Documentos de Académico

Documentos de Profesional

Documentos de Cultura

09 Samss 091

Cargado por

Sohail TisekarTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

09 Samss 091

Cargado por

Sohail TisekarCopyright:

Formatos disponibles

Materials System Specification

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings Paints and Coatings Standards Committee Members

Barouky, F.F., Chairman Hammad, B.S., Vice Chairman Al-Homayed, M.A. Al-Khashram, M.S. Al-Nujaim, S.A. Al-Seba, Z.A. Suller, A.A.

30 March 2005

Saudi Aramco DeskTop Standards

Table of Contents

1 2 3 4 5 6 7 8 9 10 11 12 13

Scope............................................................. 2 Conflicts and Deviations................................ 2 References..................................................... 2 Definitions...................................................... 3 Material.......................................................... 4 Handling of Pipe............................................ 6 Cleaning and Surface Preparation................. 6 Coating Application........................................ 7 Quality Requirements.................................... 9 Inspection Requirements............................... 9 Recheck on Coating Material Qualities........ 15 Repairs......................................................... 15 Pipe Storage and Preparation for Shipment.............................................. 16

Appendix A - Qualification Procedure for Initial Product Approval................................ 17

Previous Issue: 31 October 1999 Next Planned Update: 1 April 2009 Revised paragraphs are indicated in the right margin Primary contact: Fikry F. Barouky on 873-4170

Page 1 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

Scope 1.1 This specification defines the minimum mandatory requirements of shop-applied fusion bonded epoxy FBE powder coating systems for the internal surfaces of steel tubular products and associated fittings and couplings. Unless stated otherwise in the Purchase Order, pieces coated in accordance with this specification shall be suitable for continuous service at 3000 psig pressure and for exposure to hydro-testing at 5575 psig. Information Required with the Quotation 1.3.1 1.3.2 Cost if burn-off is required to remove oily contaminants from the surface prior to blast cleaning (see paragraph 7.1). Procedure of the field girth weld internal coating application, quality control, and coating defects repair.

1.2

1.3

Conflicts and Deviations 2.1 Any conflicts between this specification and other Saudi Aramco Materials System Specifications (SAMSSs), Engineering Standards (SAESs), Standard Drawings (SASDs), or industry standards, codes and forms shall be resolved in writing by the Company or Buyer Representative through the Manager, Consulting Services Department of Saudi Aramco, Dhahran. Direct all requests to deviate from this specification in writing to the Company or Buyer Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

References Referenced standards and specifications shall be the latest edition, revision or addendum in effect on the date of the purchase order, unless stated otherwise. 3.1 Saudi Aramco Documents Saudi Aramco Engineering Procedure SAEP-302 Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement

Page 2 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

Saudi Aramco Engineering Standards SAES-H-002 SAES-H-100 Internal & External Coatings for Steel Pipelines & Piping Appendix I "Qualification Procedure for Sand for Abrasive Blasting"

Saudi Aramco Materials System Specification 01-SAMSS-024 Pipe Handling and Nesting

Saudi Aramco Inspection Requirement Form 175-091300 3.2 Industry Codes and Standards The Society for Protective Coatings SSPC PA 2 SSPC SP 1 SSPC SP 5 Measurement of Dry Coating Thickness with Magnetic Gages Solvent Cleaning White Metal Blast Saudi Aramco Inspection Requirements

International Organization of Standardization ISO 8501-1/SIS [SS 05 59 00 (1988)] 4 Definitions Buyer: Saudi Aramco Purchasing Department representative. RSA: Responsible Standardization Agency representative - Coating Engineer designated by the Manager, Consulting Services Department. He is responsible for product approvals and for interpretation of this specification. Buyer's Representative: The person or persons designated by the Purchasing Department to monitor / enforce the contract. Normally, this is the on-site inspector. Manufacturer: Company which manufactures the required powder coatings. Vendor: FBE coating applicator. Pipe: For purposes of this specification "pipe" is used to refer to steel tubular, including line pipe and OCTG casing and tubing. Pictorial Surface Preparation Standard for Painting Steel Surfaces

Page 3 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

Custom Coated Pieces: All pieces not coated by automated in-plant equipment. Generally, short spools and fittings are less than 12 meter. Fitting: For purposes of this specification, "fitting" is used to refer to any custom coated piece including valves and pumps. Corrosive Service: Generally, everything except treated seawater and refined products. Non-Corrosive Service: Treated Seawater or Refined Products. DFT: Dry film thickness. FBE: Fusion bond epoxy coating. High Temperature FBE: FBE powder that have a Tg > 105 and shall stand operating temperatures up to 125C. 5 Material 5.1 FBE Internal Coating 5.1.1 Material for the shop-applied internal coating shall be in a form of thermosetting resin powder suitable for application by the fusion bond process, with or without primer, as tested and approved by Saudi Aramco, and applied according to the Manufacturer's recommendation. Use of reclaimed powder shall not exceed the Manufacturer's recommendation. In no cases shall such use be greater than a maximum of 10% by weight without written approval from the RSA. If the reclaimed powder found contaminated at the end of the production, reclaimed powder shall be stopped. The Vendor should select any of the Buyer approved products. Equal alternative products which are not in Saudi Aramco approved list must be agreed upon by the Buyer in writing. Proposed alternative coating powders must pass the relevant qualification tests outlined in Appendix A of this specification and any other qualification tests deemed necessary by the Buyer or the RSA. Powder coating materials supplied to the Vendor shall be marked and supplied with the following information: a) b) The Manufacturer's name The material identification number

Page 4 of 19

5.1.2

5.1.3

5.1.4

5.1.5

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

c) d) e) f) 5.1.6

The batch number Date of manufacture The shelf life and storage temperature limits The material identification fingerprints from the FBE Manufacturer certified by a third party individual laboratory.

The Vendor shall retain samples of each powder batch for a period of 2 years. The sample shall be of sufficient size to run duplicates for the following tests if required: a) b) c) d) e) Instrumental Analyses for identification, IR and DSC Gel Time Moisture Content Bend tests Autoclave tests.

5.1.7 5.2

Coating material shall be stored and handled in accordance with the coating Manufacturer's recommendations.

Repair Material Touch-up or repairs shall be made with FBE or other Saudi Aramco-approved materials tested in accordance with, and meeting the applicable requirements of, Appendix A of this specification. Touch-up material shall also be approved by the Manufacturer. Repair and/or touch-up material shall be tested for adhesion, hardness and autoclave performance. Repair materials shall be marked with the information in paragraph 5.1.5.

5.3

Blast Abrasives 5.3.1 Abrasives for blast cleaning shall have less than 100 PPM sulfates and less than 100 PPM chlorides. They shall be of a particle size that will produce a clean, angular surface profile as specified in paragraph 7.4 of this specification. The abrasives shall be stored in a dry condition and kept dry during use. Sand is prohibited as an abrasive for pre-cleaning, cleaning, and all other abrasive blasting processes. The Vendor shall furnish a chemical analysis for all batches of abrasives to verify compliance with the requirements in paragraph 5.3.1. The use of reclaimed non-metallic abrasives shall be according to the manufacturer's recommendation.

Page 5 of 19

5.3.2

5.3.3

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

Handling of Pipe 6.1 Suitable equipment for handling, unloading and temporary storage of bare pipe shall be used to avoid any damage to bare pipe or pipe ends, or obliteration of necessary pipe markings. The stacking height of bare pipe shall be limited by the requirements of 01-SAMSS-024. Pipe or fittings received in a damaged condition or showing serious defects that may impair the coating, such as extensive laminations, burrs, gouges, pits, metal slivers or cold laps, or uneven weld cap or weld irregularity shall be reported to the Buyer's Representative for disposition. The Vendor shall determine final disposition due to the coating inability. Vendor shall submit his handling, loading, unloading, storage and preparation for shipment procedures for pipe and fittings for Saudi Aramco approval to the Buyer's representative prior to coating.

6.2 6.3

6.4

Cleaning and Surface Preparation 7.1 Prior to abrasive cleaning, all oil, grease and other deleterious materials shall be removed by solvent cleaning in accordance with SSPC SP 1 or by detergent washing or steam cleaning. No residue that will affect adhesion shall be left on the surface. Oven burn-off at a temperature of 370 - 400C may also be employed, if, in the opinion of the Vendor, this is the only satisfactory method of insuring that the steel is free of oily contaminants. The reported oily contamination shall be investigated and confirmed by the Buyer's Representative and written approval shall be obtained from the Buyer prior to burn-off. All pipe and fittings which have been received with internal mill varnish or other deleterious coatings or have been in previous oil service shall always be burned off. 7.2 The pipe or fitting surface temperature shall be at least 3C above the dew point before and during abrasive blasting until the primer application (if required) or until start up of pre-heating. If preheating is used, it shall be carried out in a uniform manner to avoid distortion. The surface to be coated shall be abrasive cleaned to a "white" metal surface finish equal to Sa3 as described in ISO 8501-1/SIS SS 05 59 00 (1988) or SSPC SP 5. The anchor profile shall be 50 - 100 micrometers.

7.3

7.4

Page 6 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

7.5

Defects 7.5.1 7.5.2 Weld spatter, rough weld surfaces, and sharp protrusions shall be ground smooth. When serious defects such as mentioned in paragraph 6.3 are found following the abrasive cleaning operation, the affected pipe or fitting shall be set aside for disposition by the Buyer's Representative. If these anomalies affect enough of the pipe or fitting to the extent that the coating process is severely disrupted, the coating process shall be stopped and the Buyer informed. The Vendor shall advise the Buyer of any remedial measures that could be taken to achieve an acceptable coating. The Vendor shall make the final decision, after consultation with the Buyer's Representative, whether the affected pipe or fittings can be coated.

7.5.3

7.6

Dew Point readings shall be recorded at the start and every 2 hours during the blasting operation in the immediate vicinity of the operation. Blasting and coating operations shall be suspended if the substrate temperature is less than 3C above the dew point. Any metal surface showing evidence of flash rusting shall be re-blasted prior to coating.

7.7

Chloride Contamination 7.7.1 The blasted surface of pipes and fittings shall be tested for the presence of residual chlorides after blasting using a test method that has been prior-approved in writing by the RSA. Residual chlorides shall be no greater than 40 mg/m. Test a random location on the first pipe and/or fitting coated on any given day. After that, test one pipe joint out of every 50 pipes or 50 fittings. In the event of a failure, re-test the piece. If it fails the re-test, test all pieces that were blast cleaned both before and after the contaminated piece until three in a row pass the test. All pieces coated after the last good test must be re-blasted, re-tested, and re-coated.

7.7.2

7.7.3

Coating Application 8.1 The FBE and its primer coating material shall be applied according to the Vendor's written application procedure, which incorporates the Manufacturer's

Page 7 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

recommendations. The Vendor shall submit his application procedure to the RSA for Saudi Aramco approval prior to application. Already approved procedures do not require RSA review and approval on new purchase orders, unless otherwise it is required by the Buyer's representative or any other standards documents. 8.2 The coating dry film thickness DFT for pipe joints shall be in the range of 375 to 625 microns (15 25 mils) unless otherwise agreed upon in writing by the Buyer. 8.2.1 For girth weld areas (pipe and custom coated pieces), the allowable DFT shall be in the range of 375 to 625 microns (15 25 mils). The total dry film thickness in the overlap area between the girth weld coating and the adjacent coating shall not exceed 1250 microns. 8.2.1.1 For pipes with diameters less than 24" and/or too small to access the girth weld area, the Vendor shall submit his proposed procedure for controlling the DFT to the RSA for written approval, which must be obtained prior to commencing coating application. The girth weld coating is not required to meet the acceptance criterion in paragraph 10.7, Bend Test.

8.2.1.2 8.2.2

Custom coated pieces shall have a nominal DFT of 625 micrometers. The minimum DFT shall be 375 microns and the maximum DFT on the coating overlap area shall be 1250 microns, inclusive of girth welds and repair areas larger than 645 mm (see paragraph 10.6.8.). Within 15 cm from a butt-welding end, the maximum DFT shall be 625 microns to allow field coating of the girth weld without exceeding 1250 microns DFT in the coating overlap area.

8.3

Line pipe and ancillary piping products for subsequent welding shall have a cutback at each end in the range of 50 to 75 mm measured from the end of pipe unless otherwise specified. In the case of fittings 6" diameter or less, the cutback range of 25 to 50 mm. The internal root reinforcement shall be 2.5 mm or less, as per SAES-W-012, paragraph 16.6.5.

8.4

The range of acceptable shades of color shall be established prior to production coating. The color and gloss of the cured coating shall be within the approved range and the cured coating shall be free of blisters and fish eyes as defined in SSPC Vol. 1. Cosmetic sags, runs, and other non-injurious irregularities are

Page 8 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

acceptable as long as the total DFT does not exceed 1250 microns. 8.5 Pipe or fittings which have been primed and waiting for FBE coating application must be covered to be protected against any dirt or other deleterious materials and not to be hold more than 12 hours for FBE coating application. For pipes and fittings, the final curing process of the FBE coated items must begin within two hours of the FBE application. Custom coated fittings are subject to a size limit of maximum 36" diameter and 10 feet in length. For pieces larger than this, the Vendor must have a written approval from the RSA prior to coating application.

8.6

Quality Requirements The Vendor's quality assurance system during the coating application shall include the following as minimum requirements: a) b) c) Checking cleanliness of pipe and/or fittings immediately prior to blasting (see paragraph 7.1). Monitoring of size, shape, dryness and cleanliness of the blasting material and process (see paragraph 5.3). Checking visually, in good light, the inner surface for metal defects, dust and surface debris (see paragraph 7.5). If blasting and primer applications are taking place on the same vicinity, Primer application shall be stopped while blasting is in progress. Checking blasted surface profile (see paragraph 7.4). Checking temperature control of the surface (see paragraph 7.2). Checking thickness of cured coating (see paragraph 10.4). Checking on the coating adhesion properties (see paragraph 10.5). Holiday detection of 100% of the surface area of all pipes and fittings (see paragraph 10.6). Supervision of adequate and proper repair of all defects. Checking of coating color, appearance and uniformity (see paragraph 8.4). Cure Test - See paragraph 10.8.

d) e) f) g) h) i) j) k) 10

Inspection Requirements 10.1 Notice The Vendor shall notify the Buyer not less than 5 days in advance of the start of

Page 9 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

each production run. The Vendor shall provide the Buyer's Representative with a detailed time schedule to allow him to witness or monitor all processing and testing phases. 10.2 Responsibility for Inspection 10.2.1 The Vendor shall be responsible for all quality control checking including visual inspection, thickness measurements, and holiday testing, and shall keep records on the results of all such inspections in a form suitable to the Buyer's Representative. Pipe coated in accordance with this specification is subject to verification by the Buyer's Representative per Saudi Aramco Form 175-091300, "Inspection Requirements", attached to the Purchase Order. The Buyer's Representative shall have access to each part of the process, and shall have the right to witness the quality control tests and/or perform tests by himself on a random sampling basis. The Buyer's Representative shall have the right to halt the application requesting alterations or corrections to the process in order to correct all faults found in the work, which conforms to this specification.

Commentary Note: Quality control on custom coated pieces (including valves) has proven to be difficult. For applications where internal coating failures could have serious operational impact, the Proponent should consider providing his own (or third-party) full-time inspection coverage in addition to the requirements of this specification.

10.2.2

10.2.3

10.3

Visual Inspection The internal surfaces being coated shall be inspected visually at each stage of the operation, using suitable illumination and inspection tools with sufficient frequency to ensure full compliance with the requirements of this specification.

10.4

Thickness Test Every pipe and fitting shall be checked in accordance with SSPC PA 2 at each end using a non-destructive type of thickness gauge which has been calibrated as required in paragraph 10.9.1. All results shall be as specified in paragraph 8.2 and shall be recorded.

10.5

Adhesion Test 10.5.1 General Requirements

Page 10 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

10.5.1.1

For pipe, determine the adhesion of the coating at one location for each of the following cases: a) b) c) The first production joint, The first joint after any interruption in production, and Once every hour or every twenty pipe lengths, whichever is more frequent.

If 3 tests have been successful, the test frequency may be reduced to once every 2 hours or 50 pipe lengths. 10.5.1.2 10.5.1.3 For custom coated pieces test one sample per production lot. Failure of the adhesion test shall require lot narrowing by testing the pipes or fittings until three in a row (coated both before and after the piece that failed) show satisfactory adhesion. A lot is defined as one shift's production, except in the case of custom coated pieces where a lot is defined as any number of pieces processed through the custom coating oven at the same time. The weld cutback on selected pipe lengths or fittings (see paragraph 8.3) shall be left partly unmasked to facilitate the adhesion test. The unmasked area shall be cleaned of coating following the test. Where this procedure is not practical, the test may be conducted on a selected area of the coating, and the test area be repaired in accordance with paragraph 12 of this specification.

10.5.1.4

10.5.2

Adhesion Test Procedure 10.5.2.1 With a sharp, narrow bladed knife, two incisions (approximately 13 mm long) shall be made, in the form of an X, through to the metal substrate. At the intersection of the X, an attempt shall be made to force the coating from the steel substrate with the knife point. The point of the knife shall be inserted horizontally i.e., the flat of the blade under the coating at the point of intersection of the X such that the blade point is on the metal surface. Using a levering action, the flat point shall be forced away from the steel in an attempt to pry off the coating. Refusal of the coating to disband from the substrate shall be recorded as a "pass". A "pass" shall also

Page 11 of 19

10.5.2.2

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

be recorded where the coating fails cohesively. Partial or complete adhesive failure between the coating and the substrate shall be recorded as a failure. Disbondment at the point of the intersection is common due to the action of marking the 'X' cut. Therefore, for 1 mm away from the tip of the intersection any disbondment shall be ignored. 10.5.2.3 The pipe shall be allowed to cool to below 80C prior to conducting the adhesion test. Failure of the test shall require each piece coated on that day to be subjected to the test until a total of three tests in a row (three done both before and after the piece which failed) are satisfactory.

10.6

Holiday Detection 10.6.1 100% of the internally coated surface area of the pipe shall be tested with a hot spark, pulse-type DC holiday detector employing an audible signaling device. The electrode used for locating holidays shall be designed to ensure direct contact with the coating (with no visible gaps). Travel rate of the detector electrode shall not exceed 75 cm/sec. The electrode shall not be allowed to remain stationary while the power is on. The holiday test voltage of the hot spark detector shall be 125 volts DC per 25 micrometers of maximum coating thickness. However, to eliminate the need for continual adjustment during shop production, a maximum voltage of 2200 volts 50 volts shall be used for coating thickness in the range from 375 to 625 micrometers and a maximum voltage of 1300 volts 50 volts shall be used for coating thickness in the range from 225 to 475 micrometers. All holidays in pipe coated above 24" diameter shall be repaired. The maximum number allowed for repair is 20 holidays. They shall be holiday free when re-tested after repair in accordance with paragraph 12.3. If the number is excessive than 20 holidays, the pipe joint shall be rejected. The number of holidays in a pipe joint with diameters up to 20" shall be permitted a maximum of 4 holidays per 12.2 m length. Repair if these holidays are accessible, otherwise leave them unrepaired and inform the Buyer's representative and log it in the quality control document.

10.6.2

10.6.3

10.6.4

10.6.5

Page 12 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

10.6.6

Internal girth weld coatings on the double-joints pipe shall be tested in accordance with the following: 10.6.6.1 Pipe diameters equal and greater than 24": All holidays shall be repaired. The coating on the girth weld area shall be holiday free when tested in accordance with paragraph 12.3. There is no limitation on the number of holidays that can be repaired (see paragraph 12.4). Pipe diameters less than 24", but large enough to allow visual inspection of the girth weld area coating by remote controlled crawling equipment; holiday(s) shall be marked and repaired. Otherwise, the coating shall be rejected. Pipe diameters too small (less than 6") to allow visual inspection of the girth weld area coating: The holiday test shall be made and the presence of holiday(s) shall be recorded for information purposes only.

10.6.6.2

10.6.6.3

10.6.7 10.6.8

Custom coated fittings shall be free of holidays when tested in accordance with paragraph 10.6 of this specification. The total dry film thickness of coating in repaired areas shall not exceed 1250 microns for repair areas exceeding 645 mm and 1875 microns for repair areas less than or equal to 645 mm.

10.7

Bend Test 10.7.1 Once per shift (or, for pipe, every one hundred pipe lengths, whichever is the more frequent) and at the start of using a new batch of powder the flexibility of the coating shall be determined by a bend test. The powder utilized for the test shall be taken from the plant application fluidizing bed. Two test bars measuring approximately 25 mm x 192 mm x 9.5 mm shall be coated at a dry film thickness of 475 - 575 micrometers. The coating thickness shall be measured at 5 locations 25 mm apart on each sample, and the thickness recorded. The average of these readings shall fall in the range in paragraph 10.7.2. The test bars shall be holiday detected in accordance with paragraph 10.7.7 of this specification, and all holidays marked and recorded. The specimens shall be at three different temperatures 5, 10, and 25C 3C when clamped in the bender with the coated side up. The

Page 13 of 19

10.7.2 10.7.3

10.7.4 10.7.5

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

specimens shall be bent flat wise at 60 degrees over a 25.4 mm thick shoe of the following dimensions: Shoe radius Chord Arc 10.7.6 10.7.7 95.2 mm 152 mm 178 mm

Bending shall be accomplished in less than 30 seconds. The coated specimens shall show no cracks to base metal when examined at 10X magnification except where gripped or clamped. If visual examination cannot determine whether a crack extends to base metal, holiday testing using the hot spark detector method with a conductive rubber electrode shall be used. Tests are to be carried out as required in paragraph 10.6.3 of this specification. If no holidays are signaled, the crack-like defect is acceptable. If either of the bend tests fail, the tests shall be repeated. 10.7.8.1 10.7.8.2 If both bend retests are satisfactory, the bend test shall be accepted. If either (or both) of the retests fail, immediately discontinue further coating with the suspect batch of powder and proceed as follows: a) Pipe: All pipes coated since the previous successful bend test shall be set aside. Two specimens with the same dimensions as given in paragraph 10.7.2 shall be cold cut from the production coated pipes in question and subjected to the bend test. The edges of the specimens as necessary shall be chamfered to remove stress raisers. As many specimens as necessary shall be tested until the Buyer's Representative is satisfied that all pipes with substandard coatings have been identified. These pipes shall be rejected. Fittings: All fittings coated with the suspect powder shall be re-blasted and recoated.

10.7.8

b) 10.7.9

If deemed necessary in some critical applications or according to an end-user request, the RSA shall request the Vendor to prepare the Bend test samples from a coated pipe section. Samples shall be cut in both radial and longitudinal directions from the pipe section to suit the Bend test requirements. The procedure of the test shall be as shown above.

Page 14 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

10.8

Cure Test Twice per shift the coating on production pipes shall be tested by Differential Scanning Calorimeter analysis. Custom coated fittings shall be subjected to the same test at a frequency of one sample per production lot. Girth welds shall be checked twice per day. Failure of the test shall require each piece coated on that day to be subjected to the test until a total of three tests in a row (three done both before and after the piece which failed) are satisfactory. The glass transition difference (Tg2-Tg1) must be in the range specified by the FBE Manufacturer. Any coated pipes, girth welds, or fittings fail the test within the acceptable range shall be re-cured and retested.

10.9

Calibration of Inspection Equipment 10.9.1 The coating thickness gauge (see paragraph 10.4) shall be calibrated in accordance with SSPC PA 2 at the start of production and every 3 hours during production, against a certified or known standard. The holiday detector shall be calibrated at least twice per 8-hour shift against a suitable calibrated voltmeter.

10.9.2

11

Recheck on Coating Material Qualities The Buyer's Representative at any time may require that the Vendor prepare a set of test specimens as defined in Appendix A, and arrange for the performance of any or all of the tests covered by Appendix A at a laboratory agreeable to the Buyer. Provided the coating on the specimens passes the tests, the Buyer shall pay for the tests; otherwise the Vendor shall pay the costs.

12

Repairs 12.1 12.2 12.3 12.4 Repair materials shall be as specified under paragraph 5.2 of this specification, and repairs shall be in accordance with the approved, written procedures. Abrasive blasting and patch repair work shall not be conducted when the metal surface temperature is less than 3C above the dew point. Repaired areas shall be retested for holidays per paragraph 10.6 and shall be holiday free. Any coated joint with defective or damaged coating exceeding 930 cm shall be rejected and completely recoated at the Vendor's expense.

Page 15 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

12.5

Custom coated fittings or girth welds with defective or damaged coating exceeding 233 cm shall be rejected and recoated at the Vendor's expense.

13

Pipe Storage and Preparation for Shipment 13.1 Each coated length of pipe or fitting shall be externally or internally stenciled to identify the type of coating applied, coating Purchase Order number, original pipe or fitting Purchase Order number (if known), pipe size, pipe grade, fitting size, fitting class and date coated. 13.1.1 Pipe diameters of 16 inches and less shall be stenciled externally starting at a point approximately 60 cm from the end. Size permitting, fittings of these diameters shall be stenciled externally at any convenient location. Pipe diameters greater than 16 inches shall be stenciled internally starting at a point approximately 15 cm from the end. Size permitting, fittings of these diameters shall be stenciled internally at any convenient location. Fittings that cannot be stenciled as required above shall be marked in accordance with the Buyer's written instructions.

13.1.2

13.1.3 13.2 13.3

All pipes shall be stored on polyethylene-sheathed sand berms until time for delivery. Fittings shall be stored on pallets or padded elevated racks. All booms, hooks, forks, supports and skids used in handling or storing coated pipe shall be designed and maintained in such a manner as to prevent any damage to the pipe or to the coating, and shall be approved by Buyer's Representative. The Buyer's Representative will have authority to stop any storage procedure or means of transport from the yard if, in his opinion, there is a possibility of damage to the coating because of improper procedures.

Revision Summary Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued with minor revisions.

13.4

30 March 2005

Page 16 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

Appendix A Qualification Procedure for Initial Product Approval 1. General Requirements In order to qualify a coating material as acceptable under this specification, the Supplier of the coating material shall submit the following certification in writing to the Responsible Standardization Agency (RSA): a) Certification from an independent testing laboratory or inspection agency that they witnessed or performed the preparation and testing of the samples, and that all procedures were in accordance with this qualification procedure. Certification by the Supplier that the proposed coating meets the following criteria: Has passed all the tests and met all the requirements of this qualification procedure. Is suitable for the intended service conditions as detailed in Saudi Aramco Engineering Standard SAES-H-002, APCS-102 "Shop or Field-applied Fusion Bonded Epoxy (Internal)".

b)

c)

A record of all test results: Any and all initial qualification tests shall be carried out at no cost to Saudi Aramco. The RSA shall decide if the data presented by the Supplier satisfy the requirements of the tests outlined below.

2.

References 2.1 Saudi Aramco Engineering Standard SAES-H-002 2.2 Internal and External Coating for Steel Pipelines and Piping

Industry Codes and Standards ASTM D714 ASTM D4541 ISO 8501-1/ SIS SS 05 59 00 Evaluating the Degree of Blistering of Paints Pull Off Strength of Coatings Pictorial Surface Preparation Standard For Painting Steel Surfaces (1988)

Page 17 of 19

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

3.

Qualification Tests 3.1 Instrumental Analysis Instrumental analyses of the coating powder and its primer shall be conducted by the infrared (IR) approved method, and FBE differential scanning calorimetric (DSC) analysis. Both tests shall be conducted in a laboratory acceptable to the RSA. 3.2 Preparation of Test Specimens 3.2.1 3.2.2 Test specimens shall be as outlined in the applicable test specification unless otherwise stated. Surface preparation, application, dry film thickness and curing parameters for the test specimens shall be identical to that used in this coating specification.

3.3

Flexibility/Bending Test Three (3) test specimens as detailed in paragraph 10.7.2 of this specification shall be tested and evaluated in accordance with paragraphs 10.7.3 through 10.7.7 of this specification.

3.4

Adhesion Test (ASTM D4541) An adhesion test shall be conducted on specimens after exposure (up to 24 hours recovery time allowed) to the chemical resistance tests in paragraph 3.6 below using an Elcometer or Hate Adhesion Tester. A pull-off value of not less than 2000 psi is required. Tester must be run and a pull-off value of not less than 2000 psi confirmed.

3.5

Chemical Resistance (ASTM D714) 3.5.1 High temperature - high pressure (autoclave) chemical resistance test results shall not show more than a few blisters of size 8 or greater, as defined in ASTM D714 and no loss of adhesion per the procedure outlined in paragraph 10.5.2 of this specification. The tested samples shall not show any cracking or delamination. The fully cured specimens will be immersed half-way in the specified test solutions in the autoclave. After sealing, the test chamber shall be heated to the test temperature specified in Table A1 below. Stable condition (temperature/pressure) shall be maintained for a minimum of 18 hours, after which the heat

Page 18 of 19

3.5.2

Document Responsibility: Paints and Coatings Issue Date: 30 March 2005 Next Planned Update: 1 April 2009

09-SAMSS-091 Qualification Requirements for Shop-Applied Internal FBE Coatings

shall be discontinued. The unit shall be cooled to 90C and the pressure released over a time period of a minimum of one minute and a maximum of three minutes. The specimens shall be conditioned for one hour at 25C prior to being assessed. 3.5.3 The pressurizing gas shall be Nitrogen (N2) unless otherwise specified.

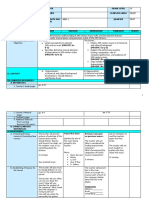

Table A1 Chemical Resistance Test Parameters

a) Service Treated Seawater Test Medium ASTM D1141, Stock Solution 1 plus Stock Solution 2 Formation Water Brine 3 mole% CO2 3 mole% H2S 94% mole% Methane Wasia Water 100% CO2 10 vol. % HCl Test Temp. 95C Test Pressure 20.68 MPa (3000 psig) 20.68 MPa (3000 psig) Test Time 24 hrs

b) Brine Reinjection Wet, Sour Gas or Crude

95C

24 hrs

c) d)

Wasia Water Acid

95C 50C

20.68 MPa (3000 psig) Covered Vented Container

24 hrs 24 hrs

Formation Water Brine Composition (mg/l): Na = 65,000; Ca = 23,000; Mg = 3,000; Cl = 150,000; SO4 = 100; HCO3 = 300 Wasia Water Composition (mg/l): Na = 2,500; Ca = 600; Mg = 120; Cl = 4,000; SO4 = 1,000; HCO3 = 200; pH = 6.8 - 7.2

Note: In order for full and unrestricted approval of a coating system it must pass all above tests and also pass the bending tests. However, it is possible to get limited approval by passing the individual tests in a specific service. All systems shall pass (d) as well as be bendable in order to qualify except as otherwise noted in this SAMSS.

Page 19 of 19

También podría gustarte

- Materials System SpecificationDocumento10 páginasMaterials System SpecificationAjeetKumar100% (1)

- 09 Samss 069Documento10 páginas09 Samss 069Selvakpm06Aún no hay calificaciones

- 09-SAMSS-089 Shop Applied FBE Coating Jan 2018Documento28 páginas09-SAMSS-089 Shop Applied FBE Coating Jan 2018Ahmed & Rehana MoinuddinAún no hay calificaciones

- 09 SAMSS 089 (Final Draft - 2018)Documento28 páginas09 SAMSS 089 (Final Draft - 2018)lhanx2Aún no hay calificaciones

- Saes H 201Documento9 páginasSaes H 201heartbreakkid132Aún no hay calificaciones

- SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersionDocumento13 páginasSAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersiondanishAún no hay calificaciones

- 09 Samss 091Documento27 páginas09 Samss 091AbhilashAún no hay calificaciones

- Shop-Applied Internal FBE CoatingsDocumento18 páginasShop-Applied Internal FBE CoatingsFahad AhmadAún no hay calificaciones

- 09 Samss 021Documento8 páginas09 Samss 021Kalanithi KasirajanAún no hay calificaciones

- Materials System SpecificationDocumento10 páginasMaterials System SpecificationAjeetKumar100% (1)

- 09 Samss 089-2016Documento26 páginas09 Samss 089-2016lhanx2Aún no hay calificaciones

- 09 Samss 060Documento4 páginas09 Samss 060asimazami69Aún no hay calificaciones

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Documento9 páginas09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Materials System SpecificationDocumento7 páginasMaterials System SpecificationAjeetKumarAún no hay calificaciones

- Materials System SpecificationDocumento6 páginasMaterials System SpecificationAjeetKumarAún no hay calificaciones

- Epoxy Coating Systems Guide for Atmospheric & Immersion ApplicationsDocumento3 páginasEpoxy Coating Systems Guide for Atmospheric & Immersion ApplicationsnasirAún no hay calificaciones

- Saes H 204Documento34 páginasSaes H 204heartbreakkid132Aún no hay calificaciones

- Saes H 101VDocumento83 páginasSaes H 101Vacolombel100% (2)

- APCS DeatailsDocumento3 páginasAPCS DeatailsDandaman100% (3)

- Surface Prep Methods for Protective CoatingsDocumento27 páginasSurface Prep Methods for Protective CoatingsAnonymous S9qBDVkyAún no hay calificaciones

- Saes H 102Documento10 páginasSaes H 102Kaleelur RahmanAún no hay calificaciones

- Abrasives and SAMSS Numbers GuideDocumento2 páginasAbrasives and SAMSS Numbers GuideSivaratnam Navatharan100% (1)

- Aramco Apcs 1bDocumento55 páginasAramco Apcs 1bSadek Sad100% (2)

- 12 Samss 007Documento33 páginas12 Samss 007marghoobAún no hay calificaciones

- SSPC Ab2 1996 PDFDocumento4 páginasSSPC Ab2 1996 PDFmarklesterAún no hay calificaciones

- Ad 036821 001Documento1 páginaAd 036821 001AmolAún no hay calificaciones

- Saes H 101Documento77 páginasSaes H 101Henry Ocbina Luares100% (6)

- Apcs 113a Rev 3 Pid ApprovalDocumento19 páginasApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- Method Statement For APCS-113A For Alloy Steel - Otc - Fbe-002Documento7 páginasMethod Statement For APCS-113A For Alloy Steel - Otc - Fbe-002sharif339100% (2)

- SAEP-303: 2 Conflicts and DeviationsDocumento19 páginasSAEP-303: 2 Conflicts and DeviationsnasirAún no hay calificaciones

- Saes H 102Documento10 páginasSaes H 102HaleemUrRashidBangash100% (1)

- Saep 1200Documento9 páginasSaep 1200Anonymous 4IpmN7On100% (1)

- Saes H 200Documento9 páginasSaes H 200راجہ شہزاد انورAún no hay calificaciones

- SAUDI ARAMCO ID/PIEU-30-Nov-2018Documento2 páginasSAUDI ARAMCO ID/PIEU-30-Nov-2018Moghal AliAún no hay calificaciones

- 01-SAMSS-333-HF Welded Line Pipe PDFDocumento35 páginas01-SAMSS-333-HF Welded Line Pipe PDFmunnaAún no hay calificaciones

- Saep 316 2016 PDFDocumento25 páginasSaep 316 2016 PDFAllan LindoAún no hay calificaciones

- SATIP H 002 08 Pipe Internal CoatingDocumento3 páginasSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyAún no hay calificaciones

- Aramco Painting SpecificationDocumento6 páginasAramco Painting Specificationvicky100% (1)

- Satr H 1003Documento2 páginasSatr H 1003Thouseef MaAún no hay calificaciones

- Coating Inspector Interview QuestionsDocumento14 páginasCoating Inspector Interview Questionshabib79% (14)

- 12 Samss 007 PDFDocumento30 páginas12 Samss 007 PDFMohammadAseef100% (1)

- 20 Samss 001Documento9 páginas20 Samss 001asimazami690% (1)

- Sania InternshipDocumento28 páginasSania InternshipZareen RehanAún no hay calificaciones

- 09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFDocumento10 páginas09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFsuresh_viki100% (1)

- Material Guide For Horizontal and Vertical In-Line PumpsDocumento1 páginaMaterial Guide For Horizontal and Vertical In-Line PumpsEr Bishwonath Shah100% (1)

- Renovation Coating Inspection PlanDocumento10 páginasRenovation Coating Inspection PlanMoghal AliAún no hay calificaciones

- SAIC-H-2032 Rev 7Documento4 páginasSAIC-H-2032 Rev 7Satheesh Rama SamyAún no hay calificaciones

- De-119951 Monel Sheathing InstallationDocumento8 páginasDe-119951 Monel Sheathing InstallationJithuJohn100% (1)

- SATIP SAIC SATR IndexDocumento87 páginasSATIP SAIC SATR Indexlhanx2100% (8)

- 09 Samss 068Documento7 páginas09 Samss 068AjeetKumarAún no hay calificaciones

- Ph value shows acidity of solutionDocumento3 páginasPh value shows acidity of solutionNidhin Joseph100% (1)

- SAEP-379 Quality Issues NotificationDocumento4 páginasSAEP-379 Quality Issues NotificationMusic And FunAún no hay calificaciones

- 09 Samss 091.Documento18 páginas09 Samss 091.MahmoudAún no hay calificaciones

- Yerp 09 Samss 107Documento15 páginasYerp 09 Samss 107azhar enggAún no hay calificaciones

- Apcs-113a Method StatmentDocumento7 páginasApcs-113a Method StatmentNoman AhmedAún no hay calificaciones

- Shop Applied Internal Cement Mortar Lining SpecDocumento5 páginasShop Applied Internal Cement Mortar Lining SpecansarimehmoodAún no hay calificaciones

- Method Statement For APCS-113A (1) 22-6-2011Documento7 páginasMethod Statement For APCS-113A (1) 22-6-2011sharif339Aún no hay calificaciones

- SAMSS New StandardDocumento25 páginasSAMSS New Standardlhanx2100% (1)

- Materials System SpecificationDocumento28 páginasMaterials System SpecificationAli RazaAún no hay calificaciones

- 09-Samss-089 (2018)Documento28 páginas09-Samss-089 (2018)Ali RazaAún no hay calificaciones

- Carboguard 703 GFDocumento2 páginasCarboguard 703 GFSohail Tisekar100% (1)

- Twi C.V. ProformaDocumento6 páginasTwi C.V. ProformaSohail TisekarAún no hay calificaciones

- ScannedCopyof CircularNo11Documento3 páginasScannedCopyof CircularNo11Sohail TisekarAún no hay calificaciones

- D 197 - 87 R02 - Rde5nw - PDFDocumento7 páginasD 197 - 87 R02 - Rde5nw - PDFSohail TisekarAún no hay calificaciones

- NEW TWI Enrollment FormDocumento4 páginasNEW TWI Enrollment FormSohail TisekarAún no hay calificaciones

- 111873-423012 Critical PDFDocumento32 páginas111873-423012 Critical PDFSohail TisekarAún no hay calificaciones

- Apcs 113aDocumento2 páginasApcs 113aSohail TisekarAún no hay calificaciones

- Vision Certificate FormatDocumento2 páginasVision Certificate FormatSatish Totawar100% (1)

- Surface Defects in Powder Coating: 1.1 Craters Possible Causes SolutionDocumento2 páginasSurface Defects in Powder Coating: 1.1 Craters Possible Causes SolutionEidrish ShaikhAún no hay calificaciones

- CapsDocumento1 páginaCapsSohail TisekarAún no hay calificaciones

- Entry-Offer R PDFDocumento1 páginaEntry-Offer R PDFSohail TisekarAún no hay calificaciones

- WebJuly11 Subscription Pack PDFDocumento1 páginaWebJuly11 Subscription Pack PDFSohail TisekarAún no hay calificaciones

- Clad PipesDocumento4 páginasClad PipesSohail Tisekar100% (1)

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocumento1 páginaScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarAún no hay calificaciones

- Safety Instruction SheetDocumento32 páginasSafety Instruction SheetAdamuAún no hay calificaciones

- Engineering standard for spacing and diking of atmospheric and low-pressure tanksDocumento9 páginasEngineering standard for spacing and diking of atmospheric and low-pressure tanksSohail TisekarAún no hay calificaciones

- Awwa C205-00Documento32 páginasAwwa C205-00Sohail Tisekar100% (1)

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocumento1 páginaScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarAún no hay calificaciones

- Providing Training Solutions Worldwide: World Leaders in Welding, NDT, HSE and Inspection TrainingDocumento33 páginasProviding Training Solutions Worldwide: World Leaders in Welding, NDT, HSE and Inspection TrainingSohail TisekarAún no hay calificaciones

- 175 000003 PDFDocumento1 página175 000003 PDFSohail TisekarAún no hay calificaciones

- D714Documento6 páginasD714Sohail TisekarAún no hay calificaciones

- D714Documento6 páginasD714Sohail TisekarAún no hay calificaciones

- 09 Samss 088Documento5 páginas09 Samss 088Sohail TisekarAún no hay calificaciones

- ASTM D4541 Coating Adhesion Testing in Accordance With PDFDocumento2 páginasASTM D4541 Coating Adhesion Testing in Accordance With PDFHaldirLeao100% (1)

- Clad PipesDocumento4 páginasClad PipesSohail Tisekar100% (1)

- Materials System SpecificationDocumento9 páginasMaterials System SpecificationSohail TisekarAún no hay calificaciones

- QC AbrasiveBlast 10-19-11Documento62 páginasQC AbrasiveBlast 10-19-11Sherif AbdelhameedAún no hay calificaciones

- Design and Installation of Submarine PipelinesDocumento8 páginasDesign and Installation of Submarine PipelinesSohail TisekarAún no hay calificaciones

- 09 Samss 091Documento19 páginas09 Samss 091Sohail Tisekar100% (1)

- Make a Roman mosaic activityDocumento6 páginasMake a Roman mosaic activityRaluca Cascaval100% (1)

- Haiku Poem AnalysisDocumento3 páginasHaiku Poem Analysisapi-295870083100% (1)

- Al-Jazeera Firedamp 263Documento2 páginasAl-Jazeera Firedamp 263EngTamer100% (1)

- How To Make A Persian Outer CaftanDocumento5 páginasHow To Make A Persian Outer CaftanZahida MariyamAún no hay calificaciones

- Production Designer Profile - Hans BacherDocumento2 páginasProduction Designer Profile - Hans BacherParis100% (1)

- 32Documento46 páginas32solitarysoulAún no hay calificaciones

- Book Review: Alain de Botton's The Art of TravelDocumento8 páginasBook Review: Alain de Botton's The Art of TravelharroweenAún no hay calificaciones

- Zaha Hadid Early Paintings and Drawings: Press ReleaseDocumento63 páginasZaha Hadid Early Paintings and Drawings: Press ReleaseAlbert Mezewula100% (1)

- Custom Sim Cards TutorialDocumento26 páginasCustom Sim Cards Tutorialkuku2008Aún no hay calificaciones

- Western Classical Art Traditions (Report in Arts)Documento3 páginasWestern Classical Art Traditions (Report in Arts)JanineP.DelaCruz0% (1)

- Thesis Report AshishDocumento53 páginasThesis Report AshishSonu Sharma100% (1)

- Everyday Electronics 1974 10.CV01Documento6 páginasEveryday Electronics 1974 10.CV01marcosscarato0% (1)

- Chap 018Documento12 páginasChap 018Abdullah Hamadi100% (2)

- Training & Certification UpdatesDocumento64 páginasTraining & Certification UpdatesRoger MachaAún no hay calificaciones

- 8073 Colette Kingston-Martin NEA EvaluationDocumento4 páginas8073 Colette Kingston-Martin NEA EvaluationMark GroganAún no hay calificaciones

- Quarter 3-Arts Lesson 1-4Documento52 páginasQuarter 3-Arts Lesson 1-4Sarah Grace ManuelAún no hay calificaciones

- DINH, Giang - Origami-B-21Documento1 páginaDINH, Giang - Origami-B-21Zebek McKlauAún no hay calificaciones

- Title: Bedsheet TensionerDocumento6 páginasTitle: Bedsheet TensionerRA Mikael Master MindAún no hay calificaciones

- Quarter 1 Grade 10 Music DLL Week 1Documento12 páginasQuarter 1 Grade 10 Music DLL Week 1vince millanteAún no hay calificaciones

- IKEA Catalogue 2011Documento189 páginasIKEA Catalogue 2011Ahmed SamiAún no hay calificaciones

- Chinese pagodas and the Chicago Tribune TowerDocumento8 páginasChinese pagodas and the Chicago Tribune TowerJehan Mohamad100% (1)

- Glass On Metal Online - Past Articles - Hydraulic Die FormingDocumento13 páginasGlass On Metal Online - Past Articles - Hydraulic Die FormingSotiris AslanopoulosAún no hay calificaciones

- Hot Dip GalvanizedDocumento6 páginasHot Dip GalvanizedNestor GalianoAún no hay calificaciones

- Puducherry Artwork.Documento14 páginasPuducherry Artwork.Yukta SainiAún no hay calificaciones

- Jan MielDocumento6 páginasJan MielBenjamin KonjicijaAún no hay calificaciones

- Hard Ceramic Porcelain Physical Test Through Potential Formulation ParameterDocumento545 páginasHard Ceramic Porcelain Physical Test Through Potential Formulation ParameteranuarAún no hay calificaciones

- Crafts of Sarajevo - Keepers of Baščaršija TraditionsDocumento8 páginasCrafts of Sarajevo - Keepers of Baščaršija TraditionsdexAún no hay calificaciones

- SyriaDocumento2 páginasSyriaabir akAún no hay calificaciones

- Alvar AaltoDocumento27 páginasAlvar AaltoPragya Singh100% (2)

- Sully: The Untold Story Behind the Miracle on the HudsonDe EverandSully: The Untold Story Behind the Miracle on the HudsonCalificación: 4 de 5 estrellas4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldDe EverandThe Fabric of Civilization: How Textiles Made the WorldCalificación: 4.5 de 5 estrellas4.5/5 (57)

- Packing for Mars: The Curious Science of Life in the VoidDe EverandPacking for Mars: The Curious Science of Life in the VoidCalificación: 4 de 5 estrellas4/5 (1395)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDe EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaAún no hay calificaciones

- The Weather Machine: A Journey Inside the ForecastDe EverandThe Weather Machine: A Journey Inside the ForecastCalificación: 3.5 de 5 estrellas3.5/5 (31)

- Highest Duty: My Search for What Really MattersDe EverandHighest Duty: My Search for What Really MattersAún no hay calificaciones

- Hero Found: The Greatest POW Escape of the Vietnam WarDe EverandHero Found: The Greatest POW Escape of the Vietnam WarCalificación: 4 de 5 estrellas4/5 (19)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestCalificación: 4 de 5 estrellas4/5 (28)

- Transformed: Moving to the Product Operating ModelDe EverandTransformed: Moving to the Product Operating ModelCalificación: 4 de 5 estrellas4/5 (1)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDe EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellCalificación: 4.5 de 5 estrellas4.5/5 (80)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980De Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Calificación: 4 de 5 estrellas4/5 (21)

- A Place of My Own: The Architecture of DaydreamsDe EverandA Place of My Own: The Architecture of DaydreamsCalificación: 4 de 5 estrellas4/5 (241)

- The Future of Geography: How the Competition in Space Will Change Our WorldDe EverandThe Future of Geography: How the Competition in Space Will Change Our WorldCalificación: 4.5 de 5 estrellas4.5/5 (4)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDe EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureCalificación: 5 de 5 estrellas5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceDe EverandPale Blue Dot: A Vision of the Human Future in SpaceCalificación: 4.5 de 5 estrellas4.5/5 (586)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsDe EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsAún no hay calificaciones

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDe EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseCalificación: 3.5 de 5 estrellas3.5/5 (12)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesDe EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesAún no hay calificaciones

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDe EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseCalificación: 4.5 de 5 estrellas4.5/5 (50)

- Reality+: Virtual Worlds and the Problems of PhilosophyDe EverandReality+: Virtual Worlds and the Problems of PhilosophyCalificación: 4 de 5 estrellas4/5 (24)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDe EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationCalificación: 4.5 de 5 estrellas4.5/5 (46)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDe EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterCalificación: 5 de 5 estrellas5/5 (3)

- Grunt: The Curious Science of Humans at WarDe EverandGrunt: The Curious Science of Humans at WarCalificación: 4 de 5 estrellas4/5 (429)

- Fallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldDe EverandFallout: The Hiroshima Cover-up and the Reporter Who Revealed It to the WorldCalificación: 4.5 de 5 estrellas4.5/5 (82)

- The Path Between the Seas: The Creation of the Panama Canal, 1870-1914De EverandThe Path Between the Seas: The Creation of the Panama Canal, 1870-1914Calificación: 4.5 de 5 estrellas4.5/5 (124)