Documentos de Académico

Documentos de Profesional

Documentos de Cultura

IMECE2013-66029: Numerical Analysis of The Flow and Heat Transfer in The Sub-Channel of Supercritical Water Reactor

Cargado por

Jorge SanangoTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

IMECE2013-66029: Numerical Analysis of The Flow and Heat Transfer in The Sub-Channel of Supercritical Water Reactor

Cargado por

Jorge SanangoCopyright:

Formatos disponibles

1 Copyright 2013 by ASME

Proceedings of the ASME 2013 International Mechanical Engineering Congress and Exposition

IMECE2013

Novemer 1!"21# 2013# San $iego# California# %SA

IMECE2013"&&02'

N%ME(ICA) ANA)*SIS +, -.E ,)+/ AN$ .EA- -(ANS,E( IN -.E

S%0" C.ANNE) +, S%PE(C(I-ICA) /A-E( (EAC-+(

A1o2 $earma

Research Scholar, Department of Mechanical Engineering

National Institute of Technology, Silchar, Assam,

India

E-mail ID: eril!oym e"#$gmail%com

34M Pande2

&rofessor, Department of Mechanical Engineering

National Institute of Technology, Silchar, Assam,

India E-mail ID: ' m pand e y "(()$gmail%com

A0S-(AC-

Research activities are ongoing for High performance light

ater reactor !H"#$R% ith s&'are (o'ble ros f'el assembly

to (evelop n'clear poer plants ith the p'rpose to achieve a

high thermal efficiency an( to improve their economical

competitiveness) Hoever* there is still a big (eficiency in

'n(erstan(ing an( pre(iction of heat transfer in s'percritical

fl'i(s) +his paper eval'ates three,(imensional t'rb'lent flo

an( convective heat transfer in a single,phase an( stea(y,state

s'b,channel of H"#$R by 'sing general comp'tational fl'i(

(ynamics co(e* Ansys 1- .l'ent) +he ma/or concern 'sing

s'percritical ater as or0 fl'i( is the heat transfer

characteristics ('e to large variations of thermal properties of

s'percritical ater near pse'(o,critical line) 1n or(er to ens're

the safety of operation in High performance light ater reactor

!H"#$R%* heat transfer (eterioration !H+2% m'st be avoi(e()

3'merical res'lts prove that the R34 0,e mo(el ith the

enhance( near,all treatment obtaine( the most satisfactory

pre(iction an( lea( to satisfactory sim'lation res'lts) +he

H"#$R S&'are f'el assembly has many s&'are,shape( ater

ro(s* 5't of fo'r types of s'b,channels6 three s'b,channels SC,

1* SC,2 an( SC,3 are investigate( !a(/acent to the si(e of the

mo(erator flo channels !SC,1% !mo(erator t'be an( assembly

gap%* central s'b,channels forme( by fo'r f'el ro(s !SC,2%*

a(/acent to the corner of the mo(erator t'be !SC,3%) Since

coolant flo (istrib'tion in the f'el assembly strongly (epen(s

on the gap i(th beteen the f'el ro( an( ater ro(* f'el ro(

pitch to (iameter ratio 1)1 , 1)- ith 7mm (iameter are

consi(ere( for sim'lation) S'b,channel analysis clarifies that

coolant flo (istrib'tion becomes 'niform hen the gap i(th

is set to 1)0 mm) as less than 8209C) Effects of vario's

parameters* s'ch as bo'n(ary con(itions an( pitch,to,(iameter

ratios* on the mi:ing phenomenon in s'b,channels an( heat

transfer are investigate() +he effect of pitch,to,(iameter ratio

!";2% on the (istrib'tions of s'rface temperat're an( heat

transfer coefficient !H+C% in a s'b, channel* it as fo'n( that

H+C increases ith ";2 1)1 first an( then (ecreases ith

increasing ";2 ratio) Apart from the basic geometry s'b,

channel* a s&'are s'b,channel ith a ire,rappe( ro( insi(e

has been chosen to investigate the <ire effect=)

3e25ords6 H"#$R s'b,channels6 S'percritical* Heat transfer

(eterioration* R34 0,e mo(el)

IN-(+$%C-I+N

+he High "erformance #ight $ater Reactor !H"#$R%* ho the

E'ropean S'percritical $ater Coole( Reactor is calle(* is a

press're vessel type reactor operate( ith s'percritical ater at

2> M"a fee( ater press're an( >00

o

C average core o'tlet

temperat'res) 1t is (esigne( an( analy?e( by E'ropean

consorti'm of 10 partners an( 3 active s'pporters from 7

E'ratom member states in the secon( phase of the H"#$R

pro/ect) Most emphasis has been lai( on a core ith a thermal

ne'tron spectr'm* consisting of small f'el assemblies in bo:es

ith -0 f'el pins each an( a central ater bo: to improve the

ne'tron mo(eration (espite the lo coolant (ensity) "ea0

cla((ing temperat'res of the f'el ro(s have been minimi?e( by

heating 'p the coolant in three steps ith interme(iate coolant

mi:ing) +he containment (esign ith its safety an( resi('al

heat removal systems are base( on the latest boiling ater

reactor concept* b't ith (ifferent passive high press're coolant

in/ection systems to ca'se a force( convection thro'gh the core)

+he (esign concept of the steam cycle is in(icating the

envisage( efficiency increase to aro'n( --@)Moreover6 it

provi(es the constraints to (esign the components of the

balance of the plant)

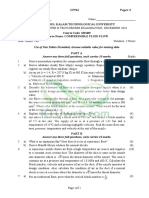

,I7%(E 1

&roperties of supercritical *ater *ithin pseudo-critical point

+he 'se of ater at s'percritical press're as coolant an(

mo(erator intro('ces a challenge in the (esign of High,

"erformance #ight ater Reactor !H"#$R% f'el assembly)

Heat,transfer at s'percritical press'res is infl'ence( by

significant changes in thermo physical properties at these

con(itions) +he most significant properties variations occ'r

ithin critical an( pse'(o,critical points) S'percritical fl'i(s

have 'ni&'e properties) .ig) 1 shos properties variations in

ater passing thro'gh the pse'(o,critical point at 2> M"a* the

propose( operating press're for H"#$R) +he most significant

changes in properties occ'r ithin A2>BC from the pse'(o,

critical temperat're !37-)CBC%) D1E

.I7. PE(,+(MANCE )I7.- /A-E(

(EAC-+(

High "erformance #ight $ater Reactor !H"#$R% has been

selecte( as one of the 4eneration 1F n'clear systems) 1t is a

high,press're ater,coole( reactor hich operates above the

thermo(ynamic critical point of ater !3G- 9C* 22 M"a%) 1t as

fo'n( that a heat 'p of the coolant from 270

o

C to >00

o

C in one

single step o'l( locally e:cee( the temperat're limits of the

core internals !in (etailH ma:) cla((ing temperat're of 820

o

C%

D2E) +herefore* in a H"#$R the coolant is heate( in three

stages) Ieteen these three stages* there are to interme(iate

mi:ing ?ones) At that ay the coolant flo from f'el

assemblies ith an enthalpy rise in respect to the operating

point , the so, calle( hot spots J ill be homogeni?e( in

temperat're) Hence* an interme(iate mi:ing lea(s to a more

'niform heating an( avoi(s hot spots) .ig) 2 shos a scheme of

the coolant flo in the 111,pass,core)

1n the center of the core* >2 f'el assembly cl'sters

form the first heat,'p stage) .olloing the (enotation of ..""

they are calle( evaporator) After gap* mo(erator an( (on

comer ater has been mi:e(* it flos 'par(s as coolant into

the evaporator ith an average entrance temperat're of 310 C)

,I7%(E 2

Three-pass core concept *ith target temperatures for each heat up step

+left, and cross-section of the core *ith the conceptual arrangement of

the fuel assemlies +right, +Schulenerg et al%, "((-,

1t ill be heate( 'p to an average temperat're of 3C0 C) 3e:t*

the coolant ill be mi:e( in the 'pper mi:ing ?one before it

flos (onar(s thro'gh the secon( heat,'p stage* the so,

calle( s'per heater 1) +he s'per heater 1 consists of >2 f'el

assembly cl'sters s'rro'n(ing the center ?one of the core) After

the s'per heater 1 the coolant ill have an average temperat're

of -3> C an( a (ensity of 121 0g;m3) .olloing the flo

schema* the coolant flos thro'gh a thir( mi:ing ?one before it

rises thro'gh the s'per heater 11 into the steam plen'm) +he

s'per heater 11 is compose( of >2 f'el assembly cl'sters

arrange( in an o'ter cycle aro'n( the s'per heater 1) .rom the

steam plen'm the coolant flos (irectly to the t'rbines ith a

pro/ecte( average temperat're of >00 C

,I7%(E 3

.luster of nine assemlies *ith a central moderator o/

+he assembly cl'ster* b'ilt ith nine assemblies an( ith a

gap of 10mm beteen the bo:es D3E* is shon in .ig) 3 )A total

n'mber of -0 f'el ro(s per assembly ith 7mm o'ter cla((ing

(iameter at a pitch of C)--mm is ho'se( ithin a stainless steel

bo: of 2)>mm all thic0ness an( G2)>mm o'ter si?e) A single

ire of 1)3-mm (iameter is rappe( aro'n( each f'el ro( ith

an a:ial pitch of 200mm* leaving a tolerance of 0)1mm beteen

the ire an( the f'el ro(s or the bo: alls* respectively) +he

rappe( ires are capable to g'arantee a cross mi:ing in both

'par( an( (onar( flo of the coolant in the f'el

assemblies an( also to prevent the neighboring ro(s from

coming close to each other ('e to the thermal stresses an( the

possible e:ternal forces)

"arameters Range

Ro( b'n(le arrangement S&'are

Ro( (iameter 7)0 mm

"itch,to,(iameter ratio 1)1 J 1)-

"ress're 2>)0 M"a

Mass fl': >00,1>00 0g;!m

2

s%

Heat fl': -00,1-00 0;m

2

.l'i( b'l0 temperat're 270,>00

o

C

Reynol(s n'mber >0*000,>00*000

+'rb'lence mo(els R34 k

+he coolant mi:ing insi(e assemblies in('ce( by ire

spacer has been investigate( by Himmel et al) D-E) +he res'lts

(emonstrate( that ire spacer is capable of provi(ing s'fficient

mi:ing to coolant) +he (esign st'(ies foc'se( on several

important iss'es of the core (esign* for instance* heat transfer

analyses by Koshi?'0a et al) D>E* a 32 ne'tronics;thermal,

hy(ra'lics co'ple( core (esign !Kamei et al)* D8E% ith

s'bchannel analyses !Lama/i et al)* DGE%* f'el ro(

thermal;mechanical analyses !Lama/i et al)* D7E%* safety

analyses incl'(ing #oss of Coolant Acci(ent !#5CA%

!1shiatari et al)* DCE%* an( so on) 1n 200>* a research pro/ect of

a S'per .ast Reactor has starte( in Mapan !1shiatari et al)*

D10E%) 1t aims at ma:imi?ing the poer (ensity an( 'tili?ing

pl'toni'm from the #$R spent f'el rather than the f'el

bree(ing !1shiatari et al)* D11E%) An improve( core has been

(esigne( to 0eep both overall an( local voi( reactivity negative

by 'p(ating the ('el an( core config'rations !Cao et al)* D12E%)

1n or(er to (evelop a basic thermal,hy(ra'lic (atabase for the

S'per .ast Reactor* a set of e:perimental tests have been

carrie( o't ith HC.C22 as the or0 fl'i() 1t starte( from a

smooth circ'lar t'be !Mori et al)* D13E% an( afterar(s to a G,

ro( b'n(le !Mori et al)* D1-E%) Iesi(es the fast,spectr'm

concept* a ne RN2 pro/ect on thermal,spectr'm SC$R

concept as grante( in 2007 D11E) Op to no* both of the fast

an( thermal options are ongoing in Mapan) A preliminary reactor

core ith mi:e( ne'tron spectr'm has been propose( by

Cheng et al) D1>E) 5ther or0 on aspect of heat transfer

investigation an( materials test is s'mmari?e( by Cheng D11E)

N%ME(ICA) AN$ P.*SICA)

M+$E)

1n or(er to 'n(erstan( the geometry effect an( the mechanisms

of the H+2* the pitch to (iameter ratio !";2% of a s&'are f'el

assembly are chosen as follos 1)1* 1)2* 1)3* an( 1)-) 1n

partic'lar* the mechanisms of the H+2 also have to be

'n(erstoo( for the p'rpose of the safety analysis) Iase on the

first tas0 res'lt* 32 ann'lar s'b,channel relevant to the H"#$R

(esign are ta0en in to acco'nt for secon( tas0 of the st'(y) +he

P part geometry of a s&'are f'el assembly is chosen for

sim'lation as shon in .ig) -

consi(ere( ith vario's ";2 ratio an( 1mm constant for gap

beteen mo(erator bo: an( f'el ro() 4eometrically* fo'r type

of s'b,channels can be consi(ere(* i)e) a(/acent to the si(e of

the mo(erator flo channels !SC,1% !mo(erator t'be an(

assembly gap%* central s'b,channels forme( by fo'r f'el ro(s

!SC,2%* a(/acent to the corner of the mo(erator t'be !SC,3% an(

corner of the assembly gap !SC,-%)

,I7%(E !

Selected Su-channel types of the s0uare fuel assemly

A proper t'rb'lence mo(el is alays cr'cial to a correct

pre(iction on the heat transfer behavio'r in s'percritical fl'i(s

an( so (oes the mo(el config'ration) Heat transfer to ater at

s'percritical press'res has been n'merically investigate( 'sing

a to,(imensional mo(eling approach) +he sim'lations in a

to,(imensional (omain have been performe( 'sing the lo,

Reynol(s 0J t'rb'lence mo(el* an( the 1A"$S,1.CG

form'lation to (escribe the properties of ater at (ifferent

con(itions) +he e:perimental (ataset as obtaine( in

s'percritical ater floing 'par( in a - m long vertical bare

t'be ith 10 mm 12) +he temperat're (ata ere collecte( at

m'ltiple heights in the t'be an( at press'res of abo't 2-)> M"a*

an inlet temperat're of 300

o

C)

-A0)E6 14 Detailed parameters of the 1&23R used for

425ENT

simulation%

+he governing e&'ations !A3SLS1- .#OE3+ Oser Man'al%

are as follosH

Mass conservation e&'ationH

,I7%(E 8

6ne-fourth part of 1&23R fuel assemly

x

i

( u

i

)

0

!0)1%

Moment'm conservation e&'ationH

+hree s'b,channels for present sim'lation ere consi(ere(

u u j _

2

u

1

p

from a &'arter of the thermal f'el assembly an( is calc'late(

(

u u

j

)

eff

+

3

eff

1

+

g

i

i k

x

i

x

x x x x

ta0ing symmetry into consi(eration) 4ap beteen to ro(s are

j j

j i

,

k

1

]

k !0)2%

x x

j

2

Energy conservation e&'ationH

MES. SENSI-I9I-* S-%$*

(

u C T

)

T _1

u

+

i

u

i

+

u

j

_

u

k

1

1n the .ig) G three (ifferent val'es of no(e n'mber along ra(i's

x

i p

x

T

x

1

u

eff

u u

3

eff

u

ij

1

j j

i ,

] j

j i ,

k 1

]

!0)3%

are 'se( in sim'lations) +he coarse mesh has a no(e n'mber of

R34 k mo(el is a(opte( to close the t'rb'lence 0inetic

20 an( the refine,factor is - for mi((le mesh !200% an( fine

energy an( (issipation e&'ation)

+'rb'lent 0inetic energy e&'ationH

mesh !700%) As is shon in the .ig* the res'lts become

in(epen(ent of the no(e n'mber hen it is more than 200) +he

information reveale( by .ig) G* it is clear that the no(e n'mber

of 200 can be treate( as a stan(ar( mesh config'ration near the

( k ) ( ku

i

)

+

k

_

+ G

+ G

!0)-%

t x

j

k eff

k b

j

j

,

heate( all)

$here G

b

is the effect of b'oyancy on t'rb'lent 0inetic

energy* an( is (efine asH

G g

1

t

T

_ !0)>%

b i

" r

x

$here G

k

gra(ient

t i

, p

is t'rb'lent 0inetic energy pro('ce( by velocity

G

k

t

S !0)8%

,I7%(E :

S 2S S *

S

u

u

j

1

i

+ ; 2

Sensiti7ity studies of node numer along radius

ij ij ij

x

1

j i

1

]

!0)G%

MES. S-(%C-%(ES AN$ 0+%N$A(* C+N$I-I+NS

+'rb'lent 0inetic energy (issipation ratioH

_

2

A cross,sectional schematic (iagram of a 32 comp'tational

(

)

+

t

xj

( u

i

)

eff

x

j

x

+C

1

(G

k

+C

2

G

b

) C

2

k k

R

(omain is shon in .ig) 7) +he inlet an( o'tlet bo'n(ary

,

!0)7%

2

con(itions are mass fl': (ensity an( o'tflo* respectively) As

C

k

1

+

ill'strate( in the fig're* the cla((ing material has been alrea(y

eff mol

1

1

ta0en into acco'nt) +he mesh in the flo (omain gra('ally

mol

1

]

!0)C% refine( toar(s the li&'i(,soli( interface to ma0e a smooth

$here

mol

is the molec'le viscosity

C

3

(

1 ;

)

2

mesh transition from the flo (omain to the soli( (omain)

R

0

1 +

3

k

!1)0%

$here

Sk ;

*

0

-)37

an(

0)012

.ig)8 shos the comparison beteen o'r calc'lation

(ata an( the e:perimental (ata !Lamagata et al)* 1CG2%) +he

heat transfer coefficient (istrib'tion in the s'per critical

press're region is calc'late( 'sing R34 k mo(el) +he

,I7%(E &

.omparison et*een present results and the e/perimental data

R34 k mo(el ith the enhance( near,all

treatment obtaine( the most satisfactory pre(iction)

+herefore in this

,I7%(E ;

Su-channel +S.-) AND S.-", geometry and mesh

,I7%(E '

st'(y the R34 k

flo)

mo(el is a(opte( to sim'late the t'rb'lent

3rapped-*ire geometry and mesh

.ig) C ill'strates a str'ct're( mesh* hich (iscreteness

the flo an( soli( (omain ith he:ahe(ral elements) +he mesh

strategy is one of the most important iss'es associate( ith the

rappe(,ire geometry )+he mesh is compose( of to partsH a

circ'lar mesh in the core an( a all mesh) +he mesh in the flo

(omain is compresse( toar(s heate( ro( in or(er to f'lly

resolve the visco's s'b,layer !y1QR 1%* hich is a prior

con(ition to pre(ict the cla((ing temperat're precisely an(

f'rthermore to capt're the onset of a possible 2H+) +he mesh

in the soli( (omain is also gra('ally refine( toar(s the li&'i(,

soli( interface to ma0e a smooth mesh transition from the flo

(omain to the soli( (omain)

enthalpy* reaches the ma:im'm val'e near the pse'(o,critical

point* an( then (ecreases) $ith the increase of ";2* the heat

transfer coefficient (ecreases an( the location of the ma:im'm

heat transfer coefficient moves toar(s the loere enthalpy

region) As the Reynol(s 3'mber is fi:e(* the flo velocity is

relatively small) Iefore the main stream enthalpy reaches a

high val'e* H+2 alrea(y ccc'ts) $hen the lecocity is small* the

b'oyancy force accelerates the flo velocity of the fl'i( in the

near,all region) +his ma0es the flo velocity (istrib'tion to

be flat an( generation of t'rb'lence energy re('ce() +h's the

heat transfer is (eteriorate()

(ES%)-S AN$ $ISC%SSI+N

+he st'(y on the heat transfer behavio'r of the s'percritical

fl'i(s ill carry o't an( e:ten( to a i(er range of or0ing

con(itions to gain a (eeper insight into the heat transfer

behavio'r an( also the mechanisms of heat transfer

(eterioration* hich is one of the most important targets in this

or0)

.o'r "itch,to,2iameter ratio !";2% cases of vertical 'par(

flo !S'b,channel 22% in beteen to ro(s of a S&'are s'b,

channel are sim'late( base( on the test con(itions from

Lamagata an( D18E* for Heat transfer enhancement) .'rther

sim'lations are carrying o't ith best !";2% ratio for High mass

fl': ith #o heat fl': an( #o mass fl': ith High heat fl':)

As the !";2% is increase(* the all temperat're meas're( in

sim'lation strongly increases at the beginning of the heate(

section) .ig 10 shos the all temperat're (istrib'tion in

beteen to parallel f'el ro(s -m vertical height) $all

temperat're increases ith the main stream enthalpy an( the

increase is &'ite significant after pse'(o,critical point) $hen

the main stream enthalpy reaches abo't 1800,1G00 0M 0g

,1

* the

all temperat're increases very sloly) .or main enthalpy

val'e of S1C00 0M 0g

,1

* (ifferent tren(s appear (epen(ing on

";2 val'e) 1f ";2 is small* the all temperat're increases

sloly) I't if ";2 is larger* the all temperat're increases very

rapi(ly)

,I7%(E 11

1eat transfer coefficient

,I7%(E 12

1eat transfer coefficient, 8*9m

"

8 +&9D )%", :;)((( 'g m

-"

s

-)

,

,I7%(E 10

3all temperature distriution

.ig)11 shos the heat transfer coefficient c'rves for (ifferent

";2 an( main stream enthalpy beteen f'el ro(s) 1t can be seen

that the heat transfer coefficient increases ith the main stream

,I7%(E 13

1eat transfer coefficient, 8*9m

"

8 +&9D )%", 0;-(( '*

%

m

-"

,

.ig)12 shos heat transfer coefficient (istrib'tion) As

the ro( (iameter an( the gap si?e beteen the ro( an( all is

fi:e(* ith the increase of heat fl': the heat transfer coefficient

increases an( reversely occ'r hen heat fl': (ecreases)

.'rthermore* the location of the ma:im'm val'e of the heat

transfer coefficient moves toar(s the lo enthalpy region ith

the ";2 (ecreasing)

I'l0 fl'i( temperat're Ro( -

Ro( 1 Ro( 8

Ro( 2 Ro( G

Ro( 3 Ro( 12

.ig 13 shos the heat transfer occ'r ith (ifferent mass

fl':) 1t can seen that at lo mass fl': !&;4S7% *in the inlet

region all temperat're increases sharply* f'rther along higher

enthalpy in the mi((le region the all temperat're (ecreases

an( then again increases in the procee(ing higher region) Also

n'merical res'lt shos that ith increasing mass fl':

!&;4TG)>%* the all temperat're increases sloly itho't any

pic0 temperat're in the inlet region) +herefore goo( agreement

heat transfer ta0e place hen &;4 RG)>* hich is shon on

.ig)13* b't hen &;4 SG)> is lea(ing to (ecrease heat transfer

coefficient)

5ne,fo'r part of vertical 'par( flo f'el assembly is

sim'late() .ig)1- a,b shos the Conto'rs of velocity Magnit'(e

an( Static +emperat're at o'tlet) More concerning on heat

transfer enhancement hich means at high mass flo rate ith

lo heat fl': is sim'late() As mention above three s'b,channels

!SC,1* SC,2* an( SC,3% ere consi(er to 'n(erstan( the effect

of heat transfer in high mass flo rate) .ig) 1> shos the

velocity (istrib'tion at o'tlet section)

!a% !b%

,I7%(E 18

.ontours of 7elocity Magnitude +2E4T,, Static Temperature +RI:1T, at

outlet%

.ig) 18 shos the temperat're (istrib'tion at o'tlet section of

each in(ivi('al channels) 1t is seen that toar(s the ro(s all*

temperat're is higher than toar(s mo(erator all) .ig) 1G

(escribes the temperat're (istrib'tion thro'gho't the a:ial

(irection of the channels) 1nlet temperat're increases rapi(ly in

the entry region* it can be seen in the mi((le region ere the

temperat're increases sloly an( last region increases rapi(ly

again)

SC,2 SC,3

,I7%(E 1&

.ontours of Static Temperature at outlet

SC,2

SC,1

SC,3

SC,2

,I7%(E 1!

.ontours of 7elocity Magnitude at outlet

,I7%(E 1:

Temperature distriution

.ig) 17 shos in the flatten region heat transfer coefficient

increases) As a res'lt* the cla((ing temperat're increases from

the inlet as the heat transfer coefficient increases) At the point

here the heat transfer has a ma:im'm* the cla((ing

temperat're (ecreases) Ieyon( the pse'(o,critical line* here

the heat transfer coefficient (ecreases* the cla((ing temperat're

increases) +he ma:im'm cla((ing temperat'res in the (ifferent

s'b,channels ith ";2 1)2 are ithin the alloable limits of

820

o

C for the H"#$R)

Cla((ing s'rface

$ire s'rface

SC,2

,I7%(E 20

1eat transfer distriution in 3ire-3rapped Rod in a S0uare

SC,3

,I7%(E 1;

1eat transfer distriution

.ig) 1C,20 shos the temperat're (istrib'tion in Iare

Ro( S&'are ith an( itho't ire) +he p'rpose of s&'are

ann'lar channel is to the performance in the non,circ'lar

channels* hich is closer to the realistic flo channel in the f'el

assembly) 1n H"#$R the (esign ith ire spacers raise several

challenging iss'es ith regar( to the transfer behavio'r of the

ater 'n(er a s'percritical press're* ith the spacers lea( to a

goo( mi:ing an( a lo press're (rop in the assembly)

Cla((ing s'rface

Iare Ro( in a S&'are

Cla((ing s'rface

$ire s'rface

$ire,$rappe( Ro(

in a S&'are

Channel

,I7%(E 1'

Temperature distriution

+he sim'lations are performe( at a mass fl': (ensity

of 1000 0g;m2s an( at heat fl':es of 8000;m2) +he res'lts of

the non,circ'lar channel ith an( itho't ire,rappe( are

shon .ig) 1C* its shos the (ifference of the temperat're

(istrib'tion beteen the bare ro( an( ire,rappe( channel)

+he res'lt of the comparison shos that cla((ing temperat're

(ecreases ith ire,rappe() At high mass flo rate b'oyancy

effect can be neglecte( 'nless ith lo flo rate* even tho'gh

the b'oyancy sho'l( not be relevant* heat transfer is still

(eteriorate() .ig) 20 shos the effect of heat transfer coefficient

ith ire,rappe() $ith the ire affect its give the goo(

agreement ithin the temperat're range limits for cla((ing

s'rface temperat're) 5n the set of heat transfer (eterioration*

near the pse'(o,critical point this all temperat're increase is

m'ch sloer ('e to the higher heat transfer coefficient)

C+NC)%SI+NS

3'merical st'(y as performe( on the ro( b'n(le s'b,channels

base( on one of the H"#$R propose( mo(el) +he R34

k mo(el ith the enhance( near,all treatment obtaine( the

most satisfactory pre(iction ith Lamagata e:periment* an(

eval'ate( for the flo an( heat transfer characteristics in

U'arter channel* S'b,channel* an( typical S&'are Iare ro(

channels ere investigate() +he folloing concl'sions have

been obtaine()

1n the s'b,channel* the effect of ";2 on H+C as st'(ie()

$hen ";2 is R1)-* H+C increase ith ";2 first an( then

(ecreases significantly) $hen ";2 is 1)2* there is a VVflat

region= at the ma:im'm val'e) 1f it is larger than1)2* H+2

occ'rs hen the main stream enthalpy is still very small an(

more than one pea0 occ'rs) $ith the increase of ";2* the

temperat're (ifference beteen the all an( main stream

increases* an( H+C (ecreases) .'rthermore* the locations of

the ma:im'm val'e of the H+C move toar(s the lo

enthalpy region ith the ";2 (ecreasing)

S'b,channels hich consi(ere( in this paper* shos near

the pse'(o,critical point* the temperat're (ifference is small*

hile in the s'b,critical an( s'per critical regions it is large)

+he non 'niformity at the o'tlet is largest) 1n the mi((le height

of the channel* the fl'i( reaches the pse'(o,critical point in the

near,all region* hich ca'ses the heat transfer coefficient to

(ecrease an( the all temperat're increases rapi(ly)

+he res'lt of the non,circ'lar channel ith an( itho't

ire,rappe( res'lt of the comparison shos that cla((ing

temperat're (ecreases ith ire,rappe() $ith the ire affect

its give the goo( agreement ithin the temperat're range limits

for cla((ing s'rface temperat're)

1t has to be pointe( o't that the concl'sions achieve( in this

paper are only vali( for the parameter ranges consi(ere()

.'rther analysis ith a i(er range of parameters is nee(e( an(

'n(eray)

REFERENCES

D1E Sarah Mo0ry* Am/a( .arah* Krysten King* Sahil 4'pta*

1gor "ioro) Development of Supercritical Water Heat-

Transfer Correlation for ertical !are Tubes)

1nternational Conference 3'clear Energy .or 3e

E'rope200C Ile( ; Slovenia ; September 1-,1G

D2E +) Sch'lenberg* M) Starflinger* an( M) Heinec0en* T"ree

pass core #esign proposal for a Hig" $erformance %ig"t

Water Reactor* 2n( C5E,13ES,2 1nternational

Conference on 1nnovative 3'clear Energy Systems* 13ES,

2* Lo0ohama* Mapan* 2008* !2008%)

D3E K) .ischer* +) Sch'lenberg* E) #a'rienc* Design of a

supercritical &ater-coole# reactor &it" a t"ree-pass core

arrangement* 3'clear Engineering an( 2esign 23C* 700J

712* 200C

D-E S) Himmel* A) Class* E) #a'rien* an( +) Sch'lenberg*

<Sub-c"annel 'nal(sis of a H$%WR )uel 'ssembl( &it"

S+AR,C2*= T"e *+t" $acific !asin ,uclear Conference*

Aomori* MapanH 2007)

D>E S) Koshi?'0a* 3) +a0ano* an( L) 50a* <,umerical

anal(sis of #eterioration p"enomena in "eat transfer to

supercritical &ater*= 1nternational Mo'rnal of Heat an(

Mass +ransfer* vol) 37* 3ov) 1CC>* pp) 30GG,307-)

D8E K) Ka?'hiro* L) A0if'mi* 1) L'0i* 5) Loshia0i* an( #) Mie*

<)uel an# Core Design of Super %ig"t Water Reactor &it"

%o& %eakage )uel %oa#ing $attern*= M) 3'cl) Sci)

+echnol* vol) -3* 2008* pp) 12C,13C)

DGE A) Lama/i* +) +anabe* an( L) 50a* <-valuation of t"e

,ominal $eak Cla##ing Surface Temperature of t"e Super

%WR &it" Subc"annel 'nal(ses*= "rocee(ings of

4#5IA# 200>* +s'0'ba* MapanH 200>)

D7E A) Lama/i* L) 50a* L) 1shiatari* M) #i'* an( M) S'?'0i*

<$rinciple of rationali.ing t"e criteria for abnormal

transients of t"e Super %WR &it" fuel ro# anal(ses*=

Annals of 3'clear Energy* vol) 33* A'g) 2008* pp) C7-,

CC3)

DCE L) 1shiatari* L) 50a* S) Koshi?'0a* A) Lama/i* an( M)

#i'* <Safet( of Super %WR/ 0112 Safet( 'nal(sis at

Supercritical $ressure/= Mo'rnal of 3'clear Science an(

+echnology* vol) -2* 200>* pp) C3>,C-7)

D10E L) 1shiatari* M) Lama0aa* an( L) 50a* <Researc" an#

#evelopment of a Super )ast Reactor 3vervie& an#

Hig"-Temperature Structural #esign/= Aomori* MapanH

2007)

D11E W) Cheng* <RN2 Activities on SC$R in China*= 4t"

1nternational S(mposium on Supercritical Water-Coole#

Reactors* Hei(elberg* 4ermanyH 200C)

D12E #) Cao* L) M'* L) 50a* an( S) 10e/iri* <Researc" an#

Development of a Super )ast Reactor Core Design

1mprovement on %ocal oi# Reactivit(*= Aomori* MapanH

2007)

D13E H) Mori* S) Loshi(a* S) Moroo0a* an( H) Komita* <Heat

+ransfer St'(y 'n(er S'percritical "ress're Con(itions for

Single Ro( +est Section*= "rocee(ings of 1CA"" X0>*

Seo'l* K5REAH 200>)

D1-E H) Mori* M) 5hno* K) 5hishi* an( L) Hamamoto*

<Researc" an# Development of a Super )ast Reactor Heat

Transfer to a Supercritical $ressure )lui# )lo&ing in a

Sub-bun#le C"annel*= Aomori* MapanH 2007)

D1>E W) Cheng* W)M) #i'* an( L)H) Lang* <' 5ixe# Core for

Supercritical Water-coole# Reactors*= 3'clear

Engineering an( +echnology* vol) -0* .eb) 2007* pp) 11G,

128)

D18E K) Lamagata* K) 3ishi0aa* S) Hasegaa* +) .'/ii* an(

S)

Loshi(a* <)orce# convective "eat transfer to supercritical

&ater flo&ing in tubes*= 1nternational Mo'rnal of Heat an(

Mass +ransfer* vol) 1>* 2ec) 1CG2* pp) 2>G>,2>C3)

D1GE K)M) "an(ey* A) 2ebbarma*) <C.2 analysis of flo an(

heat transfer in s'b,channel of H"#$R !High "erformance

#ight $ater Reactor%*= #A" #AMIER+ Aca(emic "'blishing*

Saarbr'c0en 4ermany* !1SI3 CG7,3,8>C,-0G77,7%*2013)

También podría gustarte

- Tri Sec AphDocumento36 páginasTri Sec AphKrishnan Santhanaraj100% (1)

- Instructions: 1. Attempt All Questions. 2. Make Suitable Assumptions Wherever Necessary. 3. Figures To The Right Indicate Full MarksDocumento2 páginasInstructions: 1. Attempt All Questions. 2. Make Suitable Assumptions Wherever Necessary. 3. Figures To The Right Indicate Full MarkscharulapAún no hay calificaciones

- HW 02Documento4 páginasHW 02Tabitha HowardAún no hay calificaciones

- Lab 2 Full Reprt HEx DoaaDocumento22 páginasLab 2 Full Reprt HEx DoaaDoaa BadarnehAún no hay calificaciones

- EO-Process DesignDocumento13 páginasEO-Process DesignMarnel Roy MayorAún no hay calificaciones

- Heat Has Critical Influences On Machining. To Some Extent, It Can Increase Tool Wear andDocumento8 páginasHeat Has Critical Influences On Machining. To Some Extent, It Can Increase Tool Wear andPassmore DubeAún no hay calificaciones

- HEDocumento10 páginasHEMohamed BelallAún no hay calificaciones

- The Overall Heat Transfer Characteristics of A Double Pipe Heat Exchanger: Comparison of Experimental Data With Predictions of Standard CorrelationsDocumento12 páginasThe Overall Heat Transfer Characteristics of A Double Pipe Heat Exchanger: Comparison of Experimental Data With Predictions of Standard CorrelationsEngr. AbdullahAún no hay calificaciones

- 3235Documento4 páginas3235fotickAún no hay calificaciones

- Transient Heat Conduction Lab ResultsDocumento32 páginasTransient Heat Conduction Lab ResultsVic LiAún no hay calificaciones

- Lab 2Documento17 páginasLab 2Callum BiggsAún no hay calificaciones

- Chemical Engineering - MCQs 2012Documento17 páginasChemical Engineering - MCQs 2012Surjendu Maity100% (5)

- Finite Element Method Simulation and Characterization of A Thermal Flow Sensor Based On Printed Circuit Board Technology For Various FluidsDocumento5 páginasFinite Element Method Simulation and Characterization of A Thermal Flow Sensor Based On Printed Circuit Board Technology For Various FluidsCông ĐôAún no hay calificaciones

- Thermal Diffusivity Determination of Polyester Resin and Steel PDFDocumento8 páginasThermal Diffusivity Determination of Polyester Resin and Steel PDFRenz AsprecAún no hay calificaciones

- SPE 133428 Modeling Thermal Effects On Wellbore StabilityDocumento23 páginasSPE 133428 Modeling Thermal Effects On Wellbore StabilityMaria Fernanda LopezAún no hay calificaciones

- Cross Flow Heat Exchanger ExperimentDocumento6 páginasCross Flow Heat Exchanger ExperimentChristopher SequeraAún no hay calificaciones

- (Ref. Code: ME/LM/HTHP/R00) : Centurion Institute of TechnologyDocumento79 páginas(Ref. Code: ME/LM/HTHP/R00) : Centurion Institute of TechnologyNabin Chandra SahuAún no hay calificaciones

- Heat Exchanger Lab ReportDocumento5 páginasHeat Exchanger Lab ReportYingyMnisi100% (1)

- CFD Analysis of Flow in After BurnerDocumento10 páginasCFD Analysis of Flow in After BurnermortezaastroAún no hay calificaciones

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDocumento5 páginasSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVAún no hay calificaciones

- SCHA1301_033251-66-130Documento65 páginasSCHA1301_033251-66-130danifexAún no hay calificaciones

- Numerical and Experimental Study On Temperature Crossover in Shell and Tube Heat ExchangersDocumento17 páginasNumerical and Experimental Study On Temperature Crossover in Shell and Tube Heat ExchangersRisto FilkoskiAún no hay calificaciones

- Experiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural ConvectionDocumento6 páginasExperiment No. 03 Aim: To Determine The Heat Transfer Coefficient in Natural Convectionpriya3939Aún no hay calificaciones

- Dynamic Model of a Once-Through Steam GeneratorDocumento8 páginasDynamic Model of a Once-Through Steam GeneratorFrancesco CordellaAún no hay calificaciones

- A Theoretical Analysis and CFD Simulation On The Ceramic Monolith Heat ExchangerDocumento12 páginasA Theoretical Analysis and CFD Simulation On The Ceramic Monolith Heat ExchangerMohamed AshrafAún no hay calificaciones

- Determination of OD cooling parametersDocumento12 páginasDetermination of OD cooling parametersmpu682Aún no hay calificaciones

- PerpanDocumento7 páginasPerpanT Bagus Tri LusmonoAún no hay calificaciones

- Calculating Core TemperatureDocumento6 páginasCalculating Core TemperatureAnonymous sAmJfcVAún no hay calificaciones

- Air PreheaterDocumento6 páginasAir Preheaternx302Aún no hay calificaciones

- Thermal BowingDocumento8 páginasThermal BowingA. VenugopalAún no hay calificaciones

- Ay1011sem1 Me3122eDocumento3 páginasAy1011sem1 Me3122eCammy MiunoAún no hay calificaciones

- Heat Transfer and Heat - ExchangersDocumento6 páginasHeat Transfer and Heat - ExchangersVinh Do ThanhAún no hay calificaciones

- Improvement of New Fin Design For Automotive Water Cooling SystemDocumento8 páginasImprovement of New Fin Design For Automotive Water Cooling SystemMurali KrishnaAún no hay calificaciones

- Supply Water Temperature Regulation Problems in District Heating Network With Both Direct and Indirect Connection PDFDocumento6 páginasSupply Water Temperature Regulation Problems in District Heating Network With Both Direct and Indirect Connection PDFSrbislav GenicAún no hay calificaciones

- Three Days Workshop On Computational Fluid Dynamics 7 To9 February 2014Documento4 páginasThree Days Workshop On Computational Fluid Dynamics 7 To9 February 2014heloverAún no hay calificaciones

- Three Days Workshop On Computational Fluid Dynamics 7 To9 February 2014Documento4 páginasThree Days Workshop On Computational Fluid Dynamics 7 To9 February 2014heloverAún no hay calificaciones

- CBE 362L 1 Double PipeDocumento8 páginasCBE 362L 1 Double PipeDodOng GwapoAún no hay calificaciones

- Modeling of Counter Current Moving Bed Gas-Solid Reactor Used in Direct Reduction of Iron Ore - PlusDocumento10 páginasModeling of Counter Current Moving Bed Gas-Solid Reactor Used in Direct Reduction of Iron Ore - PlusJavier GómezAún no hay calificaciones

- Analysis of A Helical Coil Once-Through Molten Salt Steam Generator: Experimental Results and Heat Transfer EvaluationDocumento10 páginasAnalysis of A Helical Coil Once-Through Molten Salt Steam Generator: Experimental Results and Heat Transfer EvaluationCristina VladutaAún no hay calificaciones

- International Communications in Heat and Mass Transfer: Sheng-Chung Tzeng, Tzer-Ming Jeng, Yi-Liang LinDocumento9 páginasInternational Communications in Heat and Mass Transfer: Sheng-Chung Tzeng, Tzer-Ming Jeng, Yi-Liang Linvijay2293Aún no hay calificaciones

- Gtaw of 800hDocumento9 páginasGtaw of 800hpradeepAún no hay calificaciones

- 3013 PDFDocumento42 páginas3013 PDFOlbira Dufera100% (1)

- Heat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersDocumento5 páginasHeat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersShalehAhmad100% (1)

- Simulation Studies On A Cross Flow Plate Fin Heat ExchangerDocumento4 páginasSimulation Studies On A Cross Flow Plate Fin Heat ExchangerHemant KumarAún no hay calificaciones

- Unesco - Eolss Sample Chapters: Pinch AnalysisDocumento9 páginasUnesco - Eolss Sample Chapters: Pinch AnalysissumitAún no hay calificaciones

- Review B InggrisDocumento10 páginasReview B InggrisWillyam PrizkiabiAún no hay calificaciones

- Experiment 2 Lab SheetDocumento6 páginasExperiment 2 Lab SheetHesapAún no hay calificaciones

- Case Studies in Thermal Engineering: Ashkan Alimoradi, Farzad VeysiDocumento6 páginasCase Studies in Thermal Engineering: Ashkan Alimoradi, Farzad Veysimohamed mostafaAún no hay calificaciones

- Heat Exchanger HandoutDocumento11 páginasHeat Exchanger Handoutchegg userAún no hay calificaciones

- Design and Simulation of MEMS-based Dual-Axis Uidic Angular Velocity SensorDocumento6 páginasDesign and Simulation of MEMS-based Dual-Axis Uidic Angular Velocity SensorRahul ParkAún no hay calificaciones

- Shell-and-Tube Heat Exchangers R. Shankar Subramanian: AdvantagesDocumento10 páginasShell-and-Tube Heat Exchangers R. Shankar Subramanian: AdvantagesCherry May SerionAún no hay calificaciones

- Final Exam Review ProblemsDocumento9 páginasFinal Exam Review ProblemsalvinchuanAún no hay calificaciones

- Heat Exchanger DesignDocumento35 páginasHeat Exchanger Designdarkbreaker3244Aún no hay calificaciones

- Process Heat Transfer: Principles, Applications and Rules of ThumbDe EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbCalificación: 4.5 de 5 estrellas4.5/5 (11)

- Quiz 3Documento2 páginasQuiz 3Vishruta KathuriaAún no hay calificaciones

- SCI04 - Acoustic Design For Auditorium - Student NotesDocumento8 páginasSCI04 - Acoustic Design For Auditorium - Student NotesurmanjmAún no hay calificaciones

- 2015.12.09 - Vibration of Reinforced Concrete Floor Systems - Part 1Documento77 páginas2015.12.09 - Vibration of Reinforced Concrete Floor Systems - Part 1Bavedi SanAún no hay calificaciones

- Key to SOZ BY keenplify (WEEK 11-20Documento7 páginasKey to SOZ BY keenplify (WEEK 11-20Seah FuegoAún no hay calificaciones

- Fronts 1Documento40 páginasFronts 1Jeycule BerendezAún no hay calificaciones

- Physlab Report 7Documento2 páginasPhyslab Report 7Pugee ChavezAún no hay calificaciones

- Solucionario Capitulo 13 Física Serway and FaughnDocumento13 páginasSolucionario Capitulo 13 Física Serway and FaughnRafael Colindres100% (1)

- Satellite Communication: by Dr. Taimoor Khan, Associate Professor, Department of ECE, Associate Dean (Academic)Documento74 páginasSatellite Communication: by Dr. Taimoor Khan, Associate Professor, Department of ECE, Associate Dean (Academic)Himangshu DekaAún no hay calificaciones

- Wgrav = -m g Dy (work done by gravityDocumento2 páginasWgrav = -m g Dy (work done by gravityNasim AkhtarAún no hay calificaciones

- HT Lecture 13 ConvectionSolvedProblemsDocumento17 páginasHT Lecture 13 ConvectionSolvedProblemsclaudette colladoAún no hay calificaciones

- Circular Motion PDFDocumento47 páginasCircular Motion PDFAryan100% (1)

- Particles and Waves Course Questions and SolutionsDocumento33 páginasParticles and Waves Course Questions and SolutionsDaveyAún no hay calificaciones

- Use of Gas Tables Permitted, Assume Suitable Value For Missing DataDocumento2 páginasUse of Gas Tables Permitted, Assume Suitable Value For Missing DataVenkitaraj K PAún no hay calificaciones

- Lakhmir Singh Solutions Class 9 Physics Chapter 4Documento15 páginasLakhmir Singh Solutions Class 9 Physics Chapter 4DarshilAún no hay calificaciones

- OCEN 201 Introduction To Ocean & Coastal EngineeringDocumento28 páginasOCEN 201 Introduction To Ocean & Coastal EngineeringbalumaxAún no hay calificaciones

- Basic Laser Principles: Leon MupaDocumento31 páginasBasic Laser Principles: Leon MupaLeon MpalsAún no hay calificaciones

- Boundary Layer Full PDFDocumento10 páginasBoundary Layer Full PDFNasser93100% (1)

- A'level Modern Physics NotesDocumento64 páginasA'level Modern Physics NotesLubangula UthumanAún no hay calificaciones

- Folded Dipole Antenna: Presented By: Navin Mandal (700415)Documento18 páginasFolded Dipole Antenna: Presented By: Navin Mandal (700415)Narayan Mishra MishraAún no hay calificaciones

- Problem 130 DynamicDocumento8 páginasProblem 130 DynamicKoffi3100% (2)

- Name - Student ID - ScoreDocumento2 páginasName - Student ID - ScoreBowen XuAún no hay calificaciones

- Flat Plate Collectors 1st 6th LectureDocumento39 páginasFlat Plate Collectors 1st 6th LectureRami ZakoutAún no hay calificaciones

- Questions OC Class Test CorrectedDocumento1 páginaQuestions OC Class Test CorrectedsrinivasAún no hay calificaciones

- Ray Optics and Optical Instruments - Short Notes - Lakshya JEE 2024Documento4 páginasRay Optics and Optical Instruments - Short Notes - Lakshya JEE 2024bhaveshkumarbijaniAún no hay calificaciones

- DOE Ionizing Radiation Dose Ranges (Rem) ChartDocumento2 páginasDOE Ionizing Radiation Dose Ranges (Rem) ChartEnformableAún no hay calificaciones

- Resonance-Kinematics PDFDocumento60 páginasResonance-Kinematics PDFAnuj jainAún no hay calificaciones

- Newton's Laws in MotionDocumento5 páginasNewton's Laws in MotionMira VeranoAún no hay calificaciones

- C12 Electromagnetic WavesDocumento48 páginasC12 Electromagnetic WavesRosemarie Cabanilla50% (2)

- Physical Science DLP DLPDocumento8 páginasPhysical Science DLP DLPMossolb EquiperAún no hay calificaciones

- NASAHandbook Sec1Documento129 páginasNASAHandbook Sec1Pradeep SinglaAún no hay calificaciones