Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Dust Explosion

Cargado por

Khoirul WaladDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Dust Explosion

Cargado por

Khoirul WaladCopyright:

Formatos disponibles

About this document

This document contains screenshots of software available from Cheresources.com. You can find this title in our online store at: http://www.cheresources.com/cheplusstore/catalogue.php Clicking the above link should activate your default browser and launch the site. We recommend using our search feature to find the title. If you havent visited our site before, you can find the main page at: http://www.cheresources.com Thanks for visiting our site, Chris Haslego President Cheresources, Inc.

COPYRIGHT, 2005. CHERESOURCES, INC.

1422 Goswick Ridge Road Midlothian VA 23114

Fax: 561-658-6489 Email: support@cheresources.com

Content Based Chemical Engineering

NFPA Vent - HELP!

NFPA 68 Standard on Explosion Protection by Deflagration Venting - 2007 Edition

BASIS: NFPA 68 Standard on Explosion Protection by Deflagration Venting - 2007 Edition NOTE: Always begin a new case by retrieving the original file. Direct entry of data in cells that originally contain table lookups could cause functions to be lost, or incorrect calculations. I format cells requiring entry colored RED; calculated values are black. Print out using direct Excel commands. This application is provided by Chemical Engineers Resource Website, visit @ cheresources.com for additional selections. RULES AND LIMITATIONS FOR NFPA 68 DUST MODELS: Model Application 0.8 P0 1.2 bar-abs Panel density MT and 40 kg/m2 Vent ducts Allow partial volume 1 L/D 6 (calculate vent duct effect last) Allow vent duct Panel density 40 kg/m2 Partial volume 0.8 P0 1.2 bar-abs 1 L/D 6 (calculate vent duct effect last) No vent duct Panel density MT and 40 kg/m2 Elevated initial pressure 0.2 P0 4 bar-g Full volume deflagration 1 L/D 6 (calculate elevated initial pressure effect last) Panel inertia 0.8 P0 1.2 bar-a Panel inertia No vent duct Panel density 40 kg/m2 Allow partial volume 1 L/D 6

Print out using direct EXCEL commands.

<<<<<<< Psafety January 2001, by Don Coffman >>>>>>>

The originator of these spreadsheet(s) specifically excludes all warranties, expressed or implied, as to the accuracy of the data and other information set forth and assumes NO liability for any losses or damage resulting from the use of the materials or application of the data. Consistent with GOOD ENGINEERING PRACTICE, the burden rests with the USER of these spreadsheets to review ALL calculations, and assumptions. The USER IS FULLY RESPONSIBLE for the results or decisions based on calculations. This Spreadsheet Requires MACROS to be ENABLED to ASSURE proper operation. See the Workbook Help Sheet for Additional Instructions on Use. dmcoffman@aol.com

explosion dusts - NFPA

Psafety January 2001

NFPA 68 Standard on Explosion Protection by Deflagration Venting - 2007 Edition

1 1. 2. Service: Client: Dust Handling - Collection Confidential Project No: Equipment: BR 549 BR-549 Building 45 Baghouse Date: 8/1/2009

Equipment / System Specifics 3 3. 4. 5 5. 6. 7 7. 8. 9 9. 8.2.2 10. 8 8.2.3 23 11. 8.2.6.7 12 12. 13. 14 14. 15. 16 16. 17. 8.2.7.2 18 18. 19. 20 20. 8 8.3.1 31 21. 22 22. 8 8.4.1 23 23. 24. 25 25. Pinitial =

E P max

D t PAPER DUST Dust: M t i Metric Pred: Pstat: Pmax: V V: L/D Ratio: Kst: 3.522 0 250 0.250 8.000 25 00 25.00 4.00 200

U it Unit bar-g bar g bar g bar-g bar-g bar g cu meter t b bar-m/sec /

I Imperial i l 51.06 3 63 3.63 116.00 882 77 882.77

U it Unit psig psig psig cu ft

R f Reference

Maximum pressure p developed p during g a vented deflagration f g Pressure that activates a vent closure Maximum pressure developed in a contained deflagration Volume of equipment being analyzed Ratio of height -toto diameter D fl Deflagration ti index i d of fad dust t cloud l d

- Venting g by y Means of Low-Inertia Vent Enclosures .. for Enclosures L/D / </= / 2.0 Av0 = 0.3133 sq meter 3.37 sq feet Av0 (1+1 54Pstat 0=110 (1+1.54P t t

-4 4/3

)Kst tV

3/4

[(Pmax/Pred d)-1]

2

0.5

- Elongated Enclosure Area, Area L/D > 2 & L/D </= 6 6, if L/D </= 2 2.0 0 Eq Eq. 8.2.2 8 2 2 result is shown Av1 = 0.3133 sq meter 3.37 sq feet Av1= Av0[1+0.6(L/D-2) [ ( / )

0 75 0.75

exp(-0.95P p( red )

- High Turbulnce Correction, if velocity is greater than 20 20-m/sec m/sec Qair i = Lequip = 0 118 0.118 3.64 0 00 0.00 0 0.3133 meter /sec meter meter/sec meter/sec / meter/sec meter

2

3

14 998 14,998 11.94

SCFH feet feet/sec feet/sec / feet/sec sq feet

Air flow rate through the equipment Equipment overall length in direction of air product flow Maximum tangential air velocity in the equipment Circumferential f ( (tangential) g ) air velocity y in the equipment q p

Vtan_max = Vtan = Av2 =

0 00 0.00 0.00 0 06 0.06

3.37

Vaxial = 0.01717608 0 01717608

Vaxiall = ( Qair L ) / V Av2=[(1+max(v [( a ( axial, vtan) )-20)/36]0.7]A 0)/36] 0 ] v1

- Effects of Panel Inertia, if panel mass 40-kg/m2 & Kst 250 n = MT = Av3 = 1 93.7777 0 3133 0.3133 no vents no. kg/m

2 2

M = 19.20 3 37 3.37

12 20 12.20 lb/ft

2

k / kg/m

2 0.2

2 50 2.50 )(n ) (n

0.3

lb/sq ft

0.5 1.67

Mt=[6.67 =[6.67(P (Pred

)(V/K ) (V/Kst

05 0.5

)]

meter

sq f feet t

Av3=[1+(0.0075)M [1 (0 0075) M

06 0.6

K Kst

/( /(n

03 0.3

VP V Pred

02 0.2

)] Av2 )]A

- Eff Effects t of fP Partial ti l V Volume l C Correction, ti .. if Xr can be b determined d t i d = 0.440195197 Av4 = 0 3133 0.3133 Pred/Pmax meter

2

Xr = 3 3726 3.3726

1.000 sq f feet t

fill fraction > Av4=Av3Xr

-1/3

(X ( r-/1-)

05 0.5

- Effects ec s o of Initially a y Elevated e a ed Pressure essu e 0 8.0000 0 2527 0.2527 bar-g bar-g g meter

2

0 00 0.00 2 72 2.72

psig sq feet

Peffective = bar-g g

-4

bar-g

4/3 /

effective = 0.440195197

Avep =

Avep=Av1/Av010 (1+1.54((P (1+1 54((Pstat-P Pinitial)/1+Peffective) K KstVol Vol

3/4

(1/ (1/effective-1) 1)

05 0.5

8.5.1 26 26. 27. 28 28. 29. 30 30. 31. Lduct = d Dh = Kinlet : Kelbows : f DL/D L/Dh = Avf =

- Effects of Vent Ducts 12 00 12.00 1.5 5 15 1.5 2.4 0 107 0.107 1.7700

2

meter meter ee Kexit : K = assum Avent = meter

39 37 39.37 4.92 9 0 75 0.75 4.757 1 77 1.77 19.0523

feet feet ee E1 = E2 = meter t

2

= fD = 0 85 0.85 6.37 19 05 19.05 Avf=Av4(1+1.18E (1+1.18 E1

0 26 0.26 0.0133 0 0 33

4

effective roughness, roughness mm fD=[1/(1.14-2log [1/(1.14 2log10(/Dh)]

4/3 /3 2

E1=( Avf Lduct )/V E2=(10 A Avf)/(1+1.54 )/(1+1.54P Pstat sq feet

0.8

)K ) KstV V

3/ 3/4

%error = )(K/K ) (K/Ko)

0.5

0 00% 0.00%

sq feet

E E2

0.4

explosion dusts - NFPA

Psafety January 2001

También podría gustarte

- Ped Med HandbookDocumento27 páginasPed Med HandbookSoad Shedeed0% (1)

- Pit Explosion ProtectionDocumento32 páginasPit Explosion ProtectionVictor VazquezAún no hay calificaciones

- NFPA 68 2012 Revised 20130122Documento99 páginasNFPA 68 2012 Revised 20130122Sharon Lambert100% (2)

- Remedies FlowDocumento44 páginasRemedies Flowzeebeelo100% (1)

- Single Line DiagramDocumento1 páginaSingle Line DiagramGhanshyam Singh100% (2)

- 02.1 Temperature NV Sup1Documento8 páginas02.1 Temperature NV Sup1uki12345Aún no hay calificaciones

- (Page Chapter 5 - ACGIH) : Velocity Pressure Method Calculation SheetDocumento2 páginas(Page Chapter 5 - ACGIH) : Velocity Pressure Method Calculation SheetBukhory Tajudin0% (1)

- 03 HRR Flame Height Burning Duration CalculationsDocumento2 páginas03 HRR Flame Height Burning Duration Calculationslutfi awnAún no hay calificaciones

- Calculations For Heat FluxDocumento10 páginasCalculations For Heat FluxSiva Kumar SalumuriAún no hay calificaciones

- ATEXDocumento12 páginasATEXJacqueline AdamsAún no hay calificaciones

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocumento107 páginasA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- Engineering Units ConverterDocumento23 páginasEngineering Units ConverterahmadlieAún no hay calificaciones

- Chimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficeDocumento1 páginaChimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficemohdnazirAún no hay calificaciones

- Dust VdiDocumento4 páginasDust VdiFrancesco RamaccioniAún no hay calificaciones

- 15 Explosion CalculationsDocumento6 páginas15 Explosion CalculationsNakkolopAún no hay calificaciones

- Steam BypassDocumento39 páginasSteam BypassKhoirul WaladAún no hay calificaciones

- PPS DOC-USM0001 (CTX-V - Design, Installation, Operation & Maintenance Manual) Rev ADocumento55 páginasPPS DOC-USM0001 (CTX-V - Design, Installation, Operation & Maintenance Manual) Rev AdraganvranesAún no hay calificaciones

- Effects ManualDocumento213 páginasEffects Manualliamsutd99Aún no hay calificaciones

- 418-250-D00-Q2-001 (Calculation For Compressed Air Package - Rev.01)Documento9 páginas418-250-D00-Q2-001 (Calculation For Compressed Air Package - Rev.01)mehdi227Aún no hay calificaciones

- Restrictive Orifice Calc For Tube FinalDocumento12 páginasRestrictive Orifice Calc For Tube FinalsafaldAún no hay calificaciones

- 04 Flame Height CalculationsDocumento22 páginas04 Flame Height Calculationsscrbdgharavi100% (1)

- Quentin A. Baker Et Al - Update of "Guidelines To Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE and Flash Fire Hazards"Documento10 páginasQuentin A. Baker Et Al - Update of "Guidelines To Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE and Flash Fire Hazards"SodaMoussezAún no hay calificaciones

- 10 Detector Activation Time Sup1 SiDocumento16 páginas10 Detector Activation Time Sup1 SiShazreel AmirAún no hay calificaciones

- Sizing of Dust Explosion Vents in The Process IndustriesDocumento12 páginasSizing of Dust Explosion Vents in The Process IndustriesjosethompsonAún no hay calificaciones

- Choice of Runaway Reaction Scenarios For Vent Sizing Based Onpseudo Adiabatic Calorimetric TechniquesDocumento48 páginasChoice of Runaway Reaction Scenarios For Vent Sizing Based Onpseudo Adiabatic Calorimetric TechniquesgiovanniAún no hay calificaciones

- Power Plant Design HandbookDocumento135 páginasPower Plant Design HandbookRehman Zahid100% (1)

- Fire Resisting Construction 1996-AllDocumento39 páginasFire Resisting Construction 1996-AlliyhkAún no hay calificaciones

- Flameless Vents Research Report - hsl06105Documento36 páginasFlameless Vents Research Report - hsl06105dale_hansen_5Aún no hay calificaciones

- Test Help StatDocumento18 páginasTest Help Statthenderson22603Aún no hay calificaciones

- Fixed Water Spray Demand Calculations For Fire Protection of TanksDocumento2 páginasFixed Water Spray Demand Calculations For Fire Protection of TanksKyaw Kyaw AungAún no hay calificaciones

- 10 Sprinkler Activation TimeDocumento29 páginas10 Sprinkler Activation TimeNapoleon SoldevillaAún no hay calificaciones

- Seminario Venezuela - PROTEGODocumento226 páginasSeminario Venezuela - PROTEGOrohl55Aún no hay calificaciones

- Protego PDFDocumento18 páginasProtego PDFNemezis1987Aún no hay calificaciones

- Production of BiodieselDocumento49 páginasProduction of Biodieselteja100% (1)

- Organic Fertilizer RRLDocumento8 páginasOrganic Fertilizer RRLEldon Jay MaltoAún no hay calificaciones

- Design of AgitatorDocumento3 páginasDesign of AgitatorDanEstradaAún no hay calificaciones

- At Ex Explosion GuidelinesDocumento16 páginasAt Ex Explosion GuidelinesjovanivanAún no hay calificaciones

- Msds - Auto I.T KeroseneDocumento6 páginasMsds - Auto I.T KeroseneCharith LiyanageAún no hay calificaciones

- A1. Protego - Venting of Atmospheric and Low-Pressure Storage TanksDocumento56 páginasA1. Protego - Venting of Atmospheric and Low-Pressure Storage TanksAnnie De WildeAún no hay calificaciones

- Dust Explosion Venting in Silos: A Comparison of Standards NFPA 68 and EN 14491Documento23 páginasDust Explosion Venting in Silos: A Comparison of Standards NFPA 68 and EN 14491david07750% (1)

- Muscovy DucksDocumento27 páginasMuscovy DucksStephenAún no hay calificaciones

- An Improved Flammability Diagram ForDocumento19 páginasAn Improved Flammability Diagram ForMohanad El-HarbawiAún no hay calificaciones

- Process Design ParametersDocumento6 páginasProcess Design ParametersDeden SobirinAún no hay calificaciones

- Sfpe Handbook 5th Ed IndexDocumento42 páginasSfpe Handbook 5th Ed Indexmohammed el erian50% (2)

- Estimate Emissions AicheDocumento4 páginasEstimate Emissions Aichecymy100% (1)

- CEN - TR 15281-2006 Guidance On Inerting For The Prevention of ExplosionsDocumento54 páginasCEN - TR 15281-2006 Guidance On Inerting For The Prevention of Explosionsstion100% (1)

- PGS2-1997 Methods For The Calculation of Physical Effects Chapter 3 Pool EvaporationDocumento128 páginasPGS2-1997 Methods For The Calculation of Physical Effects Chapter 3 Pool EvaporationPieter GrendelAún no hay calificaciones

- Shapa Venting Paper 10Documento10 páginasShapa Venting Paper 10nshsharma7475Aún no hay calificaciones

- Report Dust Explosion Protection Using Flameless VentingDocumento18 páginasReport Dust Explosion Protection Using Flameless Venting설동하Aún no hay calificaciones

- Recommendation Handling of Norit GL 50Documento9 páginasRecommendation Handling of Norit GL 50Mátyás DalnokiAún no hay calificaciones

- Consequence Assessment of Vapour Cloud Explosion Involving Hydrogen ReleaseDocumento7 páginasConsequence Assessment of Vapour Cloud Explosion Involving Hydrogen ReleaseRiccardo CozzaAún no hay calificaciones

- Case Study Vent SizingDocumento5 páginasCase Study Vent SizingLluís Vidales SerresAún no hay calificaciones

- Phast To Phast Risk PDFDocumento6 páginasPhast To Phast Risk PDFHimanshu ChichraAún no hay calificaciones

- Nordtest Method NT Fire 049Documento16 páginasNordtest Method NT Fire 049mail2021Aún no hay calificaciones

- NPSHADocumento5 páginasNPSHAjokishAún no hay calificaciones

- BS EN 00003-3-1996 ScanDocumento16 páginasBS EN 00003-3-1996 ScanRinu RavikumarAún no hay calificaciones

- Marking Non Electrical Equipment Ex PDFDocumento1 páginaMarking Non Electrical Equipment Ex PDFMMAún no hay calificaciones

- Sinorix N2 300 BarDocumento41 páginasSinorix N2 300 BarDien HuynhAún no hay calificaciones

- OVERPRESSURE Neutre PDFDocumento50 páginasOVERPRESSURE Neutre PDFIgor SpirovAún no hay calificaciones

- iPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBDocumento1 páginaiPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBmlutfimaAún no hay calificaciones

- Ducting DesignDocumento31 páginasDucting DesignIrwan SattuAún no hay calificaciones

- Pressure Drop Via The Karman MethodDocumento2 páginasPressure Drop Via The Karman MethodAtul kumar KushwahaAún no hay calificaciones

- L7Documento73 páginasL7brianAún no hay calificaciones

- Reduce Hazards-Vaccum SystemDocumento7 páginasReduce Hazards-Vaccum SystemChem.EnggAún no hay calificaciones

- Vessel VolumesDocumento72 páginasVessel VolumesPaula RiveraAún no hay calificaciones

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDe EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesAún no hay calificaciones

- Engineering Units Converter (Version 1)Documento26 páginasEngineering Units Converter (Version 1)segunoyesAún no hay calificaciones

- Engineering Units ConverterDocumento26 páginasEngineering Units ConvertersegunoyesAún no hay calificaciones

- Projet Caractéristiques Des Pompes Fonctionnant en Turbines: Rapport Final, 31 Décembre 2006Documento60 páginasProjet Caractéristiques Des Pompes Fonctionnant en Turbines: Rapport Final, 31 Décembre 2006Anonymous NGXdt2BxAún no hay calificaciones

- CASO37F2012-Detailed ReportDocumento115 páginasCASO37F2012-Detailed ReportCarlos CastilloAún no hay calificaciones

- Selfheating and Spontaneous Ignition Spontaneous CombustionDocumento2 páginasSelfheating and Spontaneous Ignition Spontaneous CombustionKhoirul WaladAún no hay calificaciones

- Power Plant Manual 1Documento8 páginasPower Plant Manual 1Khoirul WaladAún no hay calificaciones

- Mathematics For Electrical Engineering I: Dr. G.A. PavliotisDocumento67 páginasMathematics For Electrical Engineering I: Dr. G.A. PavliotisKhoirul WaladAún no hay calificaciones

- Conservation of Mass, Momentum, and EnergyDocumento8 páginasConservation of Mass, Momentum, and EnergyKhoirul WaladAún no hay calificaciones

- TP PC 11 02Documento16 páginasTP PC 11 02Khoirul Walad100% (1)

- Fire Protection System Testing & Commissioning ProcedureDocumento268 páginasFire Protection System Testing & Commissioning ProcedureBen LimAún no hay calificaciones

- Drawing Installation JU6H D538Documento2 páginasDrawing Installation JU6H D538Khoirul WaladAún no hay calificaciones

- Temp Set Value - Siemens Motor 1RQ1Documento3 páginasTemp Set Value - Siemens Motor 1RQ1Khoirul WaladAún no hay calificaciones

- Industrial Explosion Protection InstituteDocumento4 páginasIndustrial Explosion Protection InstituteKhoirul WaladAún no hay calificaciones

- AP 01 DiverterTaurusDocumento1 páginaAP 01 DiverterTaurusKhoirul WaladAún no hay calificaciones

- Handbook For Developing Micro Hydro in British Columbia: March 23, 2004Documento69 páginasHandbook For Developing Micro Hydro in British Columbia: March 23, 2004Armand Doru DomutaAún no hay calificaciones

- Etpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsDocumento3 páginasEtpm Mód 3 Assignment 2.1 Grammar and Use of English SkillsLourdes LimaAún no hay calificaciones

- Bharati AXA Life InsuranceDocumento57 páginasBharati AXA Life InsuranceNaina_Dwivedi_6514100% (3)

- IBM Tivoli Monitoring Implementation and Performance Optimization For Large Scale Environments Sg247443Documento526 páginasIBM Tivoli Monitoring Implementation and Performance Optimization For Large Scale Environments Sg247443bupbechanhAún no hay calificaciones

- Pricelist Jan 2023Documento7 páginasPricelist Jan 2023Rahmat FadilAún no hay calificaciones

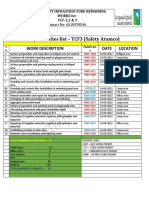

- Daily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationDocumento2 páginasDaily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationSheri DiĺlAún no hay calificaciones

- Depreciation Is A Term Used Reference To TheDocumento14 páginasDepreciation Is A Term Used Reference To TheMuzammil IqbalAún no hay calificaciones

- Hydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGDocumento20 páginasHydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGHanzil HakeemAún no hay calificaciones

- Add MITx Credentials To Resume and LinkedIn PDFDocumento5 páginasAdd MITx Credentials To Resume and LinkedIn PDFRizwanAún no hay calificaciones

- FEDocumento20 páginasFEKenadid Ahmed OsmanAún no hay calificaciones

- L11 Single Phase Half Controlled Bridge ConverterDocumento19 páginasL11 Single Phase Half Controlled Bridge Converterapi-19951707Aún no hay calificaciones

- 6 CHDocumento27 páginas6 CHjafariAún no hay calificaciones

- EC1002 Commentary 2022Documento32 páginasEC1002 Commentary 2022Xxx V1TaLAún no hay calificaciones

- Spice Board BBLDocumento24 páginasSpice Board BBLvenkatpficoAún no hay calificaciones

- Ge Washing Machine ManualDocumento52 páginasGe Washing Machine Manuallillith1723Aún no hay calificaciones

- Bảo MậtDocumento2 páginasBảo MậtMinh Nghia PhamAún no hay calificaciones

- Canon IR2016J Error Code ListDocumento4 páginasCanon IR2016J Error Code ListZahidShaikhAún no hay calificaciones

- Metrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233ADocumento3 páginasMetrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233AJulian MoraAún no hay calificaciones

- Pca - STATADocumento17 páginasPca - STATAAnonymous U5RYS6NqAún no hay calificaciones

- Best of SEO#1 SEO Training & Content Marketing Course 2022Documento2 páginasBest of SEO#1 SEO Training & Content Marketing Course 2022Oscar MascarenoAún no hay calificaciones

- Emailing Prime - Brochure - DigitalDocumento32 páginasEmailing Prime - Brochure - DigitalCASA VALLIAún no hay calificaciones

- ECON 202 Optional Problem SetDocumento3 páginasECON 202 Optional Problem SetAnthony SabarilloAún no hay calificaciones

- Jurnal Stamina: E-ISSN 2655-2515 P-ISSN 2655-1802Documento9 páginasJurnal Stamina: E-ISSN 2655-2515 P-ISSN 2655-1802Yogi TioAún no hay calificaciones

- SIConitDocumento2 páginasSIConitJosueAún no hay calificaciones