Documentos de Académico

Documentos de Profesional

Documentos de Cultura

2820-020 10f05

Cargado por

David GoldTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

2820-020 10f05

Cargado por

David GoldCopyright:

Formatos disponibles

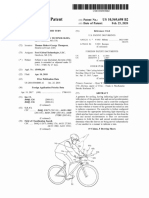

Floating Roller Peel Fixtures

Catalog Number 2820-020 and S1-11237

Features

i

Principle of Operation

The floating roller peel fixture measures the strength of adhesive bonds between a rigid adherend and a flexible adherend. The fixture is also referred to as a roller drum peel test fixture. The floating roller peel fixture is an alternative to a climbing drum peel fixture when the later is not available. The floating roller test is generally considered to be more severe because the angle of peel is greater. Test specimens are either prepared individually or cut from bonded panels. The flexible adhered is attached to the rigid adherend with the adhesive that is to be tested, in accordance with manufacturer's instructions. One end of the flexible adherend is left unbonded so that it can be gripped by the test system. It is critical that the rigid adherend be stiff enough to not bend or distort during the test. The unbonded end of the flexible adherend is bent perpendicular to the rigid adherend and then clamped in the lower grip of the testing system.

Precisely measures the relative peel resistance of high strength adhesive bonds between a rigid adherend and a flexible adherend Compliance with ASTM D 3167, ISO 4578 and EN 1464 standards

Description

The fixtures consist of two roller bearings in a frame that is connected to the test system via a pivoting adapter. This design insures that alignment between the fixture and the test specimen occurs as soon as force is applied and that the direction of the applied force is through the centerline of the fixture. As the crosshead is driven in the tensile direction, the load weighing system measures the force required to peel the flexible adherend from the rigid adherend. There are two different versions of the fixture. One complies with ASTM D 3167 and the other with ISO 4578 and EN 1464 standards. While the standards are very similar there are slight differences in the specified peel area dimensions and the diameter of the roller bearings. While the differences are small, they are large enough to yield noticeable variation in test results.

d Floating roller peel fixture

Application Range

i

Peel testing per ASTM D 3167, ISO 4578 or EN 1464 Alternative to climbing drum peel test Tests the bond strength of adhesives

i i

Floating Roller Peel Fixtures Catalog Number 2820-020 and S1-11237

Specifications

Catalog Number Associated Standards Maximum Load Roller Diameter Roller Width Peeling Zone Effective Length (A) Temperature Range Upper Fitting Additional Equipment Requirements 2820-020 ISO 4578 and EN 1464 5 kN (500 kgf, 1125 lbf) 25.0 mm (1.0 in) 30.0 mm (1.2 in) 33 mm (1.3 in) 143 mm ( 5.6 in) -40 C to 150 C (-40 F to 300 F) Instron Type D (1/2 in clevis pin) Requires appropriate lower grip (not supplied) S1-11237 ASTM D 3167 5 kN (500 kgf, 1125 lbf) 25.4 mm (1.0 in) 25.4 mm (1.0 in) 30.5 mm (1.2 in) 143 mm ( 5.6 in) -40 C to +150 C (-40 F to +300 F) Instron Type D (1/2 in clevis pin) Requires appropriate lower grip (not supplied)

d Floating roller peel fixture

Corporate Headquarters

European Headquarters

Instron Limited Coronation Road, High Wycombe, Bucks HP12 3SY, United Kingdom Tel: +44 1494 464646 Fax: +44 1494 456123

www.instron.com

Instron is a registered trademark of Instron Corporation. Other names, logos, icons, and marks identifying Instron products and services referenced herein are trademarks of Instron Corporation and may not be used without the prior written permission of Instron. Other product and company names listed are trademarks or trade names of their respective companies.

Instron Corporation 825 University Avenue, Norwood, MA 02062-2643 USA Tel: +1 800 564 8378 or +1 781 575 5000 Fax: +1 781 575 5725

Instron Industrial Products

900 Liberty Street, Grove City, PA 16127-9969, USA Tel: +1 724 458 9610 Fax: +1 724 478 9614

Copyright Instron 2005. All rights reserved. All of the specifications shown in this brochure are subject to change without notice.

pod_2820-020_rev2_1005

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Data Sheet For SINAMICS S210Documento2 páginasData Sheet For SINAMICS S210David GoldAún no hay calificaciones

- Nist HB 162 MepsDocumento170 páginasNist HB 162 MepsDavid GoldAún no hay calificaciones

- Licensing: Windows Server 2016Documento4 páginasLicensing: Windows Server 2016David GoldAún no hay calificaciones

- Sun ProjectDocumento6 páginasSun ProjectDavid GoldAún no hay calificaciones

- Iglide® 20M250 20inchDocumento19 páginasIglide® 20M250 20inchDavid GoldAún no hay calificaciones

- Thursday, September 02, 2010 1:58 PM: Unfiled Notes Page 1Documento1 páginaThursday, September 02, 2010 1:58 PM: Unfiled Notes Page 1David GoldAún no hay calificaciones

- Readme Open PropDocumento1 páginaReadme Open PropDavid GoldAún no hay calificaciones

- LSP For Carbon Fiber AircraftDocumento12 páginasLSP For Carbon Fiber AircraftDavid GoldAún no hay calificaciones

- A AB Synch GearedDocumento8 páginasA AB Synch GearedDavid GoldAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- ECEN Academy Electrical ProblemsDay 03Documento10 páginasECEN Academy Electrical ProblemsDay 03Sachin KatharotiaAún no hay calificaciones

- OnMyWhey v. RNB Digital - ComplaintDocumento16 páginasOnMyWhey v. RNB Digital - ComplaintSarah BursteinAún no hay calificaciones

- Lux Aeterna SAB+pno (Burrows)Documento10 páginasLux Aeterna SAB+pno (Burrows)Juan José Cruz GarcíaAún no hay calificaciones

- Var AgreementDocumento3 páginasVar AgreementrobogineerAún no hay calificaciones

- Astm E634-18Documento4 páginasAstm E634-18Rodrigo PizarroAún no hay calificaciones

- DL101 QuizzesDocumento11 páginasDL101 QuizzesSL100% (1)

- Dog Food in Denmark: HeadlinesDocumento3 páginasDog Food in Denmark: HeadlinesNavpreet SinghAún no hay calificaciones

- Evermotion Hdmodels Cars Vol.03Documento20 páginasEvermotion Hdmodels Cars Vol.03Thu Vien Kien TrucAún no hay calificaciones

- Ansys Act XML Reference GuideDocumento1096 páginasAnsys Act XML Reference Guidedroessaert_stijnAún no hay calificaciones

- Us 10569698Documento17 páginasUs 10569698Ninon NkoulouAún no hay calificaciones

- Untitled 6Documento50 páginasUntitled 6Cesar Rumiche HernándezAún no hay calificaciones

- Sight Word Crossword PuzzleDocumento1 páginaSight Word Crossword PuzzleRiyanna Ehra IntalAún no hay calificaciones

- Crackdown 2 (Official Prima Guide)Documento194 páginasCrackdown 2 (Official Prima Guide)mikel4carbajoAún no hay calificaciones

- Topic 1 The Mind and Heart of The NegotiatorDocumento9 páginasTopic 1 The Mind and Heart of The NegotiatorFarisha RazAún no hay calificaciones

- Test Bank For Introductory Chemistry An Active Learning Approach 5th Edition Cracolice Peters 1111990077 9781111990077Documento12 páginasTest Bank For Introductory Chemistry An Active Learning Approach 5th Edition Cracolice Peters 1111990077 9781111990077ChristopherGomezxmaq100% (23)

- BS en 13411-2 Termination of Wire Ropes-Safety - SplicingDocumento12 páginasBS en 13411-2 Termination of Wire Ropes-Safety - SplicingWalid BdeirAún no hay calificaciones

- Arachne by DM TuzDocumento7 páginasArachne by DM Tuzjoseph farris100% (1)

- The Third Form at ST Clares - Pamela CoxDocumento180 páginasThe Third Form at ST Clares - Pamela CoxdaziebbAún no hay calificaciones

- A Brief History of PlasticsDocumento10 páginasA Brief History of PlasticsHaries GarciaAún no hay calificaciones

- Test Bank For Understanding Pharmacology 1st Edition WorkmanDocumento17 páginasTest Bank For Understanding Pharmacology 1st Edition Workmancaniculecockerutbtm100% (33)

- OEB 42-30 - Recommendations On OEB ManagementDocumento6 páginasOEB 42-30 - Recommendations On OEB ManagementAndrey DanilchenkoAún no hay calificaciones

- IPR Protection Procedure With Reference To Biotechnology: Intellectual Property RightsDocumento55 páginasIPR Protection Procedure With Reference To Biotechnology: Intellectual Property RightsBindu SharmaAún no hay calificaciones

- Sistemas Auxiliares Del MotorDocumento32 páginasSistemas Auxiliares Del MotorStalin Ponce86% (7)

- Manha de Carnaval PDFDocumento4 páginasManha de Carnaval PDFNguyen Tuan KhoaAún no hay calificaciones

- Pranesh ExhaustionDocumento12 páginasPranesh ExhaustionAbhyuday NegiAún no hay calificaciones

- United States Patent (10) Patent No.: US 9,080,720 B2Documento16 páginasUnited States Patent (10) Patent No.: US 9,080,720 B2sfjhsakjfhAún no hay calificaciones

- Basf Masterflow 640 TdsDocumento2 páginasBasf Masterflow 640 Tdsgazwang478Aún no hay calificaciones

- Rigsby v. Miscik - Copyright in Litigation DocumentsDocumento17 páginasRigsby v. Miscik - Copyright in Litigation DocumentsMark JaffeAún no hay calificaciones

- RA 8293-Intellectual Property Code of The PhilippinesDocumento57 páginasRA 8293-Intellectual Property Code of The PhilippinesDha RylAún no hay calificaciones

- Gun Digest - Spring 2017Documento116 páginasGun Digest - Spring 2017Sal Ot100% (3)