Documentos de Académico

Documentos de Profesional

Documentos de Cultura

GIS Electric Chain Hoist Guide

Cargado por

JoséCevallosDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

GIS Electric Chain Hoist Guide

Cargado por

JoséCevallosCopyright:

Formatos disponibles

GIS GCH ELECTRIC CHAIN HOIST

GIS ELECTRIC CHAIN HOISTS (UP TO 5000 KG)

A further evolution in chain hoist development from GIS, specialists in chain hoist manufacture since 1963. The GIS manufacturing facility in Switzerland contains

some of the most modern machining centres and the hoist embodies the latest manufacturing techniques and technology.

Designed and manufactured to work in the most extreme of conditions

Lifting capacity from 1255000kg

Hoist body and end covers manufactured from die cast aluminium

Reliable, low wear, easy to maintain

Single or dual speeds available with many different speed options

Permanent hoist lubrication for wear resistant operation

Cast aluminium housing and end covers using the latest casting technology,

maximum solidity, no plastics used

New advanced brake design providing maximum safety with minimum maintenance

Five or six pocket chain wheel giving extremely quiet running

42V control system, electrical geared limit switches tted as standard

Fitted with mechanical stops to prevent over travel as required in FEM standards

Ergonomic design 2 or 4 button control pendant with E stop

Available with Eye or Hook suspension, push or electric trolley on I-Beams

or combined with GIS crane system

GIS GCH ELECTRIC CHAIN HOIST

Types

Duty Classication/Lifting Capacity

M3 1Bm

150 s/h

25% duty

(kg)

M4 1Am

180 s/h

30% duty

(kg)

M5 2m

240 s/h

40% duty

(kg)

M6 3m

300 s/h

50% duty

(kg)

M7 4m

360 s/h

60% duty

(kg)

Lifting

speed

(m/min)

Motor

power

(kW)

3 x 400V

50Hz

(A)

No. Of chain falls

Eye/hook

suspension

weight 3m lift

(kg)

Weight per

extra metre

lift

(kg)

GCH 250/1N

250

200

160

125

100

0.36

1.3

19

0.32

GCH 250/1NF

250

200

160

125

100

8/2

0.36/0.09

2.7/3.0

22

0.32

GCH 250/1SF

160

125

100

80

60

12.5/3

0.36/0.09

2.7/3.0

22

0.32

GCH 250/1HF

100

80

60

50

40

20/5

0.36/0.09

2.7/3.0

22

0.32

GCH 250/2N

500

400

320

250

200

0.36

1.3

22.5

0.64

GCH 250/2NF

500

400

320

250

200

4/1

0.36/0.09

2.7/3.0

23

0.64

GCH 250/2SF

320

250

200

160

125

6.25/1.5

0.36/0.09

2.7/3.0

23

0.64

GCH 500/1N

500

400

320

250

200

0.72

2.1

20

0.52

GCH 500/1NF

500

400

320

250

200

8/2

0.72/0.18

2.9/3.0

22.5

0.52

GCH 500/1SF

320

250

200

160

125

12.5/3

0.72/0.18

2.9/3.0

22.5

0.52

GCH 500/1HF

200

160

125

100

80

20/5

0.72/0.18

2.9/3.0

22.5

0.52

GCH 500/2N

1000

800

630

500

400

0.72

2.1

22.5

1.04

GCH 500/2NF

1000

800

630

500

400

4/1

0.81/0.18

2.9/3.0

25

1.04

GCH 500/2SF

630

500

400

320

250

6.25/1.5

0.81/0.18

2.9/3.0

25

1.04

GCH 1000/1N

1000

800

630

500

400

1.45

3.7

45

1.04

GCH 1000/1NF

1000

800

630

500

400

8/2

1.45/0.36

4.0/2.8

46

1.04

GCH 1000/1SF

500

400

320

250

200

16/4

1.45/0.36

5.8/2.6

48

1.04

GCH 1000/2N

2000

1600

1250

1000

800

1.45

3.7

50

2.08

GCH 1000/2NF

2000

1600

1250

1000

800

4/1

1.45/0.36

4.0/2.8

51

2.08

GCH 1000/2SF

1000

800

630

500

400

8/2

1.45/.036

5.8/2.6

53

2.08

GCH 1600/1N

1600

1250

1000

800

630

2.44

6.0

63

1.75

GCH 1600/1NF

1600

1250

1000

800

630

8/2

2.44/0.61

6.6/4.2

65

1.75

1.75

GCH 1600/1SF

1000

800

630

500

400

12.5/3

2.39/0.58

6.6/4.2

65

GCH 1600/2N

3200

2500

2000

1600

1250

2.44

6.0

73

3.5

GCH 1600/2NF

3200

2500

2000

1600

1250

4/1

2.44/0.61

6.6/4.2

75

3.5

GCH 1600/2SF

2000

1600

1250

1000

800

6.25/1.5

2.39/0.58

6.6/4.2

75

3.5

GCH 2000/1N

2000

1600

1250

1000

800

3.05

7.3

65

2.25

GCH 2000/1NF

2000

1600

1250

1000

800

8/2

3.05/0.77

8.0/4.5

67

2.25

2.25

GCH 2000/1SF

1250

1000

800

630

500

12.5/3

2.98/0.72

8.0/4.5

67

GCH 2000/2N

4000

3200

2500

2000

1600

3.05

7.3

76

4.5

GCH 2000/2NF

4000

3200

2500

2000

1600

4/1

3.05/0.77

8.0/4.5

78

4.5

GCH 2000/2SF

2500

2000

1600

1250

1000

6.25/1.5

2.98/0.72

8.0/4.5

78

4.5

GCH 2500/1N

2500

2000

1600

1250

1000

6.4

3.05

7.7

65

2.25

GCH 2500/1NF

2500

2000

1600

1250

1000

6.4/1.6

3.05/0.77

8.2/4.4

67

2.25

2.25

GCH 2500/1SF

1600

1250

1000

800

630

10/2.5

3.05/0.77

8.2/4.4

67

GCH 2500/2N

5000

4000

3200

2500

2000

3.2

3.05

7.7

76

4.5

GCH 2500/2NF

5000

4000

3200

2500

2000

3.2/0.8

3.05/0.77

8.2/4.4

78

4.5

GCH 2500/2SF

3200

2500

2000

1600

1250

5/1.25

3.05/0.77

8.2/4.4

78

4.5

Types Duty

Classication/

Capacity

1Bm

150 s/h

25% duty

Eye/hook

suspension

weight 3m lift

(kg)

Weight per

extra metre

lift

(kg)

Specication GIS-GCH Electric Chain Hoist 110V or 220V single phase power supply

Lifting

speed

(m/min)

Motor

power

(kW)

3 x 400V

50Hz

(A)

1 x 230V

50Hz

(A)

No. Of

chain

falls

GCH 250/1N 1Ph

160

0.23

8.9

19

0.32

GCH 250/2N 1Ph

320

0.23

8.9

22.5

0.64

GCH 500/1N 1Ph

250

0.36

8.9

20

0.52

GCH 500/2N 1Ph

500

0.36

8.9

22.5

1.04

GCH 500/1NL 1Ph

500

0.36

8.9

20

0.52

GCH 500/2NL 1Ph

1000

0.36

8.9

22.5

1.04

GCH 1000/1NL 1Ph

500

TBA

TBA

45

1.04

GCH 1000/2NL 1Ph

1000

TBA

TBA

50

2.08

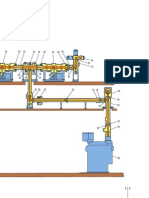

GIS GCH ELECTRIC CHAIN HOIST

A2

A1

A4

B1

C2

C1 H1 C3

B3

A3

B2

DIMENSIONS (mm)

Types

A1 mm

A2 mm

A3 mm

A4 mm

B1 mm

B2 mm

B3 mm

C1 mm

C2 mm

C3 mm

GCH 250/1

246

281

146

40

309

155

22

164

53

448

H1 mm

369

GCH 250/2

246

281

164

40

309

155

22

164

53

448

408

GCH 500/1

246

281

146

40

309

155

22

164

53

448

377

GCH 500/2

246

281

164

40

309

155

22

164

53

448

417

GCH 1000/1

321

367

190

52

367

180

32

214

69

615

482

GCH 1000/2

321

367

224

52

367

180

32

214

69

615

556

GCH 1600/1

345

424

221

75

389

180

37

230

135

696

608

GCH 1600/2

345

424

263

75

389

180

37

230

135

696

690

GCH 2000/1

345

424

221

75

389

180

37

230

135

696

608

GCH 2000/2

345

424

263

75

389

180

37

230

135

696

690

GCH 2500/1

345

424

221

75

389

180

37

230

135

696

608

GCH 2500/2

345

424

263

75

389

180

37

230

135

696

690

GIS MANUAL AND ELECTRIC TRAVEL TROLLEY

ISO (FEM)

classication

M3 (1Bm)

150 s/h

25% duty

M4 (1Am)

180 s/h

30% duty

EHF 50

M6 (3m)

300 s/h

50% duty

M7 (4m)

360 s/h

60% duty

Travelling

speed

Motor power

(M3)

3 x 400V

50Hz

(M3)

Self

weight

1,000

800

630

630

500

(m/min)

(kW)

(A)

(kg)

EMFE 50/N

1,000

800

630

630

7.5

Manual

500

12

0.25

0.8

27

EMFE 50/NF

1,000

800

630

Electric

630

500

12/4

0.15/0.045

0.65/0.75

27

EMFE 50/SF

800

800

Electric

630

630

500

20/6

0.15/0.045

0.65/0.75

27

EHF 150

2,000

Electric

2,000

1,600

1,600

1,250

13.5

Manual

Type

M5 (2m)

240 s/h

40% duty

Capacity (kg)

Electric or

manual

EMFE 150/N

2,000

2,000

1,600

1,600

1,250

12

0.25

0.8

31

Electric

EMFE 150/NF

2,000

2,000

1,600

1,600

1,250

12/4

0.15/0.045

0.65/0.75

31

Electric

EMFE 150/SF

1,600

1,600

1,600

1,600

1,250

20/6

0.15/0.045

0.65/0.75

31

Electric

EHF 300

4,000

4,000

3,200

2,500

2,500

27.5

Manual

EMFE 300/N

4,000

4,000

3,200

2500

2,500

12

0.25

0.8

50

Electric

EMFE 300/NF

4,000

4,000

3,200

2,500

2,500

12/4

0.15/0.045

0.65/0.75

50

Electric

EMFE 300/SF

3,200

3,200

3,200

2,500

2,500

20/6

0.15/0.045

0.65/0.75

50

Electric

EHF 500

5,000

4,000

3,200

3,200

2,500

27.5

Manual

EMFE 500/N

5,000

4,000

3,200

3,200

2,500

12

2x0.25

2x0.8

57

Electric

EMFE 500/NF

5,000

4,000

3,200

3,200

2,500

12/4

2x0.15/0.045

2x0.65/0.75

57

Electric

EMFE 500/SF

4,000

4,000

3,200

3,200

2,500

20/6

2x0.15/0.045

2x0.65/0.75

57

Electric

DIMENSIONS (mm)

Types

e1 (mm)

e2 (mm)

f1 (mm)

f2 (mm)

f3 (mm)

f4 (mm)

f5 (mm)

f6 (mm)

EHF 50

215

183

23

EMFE 50

215

62

209

250

241

183

23

EHF 150

250

230

27

EMFE 150

250

43

211

253

242

230

27

EHF 300

311

290

31

EMFE 300

311

12

217

259

249

290

31

EHF 500

311

290

31

EMFE 500

311

12

259

249

290

31

249

Types

g1(mm)

g2 (mm)

EHF 50

49

167

EMFE 50

49

167

h2 (mm)

EHF 50/150

EHF 50/150

EHF 300/500

EMFE 300/500

Flange

width

(mm)

GCH 250/1

GCH 250/2

GCH 500/1

GCH 500/2

418

457

426

466

50 - 99

418

457

426

466

50 - 99

GCH 1000/1

GCH 1000/2

EHF 150

60

203

542

616

76 - 139

EMFE 150

60

203

542

616

76 - 139

GCH 1600/1

GCH 1600/2

GCH 2000/1

EHF 300

55

218

637

719

637

719

120 - 179

EMFE 300

55

218

637

719

637

719

120 - 179

GCH 2500/1

GCH 2500/2

GCH 2000/2

EHF 500

55

218

637

719

120-179

EMFE 500

55

218

637

719

120-179

Options

other ange widths

electric travel trolley with brake

Standard voltages: 3Ph 230V, 50Hz; 3Ph 400V, 50Hz

Special voltages: on request

Selection of travel trolleys: GCH 250/500: EHF/EMFE 50

GCH 1600/2000: EHF/EMFE 300

GCH 1000: EHF/EMFE 150

GCH 2500: EHF/EMFE 500

EHF 50/150/300/500

EMFE 50/150/300/500

También podría gustarte

- Data Sheet Efg 213 215 216k 216 218k 218 220Documento4 páginasData Sheet Efg 213 215 216k 216 218k 218 220Dejan MitrovićAún no hay calificaciones

- Alarko Fcu İngDocumento16 páginasAlarko Fcu İngcalavera83Aún no hay calificaciones

- From 72.5 KV To 800 KVDocumento27 páginasFrom 72.5 KV To 800 KVbharath_A100% (1)

- Hoists Winches Cranes GuideDocumento41 páginasHoists Winches Cranes GuideNajmi HaikalAún no hay calificaciones

- GIS (E A4) 218hyundaiDocumento24 páginasGIS (E A4) 218hyundaivishalrediffAún no hay calificaciones

- Alimentador VibratorioDocumento24 páginasAlimentador VibratoriojgarciacochachiAún no hay calificaciones

- RV-K KabelisDocumento4 páginasRV-K KabelismaterkyAún no hay calificaciones

- WallDocumento0 páginasWallgks6043Aún no hay calificaciones

- ForkliftDocumento5 páginasForkliftpramodtry100% (1)

- 12 - 10 E Hoists ADocumento6 páginas12 - 10 E Hoists AHoang Minh HungAún no hay calificaciones

- Take-Up Winches Mk2Documento2 páginasTake-Up Winches Mk2Chandra SekharAún no hay calificaciones

- AirWinch CatalogDocumento92 páginasAirWinch CataloghlsimonAún no hay calificaciones

- 11 Lifting Blocking Clamping PDFDocumento48 páginas11 Lifting Blocking Clamping PDFEbied Yousif AlyAún no hay calificaciones

- TTS Cargo Cranes: Product SpecificationDocumento4 páginasTTS Cargo Cranes: Product SpecificationRangga Wijaya DimyatieAún no hay calificaciones

- Hydrogen Transfer Eng Hyd 1Documento4 páginasHydrogen Transfer Eng Hyd 1minsseok hhaAún no hay calificaciones

- b3311 722-2Documento7 páginasb3311 722-2Arnaldo BenitezAún no hay calificaciones

- Grove 60 Ton PDFDocumento24 páginasGrove 60 Ton PDFFabrizzio ZuñigaAún no hay calificaciones

- Kito ER2 EnglishDocumento40 páginasKito ER2 Englishkristina618Aún no hay calificaciones

- ERC 212 216 GBDocumento4 páginasERC 212 216 GBDarwin Quingua DiazAún no hay calificaciones

- AVK MTU Diesel Generators 715-3300kVADocumento2 páginasAVK MTU Diesel Generators 715-3300kVA5ofyAún no hay calificaciones

- KAT Gouging System - Arcair N7500Documento2 páginasKAT Gouging System - Arcair N7500Th NattapongAún no hay calificaciones

- Tolomatic IMA 2011 CatalogDocumento18 páginasTolomatic IMA 2011 CatalogElectromateAún no hay calificaciones

- Product Information DFG Tfg425-435Documento4 páginasProduct Information DFG Tfg425-435vikas_ojha54706Aún no hay calificaciones

- Grove AT400Documento18 páginasGrove AT400cornel_lupu100% (2)

- Catalogo Komatsu WA470-6Documento6 páginasCatalogo Komatsu WA470-6Dawn Hall100% (1)

- XFP 80C 201G TDS 60Hz USDocumento4 páginasXFP 80C 201G TDS 60Hz USMeu nomeAún no hay calificaciones

- Gis TOSHIBADocumento18 páginasGis TOSHIBATan Hong TatAún no hay calificaciones

- Mark-Vi Super Mark-Vi Super: SK200 SK200Documento12 páginasMark-Vi Super Mark-Vi Super: SK200 SK200Pavidee100% (1)

- CASE 580 Super R Series 2/590 Super R Series 2 Backhoe Loaders SpecsDocumento8 páginasCASE 580 Super R Series 2/590 Super R Series 2 Backhoe Loaders SpecsZelislav Lidija Sirka100% (1)

- 351 Equipo de PerforacionDocumento3 páginas351 Equipo de Perforacionmisael_arielAún no hay calificaciones

- XFP 80C 201G TDSDocumento4 páginasXFP 80C 201G TDSkeifferAún no hay calificaciones

- Gis 02Documento10 páginasGis 02rasheed313Aún no hay calificaciones

- 43m Reach 60 Metric Ton Truck CraneDocumento3 páginas43m Reach 60 Metric Ton Truck CraneOtto Heinrich WehmannAún no hay calificaciones

- Cat 914G2Documento20 páginasCat 914G2t1me50% (2)

- Backhoe VolvoDocumento12 páginasBackhoe Volvonadinhata100% (1)

- MKTG Info CutsheetDocumento2 páginasMKTG Info CutsheetGhazni MusllimAún no hay calificaciones

- Csa 10 To 20Documento6 páginasCsa 10 To 20peterpunk75Aún no hay calificaciones

- Wind Turbine Ge 15 BrochureDocumento4 páginasWind Turbine Ge 15 BrochureMark ForssAún no hay calificaciones

- Electric Wire Rope Hoist 950168DC BB EngDocumento8 páginasElectric Wire Rope Hoist 950168DC BB EngTh NattapongAún no hay calificaciones

- STC750Documento12 páginasSTC750Dhana Shekar50% (2)

- JCB TRACKED EXCAVATOR SPECSDocumento12 páginasJCB TRACKED EXCAVATOR SPECSMB ViorelAún no hay calificaciones

- Manitou Mid Size Cylinder Handler (EN)Documento4 páginasManitou Mid Size Cylinder Handler (EN)ManitouAún no hay calificaciones

- Data Sheet Etr 230 235 340 345 335dDocumento4 páginasData Sheet Etr 230 235 340 345 335dDejan MitrovićAún no hay calificaciones

- Low Voltage Change-over and Transfer Switches GuideDocumento116 páginasLow Voltage Change-over and Transfer Switches GuideCarolina Alicia Bravo VillegasAún no hay calificaciones

- Honny Power Generator Datasheet HGM1250HV11Documento2 páginasHonny Power Generator Datasheet HGM1250HV11AmpolAún no hay calificaciones

- TMS E: Product GuideDocumento20 páginasTMS E: Product GuideJaime SuaAún no hay calificaciones

- MWCP 2007 PDFDocumento72 páginasMWCP 2007 PDFcesar luis gonzalez rodriguezAún no hay calificaciones

- AXIAL FANS FOR SMOKE EXTRACTIONDocumento6 páginasAXIAL FANS FOR SMOKE EXTRACTIONCatalin BombeaAún no hay calificaciones

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDe EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsCalificación: 5 de 5 estrellas5/5 (2)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDe EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideCalificación: 4 de 5 estrellas4/5 (8)

- Semi-Active Suspension Control Design for VehiclesDe EverandSemi-Active Suspension Control Design for VehiclesCalificación: 5 de 5 estrellas5/5 (1)

- The IGBT Device: Physics, Design and Applications of the Insulated Gate Bipolar TransistorDe EverandThe IGBT Device: Physics, Design and Applications of the Insulated Gate Bipolar TransistorCalificación: 4.5 de 5 estrellas4.5/5 (4)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesAún no hay calificaciones

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDe EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyCalificación: 5 de 5 estrellas5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsAún no hay calificaciones

- Ford OBD-II Tren de Potencia P0102 - P0812Documento37 páginasFord OBD-II Tren de Potencia P0102 - P0812JoséCevallosAún no hay calificaciones

- Ford OBD-II Tren de Potencia P0102 - P0812Documento37 páginasFord OBD-II Tren de Potencia P0102 - P0812JoséCevallosAún no hay calificaciones

- Ford OBD-II Tren de Potencia P0102 - P0812 PDFDocumento37 páginasFord OBD-II Tren de Potencia P0102 - P0812 PDFJoséCevallosAún no hay calificaciones

- GIS Electric Chain Hoist GuideDocumento4 páginasGIS Electric Chain Hoist GuideJoséCevallosAún no hay calificaciones

- 8426 - Derricks, Cranes and Mobile Lifting FramesDocumento19 páginas8426 - Derricks, Cranes and Mobile Lifting FramesJoséCevallosAún no hay calificaciones

- Yale Shawbox EndtrucksDocumento56 páginasYale Shawbox EndtrucksJoséCevallosAún no hay calificaciones

- Yale Shawbox EndtrucksDocumento56 páginasYale Shawbox EndtrucksJoséCevallosAún no hay calificaciones

- 1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECDocumento61 páginas1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECRobert RocafuerteAún no hay calificaciones

- JHA For Hydrotest of MSRDocumento7 páginasJHA For Hydrotest of MSRM8Rskn6wcAún no hay calificaciones

- Evaluation and Application of Characteristic Values Based On Eurocode 7 Design MethodologyDocumento5 páginasEvaluation and Application of Characteristic Values Based On Eurocode 7 Design MethodologySeng SiongAún no hay calificaciones

- Auscrown Ring Burners July15Documento7 páginasAuscrown Ring Burners July15Elbin Antonio EspinalAún no hay calificaciones

- Cojinete Teflon - GGB-HSG-High-Load-Fiber-Reinforced-Composite-PTFE-Bearing-DatasheetDocumento2 páginasCojinete Teflon - GGB-HSG-High-Load-Fiber-Reinforced-Composite-PTFE-Bearing-DatasheetneodymioAún no hay calificaciones

- Types 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsDocumento44 páginasTypes 1098-EGR and 1098H-EGR Pressure Reducing RegulatorsToto TotoroAún no hay calificaciones

- Measuring wavelength of light using diffraction gratingDocumento5 páginasMeasuring wavelength of light using diffraction gratingSaksham BargujarAún no hay calificaciones

- D7E Engine ManualDocumento94 páginasD7E Engine ManualSS YS100% (1)

- Lecture 08 - ME 243 - Helical SpringsDocumento14 páginasLecture 08 - ME 243 - Helical Springssalmanalamj5Aún no hay calificaciones

- Cpci Education Recourses Brian HallDocumento22 páginasCpci Education Recourses Brian HallMahmoud Abu-eidehAún no hay calificaciones

- Transmission FundamentalsDocumento47 páginasTransmission Fundamentalsroel balolong0% (1)

- iNTERRUPTOR 3AF01 PDFDocumento27 páginasiNTERRUPTOR 3AF01 PDFJames IzquierdoAún no hay calificaciones

- Chapter 7: Communication Elements and Features: 701 GeneralDocumento30 páginasChapter 7: Communication Elements and Features: 701 GeneralawasthyAún no hay calificaciones

- Rosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & MunicipalitiesDocumento12 páginasRosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & Municipalitiesdiegoh_silvaAún no hay calificaciones

- Standard Operating Procedure - CapsuleDocumento7 páginasStandard Operating Procedure - CapsuleIntan NajiihahAún no hay calificaciones

- CS C372/IS C362 - Operating System: Birla Institute of Technology & Science, Pilani QUIZ 2 - Closed BookDocumento2 páginasCS C372/IS C362 - Operating System: Birla Institute of Technology & Science, Pilani QUIZ 2 - Closed BookVishal MittalAún no hay calificaciones

- International Journal of Soft Computing and Engineering (IJSCE)Documento1 páginaInternational Journal of Soft Computing and Engineering (IJSCE)DrShiv K SahuAún no hay calificaciones

- Me PPT About SSCMDocumento18 páginasMe PPT About SSCMSana SaleemAún no hay calificaciones

- Dev Vandana Aparnaam Samayik (VGM-375)Documento76 páginasDev Vandana Aparnaam Samayik (VGM-375)DJICRAún no hay calificaciones

- Riser PL 2023-R1Documento7 páginasRiser PL 2023-R1agung setyawanAún no hay calificaciones

- FotoControl Configuration For Fuji Frontier Minilabs v3 PDFDocumento20 páginasFotoControl Configuration For Fuji Frontier Minilabs v3 PDFIvan PasseròAún no hay calificaciones

- Factors To Consider in Foundation Design Chapter # 02Documento18 páginasFactors To Consider in Foundation Design Chapter # 02Ali ShaheryarAún no hay calificaciones

- Control of Quality Control ManualDocumento25 páginasControl of Quality Control ManualWahyu HarisantoAún no hay calificaciones

- Bushes: Hosefloat Bush Set-Up InstructionsDocumento1 páginaBushes: Hosefloat Bush Set-Up InstructionsJasmi Noor SahudinAún no hay calificaciones

- Tunnel Face Stability Analysis in Soft Ground in Urban Tunneling by EPB Shield (Case Study: 7 Line in Tehran Metro)Documento9 páginasTunnel Face Stability Analysis in Soft Ground in Urban Tunneling by EPB Shield (Case Study: 7 Line in Tehran Metro)AnggaAún no hay calificaciones

- Compiling GRBL GRBL Wiki GitHubDocumento6 páginasCompiling GRBL GRBL Wiki GitHubMarky MaypoAún no hay calificaciones

- JIT/Lean Manufacturing GuideDocumento30 páginasJIT/Lean Manufacturing GuideVirojana TantibadaroAún no hay calificaciones

- Sunil Kumar VishwakarmaDocumento5 páginasSunil Kumar VishwakarmaAnonymous qHCvNxswckAún no hay calificaciones

- ICEA-S 96-659 5kVDocumento2 páginasICEA-S 96-659 5kVAnamulKabirAún no hay calificaciones

- Fault Current CalculatorDocumento6 páginasFault Current CalculatorVũDuyTânAún no hay calificaciones