Documentos de Académico

Documentos de Profesional

Documentos de Cultura

TB82 Homogeniser in UHT 3086 US

Cargado por

Amber ChavezDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

TB82 Homogeniser in UHT 3086 US

Cargado por

Amber ChavezCopyright:

Formatos disponibles

T E C H N I CA L B U L L E T I N

Homogenizer Operation

I N U HT PLANTS

When considering equipment used for processing milk at ultra high temperatures (UHT), one should recognize that the homogenizer is an important part of the system. The homogenizer reduces the size of the fat globules in the milk and prevents creaming of the butterfat. In 1900, long before modern UHT systems, Auguste Gaulin used a homogenizer on bottled, sterilized milk to demonstrate that homogenization could produce a long-shelf-life product able to be kept, for example, on ships over long voyages.

(2) Laminar, free-falling lm: product falls through a steam chamber as a thin, laminar, free-falling lm. 2. Indirect heating: ...milk is heated through a heat-conducting barrier, usually stainless steel, which separates the heating agent from the milk.2 Some examples of indirect heating methods are plate heat exchangers, single tube-in-tube systems and multiple tube-in-tube systems. Dairy products usually use heating by injection, infusion, tubular

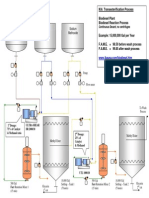

This report will review the operating requirements of the homogenizer in processing UHT milk, and UHT systems will not be described in detail here. However, it is benecial to review some different UHT methods in very general terms. UHT heating is used to produce an aseptic product that has a long shelf life. Ultra high temperatures and aseptic packaging systems are used for a variety of products such as milk, juices, sauces, creams, ice cream mix, desserts, diced fruit, soups and purees. In general, UHT milk is milk that has been heated to 132C (270F) for not less than 1 second and then aseptically packaged. These are the minimum processing conditions. Usually, UHT milk is processed at 130-150C (266302F) with 2 to 8 seconds holding time1,2. There are two basic heating arrangements used for milk, direct and indirect heating: 1. Direct heating: involves heating with culinary steam followed by a vacuum ash cooling to remove added condensate and odors. There are different ways to do this. a. Injection: steam is sprayed into the milk in a mixing chamber. b. Infusion: milk is sprayed into a steam environment. (1) Atomizing the milk into ne droplets and injecting the droplets into the steam.

heat exchangers or plate heat exchangers. The location of the homogenizer in the process is dictated by the system used (as recommended by the manufacturer of each system). For injection and infusion methods the homogenizer is usually located in the aseptic section of the system, after the heater and hold tube. A double-packing plunger design, providing a sterile barrier, is required on the homogenizer to avoid contaminating the product by exposure of the working area of the plunger to the environment. For laminar, free-falling lm the homogenizer is located before the heating section. For indirect heating the homogenizer is usually located in the non-aseptic section of the system before the heater. However, in tubular heat exchangers the homogenizer and one homogenizing valve are located before the heater, and a second aseptic homogenizing valve is located after the heater and cooler. This second homogenizing valve would have a steam barrier (or any other sterilizing medium) between the valve body and actuator. As stated above, the location of the homogenizer varies with each system, but in the UHT process there may be an advantage to homogenizing after heating.

Homogenization may be carried out before or after UHT heating. If the latter arrangement is adopted, homogenization will cost more, since the process had to be carried out aseptically. There is, however an advantge in homogenizing after UHT heating, since it prevents or reverses protein protein and fat globuleprotein aggregation. It also retards the formation of sediment of heat precipitated proteins.3

the maximum droplet size, as predicted by statistical calculations. These mean diameters are derived from analyses of actual samples prepared by HTST (high temperature short time pasteurization) and by UHT processes. The operating pressure is the actual pressure drop through the

Also, from another information source it is stated that...it is advantageous to homogenize the product after sterilization, since this order provides added heat stability to the protein system.4 Whether or not the homogenizer is before or after the heaters, the milk is homogenized in the same temperature range, usually 70 - 80C (158 -185F). Also, in either location the homogenizer is sterilized with the rest of the system and, therefore, experiences

homogenizing valve (the pressure in front of the homogenizing valve minus the pressure after the homogenizing valve). Therefore, any back-pressure should be considered when determining this value. When a two-stage homogenizing valve is used, the second-stage

S H E LF LI FE

high temperatures during sterilization and cleaning. Thus, the homogenizer components must be compatible with high temperatures regardless of its location.

2 weeks 10-12 days

M ICROM ETE R S D D (MAX)

CONVE NTIONAL PR E SSU R E / PS I ( BA R ) 1800-2000 (124-138) 2000-2200 (138-152) 3000-3500 (207-241) 3500-4000 (241-276)

M ICRO-GAP PR E SSU R E / PS I ( BA R ) 1200-1400 (83-97) 1400-1500 (97-103) 2100-2500 (145-172) 2500-3000 (172-207)

.80

3.0

.75

2.5

The purpose of homogenization is to reduce fat globule size in the milk; therefore, it is important to discuss the globule size required for the desired shelf life of the milk product. Obviously, a smaller average globule diameter means a lower rate of fat creaming. The mean globule diameter produced will depend on the homogenizing pressure used and geometry of the homogenizing valve. The globule size is also dependent on viscosity of the fat (lower viscosity is better), the source of the milk (season of the year) and the percentage of fat. The shelf life required for the milk determines what homogenizing pressure should be used. The following table gives the desired shelf life, the average fat globule diameter needed, the maximum globule diameter, and the homogenizing pressures necessary to achieve these parameters using the conventional homogenizing valve and the Micro-Gap homogenizing valve. For this application most homogenizers are supplied with a two-stage homogenizing valve. The mean diameters are given in values corresponding to determinations done with the spectroturbidity technique (Gaulin Emulsion Quality Analyzer). Other particle-size analysis methods may give different mean diameters, because of the physics and statistics used for the evaluation. The maximum diameters represent

2 months .55 1.5

6 months APV

.40

1.25

pressure should be 10 to 15% of the total homogenizing pressure. If these mean diameters are obtained, it does not mean that no creaming will occur. However, with these homogenization conditions creaming will be slight, and most of the surface cream can be readily mixed back into the milk.

References

1. Aseptic/Extended Shelf Life Processing Handbook (Wisconsin: APV Crepaco, ) 2. R. H. Mehta, Milk Processed at Ultra-High-TemperaturesA Review, J. of Food Protection 43:212 (1980) 225. 3. H. G. Kessler, Food Engineering and Dairy Technology (Germany: Verlag A. Kessler, 1981) 163. 4. N. P. Wong et al., eds. Fundamentals of Dairy Chemistry 3 (New York: Van Nostrand Reinhold, 1988) 755.

611 Sugar Creek Road, Delavan, WI 53115 P: (262) 728-1900 or (800) 252-5200, F: (262) 728-4904 or (800) 252-5012, E: wcb@spx.com SPX reserves the right to incorporate our latest design and material changes without notice or obligation. Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless conrmed in writing. Please contact your local sales representative for product availability in your region. For more information visit www.spx.com. ISSUED: 02/2009 3086-01-08-2008-US The green > is a trademark of SPX Corporation, Inc.

COPYRIGHT 2008, 2012 SPX Corporation

También podría gustarte

- Skedule Kontruksi Mekanikal Elektrical CPO PlantbetulDocumento1 páginaSkedule Kontruksi Mekanikal Elektrical CPO PlantbetulAmber ChavezAún no hay calificaciones

- Proper Piping For Vacuum SystemsDocumento5 páginasProper Piping For Vacuum SystemsDowni Oader100% (1)

- Agung Siswahyu Summary ProfileDocumento1 páginaAgung Siswahyu Summary ProfileAmber ChavezAún no hay calificaciones

- CDM Project Design Document for Fuel Switching in Glass ManufacturingDocumento30 páginasCDM Project Design Document for Fuel Switching in Glass ManufacturingAmber ChavezAún no hay calificaciones

- Tool For Measuring Piking: R Nominal Radius of The TankDocumento4 páginasTool For Measuring Piking: R Nominal Radius of The TankAmber ChavezAún no hay calificaciones

- TSG 021A-15 CSL Plus Series Marketing Brief-LRDocumento2 páginasTSG 021A-15 CSL Plus Series Marketing Brief-LRAmber ChavezAún no hay calificaciones

- Seminar Islamic Medical Fair 2007Documento46 páginasSeminar Islamic Medical Fair 2007Amber ChavezAún no hay calificaciones

- Bmri2017 2370927Documento19 páginasBmri2017 2370927Amber ChavezAún no hay calificaciones

- Electric Steam Boiler SussmanDocumento2 páginasElectric Steam Boiler SussmanChriss VzzAún no hay calificaciones

- Upload Tentative Conference Program PV Hybrid and BioenergyDocumento2 páginasUpload Tentative Conference Program PV Hybrid and BioenergyAmber ChavezAún no hay calificaciones

- SVW 12 1000kW 41000 To 3412000 BtuhDocumento2 páginasSVW 12 1000kW 41000 To 3412000 BtuhAmber ChavezAún no hay calificaciones

- Vacuum Box Bubble Leak TestingDocumento4 páginasVacuum Box Bubble Leak TestingashrafhitlerAún no hay calificaciones

- Return Calculations Subordinated Loan With EBITDA ParticipationDocumento2 páginasReturn Calculations Subordinated Loan With EBITDA ParticipationAmber ChavezAún no hay calificaciones

- Pricelist KitazawaDocumento10 páginasPricelist Kitazawariff100% (1)

- Shell For Tee JointDocumento1 páginaShell For Tee JointAmber ChavezAún no hay calificaciones

- Investasi Industri Bangunan Tumbuh Tiga PersenDocumento9 páginasInvestasi Industri Bangunan Tumbuh Tiga PersenAmber ChavezAún no hay calificaciones

- IJEETC 510fefb81c0a6Documento22 páginasIJEETC 510fefb81c0a6Amber ChavezAún no hay calificaciones

- 50 M3/jam 960 Liter/menit 9,6 JT MCS, 8,7 JTGLP, Elektrik 18,5 KW, 25 HP 7,6 Jt. Couple 1,5 JTDocumento1 página50 M3/jam 960 Liter/menit 9,6 JT MCS, 8,7 JTGLP, Elektrik 18,5 KW, 25 HP 7,6 Jt. Couple 1,5 JTAmber ChavezAún no hay calificaciones

- Oil and Fat Technology Lectures IV RefiningDocumento28 páginasOil and Fat Technology Lectures IV RefiningJakaAbuAún no hay calificaciones

- KaiyoDocumento35 páginasKaiyoAmber ChavezAún no hay calificaciones

- Incbio 1ta (2015 En) 1a1b DGB - ProposalDocumento16 páginasIncbio 1ta (2015 En) 1a1b DGB - ProposalAmber ChavezAún no hay calificaciones

- Calgary Legends Ammonia Separation Process SimulationDocumento1 páginaCalgary Legends Ammonia Separation Process SimulationAmber ChavezAún no hay calificaciones

- Biofuel Industri in Indonesia Some Critical IssuesDocumento26 páginasBiofuel Industri in Indonesia Some Critical IssuesarianzAún no hay calificaciones

- Methanol: Sodium MethoxideDocumento3 páginasMethanol: Sodium MethoxideAmber ChavezAún no hay calificaciones

- HYSYS Distillation Column Simulation TutorialDocumento7 páginasHYSYS Distillation Column Simulation Tutorialcmlim100% (2)

- Choosing Column InternalsDocumento7 páginasChoosing Column Internalspetrolhead1Aún no hay calificaciones

- Laboratory 4 Two and Three Phase Separators Oct 2, 2002: Che 365 Chemical Engineering Design IDocumento1 páginaLaboratory 4 Two and Three Phase Separators Oct 2, 2002: Che 365 Chemical Engineering Design IAmber ChavezAún no hay calificaciones

- Choosing Column InternalsDocumento7 páginasChoosing Column Internalspetrolhead1Aún no hay calificaciones

- Edible Oil TechnologyDocumento12 páginasEdible Oil TechnologyAmber Chavez0% (1)

- Reaktor Heat Call ALAT V301-3 HE101 T101 T102 RT102 PANAS UNIT JUMLAH PANASDocumento14 páginasReaktor Heat Call ALAT V301-3 HE101 T101 T102 RT102 PANAS UNIT JUMLAH PANASAmber ChavezAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- C9880046 Signed OfferLetterDocumento8 páginasC9880046 Signed OfferLetterẞhûpâthi RëddyAún no hay calificaciones

- The Dolphin: by Sergio Bambarén. Maritza - Jhunior - Cynthia - Carlos - AlexDocumento10 páginasThe Dolphin: by Sergio Bambarén. Maritza - Jhunior - Cynthia - Carlos - AlexAlexandra FlorAún no hay calificaciones

- Selected Answer:: 2 Out of 2 PointsDocumento15 páginasSelected Answer:: 2 Out of 2 PointsAkansha dwivediAún no hay calificaciones

- Expectations:: Good Manners and Right Conduct (GMRC)Documento3 páginasExpectations:: Good Manners and Right Conduct (GMRC)Jae Mae Moral BubanAún no hay calificaciones

- CIVICUS Monitoring October 2020 BriefDocumento8 páginasCIVICUS Monitoring October 2020 BriefRapplerAún no hay calificaciones

- Resusitasi Cairan Dan DarahDocumento33 páginasResusitasi Cairan Dan DarahWahyu HidayatiAún no hay calificaciones

- Write An Essay About The First of Hari Raya DayDocumento1 páginaWrite An Essay About The First of Hari Raya DayShan Tzt50% (4)

- Biomedical Engineering Study Guide 2021 sm1Documento45 páginasBiomedical Engineering Study Guide 2021 sm1Lmd LmdAún no hay calificaciones

- Single and Double Volute Casing - RodeltaDocumento3 páginasSingle and Double Volute Casing - Rodeltamasood_me60Aún no hay calificaciones

- SWOT Analysis AuchanDocumento2 páginasSWOT Analysis AuchanDaniela DogaruAún no hay calificaciones

- CHAPTER 6 Maintenance Management: Introduction, Importance, Types & ReliabilityDocumento29 páginasCHAPTER 6 Maintenance Management: Introduction, Importance, Types & Reliabilitynur aidaAún no hay calificaciones

- Orchard Mason Bee: 10-Minute University™Documento2 páginasOrchard Mason Bee: 10-Minute University™don baileyAún no hay calificaciones

- BiochemistryDocumento39 páginasBiochemistryapi-290667341Aún no hay calificaciones

- Biotechnology PDFDocumento24 páginasBiotechnology PDFShyamlaAún no hay calificaciones

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocumento6 páginasMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationHazama HexAún no hay calificaciones

- SE7000 Application GuideDocumento102 páginasSE7000 Application GuideHujiLokoAún no hay calificaciones

- Certificate: Portfolio For Self Dircted Learning For Major Project WorkDocumento22 páginasCertificate: Portfolio For Self Dircted Learning For Major Project WorkRaja ManeAún no hay calificaciones

- Turbine Stress Evaluator: 17 February 2018 PMI Revision 00 1Documento23 páginasTurbine Stress Evaluator: 17 February 2018 PMI Revision 00 1NILESHAún no hay calificaciones

- 2219 & 2219 Clad PDFDocumento22 páginas2219 & 2219 Clad PDF孙俊磊Aún no hay calificaciones

- LakesDocumento14 páginasLakesmanwartejam8Aún no hay calificaciones

- Fire Watch DutiesDocumento2 páginasFire Watch DutiesNomsa Thando100% (1)

- Flood Risk Mitigation Adis Ababa UNI PDFDocumento100 páginasFlood Risk Mitigation Adis Ababa UNI PDFshucayb cabdiAún no hay calificaciones

- Abolish SlaveryDocumento1 páginaAbolish SlaverySiyeon (Sean) LeeAún no hay calificaciones

- QAQC Mechanical EngineerDocumento6 páginasQAQC Mechanical EngineerMohammed Anwaar ShaikhAún no hay calificaciones

- Panduan Sejarah Ekologi Taman Nasional Komodo Buku 2Documento228 páginasPanduan Sejarah Ekologi Taman Nasional Komodo Buku 2Agi SemAún no hay calificaciones

- 3G3EV Installation ManualDocumento55 páginas3G3EV Installation ManualHajrudin SinanovićAún no hay calificaciones

- Raising Indigenous Chickens in UgandaDocumento9 páginasRaising Indigenous Chickens in Ugandashemks79% (38)

- Sustainable City PDFDocumento361 páginasSustainable City PDFagusbudiyonoAún no hay calificaciones

- A Qualitative Phenomenological Exploration of Teachers Experience With Nutrition EducationDocumento14 páginasA Qualitative Phenomenological Exploration of Teachers Experience With Nutrition EducationDelfin ValdezAún no hay calificaciones

- Civil Engineering Final Year Projects Topic List - HTMLDocumento4 páginasCivil Engineering Final Year Projects Topic List - HTMLJohn Meverick E EdralinAún no hay calificaciones