Documentos de Académico

Documentos de Profesional

Documentos de Cultura

OHL Design Manual

Cargado por

Ilia RazmadzeDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

OHL Design Manual

Cargado por

Ilia RazmadzeCopyright:

Formatos disponibles

Overhead Line Design Manual

Section 1

Aerial Bundled Conductor (ABC) Low Voltage Mains and Services

Asset Management

THIS IS AN UNCONTROLLED DOCUMENT, THE READER MUST CONFIRM ITS VALIDITY BEFORE USE

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 2

Table of Contents

1 2 3 4 5 Scope ................................................................................................................................5 References .......................................................................................................................6 Definitions ........................................................................................................................7 Introduction .....................................................................................................................9 Design Information ....................................................................................................... 10 5.1 5.2 5.3 5.4 6 GeneralPractice .................................................................................................... 10 Riskassessment..................................................................................................... 10 Earthing................................................................................................................. 10 DesignData ........................................................................................................... 10

Construction Information ............................................................................................ 12 6.1 6.2 GeneralPractice .................................................................................................... 12

6.1.1 Supports ................................................................................................................................. 12

Clearances ............................................................................................................. 12

6.2.1 6.2.2 General ................................................................................................................................... 12 Tree Clearances ................................................................................................................... 13

6.3 6.4 6.5 6.6 6.7 6.8 6.9

LowVoltageSupports............................................................................................ 13 Augering................................................................................................................ 13 Foundations .......................................................................................................... 13 Stays...................................................................................................................... 14 GeneralbackfillingandCompaction ..................................................................... 14 InLineConnections ............................................................................................... 15 ConnectionstotheBundle .................................................................................... 15

6.9.1 6.9.2 6.9.3 General ................................................................................................................................... 15 Limit on Number of Connections to the Bundle .......................................................... 15 Disconnections from the bundle ..................................................................................... 15 August 2012

6.10 6.11 6.12 6.13 6.14

Openpoints........................................................................................................... 15

6.10.1 General ................................................................................................................................. 15

AppendixAGADrawingsandMaterialsMains ................................................. 16 AppendixBGADrawingsandMaterialsServices ............................................. 37 AppendixCGADrawingsandMaterialsPoleMountedEquipment.................. 48 AppendixDGADrawingsandMaterialsEarthing............................................. 57

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 3

Overhead Line Design Manual

6.15 6.16 6.17 6.18 6.19 6.20 6.21 6.22 6.23 6.24 6.25

AppendixEReferenceListofallMaterialsforthisspecification ......................... 61 AppendixFDesignDataforConductorABC,4x120mm2 .................................... 66 AppendixGDesignDataforConductor,ABC,4x95mm2 .................................... 71 AppendixHDesignDataforConductor,ABC,2x95mm2 .................................... 76 AppendixIDesignDataforConductor,ABC,4x35mm2 ..................................... 81 AppendixJDesignDataforConductor,ABC,2x35mm2 ..................................... 86 AppendixKServiceSpans ................................................................................... 91 AppendixLUnstayedSupports .......................................................................... 93 AppendixMStaybaseandangleconversiontable ............................................. 95 Fulllistoftables .................................................................................................... 96 Fulllistoffigures ................................................................................................... 98

Revision Record

Issue 1.0 1.1 1.2 Date 26/08/2010 11/03/2011 17/08/2012 Prepared by Andy Horstead John Lowe Lee Strachan Details New document Document rebranded Reviewed for Publication on G81 Website

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 4

Overhead Line Design Manual

1 Scope

This specification details the design and construction requirements for all new types of Low Voltage (LV) Aerial Bundled Conductor (ABC) lines and services, operating in the range up to and including 1kV. LV ABC structures can be considered as one of three distinct types for design and construction purposes: 1. LV ABC distribution networks supported on wood poles. 2. LV ABC service connections (excludes terminations within property). 3. LV ABC pole-mounted equipment. ABC conductors comprising the following number of cores and cross-sectional areas are used in the above lines: 4. Conductor, ABC, 2x35mm2. 5. Conductor, ABC, 2x95mm2. 6. Conductor, ABC, 4x35mm2. 7. Conductor, ABC, 4x95mm2. 8. Conductor, ABC, 4x120mm2. These conductors are specified in more detail in EAS 00-0001and BS 7870-5.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 5

August 2012

Overhead Line Design Manual

2 References

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. Standard Number BS 1990 BS EN ISO 9001 BS EN ISO 14001 UKPN EDS-06 0016 ENA TS 43-12 ENA TS 43-13 ENA TS 43-14 BS 7870-5 Standard Description Wood pole for overhead lines (power and telecommunications lines) Quality Management Systems Requirements Environmental Management Systems Specification with guidance for use LV Networks Earthing Design Insulated Aerial Bundled Conductors erection requirements of low voltage overhead distribution systems Aerial Bundled Conductors (ABC) insulated with cross-linked polyethylene for low voltage overhead distribution systems Conductor fittings and associated apparatus for use with LV aerial bundled conductors Low Voltage Aerial Bundled Conductors

UKPN EM 01 UKPN EDS 09-0019 UKPN EAS 00-0001

Overhead line Construction Manual 2010 Safety signs and labelling of equipment UK Power Networks' Materials List (Overhead Lines)

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 6

Overhead Line Design Manual

3 Definitions

ABC CNE UKPN UK Power Networks DMS EDS ENA TS FoS GA JC,s IPC Manufacturer NI PME SJI XLPE Aerial Bundled Conductor Combined Neutral Earth UK Power Networks UK Power Networks Document Management System Engineering Design Standard Energy Networks Association Technical Specification Factor of Safety General Arrangement Job Cards Insulation Piercing Connector An organisation supplying equipment for use on networks owned by UK Power Networks Not Illustrated (i.e. item numbers on Figures). Protective Multiple Earthing Specific Job Instructions Cross-linked Polyethylene

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 7

August 2012

Overhead Line Design Manual

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 8

Overhead Line Design Manual

4 Introduction

The body of this specification covers general design and construction requirements. How to construct and maintain ABC is detailed in a separate manual known as the Overhead Line Construction Manual. Appendix A to Appendix C of this document comprises General Arrangement (GA) drawings with associated lists of materials for LV ABC structures as follows: 1. Appendix A comprises GAs for LV ABC distribution networks supported on wood poles. (Note that inside and outside angles are not as defined in ENA TS 43-12.) 2. Appendix B comprises GAs for LV ABC service connections, followed by a GA summarising ABC and CNE service spans 3. Appendix C comprises GAs for LV ABC pole-mounted equipment. Each list of materials identifies the components included in the associated GA and which supplementary items are needed to complete that structure. Variations within each GA for different conductors are covered by different columns in the associated list of materials. Note that the lists of materials for the connections and plant shown in Appendix B and Appendix C do not include the materials for the associated GA structure; many combinations are possible and it is not practical to cover every possible structure/connection variation here. (Refer to Appendix A for approved GA structures and materials.) Appendix E Reference List of all Materials for this specification comprises a reference list of all materials used within this specification. Appendixes F to M are tables of design data for this specification: one Appendix for each ABC type.

This specification fits into the overall design and construction process as outlined by the following process summary: (a) Carry out a risk assessment. (b) Generate a proposal taking into account the risk assessment. (c) Generate a proposal for a new line. (d) Choose a proposed route and a line survey carried out. (e) Plot pole positions, heights, clearances, and develop a line profile. (Note that the development of a line profile will require some data and parameters from Appendix F and subsequent Appendices.) (f) Compile a list of materials using the GAs and supplementary items identified in this specification (Appendix A, Appendix B, Appendix C and appropriate ES and/or ENA TS). The GAs and supplementary items shall be selected and used in accordance with the design and construction information given below and the data given in subsequent Appendices.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 9

August 2012

Overhead Line Design Manual

Appendix M provides a table to give distances in metres from pole base to stay base dependant on pole size. This has been provided to support the minimum angle of stay column provided in Appendix F to J.

Design Information

5.1 General Practice

Lines shall be designed using the GAs and supplementary items from Appendix A, Appendix B, Appendix C and the data from Appendix F to M, etc. The following information shall be taken into account during the design process.

5.2 Risk assessment

A risk assessment shall be carried out at the commencement of the design work to identify the site specific safety hazards. The design shall incorporate mitigation measures to control the risks, identified in the risk assessment, associated with the construction, operation and maintenance of the proposed overhead line and its suitability compared with an underground cable solution.

5.3 Earthing

System earthing shall meet the requirements of the current UK Power Networks LV Network Earthing Design Manual EDS 06 0016 . To provide a PME network the connection from the neutral of the bundle to the earth electrode(s) shall be installed and connected in accordance with the drawings given in Appendix D. (The PME connections are split across two drawings, because all pole mounted equipment GAs incorporate connections from bundle neutral to neutral/earth as mandatory requirements.)

5.4 Design Data

Each set of design data (Appendix F to M) contains all the information necessary for the conductor bundle specified, with the exception of poles supporting electrical plant. Design parameters used to construct the tables of design data are given for reference. Note that the basic span for this design is 50m. If ABC is to be installed onto an existing pole it is then assumed that the pole depth will be 1500 mm. The maximum wind loading span shall then be limited to the figures supplied in Table 6 and Table 12 (Appendix F and G). If an existing pole has to be changed due to decay or clearance problems then refer to tables for planting depth for new build. March 2011 For poles supporting electrical plant, strut loadings need to be re-calculated as necessary. (Note that 1000kg additional weight can be approximated to 1000kgf additional loading for this purpose.) Data in Appendix F to J, etc, are based on the minimum pole diameters included in BS 1990. In practice, if it is found that strut loadings exceed the values given in Appendix F to J, etc, the minimum pole top diameter needs to be re-calculated. Maximum service spans shall be in accordance with Figure 15: Concentric Service Spans and Figure 16: ABC Service Spans.

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 10

Overhead Line Design Manual

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 11

August 2012

Overhead Line Design Manual

6 Construction Information

6.1 General Practice

Construction practices shall be in accordance with the UK Power Networks Overhead Line Construction Manual. For reference, ABC phases and neutral shall be identified by the number of ribs on the insulation as follows: Phase L1: 1 rib. Phase L2: 2 ribs. Phase L3: 3 ribs. Neutral: fully ribbed. (Note that this applies whenever ABC is used; e.g. when neutral is run down the pole for connection to the neutral/earth connection.)

6.1.1

Supports

All fittings supporting the ABC system shall provide an insulating barrier rated at 1000V between the core insulation and the mechanical attachment. The ABC shall be attached in such a manner that it cannot make contact with any metalwork or stays. The maximum pole height for a service or service line shall be 9 metres. Weak links will be used on all poles except for the following: 1. Terminal poles 2. Section poles or 3. Either side of a road crossing.

6.2 Clearances

6.2.1 General

Clearances from external objects and structures (e.g. buildings, trees and roads) shall comply with ENA TS 43-12 In-line construction clearances shall comply with those specified in the specific job instructions detailed in the Overhead Line Construction Manual. In addition to the above, the following rules shall be followed: March 2011 1. Wherever possible, ABC conductors shall not pass directly over buildings and roofs. 2. Wherever it is necessary to over sail a building or roof, the relevant span shall not contain any in-line connections. 3. Where ABC is attached to a building which has a thatched roof, the attachment shall be a minimum of 0.5m from the thatched roof. 4. Once terminated, ABC shall be converted to concentric cable or insulated and sheathed (mechanically protected) cable within 0.5m of the point of attachment to a

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 12

Overhead Line Design Manual

building. Service cable lead-ins into the building shall be installed in accordance with the Overhead Line Construction Manual.

6.2.2

Tree Clearances

Where an ABC system is erected through trees, the following points shall be considered: 1. For additional information regarding overhead line clearances, refer to ENA TS 43-12. 2. Risks of the ABC being abraded by trees. 3. Sag variations and conductor swing due to the effects of the wind. 4. The effect of wind and snow loading on trees or branches bearing onto the ABC. 5. The danger of trees providing climbing access. 6. The amount of tree cutting required for ABC compared with conventional open wire systems can be significantly reduced. However, the XLPE insulation is susceptible to abrasion and shall not be allowed to come into contact with tree trunks, mature branches or heavy outer growth, under any circumstances. 7. Clearances through trees shall take account of maximum and minimum conductor sags, conductor swing and the anticipated tree growth rate and cutting periods.

6.3 Low Voltage Supports

All supports shall be fitted with a Safety Sign (Danger of Death) in accordance with UK Power Networks EDS 09-0019.

6.4 Augering

Augering the pole hole is the preferred method when the ground is suitable. After pole erection, the remaining hole shall be backfilled with suitable material based on soil condition. If there is a risk of movement due to poor soil conditions then a suitable cement mixture shall be used.

6.5 Foundations

Un-stayed angle poles shall be installed 0.5m deeper than the planting depth given in the Appendices to this specification. (Care shall be taken when planning un-stayed angle poles, particularly near walls.)

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 13

August 2012

Overhead Line Design Manual

6.6 Stays

Only the following types of stay are suitable for lines designed to this specification:

Load-lock anchors (Light)

Screw-in (Heavy)

Concrete blocks: Light 500 x 300 x 90mm Heavy 640 x 430 x 140mm

Refer to tables for staying arrangements. Heavy duty stay plates are useful for structures of restricted height: the overall distance between the fixing at the top of the pole and the stay insulator is less than that of an equivalent pole-top make-off. The distance of the stay-base from the pole-base are given in Appendix F J using angles in degrees from 0o to 45o measured between the pole and stay. This information is then supported by a further table 42 provided in Appendix M which gives the spread in metres between the stay and the pole at ground level.

March 2011

6.7 General back-filling and Compaction

All holes shall be backfilled with the excavated material but consideration should be given to soil condition. It may be necessary to import suitable material which can be mixed with a cement based compound for reinstatement around the pole.

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 14

Overhead Line Design Manual

6.8 In-Line Connections

Any poles erected in the highway (excluding grass verges) shall be backfilled with suitable material with reference to NRSWA requirements.

Compression fittings shall be used for all tension and in line non-tension connections. (Under no circumstances shall IPCs) be used to make in-line connections.)

6.9 Connections to the Bundle

6.9.1 General

Only ABC to ABC connections to the conductor bundle are permitted. Table 1 Number of IPCs required for Mains and service connections Scenario 120mm Mains or Service 95mm Mains or Service 35mm Mains or Service Phase 1 double bolt IPC 1 single bolt IPC 1 single bolt IPC Neutral 2 double bolt IPCs 2 single bolt IPCs 2 single bolt IPCs

6.9.1.1 Service Connections

For single phase and three phase connections to 95mm2 ABC and below, one single-bolt IPC shall be used on each phase conductor and two single-bolt IPCs shall be used on the neutral/earth conductor. For single phase and three phase connections to 120mm2 ABC, one double-bolt IPC shall be used on each phase conductor and two double-bolt IPCs shall be used on the neutral/earth conductor (as illustrated in the appropriate GAs).

6.9.1.2 Mains Connections

For all mains connections to 95mm2 and below, one single-bolt IPC shall be used on each phase conductor and two single-bolt IPCs shall be used on the neutral/earth conductor For all mains connections to 120mm2, one, double-bolt IPC shall be used on each phase conductor and two, double-bolt IPCs shall be used on the neutral/earth conductor (as illustrated in the appropriate GAs).

6.9.2

Limit on Number of Connections to the Bundle

Only two single phase or two three phase connection to the bundle is permitted at any pole position. If this number of connections is to be exceeded then a distribution box is to be provided.

6.9.3

Disconnections from the bundle

IPCs shall not be removed from the bundle. August 2012 Disconnections shall be made on the ABC tail. Refer to the appropriate SJI in the Overhead Lines Construction Manual for method of disconnection.

6.10 Open points

6.10.1 General

The following method is adopted when creating or replacing an open point. 1. Fuse Links see Figure 18

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 15

Overhead Line Design Manual

6.11 Appendix A GA Drawings and Materials - Mains

Table 2: List of GA Drawings and Materials - Mains Figure Figure 1: Figure 2: Equipment) Drawing Title ABC General Drawing Arrangement ABC Stay Arrangement, Make-Off (No Auxiliary Pole-Mounted

Figure 3: ABC Stay Arrangement, Make-Off (Restricted Height or Auxiliary Pole-Mounted Equipment) Figure 4: ABC Stay Arrangement, Stay Plate (Restricted Height, Auxiliary Pole-Mounted Equipment or Live Line Working) Figure 5: Figure 6: Figure 7: Figure 8: Figure 9: Figure 10: ABC Intermediate GA (Inside Angle up to 60o Line Deviation) ABC Intermediate GA (Outside Angle up to 30o Line Deviation) ABC Angle Section GA (up to 20o Line Deviation) ABC Angle Section GA (20o to 90o Line Deviation) ABC Terminal GA ABC Tee-off Intermediate GA

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 16

Overhead Line Design Manual

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 17

August 2012

Overhead Line Design Manual

Figure 1:

ABC General Drawing Arrangement

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 18

Overhead Line Design Manual

Figure 2: ABC Stay Arrangement, Make-Off (No Auxiliary Pole-Mounted Equipment)

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 19

August 2012

Overhead Line Design Manual

Ref No Component

(Manufacturers references are available in UKPN EAS 00-0001)

1 2 Pole-top make-off, 7/3.25mm Guy grip dead-end, 7/3.25mm 08237U or 08244Y 09532A or 08233F or 08245J 3 4 5 6&7 Insulator, stay, LV, ENA TS type 1, 110kN MFL Stay wire, 7/3.25mm, 1150 grade Steelwork, thimble, stay, type 1 Anchor, stay, load lock 08911W 08316A or 13816S 09924P 0944D and/or 0944T TBA 13818M 08237U or 08244Y 09354U, 09532A, 08233F or 08245J 08911W 08315Q or 13817C 09924P 09735S 09447X 08719K 08720F 08725E 08721Q 08730P TBA 13818M

Stores No

1 2

Staples, wire [NI] ** Stay marker [NI] *** Pole-top make-off, 7/4.00mm Guy grip dead-end, 7/4.00mm

3 4

Insulator, stay, LV, ENA TS type 1, 110kN MFL Stay wire, 7/4.00mm, 1150 grade

5 6 & 7* 6 & 7* 6 & 7* 6 & 7* 6 & 7* 6 & 7* -

Steelwork, thimble, stay, type 1 Anchor, stay rod, type 2 Concrete stay block, 640 x 430 x 140 Anchor, stay, screw-in, 8", single helix Anchor, stay, screw-in, 10", single helix Anchor, stay, screw-in, 10", twin helix Anchor, stay, screw-in, 12", single helix Anchor, stay, screw-in, 14", single helix Staples, wire [NI] ** Stay marker [NI] ***

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 20

Overhead Line Design Manual

Figure 3: ABC Stay Arrangement, Make-Off (Restricted Height or Auxiliary Pole-Mounted Equipment)

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 21

August 2012

Overhead Line Design Manual

Ref No

1 2 3 4

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Pole-top make-off, 7/3.25mm Stay wire splice, 7/3.25mm Stay wire, 7/3.25mm, 1150 grade Guy grip dead-end, 7/3.25mm

Stores No

08237U or 08244Y 09356P 08316A or 13816S 09532A or 08233F or 08245J 08910M 09924P 0944D and/or 0944T TBA 13818M 08237U or 08244Y 09357Y 08315Q or 13817C 09354U, 09532A, 08233F or 08245J 08911W 09924P 09735S 09447X 08719K 08720F 08725E 08721Q 08730P TBA 13818M

5 6 7&8 1 2 3

Insulator, stay, LV, ENA TS type 1, 110kN MFL Steelwork, thimble, stay, type 1 Anchor, stay, load lock Staples, wire [NI] ** Stay marker [NI] *** Pole-top make-off, 7/4.00mm Stay wire splice, 7/4.00mm Stay wire, 7/4.00mm, 1150 grade

Guy grip dead-end, 7/4.00mm

5 6 7 & 8* 7 & 8* 7 & 8* 7 & 8* 7 & 8* 7 & 8* -

Insulator, stay, LV, ENA TS type 1, 110kN MFL Steelwork, thimble, stay, type 1 Anchor, stay rod, type 2 Concrete stay block, 640 x 430 x 140 Anchor, stay, screw-in, 8", single helix Anchor, stay, screw-in, 10", single helix Anchor, stay, screw-in, 10", twin helix Anchor, stay, screw-in, 12", single helix Anchor, stay, screw-in, 14", single helix Staples, wire [NI] ** Stay marker [NI] ***

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 22

Overhead Line Design Manual

Figure 4: ABC Stay Arrangement, Stay Plate (Restricted Height, Auxiliary Pole-Mounted Equipment or Live Line Working)

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 23

August 2012

Overhead Line Design Manual

Ref No

1 2

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Steelwork, stay plate, heavy duty Bolt, M20, length 260mm, c/w hex full nut [NI] Washer, square curved, M20 [NI] Guy grip dead-end, 7/3.25mm

Stores No

TBA 13370X 13803U 09532A or 08233F or 08245J 09924P 08316A or 13816S 08910M 0944D and/or 0944T 13818M TBA 13370X 13803U 09354U, 09532A, 08233F or 08245J 09924P 08315Q or 13817C 08911W 09735S 09447X 08719K 08720F 08725E 08721Q 08730P 13818M

3 4 5 6&7 1 2

Steelwork, thimble, stay, type 1 Stay wire, 7/3.25mm, 1150 grade Insulator, stay, LV, ENA TS type 1, 110kN MFL Anchor, stay, load lock Stay marker [NI] ** Steelwork, stay plate, heavy duty Bolt, M20, length 260mm, c/w hex full nut [NI] Washer, square curved, M20 [NI] Guy grip dead-end, 7/4.00mm

3 4

Steelwork, thimble, stay, type 1 Stay wire, 7/4.00mm, 1150 grade

5 6 & 7* 6 & 7* 6 & 7* 6 & 7* 6 & 7* 6 & 7* -

Insulator, stay, LV, ENA TS type 1, 110kN MFL Anchor, stay rod, type 2 Concrete stay block, 640 x 430 x 140 Anchor, stay, screw-in, 8", single helix Anchor, stay, screw-in, 10", single helix Anchor, stay, screw-in, 10", twin helix Anchor, stay, screw-in, 12", single helix Anchor, stay, screw-in, 14", single helix Stay marker [NI] **

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 24

Overhead Line Design Manual

ABC Intermediate GA (Inside Angle up to 60o Line Deviation)

Figure 5:

Alternativearrangementshowing weaklink

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 25

August 2012

Overhead Line Design Manual

Materials for Figure 5: ABC Intermediate GA (Inside Angle up to 60o Line Deviation)

Conductor

ABC, 2x35mm ABC, 2x95mm ABC, 4x35mm ABC, 4x95mm

2 2 2 2

ABC, 4x120mm

Ref no

Component

(Manufacturers references are available in UKPN EAS 000001)

Nut, M20, open-ended hook, ABC Conductor fitting, clamp, suspension, ABC, 2/4x35mm Conductor fitting, clamp, suspension, ABC, 2x95mm Conductor fitting, clamp, suspension, ABC, 4x95mm

2 2 2 2

Stores No

1 2 2 2 2 3 4 5

09375W or 08365J 08372N 08369X 08374H 08367D 08302C * * 20010P

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

Conductor fitting, clamp, suspension, ABC, 4x120mm Washer, square curved, M20 Bolt, M20 Wood pole Notice, danger of death [NI]

Supplementary components needed to complete the structure

6 Stay ACD [NI] 7 Conductor fitting, clamp, weak link suspension, ABC [NI] Notices [NI] * 08136C 09385F * As required As required ** As required As required

* Select from specification identified in previous column. ** The adjacent drawing is for Illustration purposes to show position for the weak link if required as per 6.1.1Supports

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 26

Overhead Line Design Manual

ABC Intermediate GA (Outside Angle up to 30o Line Deviation)

Figure 6:

Alternativearrangementshowing weaklink

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 27

August 2012

Overhead Line Design Manual

Materials for Figure 6: ABC Intermediate GA (Outside Angle up to 30o Line Deviation)

Conductor

ABC, 2x35mm ABC, 2x95mm ABC, 4x35mm ABC, 4x95mm

2 2 2 2 2

ABC, 4x120mm

Ref No

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Steelwork, hook outrigger, pole, ABC Conductor fitting, clamp, suspension, ABC, 2/4x35mm Conductor fitting, clamp, suspension, ABC, 2x95mm Conductor fitting, clamp, suspension, ABC, 4x95mm

2 2 2 2

Stores No

1 2 2 2 2 3 4 5

09376G 08865W 08866G 08867R 08868B 08302C 09372S * 20010P

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

Conductor fitting, clamp, suspension, ABC, 4x120mm Washer, square curved, M20 Bolt, M20, 320mm Wood pole Notice, danger of death [NI]

Supplementary components needed to complete the structure

6 Stay ACD [NI] 7 Conductor fitting, clamp, weak link suspension, ABC [NI] Notices [NI] e.g pole number * 08136C 09385F * As required As required ** As required As required

* Select from specification identified in previous column. ** The adjacent drawing is for Illustration purposes to show position for the weak link if required as per 6.1.1Supports

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 28

Overhead Line Design Manual

Figure 7:

ABC Angle Section GA (up to 20o Line Deviation)

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 29

August 2012

Overhead Line Design Manual

Materials for Figure 7: ABC Angle Section GA (up to 20o Line Deviation)

Conductor

ABC, 2x35mm ABC, 2x95mm ABC, 4x35mm ABC, 4x95mm

2 2 2 2 2

ABC, 4x120mm

Ref No

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, clamp, anchor, 2x35mm Conductor fitting, clamp, anchor, 2x95mm Conductor fitting, clamp, anchor, 4x35mm Conductor fitting, clamp, anchor, 4x95mm

2 2 2 2 2

Stores No

1 1 1 1 1 2 3 3 3

08857H 08858S 08859C 08860X 08861H 08052X 08740X 08743C 08744M 08302C 08057W * 20010P

2 1 4 2 1 1 1

2 1 4 2 1 1 1

2 1 4 2 1 1 1

2 1 2 2 1 1 1

2 1 2 2 1 1 1

Conductor fitting, clamp, anchor, 4x120mm Bolt, eye, M20, 300mm

Conductor fitting, compression non tension, ABC, 2 35mm Conductor fitting, compression non tension, ABC, 2 95mm Conductor fitting, compression non tension, ABC, 2 120mm Washer, square curved, M20 Nut, eye, M20 Wood pole Notice, danger of death (wood poles) [NI]

4 5 6

Supplementary components needed to complete the structure

7 8 Stay Cleat, stand-off, plastic, ABC ACD [NI] Notices [NI] e.g pole number * Select from specification identified in previous column. * TBA * * As required As required As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 30

Overhead Line Design Manual

Figure 8:

ABC Angle Section GA (20o to 90o Line Deviation)

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 31

August 2012

Overhead Line Design Manual

Materials for Figure 8: ABC Angle Section GA (20o to 90o Line Deviation)

Conductor

ABC, 2x35mm ABC, 2x95mm ABC, 4x35mm ABC, 4x95mm

2 2 2 2 2

ABC, 4x120mm

Ref No

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, clamp, anchor, 2x35mm Conductor fitting, clamp, anchor, 2x95mm Conductor fitting, clamp, anchor, 4x35mm Conductor fitting, clamp, anchor, 4x95mm

2 2 2 2 2

Stores No

1 1 1 1 1 2 3 4

08857H 08858S 08859C 08860X 08861H 08052X 08302C * 20010P

2 2 2 1 1

2 2 2 1 1

2 2 2 1 1

2 2 2 1 1

2 2 2 1 1

Conductor fitting, clamp, anchor, 4x120mm Bolt, eye, M20, 300mm Washer, square curved, M20 Wood pole Notice, danger of death (wood poles) [NI]

Supplementary components needed to complete the structure

5 Stay ACD [NI] Notices [NI] e.g pole number * Select from specification identified in previous column. * * * As required As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 32

Overhead Line Design Manual

ABC Terminal GA

Figure 9:

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 33

August 2012

Overhead Line Design Manual

Materials for Figure 9: ABC Terminal GA

Conductor

ABC, 2x35mm ABC, 2x95mm ABC, 4x35mm ABC, 4x95mm

2 2 2 2 2

ABC, 4x120mm

Ref No

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, clamp, anchor, 2x35mm Conductor fitting, clamp, anchor, 2x95mm Conductor fitting, clamp, anchor, 4x35mm Conductor fitting, clamp, anchor, 4x95mm

2 2 2 2 2

Stores No

1 1 1 1 1 2 3 4 5

08857H 08858S 08859C 08860X 08861H 08052X 08881A 08302C * 20010P

2 1 4 2 1 1

2 1 4 2 1 1

2 1 4 2 1 1

2 1 2 2 1 1

2 1 2 2 1 1

Conductor fitting, clamp, anchor, 4x120mm Bolt, eye, M20, 300mm Conductor fitting, cap, end, ABC Washer, square curved, M20 Wood pole Notice, danger of death (wood poles) [NI]

Supplementary components needed to complete the structure

6 Stay ACD [NI] Notices [NI] e.g pole number * Select from specification identified in previous column. * * * As required As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 34

Overhead Line Design Manual

ABC Tee-off Intermediate GA

Figure 10:

Note This drawing illustrates connections for a 120mm2 ABC. For connections of 95mm2 and below refer to the material lists.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 35

August 2012

Overhead Line Design Manual

Materials for Figure 10: ABC Tee-off Intermediate GA

Conductor

ABC, 2x35mm ABC, 2x95mm ABC, 4x35mm ABC, 4x95mm

2 2 2 2 2

ABC, 4x120mm

Ref No

1 1 1 1 2 3 3 3 4 4 4 4 4 5 6 7

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, clamp, suspension, ABC, 2/4x35mm Conductor fitting, clamp, suspension, ABC, 2x95mm Conductor fitting, clamp, suspension, ABC, 4x95mm

2 2 2 2

Stores No

08865W 08866G 08867R 08868B 09375W 1 1 5 2 1 1 1 1 1 1 5 2 1 1 1 1 1 1 5 2 1 1 1 1 1 1 3 2 1 1 1 1 1 1 3 2 1 1 1 1

Conductor fitting, clamp, suspension, ABC, 4x120mm Nut, M20, open-ended hook, ABC

Conductor fitting, insulating piercing connector, ABC, 35mm 2 ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm 2 ABC, 95mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm 2 ABC, 120mm ,double bolt Conductor fitting, clamp, anchor, 2x35mm Conductor fitting, clamp, anchor, 2x95mm Conductor fitting, clamp, anchor, 4x35mm Conductor fitting, clamp, anchor, 4x95mm

2 2 2 2 2 2 2

08845E 08846P 08848J 08857H 08858S 08859C 08860X 08861H 08052X 08302C * 20010P

Conductor fitting, clamp, anchor, 4x120mm Bolt, eye, M20, 300mm Washer, square curved, M20 Wood pole Notice, danger of death (wood poles) [NI]

Supplementary components needed to complete the structure

8 Stay ACD [NI] Cable tie [NI] Cleat, stand-off, plastic, ABC [NI] Notices [NI] e.g pole number * Select from specification identified in previous column. * * TBA TBA * As required As required As required As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 36

Overhead Line Design Manual

6.12 Appendix B GA Drawings and Materials Services

Table 3: List of GA Drawings and Materials Services Figure Figure 11: Figure 12: Figure 13: Figure 14: Figure 15: Figure 16: Drawing Title ABC Service Connection (Three Phase) GA Concentric Service Connection GA Insulated Open Wire Service Connection GA Street Lighting Service Connection GA Concentric Service Spans ABC Service Spans

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 37

August 2012

Overhead Line Design Manual

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 38

Overhead Line Design Manual

Figure 11:

ABC Service Connection (Three Phase) GA

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 39

August 2012

Note This drawing illustrates connections for 95mm2 ABC and below. For connections of 120mm2 and below refer to the material lists.

Overhead Line Design Manual

Materials for Figure 11: ABC Service Connection (Three Phase) GA

Conductor

ABC, 4x35mm ABC, 4x95mm

2 2 2

ABC, 4x120mm

Ref No

1 2 2 2 3 4 4 4

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, cap, end, ABC Conductor fitting, insulating piercing connector, ABC, 35mm ABC, 2 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 2 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 2 35mm , double bolt Steelwork, hook bolt, pole, ABC Conductor fitting, clamp, anchor, 4x35mm Conductor fitting, clamp, anchor, 4x95mm

2 2 2 2 2 2

Stores No

08881A 08845E 08847Y 08848J 09372S 08859C 08860X 08861H

4 5 1 1

4 5 1 1 -

4 5 1 1 -

Conductor fitting, clamp, anchor, 4x120mm

Supplementary components needed to complete the structure

5 6 Cleat, stand-off, plastic, ABC Cable tie TBA TBA As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 40

Overhead Line Design Manual

Figure 12:

Concentric Service Connection GA (3ph service cable shown)

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 41

August 2012

Note This drawing illustrates connections for 95mm2 ABC and below. For connections of 120mm2 refer to the material lists.

Overhead Line Design Manual

Materials for Figure 12: Concentric Service Connection GA single phase

Conductor

CNE, 1-phase, 35mm

2

Ref No

1 2 2 2 3 4 5 6 7

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, cap, end, ABC Conductor fitting, insulating piercing connector, ABC, 35mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 35mm , double bolt Conductor fitting, non-tension, ABC tailed out fitting to match CNE Cable termination, break-out kit, 2-core Cable, CNE, 1-phase Conductor fitting, helical dead end, CNE, 1-phase Insulator, coach screw, service

2 2 2 2 2 2

Stores No

08885P 08845E 08847Y 08848J * 02805T 02806D * * 08927P

2 3** 3** 3** 2 1 L* 1 1

Conductor

CNE, 3-phase, 35mm

2

Ref No

1 2 2 2 3 4 5 6 7

Component

Conductor fitting, cap, end, ABC Conductor fitting, insulating piercing connector, ABC, 35mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 35mm , double bolt Conductor fitting, non-tension, ABC tailed out fitting to match CNE Cable termination, break-out kit, 4-core Cable, CNE, 3-phase Conductor fitting, helical dead end, CNE, 3-phase Insulator, coach screw, service

2 2 2 2 2 2

Stores No

08885P 08845E 08847Y TBA * 02805T 02806D 05177J 08243P 08927P 4 5** 5** 5** 4 1 L* 1 1

March 2011

Supplementary components needed to complete the structure for 3ph and single 1ph services

8 9 Cleat, stand-off, plastic, ABC Cable tie TBA TBA As reqd As reqd

L* Length as required. * Select from specification identified in previous column. ** Select to fit ABC.

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 42

Overhead Line Design Manual

Figure 13:

Insulated Open Wire Service Connection GA

Note This drawing illustrates connections for 95mm2 ABC and below. For connections of 120mm2 refer to the material lists.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 43

August 2012

Overhead Line Design Manual

Materials for Figure 13: Insulated Open Wire Service Connection GA

Conductor

Insulated open-wire

Ref No

1 1 1 1 1 2 2 2 2 2 2 3 4 4 4 5 6

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor, ABC, 2x35mm Conductor, ABC, 2x95mm Conductor, ABC, 4x35mm Conductor, ABC, 4x95mm

2 2 2 2 2 2 2

Stores No

06200R 06202L 06205Q 06207K 06208U 08845E 08847Y 08846P 08848J 08848J 08848J 08881A

2

L* L* L* L* L* ** ** ** ** ** ** 4 *** *** *** 4 4

Conductor, ABC, 4x120mm

Conductor fitting, insulating piercing connector, ABC, 35mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 95mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 35mm , double bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 95mm , double bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 120mm , double bolt Conductor fitting, cap, end, ABC Conductor fitting, non-tension, ABC, 35mm tail 400mm long transformed insulated wire Conductor fitting, non-tension, ABC, 95mm tail 400mm long transformed insulated wire Conductor fitting, non-tension, ABC, 120mm tail 400mm long transformed insulated wire Insulator, coach screw, service Conductor fitting, helical dead end

2 2 2 2 2 2 2 2 2 2 2 2

* * * 08927P *

Supplementary components needed to complete the structure

7 8 Cleat, stand-off, plastic, ABC Cable tie TBA TBA As reqd As reqd

March 2011

L* Length as required. * Select to fit insulated wire from specification identified in previous column. ** Select to fit ABC (5 required for three phase; 3 required for single phase). *** Select to fit ABC and insulated wire from specification identified in previous column (4 required for three phase; 2 required for single phase).

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 44

Overhead Line Design Manual

Street Lighting Service Connection GA

Figure 14:

Note This drawing illustrates connections for 95mm2 ABC and below. For connections of 120mm2 refer to the material lists. Lamp, control gear and tails are the property of the local Street Lighting Authority

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 45

August 2012

Overhead Line Design Manual

Materials for Figure 14: Street Lighting Service Connection GA

Conductor

ABC, all

Ref No

1 2 2 2 3 4 5 6 7 7

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, cap, end, ABC Conductor fitting, insulating piercing connector, ABC, 35mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 35mm , double bolt Conductor, ABC, 2x35mm

2 2 2 2 2 2 2 2 2

Stores No

08881A 08845E 08847Y 08848J 06200R 08765P 08757A 02805T

2

2 * * * L* 2 1 L* 1 1

Conductor fitting, compression non tension, ABC, 35mm Al 16mm Cable termination, break-out kit, 2-core Cable, Concentric, 1-phase, 4mm or 16mm Service box cut-out (diamond) Cut-Out Street Lighting PME 25 Amp

2

TBA 08361U 12000K

Supplementary components needed to complete the structure

8 9 Cleat, stand-off, plastic, ABC Local Authority Street Light Tails TBA TBA As reqd As reqd

L* Length as required. * Select to fit ABC.

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 46

Overhead Line Design Manual

Concentric Service Spans

Figure 15:

Figure 16:

ABC Service Spans

Table 11.1 Location

Service Clearances August 2012 Minimum Clearance (m) 4.0 4.3 3.5 3.5

Along the line of hedgerows, fences and boundary walls etc. Domestic driveways with an access width of 2.5 m or less which is defined by gateposts, hedges or other fixed features. Between buildings where there is no vehicular access. Normal Ground

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 47

Overhead Line Design Manual

6.13 Appendix C GA Drawings and Materials Pole Mounted Equipment

Table 4: List of GA Drawings and Materials Pole Mounted Equipment Figure Figure 17: Figure 18: Figure 19: Figure 20: Drawing Title ABC to Two Distribution Boxes ABC to ABC via Fuses GA ABC Intermediate with Cable Termination and LV Fuses GA ABC Terminal with Cable Termination and LV Fuses GA

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 48

Overhead Line Design Manual

ABC to Two Distribution Boxes

Figure 17:

Note This drawing illustrates connections for 120mm2 ABC. For connections of 95mm2 and below refer to the material lists. Please ensure that ABC droppers (Ref No 3) are adequately cleated to the pole as above drawing is for illustration purposes only.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 49

August 2012

Overhead Line Design Manual

Materials for Figure 17: ABC to Two Distribution Boxes

Conductor

ABC, 4x95mm

2

Ref No

1 2 2 3 4 5

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, cap, end, ABC Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 2 95mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 2 95mm , double bolt Conductor, ABC, 4x50mm or 95mm (line to distribution box) Conductor, ABC, 4x50mm or 95mm (line to distribution box) Distribution box, overhead, 3-phase

2 2 2 2 2 2

Stores No

08881A 08846P 08848J 06207K 06207K 08360K 8 8 8 L* L* 2

Supplementary components needed to complete the structure

Cable tie [NI] Cleat, stand-off, plastic, ABC [NI] TBA TBA As reqd As reqd

L* Length as required.

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 50

Overhead Line Design Manual

ABC to ABC via Fuses GA

Figure 18:

Note This drawing illustrates connections for 120mm2 ABC. For connections of 95mm2 and below refer to the material lists. Please ensure that ABC droppers (Ref No 3) are adequately cleated to the pole as above drawing is for illustration purposes only.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 51

August 2012

Overhead Line Design Manual

Materials for Figure 18: ABC to ABC via Fuses GA

Conductor

ABC, 4x35mm ABC, 4x95mm

2 2 2

ABC, 4x120mm

Ref No

1 1 1 2 2 2 3 4 4 4

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, insulating piercing connector, ABC, 35mm ABC, 2 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 2 95mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 2 120mm , double bolt Conductor fitting, compression full tension, ABC, 35mm Conductor fitting, compression full tension, ABC, 95mm

2 2 2 2 2 2

Stores No

08845E 08846P 08848J 08740X 08743C 08744M 12050D

2 2 2 2 2

2 1 3 1 1

2 1 3 1 1

2 1 3 1 1

Conductor fitting, compression full tension, ABC, 120mm Fuse unit, pole mounted, LV ABC

Conductor fitting, compression non tension, ABC, 35mm Cu, 16mm Conductor fitting, compression non tension, ABC, 95mm Cu, 16mm

2

08765P TBA TBA *

Conductor fitting, compression non tension, ABC, 120mm Cu, 16mm Earthing components *

Supplementary components needed to complete the structure

Cable tie [NI] Cleat, stand-off, plastic, ABC [NI] TBA TBA As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 52

Overhead Line Design Manual

ABC Intermediate with Cable Termination and LV Fuses GA

Figure 19:

Note This drawing illustrates connections for 120mm2 ABC. For connections of 95mm2 and below refer to the material lists. Please ensure that ABC droppers (Ref No 3) are adequately cleated to the pole as above drawing is for illustration purposes only.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 53

August 2012

Overhead Line Design Manual

Materials for Figure 19: ABC Intermediate with Cable Termination and LV Fuses GA

Conductor

ABC, 2x95mm ABC, 4x95mm

2 2 2

ABC, 4x120mm

Ref No

1 1 2 3 3 3 4 5 6 6 7

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 2 95mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 2 95mm , double bolt Conductor fitting, cap, end, ABC Conductor, ABC, 2x95mm (main to fuse) Conductor, ABC, 4x95mm (main to fuse) Conductor, ABC, 4x120mm (main to fuse) Cable guard, LV ABC Conductor fitting, compression non tension, ABC, 95mm Cu, 16mm Conductor fitting, compression full tension, ABC, 95mm

2 2 2 2 2 2 2 2 2 2

Stores No

08846P TBA 08881A 06202L 06207K 06208U 08172X TBA 08743C TBA 12050D ** 7 5 L* 1 1 1 3 1 5 5 L* 1 1 1 3 1 5 3 L* 1 1 1 1 1

Conductor fitting, compression full tension, ABC, 120mm ABC, 95mm Fuse unit, pole mounted, LV ABC Earthing components **

Supplementary components needed to complete the structure

Cable tie [NI] Cleat, stand-off, plastic, ABC [NI] L* Length as required. * Select from specification identified in previous column. ** Refer to Figure 22. TBA TBA TBA TBA As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 54

Overhead Line Design Manual

ABC Terminal with Cable Termination and LV Fuses GA

Figure 20:

Note This drawing illustrates connections for 120mm2 ABC. For connections of 95mm2 and below refer to the material lists. Please ensure that ABC droppers are adequately cleated to the pole as above drawing is for illustration purposes only.

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 55

August 2012

Overhead Line Design Manual

Materials for Figure 20: ABC Terminal with Cable Termination and LV Fuses GA

Conductor

ABC, 2x95mm ABC, 4x95mm

2 2 2

ABC, 4x120mm

Ref No

1 2 3 4 4 5 5 6

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Fuse unit, pole mounted, LV ABC Cable guard, LV ABC Conductor fitting, compression non tension, ABC, 95mm Cu, 16mm Conductor fitting, compression full tension, ABC, 95mm

2 2 2 2 2

Stores No

12050D 08172X TBA 08743C TBA 08846P 088485 08881A ** 3 1 1 1 2 1 1 3 1 1 1 2 1 1 1 1 1 1 2 1 1

Conductor fitting, compression full tension, ABC, 120mm ABC, 95mm Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 2 95mm single bolt Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 2 95mm , double bolt Conductor fitting, cap, end, ABC Earthing components **

2 2

Supplementary components needed to complete the structure

Cable tie [NI] Cleat, stand-off, plastic, ABC [NI] * Select from specification identified in previous column. ** Refer to Figure 22. TBA TBA As required As required

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 56

Overhead Line Design Manual

6.14 Appendix D GA Drawings and Materials Earthing

Table 5: List of GA Drawings and Materials Earthing Figure Figure 21: Figure 22: Drawing Title ABC Earthing ABC Bundle to Neutral/Earth Bracket ABC Earthing Neutral/Earth Bracket to Earth Electrodes

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 57

August 2012

Overhead Line Design Manual

Figure 21:

ABC Earthing ABC Bundle to Neutral/Earth Bracket

Materials for Figure 21: ABC Earthing ABC Bundle to Neutral/Earth Bracket

Conductor

ABC, 2x35mm ABC, 2x95mm ABC, 4x35mm ABC, 4x95mm

2 2 2 2 2

ABC, 4x120mm

Ref No

1 2 2 2 3 4

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, cap, end, ABC Conductor fitting, insulating piercing connector, ABC, 35mm 2 ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 95mm 2 ABC, 35mm , single bolt Conductor fitting, insulating piercing connector, ABC, 120mm 2 ABC, 35mm , double bolt

2 2 2 2

Stores No

08881A 08845E 08847Y 08848J 08765P 05280G *

1 2 1 L* 1

1 2 1 L* 1

1 2 1 L* 1

1 2 1 L* 1

1 2 1 L* 1

March 2011

Conductor fitting, non-tension, ABC, 35mm tail 400mm long 2 transformed Cu, bare, 16mm Cable, Cu, 16mm , green/yellow insulated earth wire Earthing components *

2

* Refer to Figure 22.

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 58

Overhead Line Design Manual

Figure 22:

ABC Earthing Neutral/Earth Bracket to Earth Electrodes

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 59

August 2012

Overhead Line Design Manual

Materials for Figure 22: ABC Earthing Neutral/Earth Bracket to Earth Electrodes

ABC, all

Ref No

1 2 3 4

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Cable, Cu, 16mm , green/yellow insulated earth wire Cable guard Earth electrode Cable, Cu, 16mm , bare earth wire

2 2

Stores No

05280G 08172X 02463T TBA 6m 1 As reqd As reqd

Supplementary components needed to complete the structure

Earth electrode, coupling ** Earth electrode, clamp ** Earth electrode, extension ** 02467K 02466A TBA As reqd As reqd As reqd

L* Length as required. * Select from specification identified in previous column. ** For use with earth electrode as required.

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 60

Overhead Line Design Manual

6.15 Appendix E Reference List of all Materials for this specification

Reference List of all Materials for this specification (supplementary components are included at the end of this list)

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Bolt, eye, M20, 300mm Bolt, M20, lengths as required Cable, CNE, 1-phase Cable, CNE, 3-phase Cable, Concentric, 1-phase, 4mm or 16mm Cable, Cu, 16mm , bare earth wire Cable, Cu, 16mm , green/yellow insulated earth wire Cable guard Cable termination, break-out kit, 2-core

2 2 2 2

Stores No

08052X TBA Various Various TBA TBA 05280G 08172X 02805T 02806D 02805T 02806D 06200R

GA Figure Ref

Figure 7, Figure 8, Figure 9 & Figure 10 Figure 4, Figure 5, & Figure 6 Figure 12 Figure 12 Figure 14 Figure 21 Figure 21 & Figure 22 Figure 19, Figure 20 & Figure 22 Figure 12 Figure 14 Figure 12 Figure 13 Figure 14

Cable termination, break-out kit, 4-core Conductor, ABC, 2x35mm

2

Conductor, ABC, 2x95mm

06202L

Figure 13 Figure 19

Conductor, ABC, 4x35mm Conductor, ABC, 4x95mm

2 2

06205Q 06207K

2

Figure 13 Figure 13, Figure 17 & Figure 19 Figure 13 & Figure 19 Figure 9, Figure 11, Figure 13, Figure 14, Figure 17 Figure 19, Figure 20 & Figure 21 Figure 12 Figure 7, Figure 8, Figure 9 & Figure 10 Figure 7, Figure 8, Figure 9 & Figure 10 Figure 7, Figure 8, Figure 9 & Figure 10 Figure 7, Figure 8, Figure 9 & Figure 10 Figure 7, Figure 8, Figure 9 & Figure 10 Figure 4 Figure 6 & Figure 10 Figure 5 Figure 6 & Figure 10

Conductor, ABC, 4x120mm

06208U 08881A

Conductor fitting, cap, end, ABC

Conductor fitting, cap, end, ABC Conductor fitting, clamp, anchor, 2x35mm Conductor fitting, clamp, anchor, 2x95mm Conductor fitting, clamp, anchor, 4x35mm Conductor fitting, clamp, anchor, 4x95mm

2

08885P 08857H 08858S 08859C 08860X

2

Conductor fitting, clamp, anchor, 4x120mm

08861H

2 2

Conductor fitting, clamp, suspension, ABC, 2/4x35mm Conductor fitting, clamp, suspension, ABC, 2/4x35mm Conductor fitting, clamp, suspension, ABC, 2x95mm Conductor fitting, clamp, suspension, ABC, 2x95mm

2 2

08372N 08865W 08369X 08866G

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 61

August 2012

Overhead Line Design Manual

Reference List of all Materials for this specification (supplementary components are included at the end of this list)

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, clamp, suspension, ABC, 4x95mm Conductor fitting, clamp, suspension, ABC, 4x95mm

2 2 2 2

Stores No

08374H 08867R 08367D 08868B

GA Figure Ref

Figure 5 Figure 6 & Figure 10 Figure 5 Figure 6 & Figure 10 Figure 7 & Figure 18 Figure 7, Figure 18, Figure 19 & Figure 20 Figure 7 & Figure 18 Figure 7 & Figure 18 Figure 7 & Figure 18 Figure 14, Figure 18 & Figure 21 Figure 14, Figure 18 & Figure 21

Conductor fitting, clamp, suspension, ABC, 4x120mm Conductor fitting, clamp, suspension, ABC, 4x120mm

Conductor fitting, compression full tension, ABC, 35mm Conductor fitting, compression full tension, ABC, 95mm

2 2

08740X 08743C

2 2 2

Conductor fitting, compression full tension, ABC, 120mm

08744M TBA 08740X 08765P 08757A

2

Conductor fitting, compression full tension, ABC, 120mm ABC, 95mm Conductor fitting, compression non tension, ABC, 35mm

2 2

Conductor fitting, compression non tension, ABC, 35mm 2 Al, 16mm Conductor fitting, compression non tension, ABC, 35mm Cu, 16mm Conductor fitting, compression non tension, ABC, 95mm

2 2 2 2

08765p 08743C TBA

Conductor fitting, compression non tension, ABC, 95mm Cu, 16mm

Figure 14 Figure 16 to Figure 18 to Figure 22 Figure 3 Figure 16 to Figure 18 Figure 23 Figure 10 Figure 9 Figure 9 Figure 6 to 11 Figure 17 Figure 18 Figure 23 Figure 8 to Figure 11 Figure 23 Figure 6 Figure 7 Figure 10 Figure 14 to Figure 22 Figure 8 to Figure 11 Figure 23

Conductor fitting, compression non tension, ABC, 120mm

2 2 2

08744M TBA

Conductor fitting, compression non tension, ABC, 120mm Cu, 16mm

Conductor fitting, compression non tension, Cu, 16mm Conductor fitting, helical dead end Conductor fitting, helical dead end, CNE, 1-phase Conductor fitting, helical dead end, CNE, 3-phase

TBA TBA Various Various

2 2

Conductor fitting, insulating piercing connector, ABC, 35mm ABC, 35mm , single bolt

08845E

Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 35mm , single bolt

08847Y

March 2011

Conductor fitting, insulating piercing connector, ABC, 95mm ABC, 95mm , single bolt

08846P

Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 35mm , double bolt

08848J

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 62

Overhead Line Design Manual

Reference List of all Materials for this specification (supplementary components are included at the end of this list)

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 95mm , double bolt

2 2

Stores No

08848J

GA Figure Ref

Figure 10 Figure 14 Figure 15 Figure 19 to Figure 22 Figure 6 Figure 7 Figure 10 Figure 16 to Figure 18 Figure 9 Figure 23 Figure 10 Figure 10 Figure 16 Figure 10 Figure 16 Figure 9 Figure 14 Figure 15 Figure 24 Figure 24 Figure 24 Figure 17 Figure 21 Figure 22 Figure 9 Figure 10 Figure 5 to Figure 10

Conductor fitting, insulating piercing connector, ABC, 120mm ABC, 120mm , double bolt

08848J

Conductor fitting, non-tension, ABC tailed out fitting to match CNE Conductor fitting, non-tension, ABC, 35mm tail 400mm long transformed Cu, 2 bare, 16mm Conductor fitting, non-tension, ABC, 35mm tail 400mm long transformed insulated wire Conductor fitting, non-tension, ABC, 95mm tail 400mm long transformed insulated wire Conductor fitting, non-tension, ABC, 95mm tail 400mm long transformed Cu 2 70mm Conductor fitting, non-tension, ABC, 120mm tail 400mm long transformed insulated wire Conductor fitting, non-tension, ABC, 120mm tail 400mm long transformed Cu 2 100mm Conductor fitting, non-tension, ABC tailed out fitting to match CNE Distribution box, overhead, 3-phase Earth electrode Earth electrode, coupling Earth electrode, clamp Fuse unit, pole mounted, LV ABC

2 2 2 2 2 2

TBA 08765P TBA TBA 087715 TBA TBA Various 08360K TBA TBA TBA 12050D

Insulator, coach screw, service Notice, danger of death

08927P 20010P

Nut, eye, M20 Nut, M20, open-ended hook, ABC Steelwork, hook bolt, pole, ABC Steelwork, hook outrigger, pole, ABC Washer, square curved, M20

08057W 09375W 09372S 09376G 08302C

Figure 1 Figure 6 Figure 8 Figure 2 Figure 1 to Figure 7

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 63

August 2012

Figure 3 Figure 7

Overhead Line Design Manual

Reference List of all Materials for this specification (supplementary components are included at the end of this list)

Component

(Manufacturers references are available in UKPN EAS 00-0001)

Wood pole

Stores No

Various

GA Figure Ref

Figure 1 to Figure 7

Supplementary components to be used as required

Anti-climbing device (ACD) Various Figure 1 to Figure 7 As required Figure 3 Figure 6 to Figure 11 Figure 14 to Figure 22 Figure 5 Figure 6 Figure 1 to Figure 7

Cable tie Cleat, stand-off, plastic, ABC

TBA TBA

Conductor fitting, clamp, weak link suspension, ABC Notices

09385F Various

Stays Anchor, stay rod, type 2 Concrete stay block, 640 x 430 x 140 Anchor, stay, screw-in, 8", single helix (Various sizes) Anchor, stay, load lock 09735S 08719K 0944D and/or 0944T 13370X Figure 2 to Figure 4 Figure 2 to Figure 4 Figure 2 to Figure 4

Bolt, M20, length 260mm, c/w hex full nut

Figure 4

Guy grip dead-end, 7/3.25mm

09532A or 08233F or 08245J 09354U, 09532A, 08233F or 08245J 08911W 08237U or 08244Y 08237U or 08244Y 08316A or 13816S 09924P

Figure 2 to Figure 4

Guy grip dead-end, 7/4.00mm

Figure 2 to Figure 4

Insulator, stay, LV, ENA TS type 1, 110kN MFL Pole-top make-off, 7/3.25mm Pole-top make-off, 7/4.00mm Stay wire, 7/3.25mm, 1150 grade Steelwork, thimble, stay, type 1 Staples, wire Stay marker Steelwork, stay plate, heavy duty

Figure 2 to Figure 4 Figure 2 to Figure 4 Figure 2 to Figure 4 Figure 2 to Figure 4 Figure 2 to Figure 4 Figure 2 to Figure 4

March 2011

13818M TBA

Figure 2 to Figure 4 Figure 4

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 64

Overhead Line Design Manual

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 65

August 2012

Overhead Line Design Manual

6.16 Appendix F Design Data for Conductor ABC, 4 x 120mm2

Table 6: Conductor ABC, 4 x 120mm2: Design Data Summary

Recommended Span = 50m. A maximum span of 90m is allowed. A FoS value of 2.5 is used on stays, wind-span, foundation and single pole strut loading capabilities.

In Line Structures Drawing No Refer to Figure 5 to Figure 7 Support Type Intermediate or Section Support Class Medium Medium Medium Stout Support Size <12m 12m only >12m Any Max Span 90m 83m 90m 90m Existing Based on medium 9m 10m 11m 12m 13m Angle Structures Drawing No Support Type Support Class Support Size Max Line Deviation Min Stay Angle Heavy 1 x 40o 1 x 20o 1 x 45o 1 x 45o 1 x 40o 1 x 25o 1 x 45o 1 x 40o 1 x 25o 1 x 45o 1 x 30o 2 x 20o Light 1 x 40o 1 x 25o 1 x 45o 1 x 45o 1 x 40o 2 x 20o 1 x 45o 1 x 40o 2 x 25o 1 x 45o 2 x 30o 2 x 25o Max Span 87m 78m 69m 62m 55m

Ref to 6.6 Stays Refer to Figure 5 to Figure 8 Intermediate Angle Intermediate Heavy Angle Medium Stout Medium Medium Stout Stout Medium Stout Stout Medium Stout Stout Any <14m Any <11m Any <12m <11m Any <12m 9m only <14m 9m only 30 30o 45o 60o 60o 60o 60o 60o 60o 90o 90o 90o

o

90m 90m 90m 90m 90m 90m 90m 90m 90m 90m 90m 90m

Section Angle

Terminal Structures Drawing No Refer to Figure 9 & Figure 10 Support Type Support Class Medium Stout Stout Support Size Min Stay Angle Heavy <11m Any <12m 1 x 45 1 x 45o 2 x 30o

o

March 2011

Light 1 x 45o 1 x 45o 2 x 30o

Max Span 90m 90m 90m

Tee off or Terminal

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 66

Overhead Line Design Manual

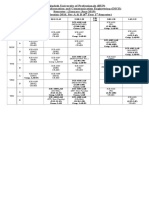

Table 7: Conductor ABC, 4 x 120mm2: Design Sag/Tension

120 mm 4 core LV ABC 380N/mm wind 4.75mm radial ice EDS limit (1000/2.62) x conductor mass at 10C basic span 50m

Temp (C) -5.6 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 Tension (kgf) 10 793.9 714.2 657.4 610.7 571.7 538.7 510.4 485.9 464.4 445.3 428.3 413.1 399.3 386.7 375.2 364.7 354.9 345.9 0.03 0.03 0.03 0.03 0.03 0.04 0.04 0.04 0.04 0.04 0.05 0.05 0.05 0.05 0.05 0.05 0.06 0.06 20 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.16 0.17 0.18 0.19 0.19 0.20 0.21 0.21 0.22 0.23 0.23 Design Sag (m) for Span Length (m) 30 0.23 0.25 0.27 0.29 0.31 0.33 0.35 0.37 0.39 0.40 0.42 0.44 0.45 0.47 0.48 0.49 0.51 0.52 40 0.40 0.45 0.49 0.52 0.56 0.59 0.63 0.66 0.69 0.72 0.75 0.77 0.80 0.83 0.85 0.88 0.90 0.93 50 0.63 0.70 0.76 0.82 0.87 0.93 0.98 1.03 1.08 1.12 1.17 1.21 1.25 1.29 1.33 1.37 1.41 1.45 60 0.91 1.01 1.10 1.18 1.26 1.34 1.41 1.48 1.55 1.62 1.68 1.74 1.80 1.86 1.92 1.97 2.03 2.08 70 1.23 1.37 1.49 1.60 1.71 1.82 1.92 2.02 2.11 2.20 2.29 2.37 2.45 2.53 2.61 2.69 2.76 2.83 80 1.61 1.79 1.95 2.10 2.24 2.38 2.51 2.63 2.76 2.87 2.99 3.10 3.21 3.31 3.41 3.51 3.61 3.70 90 2.04 2.27 2.46 2.65 2.83 3.01 3.17 3.33 3.49 3.64 3.78 3.92 4.06 4.19 4.32 4.44 4.56 4.68

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 67

August 2012

Overhead Line Design Manual

Table 8: Conductor, ABC, 4 x 120mm2: Pole Data (Ground Good/Average)

Lengt h (m)

9 10 11 12 13 14 9 10 11 12 13 14

Grade

Top dia (mm)

150 150 150 150 160 160 190 190 190 190 195 195

Dia 1.5m from butt (mm)

220 230 240 250 260 275 275 285 295 305 320 335

Planting depth (mm)

1800 1800 1800 1800 2400 2400 1800 1800 1800 1800 2400 2400

Single pole strut strength (kgf)

7308 6077 5201 4550 5000 4624 18368 15030 12662 10915 11227 10192

Maximum wind load span (m)

112 101 92 83 139 150 140 125 112 101 266 252

Medium Medium Medium Medium Medium Medium Stout Stout Stout Stout Stout Stout

Table 9: Conductor, ABC, 4 x 120mm2: Single Pole Stay Capability

Maximum angle of line deviation for stated stay type and angle of stay slope

Angle of stay slope 20 25 30 35 40 45 Grade 1150 1 x 7/3.25 27 37 47 56 66 75 Grade 1150 2 x 7/3.25 63 90 90 90 90 90 Grade 1150 1 x 7/4.00 51 68 86 90 90 90 Grade 1150 2 x 7/4.00 90 90 90 90 90 90

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 68

Overhead Line Design Manual

Strut load in pole with one or two stays (kgf)

Table 10: Conductor, ABC, 4 x 120mm2: Single Pole Strut Loading (Level Conditions)

Line Angle (Degrees) 20 Level Conditions 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 2439 3240 4037 4829 5614 6390 7157 7912 8655 9383 10096 10792 11469 12127 12764 13379 13971 14539 15081 2031 2657 3279 3897 4509 5116 5714 6303 6883 7451 8008 8551 9080 9593 10090 10571 11033 11476 11899 25

Stay Angle (Degrees)

30

35

40

45

1752 2257 2760 3259 3754 4243 4727 5203 5671 6130 6579 7018 7445 7860 8262 8649 9022 9380 9722

1547 1963 2378 2789 3197 3601 3999 4392 4778 5156 5527 5889 6241 6583 6914 7234 7541 7836 8118

1387 1735 2080 2424 2764 3101 3434 3761 4083 4399 4708 5010 5304 5589 5866 6133 6389 6636 6871

1257 1549 1839 2127 2413 2696 2975 3250 3520 3785 4044 4297 4544 4784 5015 5239 5455 5661 5859

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 69

August 2012

Overhead Line Design Manual

Table 11: Conductor, ABC, 4 x 120mm2: Single Pole Strut Loading (1:10 Downpull Conditions)

Strut load in pole with one or two stays (kgf)

Line Angle (Degrees) 20 Downpull 1:10 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 3105 3906 4703 5495 6280 7057 7823 8578 9321 10049 10762 11458 12135 12793 13430 14045 14637 15205 15747 2697 3323 3945 4563 5176 5782 6380 6970 7549 8117 8674 9217 9746 10259 10757 11237 11699 12142 12565 2418 2924 3426 3925 4420 4910 5393 5869 6337 6796 7245 7684 8111 8526 8928 9315 9689 10046 10388 2213 2629 3044 3455 3863 4267 4665 5058 5444 5823 6193 6555 6907 7249 7580 7900 8207 8503 8784 2053 2401 2746 3090 3430 3767 4100 4427 4749 5065 5374 5676 5970 6255 6532 6799 7055 7302 7537 1924 2215 2505 2793 3079 3362 3641 3916 4186 4451 4710 4964 5210 5450 5682 5905 6121 6327 6525 25 Stay Angle (Degrees)

30

35

40

45

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 70

Overhead Line Design Manual

6.17 Appendix G Design Data for Conductor, ABC, 4 x 95mm2

Table 12: Conductor, ABC, 4 x 95mm2: Design Data Summary

Recommended Span = 50m. A maximum span of 90m is allowed. A FOS value of 2.5 is used on stays, wind span, foundation and single pole strut loading capabilities.

In Line Structures Drawing No Refer to Figure 5 to Figure 7 Support Type Intermediate or Section Support Class Medium Medium Medium Stout Support Size <12m 12m only >12m Any Max Span 90m 88m 90m 90m Existing Based on medium 9m 10m 11m 12m 13m Angle Structures Drawing No Support Type Support Class Support Size Max Line Deviation Min Stay Angle Heavy

87m 78m 69m 62m 55m

Max Span

Light 1 x 35o 1 x 20o 1 x 45o 1 x 45o 1 x 35o 1 x 35o 1 x 45o 1 x 35o 1 x 35o 1 x 45o 1 x 45o 1 x 45o

Ref to 6.6 Stays Refer to Figure 5 to Figure 8 Intermediate Angle Intermediate Heavy Angle Medium Stout Medium Medium Stout Stout Medium Stout Stout Medium Stout Stout Any <14m Any <14m Any <14m <14m Any <14m <11m Any <11m 30 30o 55o 60o 60o 60o 60o 60o 60o 90o 90o 90o 1 x 35o 1 x 20o 1 x 45o 1 x 45o 1 x 30o 1 x 20o 1 x 45o 1 x 30o 1 x 20o 1 x 45o 1 x 45o 2 x 20o 90m 90m 90m 90m 90m 90m 90m 90m 90m 90m 90m 90m

Section Angle

Terminal Structures Drawing No Support Type Support Class Support Size Min Stay Angle Heavy Refer to Figure 9 & Figure 10 Tee off or Terminal Medium Stout Stout <14m Any <14m 1 x 45 1 x 45o 2 x 25o

o

Max Span

Light 1 x 45o 1 x 45o 1 x 45o 90m 90m 90m

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 71

August 2012

Overhead Line Design Manual

Table 13: Conductor, ABC, 4 x 95mm2: Design Sag/Tension

95 mm 4 core LV ABC 380N/mm wind 4.75mm radial ice EDS limit (1000/2.62) x conductor mass at 10C basic span 50m

Temp (C) -5.6 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 Tension (kgf) 10 644.1 579.8 534.0 496.2 464.6 437.9 414.9 395.0 377.5 362.0 348.2 335.8 324.6 314.4 305.0 296.5 288.5 281.2 0.03 0.03 0.03 0.03 0.03 0.04 0.04 0.04 0.04 0.04 0.05 0.05 0.05 0.05 0.05 0.05 0.06 0.06 20 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.16 0.17 0.18 0.19 0.19 0.20 0.21 0.21 0.22 0.23 0.23 Design Sag (m) for Span Length (m) 30 0.23 0.25 0.27 0.29 0.31 0.33 0.35 0.37 0.39 0.40 0.42 0.44 0.45 0.47 0.48 0.49 0.51 0.52 40 0.40 0.45 0.49 0.52 0.56 0.59 0.63 0.66 0.69 0.72 0.75 0.77 0.80 0.83 0.85 0.88 0.90 0.92 50 0.63 0.70 0.76 0.82 0.87 0.93 0.98 1.03 1.08 1.12 1.17 1.21 1.25 1.29 1.33 1.37 1.41 1.44 60 0.91 1.01 1.10 1.18 1.26 1.34 1.41 1.48 1.55 1.62 1.68 1.74 1.80 1.86 1.92 1.97 2.03 2.08 70 1.24 1.37 1.49 1.60 1.71 1.82 1.92 2.02 2.11 2.20 2.29 2.37 2.45 2.53 2.61 2.69 2.76 2.83 80 1.61 1.79 1.95 2.10 2.24 2.38 2.51 2.63 2.75 2.87 2.99 3.10 3.20 3.31 3.41 3.51 3.60 3.70 90 2.04 2.27 2.47 2.65 2.83 3.01 3.17 3.33 3.49 3.64 3.78 3.92 4.06 4.19 4.32 4.44 4.56 4.68

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 72

Overhead Line Design Manual

Top dia (mm)

150 150 150 150 160 160 190 190 190 190 195 195

Table 14: Conductor, ABC, 4 x 95mm2: Pole Data (Ground Good/Average)

Lengt h (m)

9 10 11 12 13 14 9 10 11 12 13 14

Grade

Dia 1.5m from butt (mm)

220 230 240 250 260 275 275 285 295 305 320 335

Planting depth (mm)

1800 1800 1800 1800 2400 2400 1800 1800 1800 1800 2400 2400

Single pole strut strength (kgf)

7308 6077 5201 4550 5000 4624 18368 15030 12662 10915 11227 10192

Maximum wind load span (m)

119 107 97 88 148 159 148 133 119 107 282 268

Medium Medium Medium Medium Medium Medium Stout Stout Stout Stout Stout Stout

Table 15: Conductor, ABC, 4 x 95mm2: Single Pole Stay Capability

Maximum angle of line deviation for stated stay type and angle of stay slope

Angle of stay slope 20 25 30 35 40 45 Grade 1150 1x7/3.25 32 44 56 68 80 90 Grade 1150 2 x 7/3.25 76 90 90 90 90 90 Grade 1150 1x7/4.00 61 82 90 90 90 90 Grade 1150 2x7/4.00 90 90 90 90 90 90

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 73

August 2012

Overhead Line Design Manual

Table 16: Conductor, ABC, 4 x 95mm2: Single Pole Strut Loading (Level Conditions)

Strut load in pole with one or two stays (kgf)

Line Angle (Degrees) 20 Level Conditions 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 2280 2969 3655 4336 5011 5678 6337 6986 7624 8249 8861 9457 10038 10602 11148 11675 12182 12668 13131 1888 2426 2961 3493 4020 4541 5055 5561 6059 6547 7024 7490 7944 8384 8810 9221 9617 9996 10358 1620 2054 2487 2916 3342 3762 4178 4587 4989 5383 5768 6145 6511 6867 7211 7543 7862 8168 8461 1422 1781 2137 2491 2842 3189 3531 3869 4200 4525 4843 5153 5455 5748 6032 6306 6569 6822 7063 1269 1568 1865 2161 2453 2743 3029 3310 3587 3858 4123 4382 4634 4879 5115 5344 5564 5774 5976 1144 1395 1645 1892 2138 2381 2621 2857 3089 3317 3539 3756 3968 4173 4372 4564 4748 4925 5094 25 Stay Angle (Degrees)

30

35

40

45

March 2011

Overhead Line Design Manual Section 1 LV ABC v1.2

Page 74

Overhead Line Design Manual

Strut load in pole with one or two stays (kgf)

Table 17: Conductor, ABC, 4 x 95mm2: Single Pole Strut Loading (1:10 Downpull Conditions)

Line Angle (Degrees) 20 Downpull 1:10 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 2853 3543 4228 4909 5584 6252 6911 7559 8197 8822 9434 10031 10612 11176 11722 12249 12755 13241 13705 2461 2999 3535 4066 4593 5114 5628 6135 6632 7120 7598 8064 8517 8957 9383 9795 10190 10569 10931 25

Stay Angle (Degrees)

30

35

40

45

2193 2628 3060 3489 3915 4336 4751 5160 5562 5956 6342 6718 7084 7440 7784 8116 8436 8742 9034

1996 2354 2710 3064 3415 3762 4105 4442 4773 5098 5416 5727 6029 6322 6606 6879 7143 7395 7636

1842 2141 2439 2734 3027 3316 3602 3883 4160 4431 4696 4955 5207 5452 5689 5917 6137 6348 6549

1717 1968 2218 2466 2711 2954 3194 3430 3662 3890 4112 4330 4541 4746 4945 5137 5321 5498 5667

OHL Design Manual - Section 1 - Aerial Bundled Conductor (ABC) Low Voltage Mains And Services LS BH PW Page 75

August 2012