Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Ocular Health Status and Practices Among Workers of A Steel Rolling Mill in Nigeria

Cargado por

Putt LaLuTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Ocular Health Status and Practices Among Workers of A Steel Rolling Mill in Nigeria

Cargado por

Putt LaLuCopyright:

Formatos disponibles

OCULAR HEALTH STATUS AND PRACTISES AMONG THE WORKERS OF A STEEL ROLLING MILLIN NIGERIA

DUPES. ADEMOLA-POPOOLA', TANIMOWO AKANDE',

A N D ABDULKABIR AYANNIYI'

' Department of Ophthalmology, University of Ilorin Teaching Hospital, Ilorin. Nigeria

Department of Community Health, University of Ilorin, Ilorin, Nigeria

ABSTRA~ Steel : rolling mills potentially present ocular hazard. However, no study is known as yet that would deal with the ocular health practices and ophthalmological status of the workers employed in this industry. In this study, 107 steel rolling workers were surveyed for eye protection practices, previous eye injuries, and present ocular status. Half of the workers possessed eye protective devices (EPD), however 31.6% of them never used it. Of the latter, 68.9% reported history of work-related eye injuries: 8 cases at drilling (12.9%). 18 at welding (29.0%), 13 at grinding (21%). and 23 cases at other work processes (37.1%). Uncorrected visual acuity (5 6118) was found in 54.2% of the workers (increased to 96% by refraction co1,rection) caused by uncorrected ametropia (20.6%). uncorrected presbyopia ( 1 1.3%), glaucoma (7.5%), and pterygium (2.8%). In conclusion, regular ophthalmological screening and adequate treatment of the abnormalities found should be an integral part of the occupational health measures in steel industries.

KEYWORDS: Steel industry, eye protective devices, ocular pathology

INTRODUCTION

Work-related hazards have been identified as causes of ocular morbidity among industrial workers (Griffith and Jones, 1994; Lipscomb, 2000: Schoemaker et al., 2000; Okoye and Umeh, 2002). Occupational eye injuries are most likely to result from work that generates flying particles, fragments, sparks, dust, hazardous substances, or radiation. Tasks with the highest risk of eye injuries are grinding, welding, and hammering. Other high-risk activities include cutting or spraying, smelting, sanding, chipping or chiselling. People worlung with metal are most at risk (Safetyline, 2004). Workers in the steel industry are exposed to various severe hazards (Shoemaker et al., 2000). Metal chips and welding arc rays were identified as causes of eye injury in steel industry (Okoye and Umeh, 2002). Ocular injuries vary from mild to severe which could threaten vision.

Corresporldirlg arrtlror: Dupe S. Aden~ola-Popoola Departrrlerlt of Ophthalmology U11i1~ersit.v of llorirl Teaching Hospital Ilorir~. Nigeria GPO Boar4718 Ilorirl, K~vara Srare. Nigeria Tel +23480.?3929737 E-nlail: rlr~ps~p@ynhoo.co~~i

Received: 11 October 2005 Accepted: 13 January 2006

In Nigeria, industrial accidents are usually under-reported, which makes it difficult to obtain an accurate number of accidents (FMLP, 1998: Musa et al., 2003). Previous studies showed that the eye accident rate varied from factory to factory (Garrow, 1973; Okoye and Umeh, 2002) and appeared to decrease over years. Garrow (1923) reported 70.7%, 11sa; et al (1982) reported 15.4% in Malawi, and Okoye and Umeh (2002) 12.5% among industrial workers in South-eastern Nigeria. Work-related hazards are a potential source of litigation, huge compensation, economic loss, and loss of quality of life. The International Labour Office has estimated that well over 250 million non-fatal accidents cause work absenteeism and they are often accompanied or aggravated by permanent disabilities with reduced capacity of life and work (cit. by Takala, 1999). The economic losses amount to 40% of gross national product (Takala, 1999). In America, the Bureau of Labour Statistics reported that the work place eye injuries cost over $467 million annually. Indirect costs, such as legal fees, judgments, and training replacement workers, place the estimated total above $934 million each year (Prevent Blindness America, 2003). Most work-related hazards could be avoided, prevented, or reduced through education (Griffith and Jones, 1994; Musa et al., 2003), public enlightenment (Canavan and Flaherty, 1980), compliance to work ethics, legislation (Okuyade, 1977; Factories Act,1990; Okoye and Umeh, 2002) enforcing provision and use of protective devices. Experts believe that proper eye protection could have prevented or reduced the severity of injury in at least in 90% of all accidents (Prevent Blindness America, 2003). Prevention of eye injury needs special attention in steel works (Shoemaker et al., 2000). This study was carried out to determine the ocular health practices and the ocular status among the staff of a government owned steel rolling company in Nigeria. The knowledge, attitude and behaviour of the workers towards work-related eye problems were also studied.

METHODS

The steel rolling factory where this study was carried out in the year 2003 is one of Nigeria's plants producing steel from raw iron. It has three basic functional units. The administrative unit is involved in the day to day running of the company. It generally implements policies such as ensuring the availability of protective devices and a safe working environment that impact directly or otherwise the health of the staff working in the other section of the company. The technology unit is concerned with the operation of the plant as well as the industrial safety. The production unit employs workers at the rolling mill, furnace, and fmishing. The workers are exposed to splinters of metals, welding arc rays, and hot molten metal. The technology and production units were the potential areas for work-related hazards. Consent to carry out the study was obtained from the management of the company. The workers run a three-shift duty in the production and technology units of the plant while the administrative unit runs only a morning schedule. All the workers were. however, mobilized to participate in the study irrespective of the shift duty

CENTRALEUROPEAN JOURNAL OF OCCUPATIONAL A N D ENVIRONMENTAL MEDICINE. 2005; 1 l(3): . 165

for the day. Individual consent was also obtained having explained the purpose of the study. A questionnaire was employed to learn the knowledge, attitude, and the behaviour of the workers to work-related ocular health hazard. Their ophthalmological status was determined by an assessment of visual acuity by means of Snellen chart, Jaeger chart, and ocular examination performed with an ophthalmoscope. Intraocular pressure was measured with a Perkins tonometer. Individuals with visual acuity less than 6/18 had refraction correction done while other ocular patholo,'vies were sent to hospital for further investigation and treatment. The study involved a total of 107 workers divided among the 3 main functional units: production 40 (37.4%), administration 36 (33.6%), and technology 31 (29.0%). The mean age was 43 (range: 22-59 yr). There were 85 males and 22 females giving a ratio of about 4:l. The level of education among the workers showed that about 65 (60.7%) of them had tertiary education, 19 (17.8%) had secondary education, 8 (7.5%) had primary education, while 15 (14%) had no formal education. The workers had spent between 1 and 22 years working in the industry with a mean of 11.7k7.05 yr. About 73% of the staff had worked for more than five years in the industry. About two-third (69.6%) of the workers had job specific training before starting to work. Only 20.4% of them had ever had received eye health education since joining the industry. 94.3% of the workers were aware of the fact that potential ocular hazard existed in the industry and 98.9% believed that the hazard could be prevented with the use of some eye protective device (EPD). The data were analyzed using the Epi6 statistical package. The results are presented in frequency distribution tables.

RESULTS

The most commonly known EPDs by the workers were the welding shield or goggles. The others included dark spectacles, safety garment, safety belts, and helmets. Protection is also believed to be achievable through the provision of modern, less hazardous machinery, specific training of the workers, and random checks of the workers to ensure compliance with the use of safety devices at work (Table I ) .

TABLE 1. Knowledge of protective devices among the employees investigated

Dark spectacle

Others = safety belts, garment, and modern machines

About two-thirds (49 subjects; 68.9%) of the workers in the production and technology units reported that they had had some work related eye injuries. Thirtysix (73.4%) of them did not use any protective device available. The injuries were said to have occurred duriqg drilling (8; 12.9%), welding (18; 29.0%), grinding (13; 21%), and in other procedures (23; 37.1%). The latter were from exposure to red hot billet, furnace light, electric spark, explosion of liquid metals, and lubricating fluids. Thirty-eight (53%) of the 71 employees of the production and technology units reported possessing EPD. The frequency of the use of this device is shown in Table 2. Those that had never used any device though did possess them reported different reasons; the most important were the following: low-level risk believed (3; 12%), discomfort of the device (5; 20%), inadequacy of protection (1 1; 44%), lack of practice (4; 16%), and considering it unnecessary (2; 8%).

TABLE 2. Frequency of use of eye protective devices among those who possessed them (n=38)

Sometimes

n = number of subjects

Other modalities applied and believed useful by some of the workers to reduce ophthalmic hazard from factory work included regular intake of balanced diet (2 subjects; 14.3%), partial closure of eyes when exposure to high light intensity was imminent, and when operating switches (2; 14.3%), use of prescribed glasses (4; 28.6%), temporary absenteeism from work (3; 21.4%), and (in 7.1%) other considerations, as yearly visiting the ophthalmologist, shielding the eyes with hands, or leaving the area of hazards. Less than half of the participants, i.e, 43 subjects (40.1%) had previously had their eyes checked while the remaining 64 (59.9%) had never undergone ophthalmological examination. The workers examined gave the following reasons for visiting the ophthalmologist: routine care 9 subjects, (20.9%), impaired visual acuity following exposure to workplace hazard (30; 69.8%), eye ache (1; 2.3%). and on advice (3; 7%). The result of the present ophthalmological examination (Table 3) showed that uncorrected ametropia and presbyopia shared the major part (33.7%) of the ocular pathologies found. Refraction correction increased the number of the workers with normal visual acuity to 96%.

CENTRAL EUROPEAN JOURNAL OF OCCUPATIONAL AND ENVIRONMENTAL MEDICINE ,2005; 1 1(3): . 167

TABLE 3. Result of ophthalmological investigation of employees of a steel rolling mill

Uncorrected arnetropia Uncorrected presbyopia Glaucoma

Other = maculopathy, optic atrophy, squint, and 'hypertensive retinopathy

DISCUSSION

Occupational accidents affecting the eyes are common and are major causes of morbidity and disability. This is the case in spite of the well publicized standards for industrial eye protection even in the developed and industrialized countries. It has been found that subjects working longer in their current job, reporting to have received job safety training before employment, or whose machines or equipment are maintained or repaired regularly by the employer are at lower risk of experiencing eye injuries (Yu et al., 2000). Unfortunately this was not the case in the plant studied. The potential risk of unprotected exposure to some of the hazardous objects such as metal chips, hot liquid metals and electric sparks in activities such as welding, grinding, cutting, and moulding was well known by the workers. There was also a high awareness of some protective devices among the different categories of workers including those of administration. This is important because to be effective the prevention of ocular accidents must be comprehensive and must necessarily involve the management of the industry as well as the employees (Abiose and Otache, 1981). The welding shieldlgoggles, the most popular EPDs mentioned by the workers were the most available ones in the plant. The need to have modern well maintained machinery, specific training in safety measures and insistence on compliance with the use of eye protective devices while at work as important factors to reduce risk of ocular injury was also recognized by the workers. Despite the high awareness and that about half (52%) of the workers in the production and technology units had EPDs, they did not often wear them. The fact that most of the employees agreed not to wear any protective device on ground of the false reasons listed in the Results clearly showed the attitude of the workers to EPD which was probably considered to be optional. This attitude has to be modified by continuous eye health education and supervision of the workers.

The work-related injuries found in the present study are in good agreement with the findings of Voon et al. (2001), who specify grinding, cutting of metals, and drilling as the cause of more than 90% of work-related eye injuries. In conclusion, beyond appropriate educational, institutional, and technical measures, regular follow-up of the ophthalmological status of the workers is also needed to ensure individual and collective safety in steel rolling mills.

REFERENCES

ABIOSE, A. and OTACHE, M. A. (1981). "Ophthalmic needs of Nigerian factory workers." J. Trop. Med. Hyg. 84: 161-163. CANAVAN, Y. M., O'FLAHERTY, M. J., ARCHER, D. B., and ELWOOD. J. H. (1980). "A 10-year survey of eye injuries in Northern Ireland, 1967-76." Br. J. Ophthalmol. 64:618-625. FACTORIES ACT (1990). Federal Republic of Nigeria, Federal Government Printers. Lagos, Nigeria. FMLP (1998). Annual Report. Department of Planning Research and Statistics, Federal Ministry of Labour and Productivity, Abuja, Nigeria, pp. 25-26. GARROW, A. A. (1923). "Statistical enquiry into 100 cases of eye injuries." Br. J. Ophthalmol. 7:65-80. GRIFFITH, G. A. and JONES, N. P. (1994). "Eye injury and eye protection: a survey of the chemical industry." Occup. Med. (Lond) 44:37-40. ILSAR, M., CHIRAMBO, M., and BELKIN, M. (1982). "Ocular injuries in Malawi." Br. J. Ophthalmol. 66:145-148. LIPSCOMB, H. J. (2000). "Effectiveness of interventions to prevent work-related eye injuries." Am. J. Prev. Med. 18/Suppl. 4:27-32. MUSA, A. A., AKIODE, O., TADE, A. O., and SALAMI, B. A. (2003). "Persistently disturbing pattern of injuries from small scale industrial machinery in South West Nigeria. Our Experience." Nig. Med. Pract. 4333-89. OKOYE, 0 . I, and UMEH, R. E. (2002). "Eye health of industrial workers in Southeastern Nigeria." West Afr. J. Med. 21:132-137. OKUYADE, M. A. (1977). "Industrial accidents and hazards in a large wood complex." Nig. Med. J. (Special Edition). Proceedings of the Annual Conference of Nigeria Medical Association, Ibadan, Nigeria. PREVENT BLINDNESS AMERICA (2003). Workplace Eye Safety URL: http://www.preventblindness.org/safety/pvnt-injuries.htm1 SAFETYLINE (2004). WorkSafe Western Australia. http:Nwww.safetyline.wa.gov.au SCHOEMAKER, M. J., BARRETO, S. M., SWERDLOW, A. J.. HIGGINS. C. D., and CARPENTER, R. G. (2000). "Non-fatal work related injuries in a cohort of Brazilian steel workers." Occup. Environ. Med. 57:555-562. TAKALA J. (1999). "International agency efforts to protect workers and the environment." Int. J. Occup. Environ. Health 5:30-37. VOON, L. W., SEE, J., and WONG, T. Y. (2001). "The epidemiology of ocular trauma in Singapore: perspective from the emergency service of a large tertiary hospital." Eye 15:75-8 1. YU, T. S.. LIU, H., and HUI, K. (2004). "A case-control study of eye injuries in the workplace in Hong Kong." Ophthalmology 11 1370-74.

También podría gustarte

- Inforeq CSR r12 enDocumento35 páginasInforeq CSR r12 enPutt LaLuAún no hay calificaciones

- Tracking Trash 25 Years of Action For The OceanDocumento43 páginasTracking Trash 25 Years of Action For The OceanPrograma Regional para el Manejo de Recursos Acuáticos y Alternativas EconómicasAún no hay calificaciones

- Integrity Testing FactsheetDocumento11 páginasIntegrity Testing Factsheetsuperdick14Aún no hay calificaciones

- Identifying Chemical Reactivity HazardsDocumento5 páginasIdentifying Chemical Reactivity HazardsG NavarAún no hay calificaciones

- Reference Document On Best Available Techniques in The Non Ferrous Metals IndustriesDocumento807 páginasReference Document On Best Available Techniques in The Non Ferrous Metals IndustriesPutt LaLuAún no hay calificaciones

- Evaluation of Dust Emission Properties For Hand-Operated Power Tools and DevicesDocumento132 páginasEvaluation of Dust Emission Properties For Hand-Operated Power Tools and DevicesPutt LaLuAún no hay calificaciones

- Metal Plastic RubberDocumento9 páginasMetal Plastic RubberPutt LaLuAún no hay calificaciones

- Fibreglass Guide V 1Documento29 páginasFibreglass Guide V 1Putt LaLuAún no hay calificaciones

- Waste Policy Brief-Eng - RedusedDocumento20 páginasWaste Policy Brief-Eng - RedusedPutt LaLuAún no hay calificaciones

- YVA Selostusraportti en SecuredDocumento220 páginasYVA Selostusraportti en SecuredElizabeth MillerAún no hay calificaciones

- ERA For For Industrial ChemicalsDocumento109 páginasERA For For Industrial ChemicalsPutt LaLuAún no hay calificaciones

- Event Tree AnalysisDocumento12 páginasEvent Tree Analysisbayu_pratama_18Aún no hay calificaciones

- Solid Waste Audit of LandfillDocumento71 páginasSolid Waste Audit of LandfillPutt LaLuAún no hay calificaciones

- Eia - Negril Peninsula ResortDocumento350 páginasEia - Negril Peninsula ResortPutt LaLu100% (1)

- Eia North Guwahati 07.07.12Documento276 páginasEia North Guwahati 07.07.12Putt LaLuAún no hay calificaciones

- Waste Audit of LandfillDocumento39 páginasWaste Audit of LandfillPutt LaLuAún no hay calificaciones

- Emissions of Volatile Organic CompoundsDocumento26 páginasEmissions of Volatile Organic CompoundsPutt LaLuAún no hay calificaciones

- Waste Audit Users ManualDocumento75 páginasWaste Audit Users ManualPutt LaLuAún no hay calificaciones

- Effluent Discharge StdsDocumento2 páginasEffluent Discharge StdsPutt LaLuAún no hay calificaciones

- Waste Audits SummaryDocumento27 páginasWaste Audits SummaryPutt LaLuAún no hay calificaciones

- Waste Audit GuideDocumento51 páginasWaste Audit Guidemazu_bzAún no hay calificaciones

- Landfill Review and AuditDocumento48 páginasLandfill Review and AuditPutt LaLuAún no hay calificaciones

- Inland Oil Response PlanDocumento107 páginasInland Oil Response PlanPutt LaLuAún no hay calificaciones

- Machining - Pollution Prevention Assessment and GuidanceDocumento68 páginasMachining - Pollution Prevention Assessment and GuidancePutt LaLuAún no hay calificaciones

- Mapping Health and Safety Standards in The UK Waste IndustryDocumento268 páginasMapping Health and Safety Standards in The UK Waste IndustryPutt LaLuAún no hay calificaciones

- Hafira LFDocumento4 páginasHafira LFPutt LaLuAún no hay calificaciones

- Guide For Addressing Environmental Problems - Using An Integrated Strategic ApproachDocumento115 páginasGuide For Addressing Environmental Problems - Using An Integrated Strategic ApproachPutt LaLuAún no hay calificaciones

- Killer Jeans Report Final 1Documento11 páginasKiller Jeans Report Final 1ramjee prasad jaiswalAún no hay calificaciones

- Guidance On Air Quality Monitoring in The Vicinity of Demolition and Construction SitesDocumento25 páginasGuidance On Air Quality Monitoring in The Vicinity of Demolition and Construction SitesPutt LaLuAún no hay calificaciones

- Workplace first-aid guidelinesDocumento22 páginasWorkplace first-aid guidelinesdrstein197450% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Stories of Special Children, Paknaan, Mandaue, CebuDocumento21 páginasStories of Special Children, Paknaan, Mandaue, CebuErlinda Posadas100% (1)

- Prinsip Kedokteran Keluarga 2018Documento57 páginasPrinsip Kedokteran Keluarga 2018BisukAún no hay calificaciones

- Medical Treatment For Dandruff: in This Leafl Et: 2. Before You Use Selsun ShampooDocumento2 páginasMedical Treatment For Dandruff: in This Leafl Et: 2. Before You Use Selsun ShampooCharles Franklin Joseph100% (1)

- Cavite State University drug study on mefenamic acidDocumento3 páginasCavite State University drug study on mefenamic acidAngelica Cassandra VillenaAún no hay calificaciones

- PhlebitisDocumento4 páginasPhlebitisPutriIffahAún no hay calificaciones

- Pediatric Atopic DermatitisDocumento101 páginasPediatric Atopic DermatitisTara Sefanya Kairupan100% (1)

- Example of Written AssignmentDocumento18 páginasExample of Written AssignmentyieviaAún no hay calificaciones

- Early Childhood CariesDocumento3 páginasEarly Childhood CariessreshtamukhiAún no hay calificaciones

- Kenneth J Koval, Joseph D Zuckerman PDFDocumento340 páginasKenneth J Koval, Joseph D Zuckerman PDFAnonymous hGBXIKA1Aún no hay calificaciones

- Fat Embolism Syndrome: DescriptionDocumento4 páginasFat Embolism Syndrome: DescriptionDayuKurnia DewantiAún no hay calificaciones

- Cranial NeuralgiasDocumento14 páginasCranial NeuralgiasHabib G. Moutran BarrosoAún no hay calificaciones

- Welcome To Maxfair & Company LTD - .Pdf3Documento5 páginasWelcome To Maxfair & Company LTD - .Pdf3Md Mohebbullah ChowdhuryAún no hay calificaciones

- Vitiligo - 2Documento4 páginasVitiligo - 2SHANMUGAPRIYANAún no hay calificaciones

- Sindh Child Institute of Health Science Sukkur For All SindhDocumento9 páginasSindh Child Institute of Health Science Sukkur For All Sindhghafoorjakhro786Aún no hay calificaciones

- Health Sector MainDocumento18 páginasHealth Sector MainKyla Barrera TabungarAún no hay calificaciones

- Internship Survival Guide NSHDocumento36 páginasInternship Survival Guide NSHRichardAún no hay calificaciones

- Britta K. Holzel Et Al - Investigation of Mindfulness Meditation Practitioners With Voxel-Based MorphometryDocumento7 páginasBritta K. Holzel Et Al - Investigation of Mindfulness Meditation Practitioners With Voxel-Based MorphometrySmokeysamAún no hay calificaciones

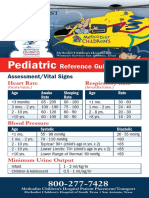

- AirCare Pediatric Reference GuideDocumento8 páginasAirCare Pediatric Reference GuideN/AAún no hay calificaciones

- GriefDocumento5 páginasGriefManuel HurtadoAún no hay calificaciones

- Zachary Siemieniak Resume 10Documento1 páginaZachary Siemieniak Resume 10api-301816885Aún no hay calificaciones

- Conservative Dentistry and Endodontics 2001-2012Documento32 páginasConservative Dentistry and Endodontics 2001-2012Sruthy SasiAún no hay calificaciones

- Basic HematologyDocumento89 páginasBasic Hematologydrafq2000Aún no hay calificaciones

- Book NutritionForThePretermNeonate PDFDocumento444 páginasBook NutritionForThePretermNeonate PDFkousikseth100% (2)

- Palodent EngDocumento3 páginasPalodent EngDrg ToddyAún no hay calificaciones

- The Newborn Intensive Care Unit Environment of CareDocumento6 páginasThe Newborn Intensive Care Unit Environment of CareSteph FergusonAún no hay calificaciones

- F5000 ManualDocumento6 páginasF5000 Manualcase1965Aún no hay calificaciones

- Childhood Cancer Resources Directory Asia - Final v170908Documento35 páginasChildhood Cancer Resources Directory Asia - Final v170908Anna VieeAún no hay calificaciones

- Flexor Tendon Protocols Ortheon MedDocumento10 páginasFlexor Tendon Protocols Ortheon MedAzmi FarhadiAún no hay calificaciones

- Semi-Rigid Ureteroscopy: Indications, Tips, and Tricks: Lily A. Whitehurst Bhaskar K. SomaniDocumento7 páginasSemi-Rigid Ureteroscopy: Indications, Tips, and Tricks: Lily A. Whitehurst Bhaskar K. SomaniUmar FarooqAún no hay calificaciones

- Nearby Hospitals in Noida and DelhiDocumento12 páginasNearby Hospitals in Noida and DelhivinaykaambleAún no hay calificaciones