Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Llautó M38 CuZn37

Cargado por

Josep TanuDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Llautó M38 CuZn37

Cargado por

Josep TanuCopyright:

Formatos disponibles

Wieland-M38

CuZn37

C27200

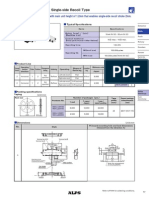

Physical Properties*

Electrical

Conductivity

MS/m

%IACS

15

26

Thermal Conductivity W/(mK) 120

Coefficient

of Electrical

Resistance** 10

-3

/K 1.7

Coefficient of

Thermal Expansion** 10

-6

/K 20.2

Density g/cm

3

8.44

Modulus of Elasticity GPa 110

Specific Heat J/(gK) 0.377

Poissons Ratio 0.34

* Reference values at room temperature

** Between 0 and 300 C

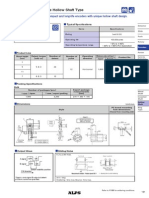

Electrical Conductivity Bendability (Strip Thickness t 0.5 mm)

Rolled Products

Corrosion Resistance

Good resistance to: fresh water,

neutral or alkaline solutions, organic

compounds as well as land, sea, and

industrial atmosphere.

Not resistant to: acids, hydrous

sulphur compounds, hydrous

ammonia (stress corrosion cracking)

in non-stress-relieved condition.

Material Designation

EN CuZn37

UNS* C27200

* Unified Numbering System (USA)

Chemical Composition (Reference)

Cu 63 %

Zn balance

Typical Applications

Components for the electrical

industry

Stamped parts

Connectors

Fabrication Properties

Capacity for Being

Cold Worked excellent

Machinability fair

Capacity for Being

Electroplated excellent

Capacity for Being

Hot-Dip Tinned excellent

Soft Soldering excellent

Resistance

Welding good

Gas Shielded

Arc Welding fair

Laser Welding less suitable

Mechanical Properties

Temper R300 R350 R410 R480 R550 R630

Tensile Strength R

m

MPa 300370 350440 410490 480560 550640 630

Yield Strength R

p0.2

MPa 180 170 300 430 500 600

Elongation A

50mm

% 38 19 8 3

Temper H055 H095 H120 H150 H170 H190

Hardness HV 5595 95125 120155 150180 170200 190

0

M37

1

2

3

4

5

6

11

R300

M37

12

13

14

15

16

17

H055

R350

H095

R410

H120

R480

H150

R550

H170

R630

H190

R300

H055

R350

H095

R410

H120

R480

H150

R550

H170

R630

H190

R

e

l

.

B

e

n

d

i

n

g

R

a

d

i

u

s

r

/

t

9

0

Temper

E

l

.

C

o

n

d

u

c

t

i

v

i

t

y

(

M

S

/

m

)

Temper

bending edge

I rolling direction

bending edge II rolling direction

0

M37

1

2

3

4

5

6

11

R300

M37

12

13

14

15

16

17

H055

R350

H095

R410

H120

R480

H150

R550

H170

R630

H190

R300

H055

R350

H095

R410

H120

R480

H150

R550

H170

R630

H190

R

e

l

.

B

e

n

d

i

n

g

R

a

d

i

u

s

r

/

t

9

0

Temper

E

l

.

C

o

n

d

u

c

t

i

v

i

t

y

(

M

S

/

m

)

Temper

bending edge

I rolling direction

bending edge II rolling direction

1

0

/

1

2

B

m

(

G

S

W

/

R

i

)

Wieland-M38

CuZn37

C27200

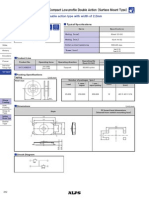

Strip thickness from 0.10 mm,

thinner gauges on request

Strip width from 3 mm,

however min. 10 x strip thickness

Standard coils with outside

diameters up to 1400 mm

Traverse-wound coils with drum

weights up to 1.5 t

Multicoil up to 5 t

Hot-dip tinned strip

Contour-milled strip

Sheet

Strip and sheet with protective

coating

Types and Formats Available Dimensions Available

Wieland-Werke AG www.wieland.com

Graf-Arco-Str. 36, 89079 Ulm, Germany, Phone +49 731 944 2030, Fax +49 731 944 4257, info@wieland.de

This leaflet is for your general information only and is not subject to revision. No claims can be derived from it unless there is evidence of intent or gross negligence. The data given are no warranty that the product is of a

specified quality and they cannot replace expert advice or the customers own tests.

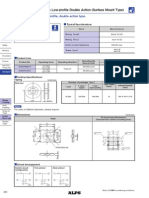

Resistance to Softening

Vickers hardness

after heat treatment

(typical values)

Fatigue Strength

The fatigue strength is defined as the maximum bending stress amplitude which a material withstands for 10

7

load cycles

under symmetrical alternate load without breaking. It is dependent on the temper tested and is about

1

/3 of the tensile

strength R

m

.

Thermal Stress Relaxation

Stress remaining after thermal relaxa-

tion as a function of Larson-Miller

parameter (F. R. Larson, J. Miller, Trans

ASME74 (1952) 765775) given by:

P = (20 + log(t))*(T + 273)*0.001.

Time t in hours, temperature T in C.

Example: P = 9 is equivalent to

1.000 h/118 C.

Measured on rolled to temper speci-

mens parallel to rolling direction. Total

stress relaxation depends on the

applied stress level. Furthermore, it

is increased to some extent by cold

deformation.

M38

60

70

80

90

100

110

120

130

140

150

160

170

180

190

0 10 20 30 40 50 60

600 C

500 C

400 C

V

i

c

k

e

r

s

H

a

r

d

n

e

s

s

H

V

Temper R410

Time (min)

M38

60

70

80

90

100

110

120

130

140

150

160

170

180

190

0 10 20 30 40 50 60

600 C

500 C

400 C

V

i

c

k

e

r

s

H

a

r

d

n

e

s

s

H

V

Temper R550

Time (min)

11.0 10.0 9.0 8.0 7.0

40

50

60

70

80

90

100

M33 (wh)

Larson-Miller parameter P

R

e

s

i

d

u

a

l

S

t

r

e

s

s

(

%

)

Temper R410, R480, R550, R630

También podría gustarte

- K48-50 Carbon Film ResistorsDocumento3 páginasK48-50 Carbon Film ResistorseminuscloudAún no hay calificaciones

- Approval Sheet: D S C Electronics Co., LTDDocumento9 páginasApproval Sheet: D S C Electronics Co., LTDJorge Vásquez CarreñoAún no hay calificaciones

- CuAg0,1P PDFDocumento8 páginasCuAg0,1P PDFirajfarji2481Aún no hay calificaciones

- SS 1.4122Documento2 páginasSS 1.4122Bipin Sadasivan100% (2)

- Tap1000 SeriesDocumento1 páginaTap1000 Seriescjsalazarb78Aún no hay calificaciones

- ThyssenKrupp Steel Data Sheet P235GHDocumento4 páginasThyssenKrupp Steel Data Sheet P235GHjaseerkannothAún no hay calificaciones

- 1011 Chapter 3Documento38 páginas1011 Chapter 3Eman Sarmiento0% (1)

- DanfossMBS3100 3150Documento6 páginasDanfossMBS3100 3150Jerine BabuAún no hay calificaciones

- Engineering Materials Data SheetDocumento6 páginasEngineering Materials Data Sheetrajarao1234Aún no hay calificaciones

- 1.2.5 Precision Temperature Sensing Resistor PRC100: Length: 13.5mm (Excl. Leads) Diameter: 5mm RS Stock NumberDocumento12 páginas1.2.5 Precision Temperature Sensing Resistor PRC100: Length: 13.5mm (Excl. Leads) Diameter: 5mm RS Stock NumberEng Bashar MufidAún no hay calificaciones

- Pressure Transmitter For General Purpose Type MBS 1700 and MBS 1750Documento8 páginasPressure Transmitter For General Purpose Type MBS 1700 and MBS 1750mquaiottiAún no hay calificaciones

- B57153S479MDocumento14 páginasB57153S479Mcasa1233333Aún no hay calificaciones

- X5CrNiCuNb 16-41.4542Documento2 páginasX5CrNiCuNb 16-41.4542nuesteAún no hay calificaciones

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocumento5 páginasLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuAún no hay calificaciones

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocumento4 páginasDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraAún no hay calificaciones

- Resistive Position Sensors Linear Type Specifications and VarietiesDocumento5 páginasResistive Position Sensors Linear Type Specifications and VarietiesshyhuAún no hay calificaciones

- ThermistorDocumento44 páginasThermistorjuca_br2002Aún no hay calificaciones

- SensorsDocumento137 páginasSensorsVarsha AcharyaAún no hay calificaciones

- 1.4878 Eng PDFDocumento3 páginas1.4878 Eng PDFRoberto_PrrAún no hay calificaciones

- Nickel-Chromium Alloy Data SheetDocumento2 páginasNickel-Chromium Alloy Data SheetsoyteleAún no hay calificaciones

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocumento3 páginas10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuAún no hay calificaciones

- DI-MC 355: Product DescriptionDocumento4 páginasDI-MC 355: Product DescriptionvinodAún no hay calificaciones

- RTD pt100Documento6 páginasRTD pt100jyotiblossomsAún no hay calificaciones

- Strain Gauge PresentationDocumento33 páginasStrain Gauge PresentationDr. Yudhishthir RautAún no hay calificaciones

- Current Sensing Chip Resistors: NCST SeriesDocumento6 páginasCurrent Sensing Chip Resistors: NCST Seriessavio77Aún no hay calificaciones

- DESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m HeightDocumento15 páginasDESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m Heightmsiddiq1100% (2)

- TACT Switch GuideDocumento3 páginasTACT Switch GuideshyhuAún no hay calificaciones

- Parkers: BS EN 10088-3: 1995Documento2 páginasParkers: BS EN 10088-3: 1995Sanath WijerathneAún no hay calificaciones

- 1.4418-Stainless Soft Martensitic Chromium-Nickel-Molybdenum SteelDocumento2 páginas1.4418-Stainless Soft Martensitic Chromium-Nickel-Molybdenum SteelwholenumberAún no hay calificaciones

- Quality 42crmo4: Lucefin GroupDocumento1 páginaQuality 42crmo4: Lucefin GroupAnonymous Gbers2EAún no hay calificaciones

- PTC Thermistors As Limit Temperature Sensors PDFDocumento11 páginasPTC Thermistors As Limit Temperature Sensors PDFmarckalhiAún no hay calificaciones

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocumento3 páginas4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuAún no hay calificaciones

- JN3R090MDocumento5 páginasJN3R090MGautham VenkatAún no hay calificaciones

- Cor-Ten - Weather & Corrosion Resistant SteelDocumento5 páginasCor-Ten - Weather & Corrosion Resistant SteelAnjan DeyAún no hay calificaciones

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetDocumento3 páginasThyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetShariq KhanAún no hay calificaciones

- Series 800 1000 TubularDocumento6 páginasSeries 800 1000 TubularRatnesh GaurAún no hay calificaciones

- Insulated Shaft Rotary EncodersDocumento3 páginasInsulated Shaft Rotary EncodersshyhuAún no hay calificaciones

- EC18A 18mm Insulated Shaft EncoderDocumento4 páginasEC18A 18mm Insulated Shaft EncodershyhuAún no hay calificaciones

- 1.2 (H) MM, Single-Side Recoil TypeDocumento4 páginas1.2 (H) MM, Single-Side Recoil TypeshyhuAún no hay calificaciones

- 10D9Documento9 páginas10D9piyushpandeyAún no hay calificaciones

- Pressure Transmitter Type MBS 33M (Marine) : Data SheetDocumento8 páginasPressure Transmitter Type MBS 33M (Marine) : Data SheetAsif HameedAún no hay calificaciones

- The Electrical Resistance and Its Temperature Coefficient: ResistivityDocumento3 páginasThe Electrical Resistance and Its Temperature Coefficient: ResistivityMohd DaudAún no hay calificaciones

- NTC Thermistor TTC03 Series Temperature Sensor <40 CharsDocumento7 páginasNTC Thermistor TTC03 Series Temperature Sensor <40 CharsBilly SilvaAún no hay calificaciones

- Study Report 3comp LabDocumento8 páginasStudy Report 3comp LabEriane GarciaAún no hay calificaciones

- SS 6mo - 1.4547Documento1 páginaSS 6mo - 1.4547f_riseAún no hay calificaciones

- 42CrMo4 Datos Tecnicos PDFDocumento2 páginas42CrMo4 Datos Tecnicos PDFjlplazaolaAún no hay calificaciones

- Stainless Steel 1.4828 Material Data SheetDocumento3 páginasStainless Steel 1.4828 Material Data SheetAvn PrasadAún no hay calificaciones

- Ankral RN: General InformationDocumento1 páginaAnkral RN: General Informationmahreza189Aún no hay calificaciones

- Micro Electric MotorDocumento1 páginaMicro Electric Motorarobertson_74Aún no hay calificaciones

- PRESENTATION ON STRAIN GAUGE MEASUREMENTDocumento18 páginasPRESENTATION ON STRAIN GAUGE MEASUREMENTaslamhossainAún no hay calificaciones

- 35mm Ring Encoder GuideDocumento3 páginas35mm Ring Encoder GuideshyhuAún no hay calificaciones

- QStE 380 TM PDFDocumento2 páginasQStE 380 TM PDFJetesh DevgunAún no hay calificaciones

- Proposal ExampleDocumento4 páginasProposal ExampleEce YağmurAún no hay calificaciones

- HTR India - Products - Wire Wound Resistors - Symmetry Resistors - HSRC (English)Documento3 páginasHTR India - Products - Wire Wound Resistors - Symmetry Resistors - HSRC (English)crplzAún no hay calificaciones

- Busbar Size CalculationDocumento5 páginasBusbar Size Calculationdermasdemo100% (6)

- Mechanical Science for Technicians: Volume 1De EverandMechanical Science for Technicians: Volume 1Calificación: 5 de 5 estrellas5/5 (1)

- Integrated Service and Auxiliary Production Processes ManagementDocumento16 páginasIntegrated Service and Auxiliary Production Processes ManagementJosep TanuAún no hay calificaciones

- Quality Manual ISO TS 16949 2009Documento46 páginasQuality Manual ISO TS 16949 2009spahicdanilo100% (2)

- DV03PUB27 Study GuideDocumento5 páginasDV03PUB27 Study GuideJosep TanuAún no hay calificaciones

- SS304 304L Data SheetDocumento2 páginasSS304 304L Data SheetPrakash KumarAún no hay calificaciones

- Research Report - Land PollutionDocumento9 páginasResearch Report - Land PollutionMisbah GroupAún no hay calificaciones

- Nace Standards and Specifications Related Oil Natural Gas InfrastructureDocumento5 páginasNace Standards and Specifications Related Oil Natural Gas InfrastructurePharmacist ShimaaAún no hay calificaciones

- Disassembly of The Parts (Indoor Unit) : LS-K1823/1863/1867/2465/2665/2669CL/CM/CNDocumento6 páginasDisassembly of The Parts (Indoor Unit) : LS-K1823/1863/1867/2465/2665/2669CL/CM/CNmanuelAún no hay calificaciones

- Consolidated 1811 SeriesDocumento16 páginasConsolidated 1811 Seriesivan_fuenzalida_1Aún no hay calificaciones

- Dickella Premakumara Final Best Practices PDFDocumento36 páginasDickella Premakumara Final Best Practices PDFjune dela cernaAún no hay calificaciones

- Shore Hardness DINDocumento6 páginasShore Hardness DINSachin LomteAún no hay calificaciones

- FMCG Sector Analysis - Long Term ProfitabilityDocumento33 páginasFMCG Sector Analysis - Long Term ProfitabilityADITYA RANJANAún no hay calificaciones

- SY35U PART FILTER PERIODICAL SERVICEDocumento2 páginasSY35U PART FILTER PERIODICAL SERVICEIman SantosaAún no hay calificaciones

- Geberit Silent-PP Pipe With One SocketDocumento2 páginasGeberit Silent-PP Pipe With One SocketeneajataganiAún no hay calificaciones

- Water Cooled Cable For Electric FurnaceDocumento4 páginasWater Cooled Cable For Electric FurnaceWAWANAún no hay calificaciones

- Storing and Sanitation TechniquesDocumento27 páginasStoring and Sanitation TechniquesMarjory Alga Omale100% (1)

- A Case Study To Bottle The Biogas in Cylinders As Source ofDocumento4 páginasA Case Study To Bottle The Biogas in Cylinders As Source ofSamir VahoraAún no hay calificaciones

- 154 Loesche Mills For Cement Raw Material E 2016Documento28 páginas154 Loesche Mills For Cement Raw Material E 2016faheemqcAún no hay calificaciones

- .Auwp Contentuploads2022030525 055 Install Guide Commercial Package Ver. 9 PDFDocumento56 páginas.Auwp Contentuploads2022030525 055 Install Guide Commercial Package Ver. 9 PDF7tddprzxbbAún no hay calificaciones

- Summary of Procedure For ASTM D 698Documento2 páginasSummary of Procedure For ASTM D 698Miller De Leon Cutora100% (1)

- 39 Tractor EmulsionDocumento4 páginas39 Tractor EmulsionJaga NathAún no hay calificaciones

- Ce133p 2 WSD NSCP 2015Documento2 páginasCe133p 2 WSD NSCP 2015RapAún no hay calificaciones

- Bioreactor and SterilizationDocumento22 páginasBioreactor and SterilizationMuhd Shukri100% (2)

- Articulado PDFDocumento90 páginasArticulado PDFMiguel Fuentes100% (1)

- Aqua Culture Brochure - Fusi TechDocumento2 páginasAqua Culture Brochure - Fusi Techsaradhi sravan kumarAún no hay calificaciones

- Painting Specification for Aegean Refinery ProjectDocumento18 páginasPainting Specification for Aegean Refinery Projectraluca_19735597Aún no hay calificaciones

- King Saud University Mass Transfer ExamDocumento7 páginasKing Saud University Mass Transfer ExamAnnisa RahmaditaAún no hay calificaciones

- GLXXMobil Vacuoline 100 SeriesDocumento3 páginasGLXXMobil Vacuoline 100 SeriesAdrian RoperoAún no hay calificaciones

- Pile Soil InteractionDocumento250 páginasPile Soil Interactionnallay1705100% (3)

- Bha Coil Tubing Tools PDFDocumento35 páginasBha Coil Tubing Tools PDFJose Leonardo Materano Perozo100% (2)

- Block Diagram Pulp PT TELDocumento1 páginaBlock Diagram Pulp PT TELEra MileniaAún no hay calificaciones

- Chemsheets GCSE 1069 Allotropes of CarbonDocumento1 páginaChemsheets GCSE 1069 Allotropes of CarbonNoah KellerAún no hay calificaciones

- Week 2 Module - CHEMDocumento13 páginasWeek 2 Module - CHEMMichael AustriaAún no hay calificaciones

- Textile and Garments InformationDocumento7 páginasTextile and Garments InformationMd.Tipu SultanAún no hay calificaciones

- Metiche AnalDesign FRP Poles PDFDocumento26 páginasMetiche AnalDesign FRP Poles PDFMojtaba Mohammad PourAún no hay calificaciones