pumps OPERATION MANUAL

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 5 of 13 27Oct09/AGAa

OPERATING INFORMATION

Hydr. motor

To get maximum lifetime of the pumps, operate the pumps within the operation range (ref. fig. 8). When starting ballasting, the ballast water will normally gravitate through the ballast piping system. Keep suction valve and discharge valve closed and open by-pass valve, to avoid gravitation through the ballast pump (ref. fig.4). Note! The ballast water must not gravitate through the pump, as this may damage the hydraulic motor.

Valve, open = Valve, closed =

Suction

WBP

Discharge

Bypass

Fig. 4 Water gravitating through the ballast piping system.

2.1 Ballasting / deballasting

As the flow caused by gravitation decreases, the pump has to be started to increase the capacity. - Check that the hydraulic system is started and enough hydraulic power is available. - Check that pressurized air for evacuation system is available. Note! HP service valve (fig. 1) should always be open except when carrying out service work on the pump.

Starting of pump

Open ballast pump suction valve. Start the pump slowly, and let it run with hydraulic motor pressure 50 bar for approx. 1 minute.

Fig. 5

Close bypass valve, open discharge valve and increase hydraulic motor pressure until required capacity is achieved. Note! Avoid running pumps against closed discharge valve for a longer period.

Fig. 6

Framo Submerged Ballast Pumps OPERATION MANUAL Pumping

The ballast pump is designed to operate with discharge head between 20 and 30 mlc (design head). When running pump at low discharge head and high motor pressure, the capacity will be higher than normal. This may lead to heavy vibrations and damage to the pump. There are two ways to bring the pump back to the operation range: a) b) Reduce speed / hydraulic motor pressure. Throttle the discharge valve.

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 6 of 13 27Oct09/AGAa

Fig. 7 Limit of operation

ress ur

e

Head H

1 00 % m o to r p

75%

Pressure loss, throttle discharge valve

b

50% OPERATION RANGE

Pressure loss discharge system

Capacity Q Fig. 8 Note! Performance diagram for the actual pump gives the operation range

End of deballasting

With low water level in the ballast tank, the pump capacity must be reduced to avoid loss of suction. An gradually increasing amount of air will enter the pump suction line via the vortex forming at the suction bell mouth. Air will accumulate in the pump casing (air separator) and the evacuation system will eventually be activated priming light in control panel switched on. The pump capacity must be reduced to match the water inflow to the suction bell mouth area (the inflow is depending of the tank layout, opening in stiffeners etc.). This is most critical when emptying a ballast tank furthest away from the pump.

Fig. 9 End of deballasting (ship in aft trim condition)

Framo Submerged Ballast Pumps OPERATION MANUAL Stopping the pump

When the ballast tank is empty, the pump will lose suction. The evacuation system will be operating continuously, indicated by the priming lamp on the control panel. Close the discharge valve, and stop the pump. Close the suction valve. Note! Do not run the pump unnecessary when the pump loses suction.

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 7 of 13 27Oct09/AGAa

Fig. 10

Operation of pump from local control valve

The ballast pump can be operated from the local control valve at the STC valve. Open local control valve by turning counter-clockwise. Set the remote control handle in the maximum position. Start the pump by closing the local control valve by turning clockwise. Run the pump as described for remote controlled operation.

300 225 150 75 0

Handle in maximum position

Local control valve, OPEN

BAR

ON

Priming activated

Fig. 11

Framo Submerged Ballast Pumps OPERATION MANUAL

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 8 of 13 27Oct09/AGAa

2.2 Cofferdam control

The pump hydraulic section is surrounded by the liquid filled cofferdam that completely segregates the hydraulic oil from the ballast. Static overpressure in the cofferdam gives clean cofferdam liquid to the seal faces and lubrication of these. Condition monitoring of the shaft seal arrangement is carried out by surveillance of the liquid level in the header tank. Clean and correct type of cofferdam liquid is important in Fill glycol water order to get a long lifetime of the shaft seal arrangement.

Remove cap Header tank

Cofferdam liquid:

Upper bleed plug cofferdam

- Demineralized water: - Glycol * Freezing point

40 60 -40C

50 % 50 %

- -35C

* Propylene glycol, C3H8O2 (monopropylene glycol, 1.2 propanediol, propanediol) or ethylene glycol, C2H6O2 (monoethylene glycol, 1.2 ethanediol, ethanediol) Propylene glycol is less toxic and less corrosive than ethylene glycol. Therefore, Framo recommend propylene glycol to be used.

Lower bleed plug cofferdam (toolbox)

Use only pure glycol without additives. Note! Think safety and health. Read the Material Safety Data Sheet before using the different glycol. Note! Never use other anti-freeze solutions. Some of the additives in anti-freeze forms deposits on seal parts and thereby causing seals to fail. Glycol is added to prevent freezing. If no danger of frost, the cofferdam can be filled with demineralized water without glycol.

Seal arrangement

Mechanical oil seal Hydraulic return oil Pressure 3 - 10 bar Cofferdam Chamber Water/glycol Pressure 1 - 2,5 bar Ballast Pressure 0 - 2,5 bar static head Mechanical sea water seal

Filling sequence:

- Hydraulic oil filling of pump must be done before cofferdam is filled. - Remove the cap on header tank and fill the cofferdam liquid through the header tank. - Air in cofferdam must be released during filling. When filling pump head, vent through the lower bleed plug (fig. 12). Pipe stack to be ventilated through the upper bleed plug. - Fill the cofferdam until liquid level stabilises at normal level on the sight glass (halfway between low and high level mark).

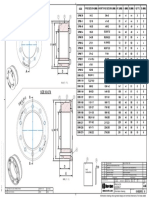

Fig. 12

The cofferdam volume depends on pump type and pump length. The following formulas give approx. volume (in litres) required to fill cofferdam to normal level in header tank: Pump type SB200 SB300 SB400 SB600 Pump head 2,5 80 95 125 Pipe stack L x 0,5 L x 3,5 L x 3,5 L x 3,5 Header tank 5 7 7 7 Total 7,5 + (L x 0,5) 87 + (L x 3,5) 102 + (L x 3,5) 132 + (L x 3,5)

L = Pump length in metres. (See Framo specification)

Framo Submerged Ballast Pumps OPERATION MANUAL Monitoring of cofferdam level

We recommend regular control of the cofferdam level.

High level

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 9 of 13 27Oct09/AGAa

The liquid level in the header tank varies with the temperature of the ballast water, hydraulic oil and ambient temperature. Figure 13 indicates normal level variations for the different pump types with a temperature change of 10C on the cofferdam liquid for the different pump types.

Low level

Normal level variations depends on pump type and pump length. Figure indicates normal level variations with 10 oC temperature variation on cofferdam liquid.

Fig. 13

Because of level changes due to temperature variations, the level should always be monitored at the same temperature, i.e. at normal operating temperature. The header tank level(H) to be measured in mm above low level mark on sight glass. By using the enclosed log form (page 12), it is possible to establish a trend towards increasing or decreasing level. The filled in example below indicates how to use the log form. Leakage rate (to be calculated) =

(H 2 H1 )x31 [ml/h]

h

Framo Submerged Ballast Pumps OPERATION MANUAL

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 10 of 13 27Oct09/AGAa

EVALUATION OF CHANGES IN LIQUID LEVEL IN HEADER TANK

When pump is not running, the leakage rate from the mechanical seals is very low (up to 0,1 ml/h). Therefore increasing or decreasing level due to leakages from mechanical seals should not be expected when pump is not in operation. Changes in liquid level Sudden decrease Decreasing level (Leak from pump cofferdam to ballast tank) Possible reason Can indicate that it is air in the cofferdam system, which most likely occurs in the first period after initial water/glycol filling or complete refill after service. Different temperature compared to the previous measurement (temperature of the ballast water, hydraulic oil and ambient temperature), ref. fig.13. When pump is running the normal leakage rate can be up to 20 ml/h from the mechanical sea water seal. This will give a decreasing level in header tank of up to approx. 0,65 mm/h, i.e 65 mm per 100 running hours. For a shorter periode of time, higher leakage peaks can occur. Abnormal decreasing level over a period of time indicate a worn out mechanical sea water seal, see chapter 4, Trouble shooting. Increasing level (Hydraulic oil leak into pump cofferdam) Different temperature compared to the previous measurement (temperature of the ballast water, hydraulic oil and ambient temperature), ref. fig.13. Normal leakage rate can be up to 5 ml/h from the mechanical oil seal. This will give a increasing level in header tank of up to approx. 0,16 mm/h, i.e. 16 mm per 100 running hours. For a shorter periode of time, higher leakage peaks can occur. A continous leakage rate > 20 ml/h or a sudden increasing level in header tank indicate a worn out mechanical oil seal, and overhauling may be necessary (ref. chapter 4, Trouble shooting). IN CASE OF ANY DOUBT, please contact Frank Mohn Services AS for assistance. If the level drop under low level, refill the header tank. Log the volume.

Drain off and log volume

If level exceed high level, the header tank must be drained. Volume and amout of oil must be logged. Empty the header tank by draining through the cofferdam bleed plug, see fig. 15. Refill the header tank.

Bleed plug cofferdam Layer of oil

High level

High level

Hose (toolbox)

Water/ glycol

Low level

Refill and log volume

Low level

Fig. 14

Fig. 15

Framo Submerged Ballast Pumps OPERATION MANUAL

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 11 of 13 27Oct09/AGAa

3 MAINTENANCE INFORMATION

Prior to entering a ballast tank for doing service it is essential to become familiar with the ship's safety rules and requirements regarding cargo-handling equipment. Do not enter a ballast tank before the tank is confirmed gas free. Before doing service on pump, always close and lock the HP service valve. Close the ballast valves (suction line and discharge line). Ensure that the valves are in closed position until the work/service is finished (info sign to be placed on the control panel/computer). Before starting to dismantle impeller, wear rings etc., make sure that pipe stack/ pump head is secured properly in order not to drop down when work is in progress. Note! To prevent contamination and hazardous situations it is important to avoid oil spill during maintenance and repair work. Drain in accordance with procedures ( Instruction for maintenance and repair for actual pump). The operator should be confident that all flange connections are in satisfactory condition so as to prevent hydraulic oil and cargo spills. After any work has been carried out in the ballast tank, always check that the tank is free for foreign objects.

TROUBLE SHOOTING

Symptom:

Ballast pump operational problem (First it is necessary to verify if the problem is in the pump control system or in the pump head itself). The pump will not start

Possible reason:

General

Remedy: *)

Ref. system service manual - Trouble shooting section

a) Ballast pump remote control system failure b) Pump control valve failure c) Pump impeller stuck. c1)Foreign objects stuck in pump or other mechanical problem

a) Ref. instruction for Remote control system b) Ref. Instruction for Pump control valve STC c1)Pump head to be inspected. a) Ref. instr. for Pump control system. b) Impurities stuck in impeller or other mechanical problem. a) Ref. instr. for Pump control system and instr. for Pump control valve. (If required interchange pump control valve as described in instr. 1000-0109-4) b) Pump head to be inspected

Pump is vibrating heavily

a) Control system problem b) Rotating parts out of balance.

Too low pumping capacity

a) Control system problem

b) Worn wear rings. Impurities stuck in impeller, or other mechanical problem

*) Ref. instruction for maintenance and repair for actual pump.

Framo Submerged Ballast Pumps OPERATION MANUAL

No. Date/sign.: Page: Rev.A :

1000-0199-4 20Sep07/HB 12 of 13 27Oct09/AGAa

Symptom:

Decreasing level in header tank. (See also chapt. 2.2)

Possible reason:

General Note! Always pressure test pump prior to and after dismantling. This is required to locate possible leakage and to confirm no leakage upon completion of repair.

Remedy: *)

Log level in header tank for a periode of time. Evaluate the changes (see chapt. 2.2). Pressure test pump cofferdam system at approx. 3 bar. Check for leakage if required spray with soapy water to locate the leakage. Note! For inspection of pump head / shaft seal it is required to lift pump out of pump casing prior to pressure test, see instruction for maintenance and repair. a) Replace mechanical seawater seal. (replaced seal to be reconditioned if feasible) b) Check for loose bolts and for pitting corrosion in seal faces in case of corrosion repair is required. Assemble using new seal element. c) Contact a Framo Service Station Log level in header tank for a periode of time. Evaluate the changes (see chapt. 2.2). Pressurize pump return side at approx 4 bar and check for and locate the leakage. Note! For inspection of shaft seal area it is required to lift pump out of pump casing prior to pressure test, see instruction for maintenance and repair.

a) Worn mechanical sea water seal b) Leaking seal element in flange connection

c) Crack in piping Increasing level in header tank. (See also chapt. 2.2) General

a) Leaking mechanical oil seal b) Leaking seal element in flange connection(s).

a) Replace mechanical oil seal (replaced seal to be reconditioned if feasible) b) Check sealing surface for possible damage repair if damaged. Assemble using new seal element. c) Contact Framo Service Station

c) Crack in piping The ejector do not start

Signal from ballast tank level Stop the pump and check level switch and switch not detected. related wiring to control panel. Signal from ballast tank level Stop the pump and check level switch and switch not detected. related wiring to control panel.

The ejector do not stop

*) Ref. instruction for maintenance and repair for actual pump.

Note! Evaluate if changed parts as sleeves, mechanical seals etc. are possible to recondition. Send these parts to Framo Service Station and ask for an evaluation

No. 1000-0199-4 Page 13 of 13 Rev. A 27Oct09/AGAa

LOG FORM FOR LIQUID FILLED COFFERDAM ON FRAMO SUBMERGED BALLAST PUMPS

VESSEL NAME: ____________________________________ TYPE OF LIQUID USED IN COFFERDAM: __________________________________

Header tank level(H) to be measured in mm above low level mark on sight glass. 1 mm on sight glass is equivalent to 31 ml volume. Pump location (P or S) Date Header tank level (H) (mm) Ballast water temperature (C) Hydraulic oil temperature (C) Ambient temperature (C) Hours of operation since last control (h) Leakage rate (ml/h )* Comments / Remarks (Action taken)

Signature / Date

*Leakage rate (to be calculated) =

(H 2 H1 )x31

h

[ml/h]

Also ref. chapter 2.2, Monitoring of cofferdam level

También podría gustarte

- Operation Manual for Framo Cargo Pumps SD100-SD350Documento20 páginasOperation Manual for Framo Cargo Pumps SD100-SD350Viijaay Nehra100% (1)

- Operation Manual for Framo Submerged Ballast PumpsDocumento13 páginasOperation Manual for Framo Submerged Ballast PumpsKamal වන්නි ஆரச்சி100% (1)

- Operation Manual for Framo Cargo PumpsDocumento16 páginasOperation Manual for Framo Cargo PumpsOana Pavel91% (11)

- FramoDocumento128 páginasFramoadi mer100% (1)

- SB300 T 1000-0163-4 PDFDocumento19 páginasSB300 T 1000-0163-4 PDFJagmohan SinghAún no hay calificaciones

- Framo Cargo Pump 1000-0131-4Documento22 páginasFramo Cargo Pump 1000-0131-4vdeviv100% (5)

- HPCE Dynamis 500+ Operations ManualDocumento24 páginasHPCE Dynamis 500+ Operations Manualods13 FilAún no hay calificaciones

- New 01 MZG s3 Ng30 ServiceDocumento108 páginasNew 01 MZG s3 Ng30 ServiceHemraj Singh Rautela100% (6)

- 380j-3 Merine Diesel Engine Set Parts CatalohueDocumento46 páginas380j-3 Merine Diesel Engine Set Parts Catalohuemavericksailor50% (6)

- Marine Control BlockDocumento13 páginasMarine Control BlockEng-Mohammed SalemAún no hay calificaciones

- Framo Pressure System Adjustment GuideDocumento8 páginasFramo Pressure System Adjustment GuideGonçalo Cruzeiro100% (2)

- Hydraulic Top BracingDocumento8 páginasHydraulic Top BracingAnonymous alQXB11EgQAún no hay calificaciones

- ODME ExplainationDocumento36 páginasODME ExplainationRachit Srivastava100% (2)

- Manual SC30TDocumento60 páginasManual SC30Tdetrusitol73% (15)

- FramoDocumento175 páginasFramoADЯIEN BЯE100% (5)

- Failure of Inert GasDocumento3 páginasFailure of Inert GasVarun Agrawal100% (2)

- K.C. LTD. ANTI-FOULING SYSTEM MANUALDocumento20 páginasK.C. LTD. ANTI-FOULING SYSTEM MANUALShivraj Naik100% (2)

- Instruction Manual GLB3026!2!2426gr Crane1-4Documento293 páginasInstruction Manual GLB3026!2!2426gr Crane1-4Jan Ernst Depacto83% (6)

- Framo Cargo Pumps MaintenanceDocumento6 páginasFramo Cargo Pumps MaintenanceOsman ŞenerAún no hay calificaciones

- A step-by-step guide to operating ODMEDocumento27 páginasA step-by-step guide to operating ODMEJOSEPH DIAS100% (1)

- Framo Service ManualDocumento210 páginasFramo Service ManualGonçalo CruzeiroAún no hay calificaciones

- TTS 80524-27 Englisch Operating Instruction+Spare Parts List PDFDocumento694 páginasTTS 80524-27 Englisch Operating Instruction+Spare Parts List PDFHemraj Singh Rautela100% (3)

- Vapour Drop CalculationsDocumento11 páginasVapour Drop Calculationskneller100% (1)

- Framo Instruction and Service ManualDocumento16 páginasFramo Instruction and Service Manualerol100% (1)

- TTS Crane User Manual 11857-Rev.2Documento256 páginasTTS Crane User Manual 11857-Rev.2armagan100% (3)

- ODME Test Procedures ColorDocumento3 páginasODME Test Procedures ColorMarshn man100% (2)

- Framo Submersible Cargo Pump System: - Janmenjay M Sawant (17ge1557)Documento16 páginasFramo Submersible Cargo Pump System: - Janmenjay M Sawant (17ge1557)sachinAún no hay calificaciones

- Crane-4 LC3527 3029.5-2Documento552 páginasCrane-4 LC3527 3029.5-2cengiz kutukcuAún no hay calificaciones

- ALFA LAVAL - PureBallast 3.1 - BALLAST WATER TREATMENT SYSTEM PDFDocumento196 páginasALFA LAVAL - PureBallast 3.1 - BALLAST WATER TREATMENT SYSTEM PDFAleksandrAún no hay calificaciones

- Automatic Unloading SystemDocumento3 páginasAutomatic Unloading Systemnirmalgupte22Aún no hay calificaciones

- Steering Gear PDFDocumento231 páginasSteering Gear PDFKaushalKishore100% (1)

- Consilium Datasheet Uk St650exDocumento7 páginasConsilium Datasheet Uk St650exFreddy CantorAún no hay calificaciones

- SCANJET General Instruction SC 45TW PDFDocumento40 páginasSCANJET General Instruction SC 45TW PDFpescarra-1Aún no hay calificaciones

- Risk Assessment Checklist - Use of Vlsfo Without Lab Analysis Report - 2022-12-20 - 16-29-43Documento2 páginasRisk Assessment Checklist - Use of Vlsfo Without Lab Analysis Report - 2022-12-20 - 16-29-43ARUN100% (1)

- Grab SMAGDocumento77 páginasGrab SMAGMihailov Alexandru90% (10)

- 13-Framo Submerged Cargo Pump-Purging RoutineDocumento12 páginas13-Framo Submerged Cargo Pump-Purging Routinepillainaveen100% (1)

- AalborgDocumento61 páginasAalborgChristopher King50% (2)

- Troubleshooting Guide for GL Cranes CC2000/CC3000 SystemsDocumento6 páginasTroubleshooting Guide for GL Cranes CC2000/CC3000 SystemsAllen Anyayahan100% (1)

- 09 - Cargo Heating - Operational Advice PDFDocumento4 páginas09 - Cargo Heating - Operational Advice PDFrpichoAún no hay calificaciones

- Framo Cargo Pumps As.cDocumento9 páginasFramo Cargo Pumps As.cPawan KumarAún no hay calificaciones

- ATLAS CYLINDER LUBRICATOR MANUALDocumento36 páginasATLAS CYLINDER LUBRICATOR MANUALKaleb Z king webAún no hay calificaciones

- Starting Air Distributor: Plate 90703-0086Documento2 páginasStarting Air Distributor: Plate 90703-0086Roshan RamachandranAún no hay calificaciones

- Framo PumpDocumento13 páginasFramo PumpHarbinder Singh100% (4)

- Framo Cargo Pumping System BrochureDocumento17 páginasFramo Cargo Pumping System BrochureAdrian Cristian100% (2)

- ODMEDocumento42 páginasODMEThirawat Thitisitthikorn100% (2)

- Tie BoltsDocumento31 páginasTie BoltsMuhammad Nasim AbbasAún no hay calificaciones

- YOOWON-MITSUBISHI Electro-Hydraulic Steering Gears FeaturesDocumento20 páginasYOOWON-MITSUBISHI Electro-Hydraulic Steering Gears FeaturesViliame D Roqica100% (1)

- 0324 - L - KaMeWa Controllable Pitch Main PropellersDocumento290 páginas0324 - L - KaMeWa Controllable Pitch Main Propellersvmike6350% (6)

- tfc02 PDFDocumento22 páginastfc02 PDFAniigiselaAún no hay calificaciones

- OMD - 24 - E. DECKMA HAMBURG Gmb.Documento30 páginasOMD - 24 - E. DECKMA HAMBURG Gmb.ИгорьAún no hay calificaciones

- 12 Peiner Grab Accessories Service 130124-MinDocumento114 páginas12 Peiner Grab Accessories Service 130124-MintrobasAún no hay calificaciones

- Acetylene: Drew MarineDocumento12 páginasAcetylene: Drew MarineGeorge RadulescuAún no hay calificaciones

- Operation Manual for Framo Submerged Ballast PumpsDocumento13 páginasOperation Manual for Framo Submerged Ballast PumpskokiAún no hay calificaciones

- RTAA 100 Ton Compressor Lip Seal FailuresDocumento4 páginasRTAA 100 Ton Compressor Lip Seal FailuresWidya Putra100% (1)

- Brio 2000 Owner's ManualDocumento16 páginasBrio 2000 Owner's ManualbinjibrilAún no hay calificaciones

- Operation Manual for Framo Submerged Ballast PumpsDocumento13 páginasOperation Manual for Framo Submerged Ballast PumpsNay LinAún no hay calificaciones

- CAMERON France S.A.S: Front SheetDocumento24 páginasCAMERON France S.A.S: Front SheetkrishnsgkAún no hay calificaciones

- Portable Cargo Pump TK80 Simillar To Marflex Portable PPDocumento18 páginasPortable Cargo Pump TK80 Simillar To Marflex Portable PPSubramoniam MarineAún no hay calificaciones

- DP 3102013Documento20 páginasDP 3102013lifemillion2847Aún no hay calificaciones

- Naiyanad Songbandid - Masterthesis - LNG TRANSPORTATION CHAIN - AN INTERPRETED RISK ASSESSMENT FROM SHIP TO END USERDocumento146 páginasNaiyanad Songbandid - Masterthesis - LNG TRANSPORTATION CHAIN - AN INTERPRETED RISK ASSESSMENT FROM SHIP TO END USERspamalstublieft1832Aún no hay calificaciones

- SVH DW Datasheet WebDocumento2 páginasSVH DW Datasheet Webspamalstublieft1832Aún no hay calificaciones

- Hamworthy Cargo Pump Manual PDFDocumento140 páginasHamworthy Cargo Pump Manual PDFspamalstublieft1832Aún no hay calificaciones

- Low Temperature Metals A. HurlichDocumento15 páginasLow Temperature Metals A. Hurlichspamalstublieft1832Aún no hay calificaciones

- 2018 10 TE CNG and LNG For Vehicles and Ships The Facts enDocumento72 páginas2018 10 TE CNG and LNG For Vehicles and Ships The Facts enspamalstublieft1832Aún no hay calificaciones

- Claw Couplings DIN 3489 / DIN 3238: of Stainless Steel 1.4401Documento1 páginaClaw Couplings DIN 3489 / DIN 3238: of Stainless Steel 1.4401spamalstublieft1832Aún no hay calificaciones

- Brochure o Pumps Pre Docking InspectionDocumento2 páginasBrochure o Pumps Pre Docking Inspectionspamalstublieft1832Aún no hay calificaciones

- SVANEHØJ Deepwell Cargo Handling SystemsDocumento8 páginasSVANEHØJ Deepwell Cargo Handling Systemsspamalstublieft1832Aún no hay calificaciones

- DW Fuel Pump Cryosump Data SheetDocumento2 páginasDW Fuel Pump Cryosump Data Sheetspamalstublieft1832Aún no hay calificaciones

- Brochure Energy Solutions 2017Documento59 páginasBrochure Energy Solutions 2017spamalstublieft1832Aún no hay calificaciones

- Corrosion: Galvanic Corrosion: DefinitionDocumento4 páginasCorrosion: Galvanic Corrosion: Definitionspamalstublieft1832Aún no hay calificaciones

- Ptfe HandbookDocumento38 páginasPtfe Handbookparthihce100% (1)

- Butterworth Filter DesignDocumento0 páginasButterworth Filter DesignAnkit ChudrahiAún no hay calificaciones

- Nickel Al Bronze Guide Engineers PDFDocumento100 páginasNickel Al Bronze Guide Engineers PDFSenakeAún no hay calificaciones

- Roxtec SPMDocumento1 páginaRoxtec SPMspamalstublieft1832Aún no hay calificaciones

- Surface RoughnessDocumento23 páginasSurface Roughnesswawawa1Aún no hay calificaciones

- Vibration-Damping Elements: Rubber and Steel or Stainless SteelDocumento7 páginasVibration-Damping Elements: Rubber and Steel or Stainless Steelspamalstublieft1832Aún no hay calificaciones

- Form, Orientation, Profile, and Runout TolerancesDocumento33 páginasForm, Orientation, Profile, and Runout Tolerancesspamalstublieft1832Aún no hay calificaciones

- Seaclean Plus 25 LTRDocumento12 páginasSeaclean Plus 25 LTRspamalstublieft1832Aún no hay calificaciones

- Coefficient of Friction Equation and Table ChartDocumento3 páginasCoefficient of Friction Equation and Table Chartspamalstublieft1832Aún no hay calificaciones

- Specifications 316 LDocumento26 páginasSpecifications 316 LAlmir PendekAún no hay calificaciones

- WILDEN Pump XPS430 StainlessDocumento1 páginaWILDEN Pump XPS430 Stainlessspamalstublieft1832Aún no hay calificaciones

- TankCleaning WallWashing November2014Documento18 páginasTankCleaning WallWashing November2014Goldy100% (3)

- 2" Metal: Wilden Pump Xps8Documento1 página2" Metal: Wilden Pump Xps8spamalstublieft1832Aún no hay calificaciones

- Aust Steel Cat - 04 Pipe Fittings 11 - WEB PDFDocumento52 páginasAust Steel Cat - 04 Pipe Fittings 11 - WEB PDFspamalstublieft1832Aún no hay calificaciones

- Lec 20pptsDocumento27 páginasLec 20pptsinam vfAún no hay calificaciones

- PaperNEMDILISpringerVerlag PDFDocumento20 páginasPaperNEMDILISpringerVerlag PDFspamalstublieft1832Aún no hay calificaciones

- Decimal (Torispherical) Heads Acc. DIN 28011: de Plaatijzerindustrie B.VDocumento1 páginaDecimal (Torispherical) Heads Acc. DIN 28011: de Plaatijzerindustrie B.Vspamalstublieft1832Aún no hay calificaciones

- Design of A Partial Admission Impulse Turbine For An Automotive ORC-ApplicationDocumento17 páginasDesign of A Partial Admission Impulse Turbine For An Automotive ORC-Applicationspamalstublieft1832Aún no hay calificaciones

- TurbinesDocumento8 páginasTurbinesShivam MehtaAún no hay calificaciones

- Chemical Injection TechnologiesDocumento2 páginasChemical Injection TechnologiesAl Patrick Dela CalzadaAún no hay calificaciones

- PC 2930-2630 User ManualDocumento6 páginasPC 2930-2630 User Manualpablo.pinonavarreteAún no hay calificaciones

- 612H Service Manual-201311000Documento284 páginas612H Service Manual-201311000luis chacon100% (1)

- Ventosa Especial Da SMCDocumento119 páginasVentosa Especial Da SMCdemetrio_sctb1868Aún no hay calificaciones

- Cofferdams Uwsh Manual Training & OperationsDocumento18 páginasCofferdams Uwsh Manual Training & OperationsBudi SatrioAún no hay calificaciones

- Bucyrus: Parts CatalogDocumento931 páginasBucyrus: Parts CatalogWalisson100% (1)

- 7600h - 7650h Cusher Pump Operation ManualDocumento19 páginas7600h - 7650h Cusher Pump Operation ManualYao WeiAún no hay calificaciones

- Diesel Injector Nozzle Tester: Instructions ForDocumento2 páginasDiesel Injector Nozzle Tester: Instructions Formuhammad marzuki0% (1)

- Chlorination Equipment & AccessoriesDocumento57 páginasChlorination Equipment & AccessoriesmailmaverickAún no hay calificaciones

- Hyundai Porter Ii 2.5 Crdi Engine Control Module Terminal DetailsDocumento2 páginasHyundai Porter Ii 2.5 Crdi Engine Control Module Terminal Detailsອູ່ ໄຊ ອິນເຕີ97% (29)

- Offshore Coiled Tubing Tension FrameDocumento2 páginasOffshore Coiled Tubing Tension FrameArgonauta_navegadorAún no hay calificaciones

- Latest Best PracticeDocumento4 páginasLatest Best PracticeJohn Kennedy FernandesAún no hay calificaciones

- Engine Room Simplified Piping and Er Arrangement PDFDocumento4 páginasEngine Room Simplified Piping and Er Arrangement PDFKranthi Kiran100% (1)

- Chemical Engineering eBook: Pumps ExplainedDocumento65 páginasChemical Engineering eBook: Pumps ExplainedMuhammad Yasar JavaidAún no hay calificaciones

- Turbine Vacuum System in Thermal Power PlantDocumento28 páginasTurbine Vacuum System in Thermal Power PlantAshwani Dogra100% (1)

- Fagor Spare Parts Manual LA, LR, 18 & 25 - November 2010 (Rev 09 - 2015)Documento37 páginasFagor Spare Parts Manual LA, LR, 18 & 25 - November 2010 (Rev 09 - 2015)Tod GreyAún no hay calificaciones

- AQT-MSV-1: Operational ManualDocumento8 páginasAQT-MSV-1: Operational ManualEdgar CastroAún no hay calificaciones

- To System & Barring GearDocumento22 páginasTo System & Barring GearPrudhvi RajAún no hay calificaciones

- STGDocumento12 páginasSTGLiji Brijesh100% (1)

- Condensate Recovery Pump: ModelDocumento2 páginasCondensate Recovery Pump: ModelCTHAún no hay calificaciones

- 15MW Steam Turbine Installation and Operation ManualDocumento83 páginas15MW Steam Turbine Installation and Operation ManualMohammed MuzzamilAún no hay calificaciones

- Vacuum Pumps Catalog PDFDocumento8 páginasVacuum Pumps Catalog PDFsriguruprasathsAún no hay calificaciones

- FWG ALFA LAVAL Type VSP-36-125CC-SWCDocumento284 páginasFWG ALFA LAVAL Type VSP-36-125CC-SWCArtjomsAún no hay calificaciones

- Ejector Data SheetDocumento5 páginasEjector Data SheetMohammad Abubakar SiddiqAún no hay calificaciones

- 10bDocumento18 páginas10bphanisai100% (2)

- Injector Specification: Nozzle Holder Assembly No. 38183Documento2 páginasInjector Specification: Nozzle Holder Assembly No. 38183johnny sabinAún no hay calificaciones

- Gas Jet Pump Paper Oct03 Ipa03 e 059Documento11 páginasGas Jet Pump Paper Oct03 Ipa03 e 059kglorstadAún no hay calificaciones

- BER 3-phase 50Hz submersible ejector system overviewDocumento4 páginasBER 3-phase 50Hz submersible ejector system overviewSERGIO RUBEN MARTINEZAún no hay calificaciones

- Rev04 en Brochure PiflowDocumento10 páginasRev04 en Brochure PiflowSyscom ServiçosAún no hay calificaciones

- JTT-150 200 250 2017 4 12Documento4 páginasJTT-150 200 250 2017 4 12Christian Marcelo VallejosAún no hay calificaciones