Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Complete installation guide for EcofilmSet underfloor heating

Cargado por

adyro12Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Complete installation guide for EcofilmSet underfloor heating

Cargado por

adyro12Copyright:

Formatos disponibles

EcofilmSet is part of the Flexel Underfloor Heating Systems product range by Flexel International Ltd, Queensway Ind Est,

Glenrothes, Fife, KY7 5QF,Scotland. Also available: Ecoflex, Ecofloor & Ecofilm .

COMPLETE INSTALLATION INSTRUCTIONS & GUARANTEE

T 01592 757313 F 01592 754535 W www.flexel.co.uk E sales@flexel.co.uk

the complete electric underfloor heating solution for wood and laminate floor s

100mm overlap

Laying the Ecofilm Set heating elements Before commencing check the labels on each of the Ecofilm Set element cartons to ensure they are the correct sizes and power rating. Following the plan prepared at the ordering stage and working from one side, roll out the first element copper side down with the connection leads closest to the thermostat wall and leaving a minimum 50mm gap from walls. Apply light finger pressure on the cable connection covers to leave an imprint on the Ecomax-Lite, move the element to avoid damage and using a sharp knife remove the Ecomax-Lite to allow the cable connection cover to sit flush with the Ecomax-Lite surface (fig.4). Laying Ecofilm Set Polyester Vapour Barrier The installed Ecofilm Set heating elements must be covered with the Ecofilm Set Polyester Vapour Barrier to provide optimum moisture and additional mechanical protection. EcofilmSet Polyester Vapour Barrier (code PVB25) is available in 1m x 25m rolls which will cover approximately 20m when installed. To install, roll out the vapour barrier, cut to length and overlap adjacent pieces by a minimum of 100mm (fig.7). Tape along the entire length of the overlap using Ecofilm Set fixing tape (1 roll of vapour barrier will require approximately 25m of fixing tape). Always remember to cover the entire floor with the vapour barrier, even unheated areas.

Fig.4 Fig.7

Adjusting the Ecofilm Set heating elements Ecofilm Set heating elements are available in standard lengths from 2.0m to 8.0m in 0.5m increments. Should the elements require to be shortened this can be easily done by cutting along the cutting line using a sharp knife and straight edge or scissors and insulating the copper strips using the insulating green polyester tape discs (4 off supplied with each heating element) as shown in the diagram (fig.5). Care should be taken not to cut closer than 3mm from the edge of the black heated area. Repeat the procedure for the remaining elements, butting adjacent elements edge to edge.

Fold Over

Making The Connections Please note the following steps must only be carried out by a qualified electrician Using the graph paper supplied draw a sketch showing the approximate position, width and length of each Ecofilm Set heating element together with the temperature controller sensor position and number each of the elements on the drawing. Ecofilm Set heating elements are connected together using the new lever action Ecofilm Set connector. A seperate conector is used for the live and neutral connections. A single pair of connectors will connect 4 Ecofilm Set elements to the thermostat output (fig.9). To connect up to 7 elements, 2 pairs of connectors will be required with each pair being connected together using a suitable link wire - maximum 2.5mm 2 solid or up to 4mm 2 fine stranded cable (fig.9). Cut the element cables inside the junction box to approximately 100mm. Carefully strip back 10mm of the cable insulation taking care to completely remove the clear inner insulation. Measure and record on the test sheet the resistance of each element and carefully insert all brown and blue cables into separate commoning blocks as shown in the diagram (fig.8). A suitable cable(maximum 2.5mm solid) will be required to connect the commoning blocks to the output of the temperature controller. Please note: if the installed load exceeds the temperature controller power rating then a suitable contactor must be used.

Commoning Block

Insulate end of copper strip with green disk

Fig.5

Fig.8

Cutting Line

Up To 4 Elements

Live (Brown) Neutral (Blue)

Taping the Ecofilm Set heating elements Measure and record the total installed load resistance and carry out an insulation check to ensure no damage to the elements has occurred during installation. A second insulation resistance measurement should be taken once the flooring has been laid. Both measurements should be at least 10M Ohms. Finally, complete the test report and guarantee certificate ensuring all measurements are correctly recorded and leave all documentation including the temperature controller instructions next to the electrical supply distribution board.

1 2 3 4 Thermostat 1 2 3 4 Thermostat

Tape along the edges of the heating elements using the Ecofilm Set fixing tape taking care not to damage the heating elements (20m of heating element will require approximately 40m of tape). Using a sharp knife, cut a channel in the Ecomax-Lite along the connection lead/thermostat wall side to accommodate the connection leads (fig.6). Run the leads in the channel to the junction box and tape over using Ecofilm Set fixing tape.

Up To 7 Elements

Live (Brown) Neutral (Blue)

Link Wire 1 2 3 Thermostat 4 5 6 7 1 2 3 Thermostat

Link Wire 4 5 6 7 Fig.9

Fig.6

Remember the guarantee must be filled in and kept with a proof of purchase to ensure you are covered by our ten year guarantee.

Congratulations on your purchase of Ecofilm Set Underfloor Heating , the ideal solution for heating laminate, engineered board and solid wood floor coverings.

ar ee ye nt a 10 ar u G

Please read the following instructions carefully to ensure ease of installation. Remember that the final electrical connections must be made by a qualified electrician and also that the guarantee certificate must be filled in and signed by the electrician to ensure you are covered by our ten year guarantee.

GUARANTEE CERTIFICATE

Typical Installations:

1. 2. 3. 4. 5.

1. 2. 3. 4. 5.

This guarantee is only valid under the following conditions: All electrical connections were connected by a qualified electrician The guarantee covers faults in material for 10 years for Ecofilm Set heating elements and 1 year for other components from the date of purchase.

1. 2. 3. 4. 5.

Wood/laminate floor Polyester Vapour Barrier EcofilmSet elements Ecomax-Lite Insulation Suspended Timber Floor

1. 2. 3. 4. 5.

Wood/laminate floor Polyester Vapour Barrier EcofilmSet elements Ecomax-Lite Insulation Concrete Sub-floor

The completed guarantee and proof of purchase must be presented in connection with warranty claims. The guarantee covers the repair/replacement of goods found to be faulty and does not cover secondary charges relating the repair/replacement of any floor covering. The Flexel warranty does not cover faults resulting from incorrect design or installation or damage caused by others.

Please take time to read carefully the following notes and instructions before commencing installation: Ecofilm Set underfloor heating systems are designed to be used under laminate, engineered board and solid wood flooring with a maximum thickness of 15mm (or thickness equivalent to a maximum thermal resistance of 0.15mK/W). When underlays is specified by the manufacturer this may reduce the thickness of flooring permitted. Always check to ensure the flooring is suitable for use with underfloor heating systems. Ecofilm Set underfloor heating systems operate on a standard 230 Volts mains electrical supply. Please check all elements are the correct voltage and power rating. Maximum loading 130W/m 2 for standard product and 160W/m 2 for PR models. Ecofilm Set underfloor heating systems are designed for simple do it yourself installation, however all electrical connections must be done by a qualified electrician and the complete installation must comply with BS 7671:2001 (IEE Wiring Regulations) and Part P of The Building Regulations. Ecofilm Set underfloor heating systems must be protected by a 30mA RCD (residual current device) and a suitably rated fuse or MCB (miniature circuit breaker). Ecofilm Set must only be installed in dry locations. Ecofilm Set underfloor heating elements must not be installed below fixed pieces of solid furniture, cupboards, wardrobes etc as this could lead to a local increase in temperature. Thick rugs, dog beds, bean bags etc must not be laid on the heated floor as this may cause localised overheating and damage the floor covering. Care must be taken to ensure the Ecofilm Set heating elements are not damaged during installation. It is advisable to lay the floor immediately after installation. Ecofilm Set heating elements must be protected by Ecofilm Set Polyester Vapour Barrier (code PVB25). Ecofilm Set underfloor heating systems are designed to be controlled by the approved range of thermostats, EB100 (maximum power 2740W), TH132F and TH132AF (both rated at 3450W). If the installed load exceeds these figures then a suitable contactor must be installed by the electrician. Ecofilm Set High Specification Fixing Tape (code ADT50) must be used for installation of the Ecomax-Lite thermal insulation, Ecofilm Set heating elements and Polyester Vapour Barrier. Total Load Resistance (Ohms)

Please contact Flexel International Ltd for a full list of terms and conditions.

Element Number

Installed Length (m)

Measured Resistance (Ohms)

Insulation Resistance Before Laying Floor (M ) After Laying Floor (M )

Address of Installation ..................................................................... ................................Postcode...................... Electrical Installation by (Company Name) ..................................................................... Signed ..................................................................... Print Name ..................................................................... Date .....................................................................

Temperature Controller Ecofilm Set temperature controllers should be positioned (fig.1) at a height approximately 1.5m from the floor in an area free from draughts, out of direct sunlight and close to the electrical supply. All Ecofilm Set temperature controllers have a floor sensor which is placed in the supplied protective plastic conduit and positioned centrally below one of the heating elements at a distance of approximately 0.5m from the wall. A single gang flush fitting minimum 25mm deep back box (35mm preferred) will be required for the controller. Junction Box Installation A junction box (fig.1, preferably 2 gang x minimum 25mm deep) is required for commoning up the Ecofilm Set heating element 5m long connection leads. This should be sited close to the thermostat and in a position to enable all the connection leads and the temperature controller sensor conduit to reach the box comfortably.

Temp. Controller

1.5m Junction Box

Fig.1

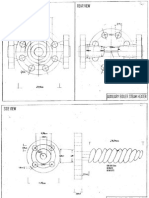

Floor Sensor Installation Cut a 13mm wide by 6-7mm deep channel in the subfloor (fig.2) to accommodate the sensor conduit so that top of the conduit will be level with the Ecomax-Lite thermal insulation surface when installed (see fig. 2). Tape over the end of the conduit using a small piece of Ecofilm Set fixing tape. Place the conduit in the channel and feed the end into the junction box. The conduit can now be cut to length leaving approximately 5cm inside the junction box. Slide the sensor into the conduit until the sensor bulb reaches the taped end. Wrap a piece of tape around the conduit and sensor cable to prevent the sensor being accidentally pulled out. Use Ecofilm Set fixing tape to hold the conduit in place in the channel.

50mm

Taped to prevent pull out

Taped over conduit end

500mm 7mm

Fig. 2

Laying The Ecomax-Lite Thermal Insulation Thoroughly clean the existing floor area taking care to remove any sharp objects. Lay the Ecomax-Lite sheets in brick work fashion as illustrated in the drawing (fig.3). Always remember to cover the total floor area with Ecomax-Lite even unheated areas. Tape along the edges using Ecofilm Set fixing tape (20m of Ecomax-Lite will require approximately 35m of fixing tape). Carefully cut a channel in the Ecomax-Lite at the position of the sensor conduit channel using a sharp knife and straight edge. Tape over the conduit using Ecofilm Set fixing tape. Please remember to number the elements on the diagram.

Fig.3

También podría gustarte

- Floor Plan SampleDocumento1 páginaFloor Plan SampleFredd Sherwin Panim100% (2)

- MeditationDocumento130 páginasMeditationadyro12100% (2)

- Sistemi Di Protezione Degli Avvolgimenti: Guida Tecnica Techical GuideDocumento7 páginasSistemi Di Protezione Degli Avvolgimenti: Guida Tecnica Techical GuidexxxxxAMSAún no hay calificaciones

- Thermobreak Tube Installation InstructionsDocumento8 páginasThermobreak Tube Installation Instructionssurya325kiranAún no hay calificaciones

- Static Calculation For FansDocumento4 páginasStatic Calculation For FansBadrul HishamAún no hay calificaciones

- Install and Operate ECO-DRAIN 32 Condensate DrainDocumento36 páginasInstall and Operate ECO-DRAIN 32 Condensate Drainadyro1275% (4)

- AutoimmuneSolution FINALDocumento24 páginasAutoimmuneSolution FINALadyro12100% (1)

- 'As Many Fireplaces As You Have Tents ..': Earthen Camp KitchensDocumento53 páginas'As Many Fireplaces As You Have Tents ..': Earthen Camp KitchensJohn U. Rees100% (6)

- Install and Maintain Oasis RC Coal Effect Gas FireDocumento29 páginasInstall and Maintain Oasis RC Coal Effect Gas Firewally_watkins4061Aún no hay calificaciones

- A Pocket-Book of Mechanical Engineering 1000086886 PDFDocumento209 páginasA Pocket-Book of Mechanical Engineering 1000086886 PDFMateusDiniz0% (1)

- Mistral 630 - en PDFDocumento44 páginasMistral 630 - en PDFTarek HareedyAún no hay calificaciones

- Underfloor Heating MaualDocumento24 páginasUnderfloor Heating MaualCesar BlAún no hay calificaciones

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Electric Heating Cable Installation Instruction: CTAV-10/18Documento50 páginasElectric Heating Cable Installation Instruction: CTAV-10/18Albert ButanAún no hay calificaciones

- Metecnopanel Information Guide NZDocumento8 páginasMetecnopanel Information Guide NZbassouadAún no hay calificaciones

- Woodsman-Installation Instructions Flare DraftDocumento22 páginasWoodsman-Installation Instructions Flare DraftEmolNZAún no hay calificaciones

- Heatcom BrochureDocumento12 páginasHeatcom BrochureShivansh Singh GautamAún no hay calificaciones

- Installation & Maintenance Instructions: C SeriesDocumento12 páginasInstallation & Maintenance Instructions: C SeriesJames AndersonAún no hay calificaciones

- New Product: Insulation For Attic FloorsDocumento4 páginasNew Product: Insulation For Attic Floorsasso2412Aún no hay calificaciones

- TT Therm 2011 EngDocumento5 páginasTT Therm 2011 EngAndriy99Aún no hay calificaciones

- Montaje y Conexionado Tipico de Controlador T7350 PDFDocumento12 páginasMontaje y Conexionado Tipico de Controlador T7350 PDFMoises Antonio Vasquez VasquezAún no hay calificaciones

- BR SpecificationDocumento6 páginasBR SpecificationqamerilyasAún no hay calificaciones

- Nectre MK ! ManualDocumento7 páginasNectre MK ! ManualmalcroweAún no hay calificaciones

- Installation Kit Joints 11kV CablesDocumento10 páginasInstallation Kit Joints 11kV CablesGuler RahimAún no hay calificaciones

- Living Heat Warranty ScreensDocumento20 páginasLiving Heat Warranty ScreensirisneveAún no hay calificaciones

- Cde-1493 R0 PDFDocumento2 páginasCde-1493 R0 PDFAli GurselAún no hay calificaciones

- Thermazone Foilboard Insulation DatasheetDocumento3 páginasThermazone Foilboard Insulation DatasheetSuthirak SumranAún no hay calificaciones

- Electric Underfloor Heating Guide - Everything You Need to KnowDocumento19 páginasElectric Underfloor Heating Guide - Everything You Need to KnowLucian CiudinAún no hay calificaciones

- PN54A001 Instalación de Heat TracingDocumento12 páginasPN54A001 Instalación de Heat TracingPedro A. Santana H.Aún no hay calificaciones

- Notice Terméo Cap' V1.1 GBDocumento16 páginasNotice Terméo Cap' V1.1 GBAdrian DavidAún no hay calificaciones

- Danby DAC 5110M Air Conditioner ManualDocumento16 páginasDanby DAC 5110M Air Conditioner ManualRJ BodenAún no hay calificaciones

- Electric floor heating guide for every spaceDocumento12 páginasElectric floor heating guide for every spaceDenisa DiaconuAún no hay calificaciones

- Chill-In Insulation KitsDocumento4 páginasChill-In Insulation KitsAuburnMfgAún no hay calificaciones

- Foil TecDocumento4 páginasFoil TecgibboofunkAún no hay calificaciones

- Section 09 Resilient Wood Flooring System Junckers Duobat 110+ SystemDocumento3 páginasSection 09 Resilient Wood Flooring System Junckers Duobat 110+ SystemLindbladJunckersAún no hay calificaciones

- Electric Surface Heating en (Main Bag House)Documento22 páginasElectric Surface Heating en (Main Bag House)Alejandra A. Nuñez Vidal100% (1)

- Electrical TapeDocumento2 páginasElectrical TapemmartincikAún no hay calificaciones

- APEX Op MaintDocumento20 páginasAPEX Op MaintelmiracellAún no hay calificaciones

- Esd 4873 Au 5 - 09 PDFDocumento13 páginasEsd 4873 Au 5 - 09 PDFGeorge IstrateAún no hay calificaciones

- Aluthermo Quattro Installation InstructionsDocumento20 páginasAluthermo Quattro Installation InstructionsthespecifierAún no hay calificaciones

- Installation Instructions Single RoomDocumento14 páginasInstallation Instructions Single RoomTony Bou-GhariosAún no hay calificaciones

- flexiro_drywall_underfloor_heating_installation_guideDocumento11 páginasflexiro_drywall_underfloor_heating_installation_guidegeorgeAún no hay calificaciones

- ThermPanManufactureInst 05Documento1 páginaThermPanManufactureInst 05imeqingenieriaAún no hay calificaciones

- T-Zone Installation GuideDocumento24 páginasT-Zone Installation GuidethermaltechnologiesAún no hay calificaciones

- Calefactor CTDocumento10 páginasCalefactor CTJonathan AliAún no hay calificaciones

- Heraklith C ENG 2012 11Documento2 páginasHeraklith C ENG 2012 11Calin AncutaAún no hay calificaciones

- Bomba de CalorDocumento30 páginasBomba de CalorMoises MalagonAún no hay calificaciones

- Aeroterma Electrica de Perete FRICO C9 9 KW 400V Fisa TehnicaDocumento6 páginasAeroterma Electrica de Perete FRICO C9 9 KW 400V Fisa TehnicacosmynnsAún no hay calificaciones

- SmartPly VapAirTight DATA SHEET Final 2015Documento4 páginasSmartPly VapAirTight DATA SHEET Final 2015WPenrithAún no hay calificaciones

- Jet Master BookDocumento29 páginasJet Master Bookphasor75Aún no hay calificaciones

- Assembly of Italian Indoor Wood Fired Pizza OvenDocumento8 páginasAssembly of Italian Indoor Wood Fired Pizza OvengrillsnovensAún no hay calificaciones

- BR Installation Instruction Flooring Justclic ENDocumento9 páginasBR Installation Instruction Flooring Justclic ENMatija BartošAún no hay calificaciones

- Eco Application GuideDocumento8 páginasEco Application GuidemsbaupartnerAún no hay calificaciones

- Carver Cascade2 RapideDocumento8 páginasCarver Cascade2 Rapidepetrica laurentiuAún no hay calificaciones

- Door Air CurtainsDocumento6 páginasDoor Air CurtainsjationonaAún no hay calificaciones

- Electric Radiant Floor Heating: Installation GuideDocumento14 páginasElectric Radiant Floor Heating: Installation GuideLucian CiudinAún no hay calificaciones

- Celotex Loft Insulation Board PDF'sDocumento3 páginasCelotex Loft Insulation Board PDF'squi06h5eyoAún no hay calificaciones

- flexiro_underfloor_heating-knob_plate-installation_guideDocumento11 páginasflexiro_underfloor_heating-knob_plate-installation_guidegeorgeAún no hay calificaciones

- Installation Instruction Sheet: Split Type Air ConditionerDocumento8 páginasInstallation Instruction Sheet: Split Type Air ConditionerSyed Noman AhmedAún no hay calificaciones

- Proofex Engage PDFDocumento2 páginasProofex Engage PDFmilanbrasinaAún no hay calificaciones

- How To Insulate A Suspended Timber Floor - Installation Guide - 1!04!10-2022Documento21 páginasHow To Insulate A Suspended Timber Floor - Installation Guide - 1!04!10-2022Vlad CasandraAún no hay calificaciones

- Eurotrace Installation Instructions: Installation On A PipeDocumento6 páginasEurotrace Installation Instructions: Installation On A PipeNicolas150956Aún no hay calificaciones

- ExHeat - IOM Instruction For ExHeat Industrial Immersion Heaters (Including Flameproof) - Issue JDocumento8 páginasExHeat - IOM Instruction For ExHeat Industrial Immersion Heaters (Including Flameproof) - Issue JVictor PomboAún no hay calificaciones

- KM304Documento16 páginasKM304Drazen PervanAún no hay calificaciones

- Kaiflex Specification DomesticDocumento5 páginasKaiflex Specification Domesticnaseema1Aún no hay calificaciones

- Index Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Documento6 páginasIndex Fidia P - Mineral Roof Deck Plant Room Acciona W2E Kwinana 03-2019Biju_PottayilAún no hay calificaciones

- APS1100BDocumento16 páginasAPS1100BpdrakewebAún no hay calificaciones

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAún no hay calificaciones

- General guidance on a hydraulic scheme for a CHP systemDocumento1 páginaGeneral guidance on a hydraulic scheme for a CHP systemadyro12Aún no hay calificaciones

- 1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating CircuitsDocumento5 páginas1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating Circuitsadyro12Aún no hay calificaciones

- 1 X TRIGON L Plus Boiler LLH 1CT Heating Circuit 1 DHW Circuit With A CalorifierDocumento4 páginas1 X TRIGON L Plus Boiler LLH 1CT Heating Circuit 1 DHW Circuit With A Calorifieradyro12Aún no hay calificaciones

- 2 TRIGON XXL 1 CHP 2 Buffers PHE 1 VT Heating Circuit and 1 DHW Calorifier 1Documento1 página2 TRIGON XXL 1 CHP 2 Buffers PHE 1 VT Heating Circuit and 1 DHW Calorifier 1adyro12Aún no hay calificaciones

- Mon2 Mon2 Mon2 Mon2 Mon2: Izvorne Upute Za RadDocumento1 páginaMon2 Mon2 Mon2 Mon2 Mon2: Izvorne Upute Za Radadyro12Aún no hay calificaciones

- SIOV Leaded StandarD-1317152Documento48 páginasSIOV Leaded StandarD-1317152adyro12Aún no hay calificaciones

- Delta Ia-Plc DVPPCC01 I Tse 20160503Documento2 páginasDelta Ia-Plc DVPPCC01 I Tse 20160503adyro12Aún no hay calificaciones

- Aragaz Nelu Parts1Documento10 páginasAragaz Nelu Parts1adyro12Aún no hay calificaciones

- Cuptor ElectricDocumento6 páginasCuptor Electricadyro12Aún no hay calificaciones

- Servomotoare HoneywellDocumento2 páginasServomotoare Honeywelladyro12Aún no hay calificaciones

- Wgo Carlin Burner Manual 1Documento29 páginasWgo Carlin Burner Manual 1adyro12Aún no hay calificaciones

- Aragaz Nelu - Parts1 PDFDocumento22 páginasAragaz Nelu - Parts1 PDFadyro12Aún no hay calificaciones

- Navicat enDocumento195 páginasNavicat enadyro12Aún no hay calificaciones

- (Ebook - PDF) Lost Books of The Bible - Gospel of Thomas, Scholars' Translation PDFDocumento13 páginas(Ebook - PDF) Lost Books of The Bible - Gospel of Thomas, Scholars' Translation PDFadyro12Aún no hay calificaciones

- Vgu VG3Documento3 páginasVgu VG3adyro12Aún no hay calificaciones

- Alev SensörüDocumento10 páginasAlev Sensörüadana123Aún no hay calificaciones

- RCDocumento7 páginasRCadyro12Aún no hay calificaciones

- 6th Gen Intel Core-Intel Xeon FactsheetDocumento13 páginas6th Gen Intel Core-Intel Xeon FactsheetTracy WilliamsAún no hay calificaciones

- A.B Steam HeaterDocumento2 páginasA.B Steam Heateradyro12Aún no hay calificaciones

- Olaer VguDocumento2 páginasOlaer Vguadyro12Aún no hay calificaciones

- ME ProgramDocumento21 páginasME Programadyro12Aún no hay calificaciones

- File 1358196026Documento18 páginasFile 1358196026adyro12Aún no hay calificaciones

- OILTECH PISTON ACCUMULATORS 250 BAR SELECTION GUIDEDocumento2 páginasOILTECH PISTON ACCUMULATORS 250 BAR SELECTION GUIDEadyro12Aún no hay calificaciones

- File 1358194781Documento1 páginaFile 1358194781adyro12Aún no hay calificaciones

- Charging Set VGU Brochure 29072013Documento2 páginasCharging Set VGU Brochure 29072013adyro12Aún no hay calificaciones

- EsabwDocumento114 páginasEsabwadyro12Aún no hay calificaciones

- Dsa842000 181Documento1 páginaDsa842000 181adyro12Aún no hay calificaciones

- SmeltingDocumento5 páginasSmeltingTrần Ngọc NamAún no hay calificaciones

- K-Fonic Poduct DetailsDocumento28 páginasK-Fonic Poduct DetailsAshish VaidAún no hay calificaciones

- SERC - Laced Reinforced ConcreteDocumento11 páginasSERC - Laced Reinforced ConcretejrasankarAún no hay calificaciones

- 7600 ICU Installation ManualDocumento12 páginas7600 ICU Installation ManualAngelo Colombo RauterAún no hay calificaciones

- Duracrete: Reducing Enhancing 3-DimensionalDocumento5 páginasDuracrete: Reducing Enhancing 3-DimensionalAmjad PervazAún no hay calificaciones

- Shielding A Room Using Aluminum Foil PDFDocumento14 páginasShielding A Room Using Aluminum Foil PDFL. J.Aún no hay calificaciones

- Cresit CR 72-HenkelDocumento4 páginasCresit CR 72-HenkelJoun SmithAún no hay calificaciones

- Mittal Steel Europe Flat Products GuideDocumento24 páginasMittal Steel Europe Flat Products GuideGeorge_Wabag_2014Aún no hay calificaciones

- Hayward Pro Grid de 4820Documento12 páginasHayward Pro Grid de 4820Mike MannoAún no hay calificaciones

- MESINIAGADocumento16 páginasMESINIAGAHaneesah GhazaliAún no hay calificaciones

- Sue's Rendezvous Illegal Certificate of OccupancyDocumento3 páginasSue's Rendezvous Illegal Certificate of OccupancySamuel L. RiversAún no hay calificaciones

- MATCH Perfect Match at The Pulse of Putra HeightsDocumento4 páginasMATCH Perfect Match at The Pulse of Putra HeightsjohnAún no hay calificaciones

- Building Hvac Compliance Sbd9720Documento1 páginaBuilding Hvac Compliance Sbd9720Haroon GhaniAún no hay calificaciones

- Earthquake EngineeringDocumento21 páginasEarthquake EngineeringAbbasabbasiAún no hay calificaciones

- PriceList - Gaur Saundaryam - 99acresDocumento5 páginasPriceList - Gaur Saundaryam - 99acresishaan singhAún no hay calificaciones

- 2011 CIVITAS Benefit JournalDocumento40 páginas2011 CIVITAS Benefit JournalCIVITASAún no hay calificaciones

- History of Benazir PalaceDocumento9 páginasHistory of Benazir Palaceshraddha100% (1)

- 11 Chapter 3Documento47 páginas11 Chapter 3Dheeraj Kumar DehranAún no hay calificaciones

- Innovation in MEP: CPVC Sprinkler PipingDocumento11 páginasInnovation in MEP: CPVC Sprinkler PipingJohn DiasAún no hay calificaciones

- Building Design To Foster A Quality and Sustainable Built EnvironmentDocumento10 páginasBuilding Design To Foster A Quality and Sustainable Built EnvironmentkevinbovoAún no hay calificaciones

- Earthbound Canada 2011Documento12 páginasEarthbound Canada 2011Christopher GarciaAún no hay calificaciones

- Multi Storey Car ParksDocumento6 páginasMulti Storey Car ParksRifat Türkkan0% (1)

- Sherman Notes PDFDocumento213 páginasSherman Notes PDFAbdul Hamid Bhatti100% (1)

- Residential Building For Mr. Satish Rao Chitpady, Udupi, KarnatakaDocumento12 páginasResidential Building For Mr. Satish Rao Chitpady, Udupi, Karnatakapratheek DasAún no hay calificaciones

- RDM Lea062.e0Documento4 páginasRDM Lea062.e0quynhanh2603Aún no hay calificaciones