Documentos de Académico

Documentos de Profesional

Documentos de Cultura

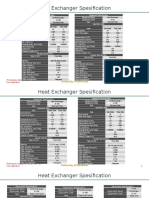

Specification Sheet

Cargado por

Kuknesvary PuniamurthyDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Specification Sheet

Cargado por

Kuknesvary PuniamurthyCopyright:

Formatos disponibles

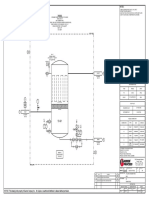

SPECIFICATION SHEET

BUBBLING FLUIDIZED BED REACTOR Equipment Name : Bubbling Fluidized Biomass Bed Gasifier Equipment No: BFBR-01 OPERATING DATA DESIGN TEMPERATURE (C) 849 DESIGN PRESSURE (bar) 1.1 OPERATING TEMPERATURE(C) 772 OPERATING PRESSURE (bar) 1.00 Bed section internal diameter (upper cylinder) (mm) 500 Bed section internal diameter (lower cylinder) (mm) 350 Dynamic bed height (mm) 600 Freeboard internal diameter(mm) 350 Freeboard height(mm) 840 Disengaging zone diameter (mm) 500 Disengaging zone height (mm) 1500 Sawdust mass flowrate (kg/hr) 25.03 Air flow rate (kg/hr) 57.79 Syngas flowrate (kg/hr) 77.33 Ash flow rate (kg/hr) 5.508 Bed temperature ( C) 772 Exiting gas temperature ( C) 750 Syngas LHV (M J/ Nm) 6.335 Hot gas efficiency (%) 78 Superficial velocity (m/s) 0.15 Air/Fuel Ratio 2.3 Equivalence Ratio 0.24 Voidage at min. fluidization velocity (m/s) 0.66 Velocity at min. fluidization (m/s) 0.075 Reynolds No 5.7 Maximum fluization velocity (m/s) 0.7 Terminal velocity, Ut 2.44 Pressure drop in the bed (k Pa) 1.39

AIR DISTRIBUTION PLATE (TUYER TYPE) Fluidization velocity (m/s) Minimum fluidization velocity(m/s) Minimum fluidization height (mm) Particlde density (kg/m) Mean particle size ( m) Bed porosity Bed zone diameter(mm) Number of tuyer lateral orifice Tuyer orifice diameter (mm) Pressure drop in distributing plate (k Pa) Tuyer internal diameter (mm) Air velocity for the orifice (m/s) Total number of tuyers Tuyer height(mm) BUBBLES Velocity of rise of bubbles, Ubr Rate of bubble rise in fluidized bed, Ub Maximum bubble diameter, dbm Initial bubble diameter, dbo

0.34 0.07 0.47 2650 385 0.46 350 4 2.38 1.1 10 18 40 6 0.65 1.24 0.2 0.0013

MECHANICAL DESIGN Material selection Sawdust inlet Air inlet Syngas outlet Ash foutlet Design stress at 850C ( reactor body) (N/mm) Design stress at ambient temperature (reatcor supoorting material) (N/mm) Welded Joint Efficiency Wall thickness (mm) Head thickness(mm) Height of head(mm) Primary stress (N/m) Longitudinal stress (N/m) Direct stress (N/m) Wind loading(N/m) Skirt (support vessel) Skirt diameter,Ds (mm) Skirt thickness, Ts (mm) Minimum height of skirt (mm) Minimum width of base (mm) Concrete width(mm) Height of concrete(mm)

Carbon steel Stainless steel 321 Stainless steel 321 Stainless steel 321 80 135 0.85 4 4 95.35 8.14 4.07 0.31 640.88 578 120 2000 76 978 52

Note: Since the flow rates are small, therefore the flanges for the nozzle could not be identified. With such small flow rates except for the syngas outlet, it is advisable to use gasket. Further studies on it is required and should be customized and send to fabrication.

También podría gustarte

- 2018 BookDocumento477 páginas2018 Bookbrahim chalhoub100% (2)

- Distillation Design and Control Using Aspen SimulationDe EverandDistillation Design and Control Using Aspen SimulationCalificación: 5 de 5 estrellas5/5 (2)

- Experienced Based Rules of Chemical EngineeringDocumento33 páginasExperienced Based Rules of Chemical Engineeringintania66Aún no hay calificaciones

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocumento31 páginasStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngAún no hay calificaciones

- Screw ConveyorDocumento6 páginasScrew ConveyorJobsonReisAún no hay calificaciones

- Heat Conduction Pipe InsulationDocumento1 páginaHeat Conduction Pipe InsulationJogender DhayalAún no hay calificaciones

- Stratigraphy MCQs With AnswerDocumento10 páginasStratigraphy MCQs With Answerkumar Harsh67% (3)

- Condensate Line SizingDocumento2 páginasCondensate Line SizingWade ColemanAún no hay calificaciones

- Geothermal PPT in ShortDocumento20 páginasGeothermal PPT in ShortYogesh VermaAún no hay calificaciones

- Combustion CalculationsDocumento6 páginasCombustion CalculationsDaniel AriefinAún no hay calificaciones

- Calculation Sheet For Pump Hydraulic (Fps Unit)Documento1 páginaCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiAún no hay calificaciones

- Fgas Refrigerant CalculatorDocumento10 páginasFgas Refrigerant CalculatorKumar sssssAún no hay calificaciones

- Ammonia Wet Scrubber System (17-7-2018)Documento12 páginasAmmonia Wet Scrubber System (17-7-2018)addin wokatuba100% (1)

- Design 2 ReboilerDocumento5 páginasDesign 2 ReboilerAbdulrazzaqAL-MalikyAún no hay calificaciones

- Line Sizing Design Basis - General Specification PDFDocumento11 páginasLine Sizing Design Basis - General Specification PDFSaiKumarAún no hay calificaciones

- Gas-Liquid Vertical Separator PDFDocumento2 páginasGas-Liquid Vertical Separator PDFRathish RagooAún no hay calificaciones

- Fixed Bed ReactorDocumento1 páginaFixed Bed Reactorojasmainkar123Aún no hay calificaciones

- Methodology For Assesing The Energy Performance of Buildings - 07aug2009Documento122 páginasMethodology For Assesing The Energy Performance of Buildings - 07aug2009Atanas StoykovAún no hay calificaciones

- World History and GeographyDocumento255 páginasWorld History and Geographyvidhisethi24Aún no hay calificaciones

- API 12j SizingDocumento1 páginaAPI 12j SizingAdewunmi OlufemiAún no hay calificaciones

- Packed Column DesignDocumento6 páginasPacked Column Designyamen-691904Aún no hay calificaciones

- HCL Scrubber DesignDocumento5 páginasHCL Scrubber DesignManish0301198375% (4)

- Data Sheet Fixed Bed ReactorDocumento1 páginaData Sheet Fixed Bed ReactorPolanqAún no hay calificaciones

- Thermal Design of Water Cooled DuctDocumento8 páginasThermal Design of Water Cooled Ductpavan100% (1)

- Plate Heat ExchangersDocumento4 páginasPlate Heat Exchangersamini_mohiAún no hay calificaciones

- SLE Experiment (REPORT)Documento8 páginasSLE Experiment (REPORT)Kuknesvary PuniamurthyAún no hay calificaciones

- Routine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsDocumento3 páginasRoutine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsMohamed Sayed AbdoAún no hay calificaciones

- Pump (English) TemplateDocumento1 páginaPump (English) TemplateMichael HaiseAún no hay calificaciones

- Basic Design of A Heat ExchangerDocumento10 páginasBasic Design of A Heat ExchangerKvspavan KumarAún no hay calificaciones

- P & I Design LTDDocumento34 páginasP & I Design LTDYunping Huang100% (1)

- Vapor Line Sizing-Mpp6Documento10 páginasVapor Line Sizing-Mpp6Nitin KurupAún no hay calificaciones

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocumento2 páginasAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanAún no hay calificaciones

- DearatorDocumento3 páginasDearatorEDUARDOAún no hay calificaciones

- Gary Pratt - Air Cooled Condensers - Key Elements For A Successful SpecificationDocumento38 páginasGary Pratt - Air Cooled Condensers - Key Elements For A Successful SpecificationNirmalAún no hay calificaciones

- Steam and Gas Tables with Computer EquationsDe EverandSteam and Gas Tables with Computer EquationsCalificación: 3 de 5 estrellas3/5 (2)

- Ambient Heat Loss From A VesselDocumento3 páginasAmbient Heat Loss From A VesselJaveed KhanAún no hay calificaciones

- Boiler Data SheetDocumento10 páginasBoiler Data Sheetameya natu100% (2)

- Thermal PSV Sizing MercerDocumento1 páginaThermal PSV Sizing MercerapgoslingAún no hay calificaciones

- Data Sheet - Gas-Gas Heat ExchangerDocumento1 páginaData Sheet - Gas-Gas Heat ExchangerPrabhakarAún no hay calificaciones

- TSV CalculationDocumento3 páginasTSV CalculationAymen KhlifiAún no hay calificaciones

- VenturiDocumento2 páginasVenturiJIAAún no hay calificaciones

- Learning Objectives: Describe What Friction Is. (S6Fe-Iiia-C-1) Q3W1D1Documento21 páginasLearning Objectives: Describe What Friction Is. (S6Fe-Iiia-C-1) Q3W1D1Gelyn Torrejos Gawaran100% (2)

- Estimating Air LeakageDocumento5 páginasEstimating Air Leakagenasirmuzaffar100% (1)

- Flash Tank Calculation ReportDocumento29 páginasFlash Tank Calculation Reporttauqeer100% (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7De EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Aún no hay calificaciones

- Simulation of Ammonia Production From Synthesis GaDocumento12 páginasSimulation of Ammonia Production From Synthesis Gasagar dasguptaAún no hay calificaciones

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFDocumento4 páginasVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezAún no hay calificaciones

- KIRK Sep-Calc SoftwareDocumento4 páginasKIRK Sep-Calc Softwaredhl_tuAún no hay calificaciones

- Energy and Mass IncinerationDocumento11 páginasEnergy and Mass Incinerationnuti_srinivasAún no hay calificaciones

- C29732-01-Pid-02.0 - P&id Scrubber TT-006Documento1 páginaC29732-01-Pid-02.0 - P&id Scrubber TT-006omarAún no hay calificaciones

- AQ10T-BFM, 363PL 2335kWDocumento2 páginasAQ10T-BFM, 363PL 2335kWLiviu ConstantinAún no hay calificaciones

- Design of Distillation Columns - ImpDocumento13 páginasDesign of Distillation Columns - ImpAlla VijayAún no hay calificaciones

- Is 14164 2008Documento45 páginasIs 14164 2008Pukhraj DagaAún no hay calificaciones

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Documento5 páginas18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaAún no hay calificaciones

- Veturi Design ProcedureDocumento2 páginasVeturi Design Procedureshivanandr2481Aún no hay calificaciones

- Key Process Indicators-Falling Film EvaporatorsDocumento20 páginasKey Process Indicators-Falling Film Evaporatorscgoveia3Aún no hay calificaciones

- Sherwood/Leva/Eckert GPDC Pressure Drop Correlation For PackingDocumento3 páginasSherwood/Leva/Eckert GPDC Pressure Drop Correlation For PackingAhmad Deyab100% (1)

- Condensate Line SizingDocumento23 páginasCondensate Line SizingNirnay Patil100% (2)

- TEMA SheetDocumento2 páginasTEMA SheetFrancisco RenteriaAún no hay calificaciones

- 9.1 Overview: 9 Wiped Film EvaporatorDocumento12 páginas9.1 Overview: 9 Wiped Film EvaporatorNoman AslamAún no hay calificaciones

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86De EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86Aún no hay calificaciones

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsDe EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsAún no hay calificaciones

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28De EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28Aún no hay calificaciones

- Assg 3 He Valve PnidDocumento7 páginasAssg 3 He Valve PnidpangiastikaAún no hay calificaciones

- Ac LGDocumento3 páginasAc LGramdhanismeAún no hay calificaciones

- API-650 11TH ED. JUNE 2007 Addendum-1, Nov. 2008: Design DataDocumento1 páginaAPI-650 11TH ED. JUNE 2007 Addendum-1, Nov. 2008: Design DataWh NgAún no hay calificaciones

- CV1 - 100 NBDocumento1 páginaCV1 - 100 NBAditya TapkirAún no hay calificaciones

- Lecture 1 - Intro To Math OptimisationDocumento8 páginasLecture 1 - Intro To Math OptimisationKuknesvary PuniamurthyAún no hay calificaciones

- Bre CourseworkDocumento9 páginasBre CourseworkKuknesvary PuniamurthyAún no hay calificaciones

- Biosafety Regulations 2010Documento29 páginasBiosafety Regulations 2010Kuknesvary PuniamurthyAún no hay calificaciones

- HP Simplify Your Thermal Efficiency Calculation PDFDocumento9 páginasHP Simplify Your Thermal Efficiency Calculation PDFGovind RaoAún no hay calificaciones

- HVDC With DMRDocumento11 páginasHVDC With DMRchandrakantnu100% (1)

- Manufacturing Cost EstimationDocumento7 páginasManufacturing Cost EstimationMadiha ZaimuriAún no hay calificaciones

- TE - Mech - RAC - Chapter 5 - Thermodyn Propertis of Moist AirDocumento48 páginasTE - Mech - RAC - Chapter 5 - Thermodyn Propertis of Moist AirAkshay ChandoleAún no hay calificaciones

- Chemistry FORM 4Documento12 páginasChemistry FORM 4danisshaAún no hay calificaciones

- Physical Constants: N Z N ZDocumento56 páginasPhysical Constants: N Z N ZVARSHITHAún no hay calificaciones

- The Geology of Ethiopia and The Horn: Chapter TwoDocumento28 páginasThe Geology of Ethiopia and The Horn: Chapter TwoMERKEBU GEZAHEGNEAún no hay calificaciones

- One-Dimensional Flow of Water Through Soils: ImportanceDocumento26 páginasOne-Dimensional Flow of Water Through Soils: ImportanceAngieAún no hay calificaciones

- Spray-Drying: Basic Theory and ApplicationsDocumento15 páginasSpray-Drying: Basic Theory and ApplicationsDarkwraith007Aún no hay calificaciones

- Fundamentals of Mass and Energy BalancesDocumento15 páginasFundamentals of Mass and Energy BalancesdeltaoperativAún no hay calificaciones

- Vanden Bro Uck e 2007Documento115 páginasVanden Bro Uck e 2007naima rhaziAún no hay calificaciones

- DSL TrainingDocumento96 páginasDSL TrainingAnonymous 47Qe2KuuHyAún no hay calificaciones

- Science RevisionDocumento7 páginasScience RevisionRoséAún no hay calificaciones

- Hortatory ExpositionDocumento5 páginasHortatory ExpositionfusthannaAún no hay calificaciones

- 01 Hints ChemicalNomenclatureDocumento7 páginas01 Hints ChemicalNomenclatureSmartsoft LibraryAún no hay calificaciones

- Thesis - Maisarah Binti Zaharudin - KH17059Documento52 páginasThesis - Maisarah Binti Zaharudin - KH17059LogamalarAún no hay calificaciones

- Dewaa BillDocumento3 páginasDewaa BillService SAVAún no hay calificaciones

- Lab Report SKL1033 (A)Documento3 páginasLab Report SKL1033 (A)Raajeshwary.TAún no hay calificaciones

- Diagnostic TestDocumento17 páginasDiagnostic TestRynCalasagsagAún no hay calificaciones

- DGFVSDVVZC Ries With AIATS For CBSE, NTSE & Olympiads 2024 - Class IXDocumento22 páginasDGFVSDVVZC Ries With AIATS For CBSE, NTSE & Olympiads 2024 - Class IXAtul KunduAún no hay calificaciones

- Science Week 2Documento10 páginasScience Week 2Bon Grace TañalaAún no hay calificaciones

- PH1 G7 Humanities W2 Slide2 Ch1 Sec2 PDFDocumento9 páginasPH1 G7 Humanities W2 Slide2 Ch1 Sec2 PDFhussienmadyanAún no hay calificaciones

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocumento9 páginas00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasAún no hay calificaciones

- 1PH0 1H MSC 20210211Documento30 páginas1PH0 1H MSC 20210211RandomAún no hay calificaciones