Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Check Lists

Cargado por

Govarthanan GopalanDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Check Lists

Cargado por

Govarthanan GopalanCopyright:

Formatos disponibles

5.5. SECTION : HSD System SYSTEM/EQUIPMENT: Board: Sl.

NO

MOTOR SOLO TRIAL RUN DATE: KKS Code: Breaker:

DETAIL OF CHECKING PRE START CHECKS

REMARKS

1. 2. 3. 4. 5. 6. 7. 8. 9.

Motor placed in its base frame and secured by bolts. Name plate details match the requirement. DOR marked clearly. Factory test certificate available. Megger value //.M

Winding resistance //.M Space heater healthiness checked. All motor protections connected. Double earthing connected.

10. Bearing greased or lub oil system in service. 11. Body cleaned thoroughly to ensure good heat transfer. 12. Terminal box closed. 13. EPB is easy to access. 14. Vibration measuring instrument available. TRIAL RUN 1. 2. 3. 4. 5. If all above are ok, give start command. Stop with EPB after current comes to normal. Note the starting current and normal current. Note the time for current to become normal from starting. If DOR is ok, allow it to run. Or stop by EPB.

6. 7. 8. 9. 10.

If no abnormalities for physical observation are there, run it. Check the current. Note bearing and winding temp. Measure vibrations. If vibration level is more, do necessary base plate correction on line.

11. If ok, run for at least 4 hrs. 12. Measure all parameters once an hour and log. 13. Stop after satisfactory completion of 4 hrs trial run.

Remarks:

Name & signature:

5.6.

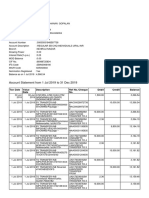

MOTOR SOLO RUN LOG SHEET

System/ Equipment: KKS Code: Name plate details:

DATE:

Time

Current (Amps)

Bearing Temp. ( C ) DE NDE R

Winding Temp ( C ) Y B

Vibration (mm/sec) DE(H/V/A) NDE(H/V/A)

Remarks: Name & signature:

5.7.

PUMP COUPLED RUN LOG SHEET

System/ Equipment: KKS Code: Name plate details:

DATE:

Time Current (Amps) Bearing Temp ( C ) Winding temp (C) Motor Bearing Vibration (H/V/A) (mm/sec) Pump Bearing Vibration(H/V/A) (mm/sec) Suction pressure Discharge Pressure Flow Strainer DP DE NDE R/Y/B DE NDE DE NDE

Remarks: Name & signature:

HSD SYSTEM CHECK LIST S. No 4.1 4.1.1. 4.1.2 4.1.3 4.1.4 4.1.5 4.1.6 4.1.7 4.1.7.1 Description Civil and Mechanical: EnsureCompressed air system commissioning completion Check for civil work completion HSD& Drain oil pump houses with all supports and clamps up to HSD tank. Erection of pumps is complete and motor solo run over. Check for HSDDecanting lines Inlet valve Connected with Hose. Erection and Clearances of HSD unloading system up to HSD tank. Erection and Clearances of Drain oil system up to HSD tank. HSD tankerection complete with all instruments as per the P&ID As linked below All Nozzles are in place forHSD tank (ENB01/BB001) N1 N2 N3A N3B N4 N5/A,B N6/A,B,C N7 N8 N9 N10/A,B OIL Inlet Nozzle for HSD Re circulation line from forwarding pump Outlet Spare outlet Drain Level Switch - High Float type level indicator Spare inlet Vent with breather valve and flame arrestor Overflow Level Switch - Low Remarks Y N

N11 N12 M1 M1 4.1.7.2 4.1.7.3 4.1.7.4 4.1.7.5 4.1.7.6 4.1.7.7 4.1.8 4.1.8.1

Level Transmitter Return line from Boiler Shell manhole with cover Roof manhole with cover

Check that all piping connections to tank nozzles are connected and properly supported. Check that all spare nozzles are closed with dummy flanges. Check that all fasteners on the nozzles flanges of tank are tightened with the respective piping with gasket and washers. Check for completion of Spiral ladder up to the tanks top. Check for hand railing completion on the tank top. Check for cleanliness of tank inside and painting completion. Drain oil tankerection complete with all instruments as per the P&ID As linked below All nozzles are in place for Drain oil tank (EGR01/BB151) N1 N2 N3 N4A/B N5A/B N6 N7 N8 N9 N10 Inlet from HFO tank. Inlet from HSD tank. Vent with flame arrestor. Level indicator. Drain. Pump outlet mounting. Pump outlet mounting. Spare nozzle. Overflow nozzle. Level transmitter.

M1 N12A/B N13A/B 4.1.8.2 4.1.8.3 4.1.8.4 4.1.8.5 4.1.9. 4.1.10. 4.1.11. 4.1.12. 4.1.13. 4.1.14. Remarks Name & Signature

Manhole. Level Switch-High Level Switch-Low

Check that all piping connections to tank nozzles are connected and properly supported. Check that all spare nozzles are closed with dummy flanges. Check that all fasteners on the nozzles flanges of tank are tightened with the respective piping with gasket and washers. Check for cleanliness of tank inside and painting completion. Check for completion Drain pipe line from HSD pump house to Drain oil tank. Erection completion and clearance place as per the P&ID from the HSD Decanting point to inlet of HSDPressurizing pump terminal point. Hydraulic Test for piping ofHSD system up to tank should have been completed. Hydraulic Test for piping from HSD tanks outlet to inlet of HSD Pressurizing pump terminal pointshould have been completed. Check that all Instruments are in place as per P&ID for HSD supply and discharge line, HSD tanks and HSDdistribution header terminal point. Ensure firefighting system availability. : :

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- 1577786160969BcF9eaIss9xkmGva PDFDocumento10 páginas1577786160969BcF9eaIss9xkmGva PDFGovarthanan GopalanAún no hay calificaciones

- TPC Technical Course DescriptionsDocumento278 páginasTPC Technical Course DescriptionsGovarthanan Gopalan25% (4)

- CatDocumento27 páginasCatGovarthanan GopalanAún no hay calificaciones

- Im - Instruction Manual For Control ValveDocumento83 páginasIm - Instruction Manual For Control ValveGovarthanan Gopalan67% (3)

- MIL 41000 New - Heavy Duty Cage Guided Control ValvesDocumento36 páginasMIL 41000 New - Heavy Duty Cage Guided Control ValvesGovarthanan GopalanAún no hay calificaciones

- Mil-Globe Control ValveDocumento8 páginasMil-Globe Control ValveGovarthanan GopalanAún no hay calificaciones

- Seven Glocon 1200 SeriesDocumento12 páginasSeven Glocon 1200 SeriesGovarthanan GopalanAún no hay calificaciones

- Leseprobe PDFDocumento14 páginasLeseprobe PDFGovarthanan GopalanAún no hay calificaciones

- Overhead Crane Safety TrainingDocumento71 páginasOverhead Crane Safety TrainingGovarthanan Gopalan100% (8)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Project GuitarDocumento11 páginasProject GuitarMns100% (2)

- 08 - Chapter 1 PDFDocumento63 páginas08 - Chapter 1 PDFRAMAún no hay calificaciones

- Construction Safety ChecklistDocumento3 páginasConstruction Safety ChecklistbangladragosAún no hay calificaciones

- Water Suction Hose - 10 Bar: Application: FeaturesDocumento2 páginasWater Suction Hose - 10 Bar: Application: FeaturesShyam BKAún no hay calificaciones

- Productsheet C-Dur Deluxe ENDocumento1 páginaProductsheet C-Dur Deluxe ENfelghazi87Aún no hay calificaciones

- Two Years' Operational Experience and Further Development of Full-Scale Co-Firing of StrawDocumento7 páginasTwo Years' Operational Experience and Further Development of Full-Scale Co-Firing of StrawvatttenfallAún no hay calificaciones

- 2015 Review and Perspectives Shape Memory Alloy CompositeDocumento54 páginas2015 Review and Perspectives Shape Memory Alloy CompositeYasmin ValadaresAún no hay calificaciones

- Fulid-Structure Interaction Webinar SlidesDocumento37 páginasFulid-Structure Interaction Webinar SlidesHarshit AgrahariAún no hay calificaciones

- ARCAP - Grades and PropertiesDocumento7 páginasARCAP - Grades and PropertiesEminent RishAún no hay calificaciones

- HCPL-0302 DatasheetDocumento15 páginasHCPL-0302 DatasheetJeziel Vazquez NavaAún no hay calificaciones

- 03 Standard Forms List PDFDocumento4 páginas03 Standard Forms List PDFShamsul Azhar MohdAún no hay calificaciones

- DGT-eex Brochure Eng 2020Documento2 páginasDGT-eex Brochure Eng 2020Ali SadiqAún no hay calificaciones

- ConductorDocumento3 páginasConductorRaimon Guitart Garcia 78151008KAún no hay calificaciones

- Electrical EstimateDocumento1 páginaElectrical EstimateJoel JusayAún no hay calificaciones

- Magpul Industries M-Lok Information BookletDocumento10 páginasMagpul Industries M-Lok Information BookletTwobirds Flying PublicationsAún no hay calificaciones

- Permalife Full CatalogDocumento76 páginasPermalife Full Catalogarchitecturalelement0% (1)

- Structural Shapes: Arcelormittal International North AmericaDocumento16 páginasStructural Shapes: Arcelormittal International North AmericaLeonardo SarriaAún no hay calificaciones

- Electric Sprayers: Graco's Complete Line of Professional Electric Airless SprayersDocumento24 páginasElectric Sprayers: Graco's Complete Line of Professional Electric Airless SprayersCalidad SteelexAún no hay calificaciones

- Cbse Class 10 Science Chapter 1 McqsDocumento5 páginasCbse Class 10 Science Chapter 1 Mcqsleena_louisAún no hay calificaciones

- ME6601 QbsdfwsdfsDocumento8 páginasME6601 QbsdfwsdfsvivekzzAún no hay calificaciones

- Cutback Bitumen Medium Curing MCDocumento3 páginasCutback Bitumen Medium Curing MCEng Venance MasanjaAún no hay calificaciones

- 3B PT3 Section A Exercise 1Documento3 páginas3B PT3 Section A Exercise 1enesus100% (1)

- Dipping TanksDocumento8 páginasDipping TanksSaid Ahmed SalemAún no hay calificaciones

- Maryland Metrics - Thread Data ChartsDocumento4 páginasMaryland Metrics - Thread Data ChartsAnonymous VC68Xndnu9Aún no hay calificaciones

- Cosmetic Material D023e7cfDocumento10 páginasCosmetic Material D023e7cfABDULRAHMAN ALSAHARAún no hay calificaciones

- c3 Structure and BondingDocumento2 páginasc3 Structure and BondingNavdha SachdevaAún no hay calificaciones

- Technical SpecificationsDocumento10 páginasTechnical Specificationsxubi_xAún no hay calificaciones

- 1 00781 Expanfluid enDocumento3 páginas1 00781 Expanfluid enFfasulljaAún no hay calificaciones

- QBCC Guide Contractor Rebuilding After FloodDocumento10 páginasQBCC Guide Contractor Rebuilding After FloodDmacAún no hay calificaciones