Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Mig Brazing

Cargado por

dselvakuu0 calificaciones0% encontró este documento útil (0 votos)

99 vistas3 páginasMig Brazing

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoMig Brazing

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

99 vistas3 páginasMig Brazing

Cargado por

dselvakuuMig Brazing

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 3

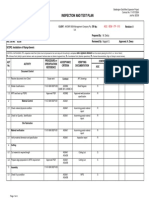

MIG brazing instead of GMA (MIG)

welding or STRSW? Can it be used on

non-structural AND structural applica-

tions? To some European automakers,

the answer is a resounding yes! After

years of being told that MIG brazing is

strictly for cosmetic purposes such as

flling joints and seams, this type of join-

ing process has advanced to the point

of being a possible substitute for GMA

(MIG) welding. European automakers

such as Vauxhall contend that MIG braz-

ing provides adequate joining strength

and maintains more of the galvanizing

that is so important to the corrosion pro-

tection of the vehicle. They believe this

so much that repair GMA (MIG) weld-

ing is not recommended on the 2002

Vauxhall Vectra.

WHY MIG BRAZING?

It is widely known that GMA (MIG)

welded, fully galvanized steel will lose

some of its properties, including corro-

sion protection, due to the heat created

during welding. We counter this prob-

lem by using weld-through primer to

restore corrosion protection along with

stitch and skip welds to control the

heat. With MIG brazing, the lower heat

input burns away a minimal amount of

the zinc corrosion protection (galvaniz-

ing) adjacent to the weld (see Figure 1).

Generally the melting temperature of

GMA (MIG) welding electrode wire is

higher than the evaporation temperature

Brazing As A Substitute For GMA (MIG) Welding?

of zinc 910 C (1,670 F), causing the

zinc to vaporize both in and around

the weld zone. However, by reducing

the welding temperature, less zinc will

vaporize adjacent to the weld bead and

the zinc disturbed by the process will

return. To achieve a temperature that

limits the amount of vaporization, it is

important to use a MIG brazing program

on the welding machine that has been

developed for the specifc coating, elec-

trode wire, and shielding gas.

In addition to protecting the galva-

nized coating, the low heat involved in

MIG brazing does not compromise the

strength of the steel. A number of other

characteristics associated with MIG

brazing include:

Less welding spatter. The material

is transferred into the weld pool

without any short circuiting. As a

result, the arc is almost entirely free

of spatter.

Easier fnishing of the welded joint.

The bronze bead is soft.

Less potential of panel warpage

when the weld heat is lowered.

reduced potential for burnthrough.

A good seal along the joint.

Cathodic corrosion protection next

to the weld bead (cathodic corro-

sion protection prevents rust creep

between zinc and steel along cut

edges of the panel).

August 2, 2004

Figure 1Note the difference in the

heat-effect zone between the MIG

brazed joint and the GMA (MIG)

welded joint.

Technical Information For The Collision Industry

ADHESION VS. FUSION

During GMA (MIG) welding, the base

metal melts and fuses with the melted

fller metal at a temperature of approxi-

mately 1,650 C (3,000 F). This is con-

sidered a fusion process. When brazing,

however, the temperature is considerably

less, with a welding temperature between

9601,000 C (1,7601,830 F). There-

fore, only the fller metal melts. It does

not melt the surrounding metal in the

weld zone, rather it lies on top without

penetrating the base metal. At these tem-

peratures, only minor superfcial melting

of the steel can occur.

EQUIPMENT

RECOMMENDATIONS

MIG brazing can be performed using a

GMA (MIG) welding machine, equipped

with a spool gun, a conventional torch,

or a push feeder with Tefon cable liner.

This type of liner is used to minimize par-

ticle throw-off from the fller material.

Pulse MIG brazing equipment has

yielded the best results when MIG braz-

ing. Pulse equipment provides lower heat

input into the base metal (see Figure 2).

It uses one molten drop of electrode per

pulse, which results in virtually spat-

ter-free welding. Generally, this type of

equipment has a computerized program

that controls a number of different param-

eters and uses a conventional torch with

a push feeder.

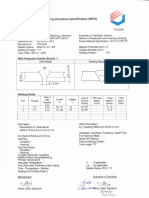

RECOMMENDED FILLER

MATERIALS

The recommended brazing wire includes

copper-silicon (CuSi3) which is most

common for sheet steel, or bronze alloy

solder (CuAl8 and CuSn6) (see Figure

3). This type of electrode is available

in 6 mm (0.025), 0.8 mm (0.030), or

1.1 mm (0.045). It is recommended to

treat this wire similar to aluminum wire.

There cannot be any abrasions to the wire

when it is fed. Therefore, use half-round,

smooth wire drive rolls. Recommended

base wire liner may include Tefon,

plastic-graphite, or carbon fber.

The recommended shielding gas is 100%

argon. However, argon with a small

amount of CO2 (18%) may be used to

improve arc stability. The shielding gas

fow rate should be set at 2530 cfh.

MACHINE SETTINGS

The most common error that techni-

cians make when setting a GMA (MIG)

welder for MIG brazing operations is

setting the output of the welding ma-

chine too high and making too hot of a

weld. When MIG brazing using a GMA

(MIG) welding machine, use a lower

wire speed (lower current) setting than

what is generally used for welding with

steel electrode wire. Also, use lower

voltage settings (shorter arc length). This

requires the power source on the welder

to deliver a stable arc in the low power

range. When using a GMA (MIG) pulse

welding machine, the specifc parameters

may be programmed into the machine, so

limited adjustments may be required. The

program will automatically adjust the arc

length and droplet detachment force, as

well as a variety of other factors that may

affect joint integrity. When welding with

lower heat, the weld bead does not lay

down fat (see Figure 4). Unlike welding

steel, this is acceptable. Do not adjust

the heat settings to get a smoother, fatter

bead. Increased heat settings defeat the

benefts of lower heat MIG brazing.

WELDING TECHNIQUE

When performing overlap welds, position

the torch 45 from vertical and 60 away

from the direction of the weld (see Figure

5). This ensures that any vaporized zinc

gas passes out of the weld zone without

affecting the quality of the weld. It is rec-

ommended to have a small groove open-

ing of 0.51.0 mm between the coupons.

This opening will help the passage of the

weld pool into the groove to create more

welded surface area, increasing adhesion.

It is recommended that you push the

torch when MIG brazing. This technique

preheats the base metal and vaporizes

zinc in the weld zone, thus reducing

weld porosity. If using pulse equipment,

Brazing As A Substitute For GMA (MIG) Welding?

Continued From Page 1

Figure 3Copper-silicon (CuSi3)

is the most common type of

electrode wire used for MIG

brazed joints.

Figure 2These welding machines

provide pulse features that provide

lower heat input.

Figure 4The bead of a MIG-

brazed weld should not lay fat on

the joint.

http://www.i-car.com 2

this method allows the background cur-

rent to preheat the base metal. Using

the pull method does not preheat the

metal as much, therefore, vaporizes less

zinc and increases weld porosity. Also,

because of the higher zinc vapor content

trying to escape the seam, the arc stability

will fuctuate more.

When working with steel electrode wire,

stick-out must remain constant along

the weld pass and the amount of recom-

mended stick-out should be between

625 mm depending on the electrode

wire thickness. The stick-out distance

with MIG brazing does not need to be

as precise. If the stick-out is not constant

while making the weld, the adverse ef-

fects, such as splatter, should be minimal.

TESTING

MIG brazing welds may be tested in a

manner similar to GMA (MIG) welds. A

proper weld will cause the top plate to

tear out along the weld bead. The de-

structive test is similar to the technique

taught in the I-CAR Steel GMA (MIG)

Welding (WCS01) program and for the

Automotive Steel GMA (MIG) Welding

Qualifcation Test (WCS03) program. To

destructively test the weld:

1. Secure the bottom coupon in a vise

with the fllet weld facing the front.

2. Use both hands to rock the top piece

back and forth until it breaks free

from the bottom piece.

The weld is good only if there is tearout

along the weld on the top coupon.

APPLICATIONS

MIG brazing can be used for all types

of joints. These include butt with back-

ing, fllet on lap, and plug weld joints.

Vehicles that recommend the use of MIG

brazing include the 2004 Vauxhall Vectra

C Opel, 2004 Volkswagen Golf, and the

PSA Peugeot Citroen1s.

On the Vauxhall Vectra, areas around the

door openings, rail fanges, roof rails, and

wheelhouse are slot welded (See Figure

6). This process is similar to plug welding

with the exception that instead of a round

hole, the area to be welded is a slot. To

make the slot, the body repair manual

recommends drilling or punching three

6 mm holes within 20 mm of each other.

That area is then drilled into a slot. Each

slot is placed 3040 mm apart. For struc-

tural member section joints, the butt joint

seams are welded with a backing.

Toyota also recommends MIG brazing.

You will most likely fnd reference to

that in body repair manuals at the roof

panelto-pillar joints and the rear body

panel to quarter panel drip channel joint.

CONCLUSION

Depending on the steel alloy used, MIG

brazed joints are as strong as a GMA

(MIG) welded joint, while maintaining

the original level of corrosion protection.

However, to ensure these characteristics

are maintained, the welders must be set

to precise settings and the proper MIG

brazing techniques must be used.

At the date of this publication, all of the

vehicles where MIG brazing is recom-

mended on structural parts are European

models that are not currently available

in North America. The recommendation

in North America is to use GMA (MIG)

welding or STRSW where applicable.

MIG brazing has not been recommended

for use on structural parts for any of the

vehicles sold in North America.

Brazing As A Substitute For GMA (MIG) Welding?

Continued From Page 2

Figure 5Proper torch position

helps ensure that vaporized zinc

gas passes out of the weld zone.

Figure 6Slotted plug weld holes

are used in place of round holes

when welding structural parts.

http://www.i-car.com 3

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- AVG27 TH Aug 20Documento6 páginasAVG27 TH Aug 20dselvakuuAún no hay calificaciones

- Css Basketball Residential Intensive CampDocumento2 páginasCss Basketball Residential Intensive CampdselvakuuAún no hay calificaciones

- HFN MAG APRIL2019-Pages PDFDocumento84 páginasHFN MAG APRIL2019-Pages PDFdselvakuuAún no hay calificaciones

- Soonya Kriya Meditation PDFDocumento1 páginaSoonya Kriya Meditation PDFdselvakuu0% (4)

- Physics FaqDocumento76 páginasPhysics FaqAbhay Thakur71% (14)

- 2013 SP 12 Chemistry 02Documento6 páginas2013 SP 12 Chemistry 02dhriti1996singhAún no hay calificaciones

- Science of ParentingDocumento1 páginaScience of ParentingdselvakuuAún no hay calificaciones

- 1 Mechanics: Cbse Neet JEE Mains AdvancedDocumento11 páginas1 Mechanics: Cbse Neet JEE Mains Advancedvsrajkumar100% (6)

- Cycle Time ReductionDocumento44 páginasCycle Time ReductiondselvakuuAún no hay calificaciones

- Emerging StdsDocumento64 páginasEmerging StdsdselvakuuAún no hay calificaciones

- MeditationDocumento3 páginasMeditationdselvakuuAún no hay calificaciones

- Basant 2020 Message English PDFDocumento8 páginasBasant 2020 Message English PDFdselvakuuAún no hay calificaciones

- Welding Questions 1Documento26 páginasWelding Questions 1dselvakuuAún no hay calificaciones

- Heartfulness Magazine - July 2019 (Volume 4, Issue 7)Documento84 páginasHeartfulness Magazine - July 2019 (Volume 4, Issue 7)HeartfulnessAún no hay calificaciones

- Visual AidsDocumento38 páginasVisual AidsdselvakuuAún no hay calificaciones

- தோல்வி நிலையென நினைத்தால் - lyricsDocumento2 páginasதோல்வி நிலையென நினைத்தால் - lyricsdselvakuuAún no hay calificaciones

- Weld Questions AwsDocumento30 páginasWeld Questions AwsdselvakuuAún no hay calificaciones

- Welding Insp QuestionsDocumento10 páginasWelding Insp QuestionsdselvakuuAún no hay calificaciones

- Weld QuestionsDocumento9 páginasWeld QuestionsdselvakuuAún no hay calificaciones

- Lecturing: STC / SBCDocumento15 páginasLecturing: STC / SBCdselvakuuAún no hay calificaciones

- MPTDocumento20 páginasMPTdselvakuuAún no hay calificaciones

- Copper Shoe WriteupDocumento2 páginasCopper Shoe WriteupdselvakuuAún no hay calificaciones

- Emerging StdsDocumento64 páginasEmerging StdsdselvakuuAún no hay calificaciones

- MMAWDocumento1 páginaMMAWdselvakuuAún no hay calificaciones

- The Power of CommunicationDocumento12 páginasThe Power of Communicationdselvakuu100% (2)

- 719 Buckling Mode Shapes in Incremental Forming of Sheet Metal PDFDocumento4 páginas719 Buckling Mode Shapes in Incremental Forming of Sheet Metal PDFdselvakuuAún no hay calificaciones

- Brahma Sutras - WikipediaDocumento15 páginasBrahma Sutras - WikipediadselvakuuAún no hay calificaciones

- Welding Problems and Defects - Causes and Remedies: Deformation Arc Blow SpatterDocumento3 páginasWelding Problems and Defects - Causes and Remedies: Deformation Arc Blow Spatterdselvakuu50% (2)

- Heartfulness - An Introduction - T3 - 20151004Documento33 páginasHeartfulness - An Introduction - T3 - 20151004dselvakuuAún no hay calificaciones

- Guru Paduka StotramDocumento3 páginasGuru Paduka Stotramhirenjjoshi100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2102)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Workshop AssignmentDocumento23 páginasWorkshop AssignmentMr. NasrullahAún no hay calificaciones

- Weld RepairsDocumento40 páginasWeld Repairsவிஷ்ணு ராஜசெல்வன்Aún no hay calificaciones

- Efco Repair RecommendationsDocumento33 páginasEfco Repair RecommendationsSamy BarreraAún no hay calificaciones

- GISL2Documento14 páginasGISL2Abdullah Sabry AzzamAún no hay calificaciones

- 34-Supporting Steel Structure 182Documento12 páginas34-Supporting Steel Structure 182RamzanAún no hay calificaciones

- QW 381Documento1 páginaQW 381Waqas WaqasAún no hay calificaciones

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Documento20 páginasMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- Agc BGM Itp 010Documento4 páginasAgc BGM Itp 010Sachin SoniAún no hay calificaciones

- Pip Stc01015Documento45 páginasPip Stc01015Kriztopher UrrutiaAún no hay calificaciones

- Fdocuments - in - Approved Brand List Electrode PDFDocumento7 páginasFdocuments - in - Approved Brand List Electrode PDFRahul BishnoiAún no hay calificaciones

- X52 L360xx Engl PDFDocumento3 páginasX52 L360xx Engl PDFmuhamad yakubAún no hay calificaciones

- A262-15 Standard Practices For Detecting Susceptibility To Intergranular Attack in Austenitic Stainless SteelsDocumento20 páginasA262-15 Standard Practices For Detecting Susceptibility To Intergranular Attack in Austenitic Stainless Steelstjt477980% (5)

- WPS Batch 1Documento12 páginasWPS Batch 1sutrimoAún no hay calificaciones

- Aws A5.12 PDFDocumento22 páginasAws A5.12 PDFMann Gurpreet0% (1)

- Soldadura de Barras de Refuerzo para Estructuras de Concreto Reforzado en Zonas SismicasDocumento59 páginasSoldadura de Barras de Refuerzo para Estructuras de Concreto Reforzado en Zonas SismicasSibyl Guardado100% (1)

- 2 - 3 Steel Connection MethodsDocumento23 páginas2 - 3 Steel Connection MethodsPo PoAún no hay calificaciones

- Final Report: Early Generation Seam WeldsDocumento53 páginasFinal Report: Early Generation Seam WeldsiMaJeniDeasAún no hay calificaciones

- 3 0 Visual Weld InspectorDocumento74 páginas3 0 Visual Weld InspectorVincent Sofia RaphaelAún no hay calificaciones

- These Industrial Heat-Resistant Gloves Offer High Levels of Durability, Control and Protection From Heat, Flame, Sparks and PunctureDocumento2 páginasThese Industrial Heat-Resistant Gloves Offer High Levels of Durability, Control and Protection From Heat, Flame, Sparks and PunctureFebrin NavarroAún no hay calificaciones

- Key Changes For 2017 BPVCDocumento56 páginasKey Changes For 2017 BPVCJeganeswaranAún no hay calificaciones

- Redesign of A Steam Strainer: Ann Jannesson Solid MechanicsDocumento61 páginasRedesign of A Steam Strainer: Ann Jannesson Solid Mechanicszayerireza0% (1)

- Electron-Beam Welding - AMS 2681Documento10 páginasElectron-Beam Welding - AMS 2681Fredo GamboaAún no hay calificaciones

- CBI Welding Journal Vert Plate Apr04Documento0 páginasCBI Welding Journal Vert Plate Apr04Mahendra RathoreAún no hay calificaciones

- 02H-T13-G65-20JI-MA-008 REV 0 Monorail CranesDocumento8 páginas02H-T13-G65-20JI-MA-008 REV 0 Monorail CranesShubhamYadavAún no hay calificaciones

- Expansion Joint Technical Specification and Data SheetDocumento9 páginasExpansion Joint Technical Specification and Data SheetAhmad Dzulfiqar RahmanAún no hay calificaciones

- Eppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawDocumento18 páginasEppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawBassem Ben FrajAún no hay calificaciones

- Introduction To Welding Technology PDFDocumento54 páginasIntroduction To Welding Technology PDFBurag HamparyanAún no hay calificaciones

- 07 - Welding Ultra High Strength SteelsDocumento17 páginas07 - Welding Ultra High Strength SteelsXAún no hay calificaciones

- 90203-1085DEB Arc Welding Operation Manual (D Series)Documento178 páginas90203-1085DEB Arc Welding Operation Manual (D Series)Ihcene BoudaliAún no hay calificaciones

- Wear Resistant Steel: Product DescriptionDocumento6 páginasWear Resistant Steel: Product DescriptionoomoomAún no hay calificaciones