Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Mta Joe1995

Cargado por

hajingukDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Mta Joe1995

Cargado por

hajingukCopyright:

Formatos disponibles

0099-2399/95/2107-0349503.

00/0 JOURNALOF ENDODONTICS Copyright 1995 by The American Association of Endodontists

Printed in U.S.A. VOL. 21, No. 7, JULY 1995

SCIENTIFIC ARTICLES Physical and Chemical Properties of a New Root-End Filling Material

Mahmoud Torabinejad, DMD, MSD, PhD, C. U. Hong, DDS, MS, F. McDonald, BDS, PhD, and T. R. Pitt Ford, BDS, PhD

This study determined the chemical composition, pH, and radiopacity of mineral trioxide aggregate (MTA), and also compared the setting time, compressive strength, and solubility of this material with those of amalgam, Super-EBA, and Intermediate Restorative Material (IRM). X-ray energy dispersive spectrometer in conjunction with the scanning electron microscope were used to determine the composition of MTA, and the pH value of MTA was assessed with a pH meter using a temperature-compensated electrode. The radiopacity of MTA was determined according to the method described by the International Organization for Standardization. The setting time and compressive strength of these materials were determined according to methods recommended by the British Standards Institution. The degree of solubility of the materials was assessed according to modified American Dental Association specifications. The results showed that the main molecules present in MTA are calcium and phosphorous ions. In addition, MTA has a pH of 10.2 initially, which rises to 12.5 three hours after mixing. MTA is more radiopaque than Super-EBA and IRM. Amalgam had the shortest setting time (4 min) and MTA the longest (2 h 45 rain). At 24 h MTA had the lowest compressive strength (40 MPa) among the materials, but it increased after 21 days to 67 MPa. Finally, except for IRM, none of the materials tested showed any solubility under the conditions of this study.

of a class I cavity and placement of a root-end filling material. A number of substances have been suggested and used as root-end filling materials (1). Recently, an experimental substance, mineral trioxide aggregate (MTA), has been suggested as a potential root-end filling material. In a series of in vitro studies, Torabinejad et al. (2-5) evaluated the sealing ability of MTA, compared with commonly used root-end filling materials. Statistical analysis of their data showed that MTA had significantly less dye (2, 3) and bacterial (4) leakage than amalgam, Super-EBA or Intermediate Restorative Material (IRM). In addition, when marginal adaptation of MTA root-end fillings was compared with those of amalgam, Super-EBA, and IRM under scanning electron microscope, they reported no noticeable gap between MTA and its surrounding dentinal walls (5). Because these studies show that MTA leaks less and has better adaptation to the root-end cavity walls than commonly used rootend filling materials, its other characteristics---such as chemical composition, physical properties, antibacterial effects, cytotoxicity, and biocompatibility--should also be investigated. The purpose of this study was first to determine the chemical composition, pH of the setting cement, and radiopacity of MTA, and second to compare the setting time, compressive strength, and solubility of this material with those of three commonly used root-end filling materials, amalgam, Super-EBA, and IRM.

MATERIALS AND METHODS Chemical Composition To study the chemical composition of MTA, we used the KVEX Delta 4460 X-ray Energy dispersive spectrometer, modified with Micro EDS software (BEMAX UK Ltd.), in conjunction with a Hitachi $520 scanning electron microscope. MTA was mixed with sterilized distilled water and allowed to set in a 37C incubator with 5% carbon dioxide and moisture. The material was set on a glass cover slip that had been previously sterilized using alcohol and flaming. Five set specimens with different proportions of water and powder were examined. For quantitative X-ray analysis, the specimens were carbon-coated to a thickness of 100 nm and again mounted in the $520 using the quantum DVEX system. Acceler349

When nonsurgical root canal therapy fails or cannot be performed, surgical root canal therapy is conducted. The procedure usually consists of root-end exposure and resection, as well as preparation

350

Torabinejad et al. TABLE 1. Material used for experiments

Journal of Endodontics

Material Sybraloy amalgam Super-EBA IRM MTA

Manufacturer Kerr Mfg. Co., Romulus, MI Harry J. Bosworth Co., Skokie, IL I.D. Caulk Co., Milford, DE Loma Linda University, Loma Linda, CA

ating voltage for standard examination was 15 kV and that for X-ray analysis was 10 kV. pH Value

The pH of MTA as it set was measured with a pH meter (Pye, Cambridge, UK) using a temperature-compensated electrode.

The setting times of test materials were determined according to the method recommended by the ISO (6). Before mixing, the test materials, mixing pads, spatulas, and fiat glass plates were placed in a room with a temperature of 23 -+ IC for 1 h. Each material was then mixed and placed in a circular metal mold (15 mm diameter and 5 mm high). The assembly, comprising mold and test material, was placed on a metal block in a cabinet at 37C and relative humidity of 95 to 100%, 2 min after the start of mixing. After a further 30 s to 1 min, the indentor needle (Gillmore) was lowered vertically onto the surface of the material (1.0 mm/min) and allowed to remain there for 5 s. This process was repeated every 30 s until the needle failed to make a complete circular indentation in the test material. The setting time was the duration of time that elapsed from start of mixing to when the indentor needle failed to make an indentation in the material. This test was repeated six times for each material.

Radiopaeity

The radiopacity of MTA was determined according to the method described by the International Organization for Standardization (ISO 6876), section 7.7 (6). After mixing, MTA was packed into a stainless steel ring mold with an internal diameter of 10 mm and a depth of i mm. The mold was placed on a glass slab before insertion of the material. It was covered with a glass slide and allowed to set for 3 h. Radiographs were taken with a target-film distance of - 3 0 cm using a cardboard extension to the cone of the X-ray machine. The dental X-ray unit (Heliodent MD, Siemens, Bensheim, Germany) was set at 70 kV, a current of 7 mA, and an exposure time of 0.25 s to give a radiographic density reading of - 2 (including base and fog) for the exposed and processed film under the 1-mm thick section of the stepwedge (Protex Ten-Step Aluminum Stepwedge, Everything X-Ray Ltd., Watford, UK). The specimens were placed directly on the film packet. A total of five films were taken for each specimen. The films were processed in an automatic developing machine (P10, Hope Industries, Letchworth, UK). The photographic densitometer (Melico/Photolog, B/W Transmission Densitometer, Model TDX, Medical and Electrical Instrumentation Ltd., London, UK) was used to take readings of the radiographic image of the specimens, each step of the stepwedge, and the unexposed part of the film. Three readings were taken for each film and the mean calculated. The net radiographic density was derived from the following equation: Net Radiographic Density = (Gross Radiographic Density) - (Base and Fog). Graphs were plotted for log-net radiographic density of the aIuminum steps versus thickness of aluminum (mm) for each group. These gave straight line plots, and from these the mean net radiographic density values of the materials were transformed into radiopacity expressed as equivalent thickness of aluminum.

Compressive Strength

The compressive strengths of test materials were determined according to the method recommended by the ISO (6). The instruments and the test materials were conditioned at 23 --- IC in the laboratory for 1 h before testing. Each material was mixed and placed in split stainless steel molds (12 mm high and 6 mm wide) within 2 min before start of mixing. Each mold was packed to excess and was placed on the bottom plate with the application of slight pressure. After removing any extruded material and placing the top plate, the mold and plates were clamped together. The whole assembly was transferred to an oven with a constant temperature of 37 -+ IC for 3 h within 3 rain after start of mixing. The specimens were removed from the molds and examined for voids and chipped edges. Defective specimens were discarded, and six acceptable samples were prepared for each test material for each time interval. The specimens were immersed in distilled water for 21 h or 3 wk before their compressive strengths were measured using an Instron 1185 Testing Machine (Instron Ltd., High Wycombe, UK). After placing each specimen with its fiat ends between the platens of the apparatus and ensuring that the load was applied in the long axis of the test sample, the maximum load required to fracture each specimen was noted, and the compressive strength (C) was calculated in Megapascals using the formula 4P ,n.D2

C-

where P is the maximum applied load in Newtons, and D is the mean diameter of the specimen in millimeters (6). One way analysis of variance with Duncan multiple comparisons were used to determine statistical differences between compressive strengths of the various test materials at both time intervals.

Solubility

The degree of solubility of test materials was determined by a modified method of the American Dental Association (ADA) specification #30 (7). The materials were prepared in line with manufacturers' recommendations. Super-EBA cement and MTA were hand-mixed, whereas amalgam and IRM were mixed in a machine. After mixing, each substance was made into a small disc

Setting Time

To determine and compare the setting time and compressive strength of MTA with other commonly used root-end filling materials, amalgam, Super-EBA, IRM, and MTA were mixed according to the manufacturers' directions and evaluated (Table 1).

Vol. 21, No. 7, July 1995

Root-End Filling Material

351

pH 13.0

1"10

[]

[]

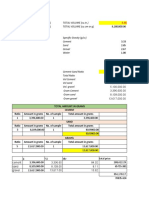

TABLE 2. Means and standard deviations (in parentheses) of compressive strength (MPa) for amalgam, Super-EBA, IRM, and MTA after two time intervals (n = 6)

12.0

Material Amalgam Super-EBA IRM

24 h 312.5 (20.1) 60.0 (5.5) 52.2 (3.4) 40.0

21 days 311.1 (23.8) 78.1 (9.3) 57.4 (5.9) 67.3

11.0

10.0

MTA

(4.4)

9.0

(6.6)

8.0 0

5o

lOO 1;o 2o0 2;0

3;0

" 1300 ' 1350

'

Time/mins

FIG 1. pH values of MTA at various time intervals. (20 mm 1.5 mm) by the use of a metal former and two glass plates. Mixing and weighing of the samples were performed by a single operator at 23 _ 2C and a relative humidity of 50 --- 5%. Six discs of each material were fabricated and tested. After fabrication, they were placed in 100% humidity for 21 h and then stored individually in glass bottles containing 50 ml of distilled water at 37C. The specimens were removed from the water after 1 day. All discs w e r e desiccated for 1 h at 37C. Each disc was then weighed to the nearest microgram. After weighing, each disc was replaced in the same glass bottle. The water in the bottles was neither changed nor added to during the test periods. The desiccation and weighing procedure was performed at 1 day, then at 7 and 21 days. Analysis of variance with Duncan multiple comparisons were used to determine statistical differences between weights of the test materials at different time intervals. RESULTS Examination of the MTA shows specific phases throughout the material. All MTA was divided into calcium oxide and calcium phosphate. Further analysis demonstrated that the former appeared as discrete crystals and the latter as an amorphous structure with no apparent crystal growth but a granular appearance. The mean value of the prisms was 87% calcium and 2.47% silica, the remainder being oxygen. In areas of amorphous structure, there seemed to be 33% calcium, 49% phosphate, 2% carbon, 3% chloride, and 6% silica. The change in pH as a function of time for MTA is shown in Fig. 1. The pH of MTA after mixing was 10.2, and it rose to 12.5 at 3 h; thereafter, it remained constant. The mean radiopacity for MTA was 7.17 mm of equivalent thickness of aluminum. The mean setting time and standard deviation for the test materials were as follows: amalgam, 4 min (+30 s); Super-EBA, 9 min (+-30 s); IRM, 6 min (+-30 s); and MTA, 2 h 45 min (+-5 min). The means and standard deviations of compressive strength of the test materials after the two time intervals are shown in Table 2. Amalgam had the highest compressive strength among the materials tested. Statistical analysis of the data regarding the remaining three materials showed that the compressive strength of Super-

EBA was significantly greater than that of IRM and MTA after 24 h (p < 0.05); compressive strength of IRM was significantly more than MTA (p < 0.05) at the same time interval. The compressive strength of all cements increased after 3 wk, and the strength of Super-EBA was significantly higher than that of IRM (p < 0.05), but there was no significant difference between the strengths of Super-EBA and MTA at these time intervals. The mean weights (g) of specimens and standard deviation for the test materials at various time intervals are shown in Table 3. Statistical analysis of the data regarding weight loss changes showed no significant changes for amalgam, Super-EBA, and MTA when the mean weight of the specimens were compared at different time intervals. However, when the mean weights of IRM specimens were compared between day 1 and those on days 7 and 21, significant differences were noted (p < 0.001). Similar differences were noted when the mean weight of the specimens were compared at day 7 versus day 21. DISCUSSION Numerous investigations have been performed to study the physical properties of dental filling materials (8-13). However, information regarding the physical properties of root-end filling materials is scant. Owadally and Pitt Ford (14) evaluated the effect of adding 10% and 20% hydroxyapatite (HAP) on the physical properties of IRM and found that IRM had longer mean working and mean setting times than IRM + 10% or 20% HAP. IRM also had a greater compressive strength than both IRM + 10% HAP or IRM + 20% HAP. In addition, their results indicated that adding 10% or 20% HAP to IRM causes disintegration of these materials in buffered phosphate and in bovine serum after 8 wk. In contrast, IRM and EBA cements showed no noticeable signs of disintegration in the same media after 6 months. MTA powder consists of fine hydrophilic particles. The principle compounds present in this material are tricalcium silicate, tricalcium aluminate, tricalcium oxide, and silicate oxide. In addition, there are small amounts of a few other mineral oxides that are responsible for the chemical and physical properties of this aggregate. Bismuth oxide powder has been added to make the aggregate radiopaque. Electron probe microanalysis of MTA powder showed that calcium and phosphorous are the main ions present in this material. Because these ions are also the principal components of dental hard tissues, MTA may prove to be biocompatible when used in contact with cells and tissues. In vitro and in vivo studies are in progress to test the biocompatibility of this material in cell culture and tissues. Induction of a hard tissue barrier, similar to that obtained in apexification procedures, following root-end

352

Torabinejad et al.

Journal of Endodontics

TABLE 3. Mean weight (g) of specimens and standard deviation for the four materials at various times

Time 1 day 7 days 21 days Amalgam 5.3961 _+ 0.1549 5.3959 + 0.1547 5.3961 _+ 0.1548 Super-EBA 1.4484 _+ 0.1147 1.4466 _+ 0.1148 1.4465 _+ 0.1144 IRM 1.1885 + 0.0319 1.1811 _+ 0.0315 1.1774 _+ 0.0315 MTA 1.1794 _+ 0.1100 1.1814 +_ 0.1122 1.1746 _+ 0.1130

filling would minimize the interaction between material and host tissues. Because MTA has a high pH similar to calcium hydroxide cement, it is possible that induction of hard tissue formation may occur following the use of this substance as a root-end filling material. Among other characteristics, an ideal root-end filling material should be more radiopaque than its surrounding structures when placed in a root-end cavity preparation. Shah et al. (15) determined the radiopacity of potential root-end filling materials using the same method utilized in our study and found that amalgam was the most radiopaque material tested ( > 10 mm equivalent thickness of aluminum). The radiopacity of other relevant test materials in their experiment was as follows: Kalzinol (7.97), gutta-percha (6.14), IRM (5.30), Super-EBA (5.16), and dentin (0.70). A comparison between the radiopacity of MTA and those of other potential root-end filling materials in Shah et al.'s (15) study shows that MTA is slightly less radiopaque than Kalzinol (reinforced zinc oxide-eugenol-based cement) and more radiopaque than IRM and Super-EBA. Because MTA is more radiopaque than conventional gutta-percha and dentin, it should be easily distinguishable on radiographs when used as a root-end filling material. Hydration of MTA powder results in a colloidal gel that solidifies to a hard structure in less than 3 h. The characteristics of the aggregate depend on the size of the particles, powder-to-water ratio, temperature, presence of water, and entrapped air (2). In this study, the ISO method of determining setting time was used (6). The results showed that amalgam had the shortest setting time and MTA the longest. The setting time for IRM in this study was very similar to that found by Owadally and Pitt Ford (14). It has generally been considered that a potential root-end filling material should set as soon as it is placed in the root-end cavity without significant shrinkage. This condition would allow dimensional stability of the material after placement and less time for an unset material to be in contact with vital tissues. However, in general terms, the quicker a material sets the more it shrinks. This phenomenon may explain why MTA in previous experiments had significantly less dye (2, 3) and bacterial (4) leakage than other materials tested as root-end filling materials. Compressive strength is an important factor to consider when a filling material is placed in a cavity that bears occlusal pressure. Because root-end filling materials do not bear direct pressure, the compressive strength of these materials is not as important as those materials used to repair defects in occlusal surfaces. In the present study, MTA initially had the lowest compressive strength among materials tested, but its value increased with time. In a previous report, the compressive strength of MTA was reported by mistake as being equal to amalgam (2). The increase in compressive strength of MTA required the presence of moisture. Longer term studies might provide further information on compressive strength of MTA in the presence of moisture. However, the compressive strength value obtained for MTA is similar to those obtained for Super-EBA, IRM, and zinc phosphate (69-117), (16). Solubility is another factor in assessing the suitability of potential substances to be used as restorative materials in dentistry

(8-13). Lack of solubility has also been stated as an ideal characteristic for root-end filling materials (1). Despite some advantages of controlled long-term clinical studies, variations in the oral environment among participating patients are a major drawback of such investigations. Because of the long setting time of MTA, the recommended methods by ISO (6) or ADA specification #30 (7) to test the solubility of MTA had to be modified. From our results, it seems that amalgam, Super-EBA, and MTA showed no signs of solubility in water; despite statistical differences between the mean weights of IRM specimens at three time intervals, the clinical significance of the mean differences-0.0074 g (day 1 versus day 7) and 0.0037 g (day 7 versus day 21)--is questionable. Owadally and Pitt Ford (14) evaluated the rate of disintegration of some zinc oxide-eugenol cements utilizing a replica method in conjunction with scanning electron microscopy, and found that IRM and Super-EBA showed no noticeable signs of disintegration after 6 months in buffered phosphate solution. Erosion of restorative filling materials can occur either by acids generated by bacteria, acids present in foods or beverages (17), or by mechanical wear. The root-end filling materials are normally in contact with periradicular tissue fluid until they are covered either with fibrous connective tissue or cementum. Clinically, biocompatible root-end filling materials with good sealing ability should generate little or no inflammatory response in periradicular tissues, and encourage formation of fibrous connective tissue and/or cementum covering the entire root-end. Mechanical wear, an important factor in coronal restoration, is not a significant factor in erosion of root-end filling materials. Based on the results of this study, it seems that MTA has adequate physical properties for use as a root-end filling material.

We thank Mr. PMM Shah for determining the radiopacity of MTA and Dr. M. Sherriff for determining the pH of MTA. Dr. Torabinejad is Professor of Endodontics and Director of Graduate Program in the Department of Endodontics, School of Dentistry, Loma Linda University, Loma Linda, CA. Dr. Hong is Associate Professor in Dankook University, School of Dentistry, Seoul, South Korea. Drs. McDonald and Pitt Ford are senior lecturers in the Departments of Oral Biology and Conservative Dental Surgery, United Medical and Dental Schools of Guy's and St. Thomas's Hospitals, University of London, London, UK.

References

1. Owadally ID, Chong BS, Pitt Ford TR, Watson TF. The sealing ability of IRM with the addition of hydroxyapatite as a retrograde root filling. Endod Dent Traumato11993;9:211-5. 2. Torabinejad M, Watson TF, Pitt Ford TR. The sealing ability of a mineral trioxide aggregate as a retrograde root filling material. J Endodon 1993;19:591-5. 3. Torabinejad M, Higa RK, McKendry DJ, Pitt Ford TR. Effects of blood contamination of dye leakage of root-end filling materials. J Endodon 1994; 20:159-63. 4. Torabinejad M, Falah Rastegar A, Kettering JD, Pitt Ford TR. Bacterial leakage of mineral trioxide aggregate as a root end filling material. J Endodon 1995;21:109-112. 5. Torabinejad M, Wilder Smith P, Pitt Ford TR. Comparative investigation of marginal adaptation of mineral trioxide aggregate and other commonly used root end filling materials. J Endodon 1995;6:295-299.

Vol. 21, No. 7, July 1995

6. International Organization for Standardization. Specification for dental root canal sealing materials. ISO 6876. London: British Standards Institution, 1986. 7. ANSI/ADA. Revised American National Standard/American Dental Association Specification No. 30 for dental zinc oxide eugenol cements and zinc oxide noneugenol cement 7.5, 1991. 8. Eichner K, Lauten Schlager EP, Von Radnoth M. Investigation concerning the solubility of dental cements. J Dent Res 1968;47:280-5. 9. Wilson AD. Specification test for the solubility and disintegration of dental cements: a critical evaluation of its meaning. J Dent Res 1976;55: 721-9. 10. Osborne JW, Swartz ML, Goodacre C J, Phillips RW, Gale EN. A method for assessing the clinical solubility and disintegration of luting cements. J Prosthet Dent 1978;40:413-7. 11. Beech DR, Bandyopadhyay S. A new laboratory method for evaluating

Root-End Filling Material

353

the relative solubility and erosion of dental cements. J Oral Rehabi11983;10: 57-63. 12. Kuhn AT, Wilson AD. The dissolution mechanisms of silicate and glass-ionomer dental cements. Biomaterials 1985;6:378-82. 13. Ono K, Matsunoto K. The physical properties of a new sealing cement. Int Endod J 1992;25:130-3. 14. Owadally ID, Pitt Ford TR. Effect of addition of hydroxyapatite on the physical properties of IRM. Int Endod J 1994;27:227-32. 15. Shah PMM, Chong BS, Sidhu SK, Pitt Ford TR. Radiopacity of potential root end filling materials. Oral Surg (in press). 16. Craig RG. In: Restorative dental materials. 7th ed. St. Louis: CV Mosby, 1985:170. 17. Pluim LJ, Arends J. The relationship between salivary properties and in vivo solubility of dental cements. Dent Mater 1987;3:13-8.

A Word for the Wise A recent article, written by a person not in the legal profession but who had once been, was attributed to a "recovering" lawyer. I like that; will they form a Barristers Anonymous organization?

I. Solon

También podría gustarte

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Ford Everes PDFDocumento584 páginasFord Everes PDFTiến Hồ100% (6)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Machine Element Design CheatsheetDocumento25 páginasMachine Element Design CheatsheetDarien ChiaAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- (Conectores) SandhaasC Munch-AndersenJ DietschP DesignofConnectionsinTimberStructures PDFDocumento332 páginas(Conectores) SandhaasC Munch-AndersenJ DietschP DesignofConnectionsinTimberStructures PDFClaudio Ignacio Zurita MillónAún no hay calificaciones

- Psychrometrics FormulaeDocumento5 páginasPsychrometrics Formulaetmy3dataAún no hay calificaciones

- AGMA 9002-A86 Inch Bore and ANSI B17.1 Square Keyway TolerancesDocumento6 páginasAGMA 9002-A86 Inch Bore and ANSI B17.1 Square Keyway TolerancesEmmanuel García100% (1)

- 240-109607332 Eskom Plant Labelling Abbreviation StandardDocumento638 páginas240-109607332 Eskom Plant Labelling Abbreviation StandardiabhuaAún no hay calificaciones

- Fortranv 7Documento173 páginasFortranv 7mu4viewAún no hay calificaciones

- 380LC9S Performance PDFDocumento21 páginas380LC9S Performance PDFLuis Antonio Vega ParangueoAún no hay calificaciones

- ACI 232.1 Use of Pozzolans in ConcreteDocumento24 páginasACI 232.1 Use of Pozzolans in ConcreteSree Nivas100% (1)

- Biochimica Et Biophysica ActaDocumento6 páginasBiochimica Et Biophysica ActahajingukAún no hay calificaciones

- The Reactions of Copper Proteins With Nitric Oxide: ReviewDocumento13 páginasThe Reactions of Copper Proteins With Nitric Oxide: ReviewhajingukAún no hay calificaciones

- Polymer: Fei Zeng, Ying Han, Zhi-Chao Yan, Chen-Yang Liu, Chuan-Feng ChenDocumento7 páginasPolymer: Fei Zeng, Ying Han, Zhi-Chao Yan, Chen-Yang Liu, Chuan-Feng ChenhajingukAún no hay calificaciones

- Journal of Environmental Chemical Engineering: Farooq Sher, Atiq Malik, Hao LiuDocumento6 páginasJournal of Environmental Chemical Engineering: Farooq Sher, Atiq Malik, Hao LiuhajingukAún no hay calificaciones

- JCPDS 2Documento8 páginasJCPDS 2hajingukAún no hay calificaciones

- Industrial Engineering - Paradoxical Twins - Acme and Omega ElectronicsDocumento2 páginasIndustrial Engineering - Paradoxical Twins - Acme and Omega Electronicslollypop0606Aún no hay calificaciones

- Enemy Territory - Quake Wars - ManualDocumento22 páginasEnemy Territory - Quake Wars - ManualM_MolliAún no hay calificaciones

- TK3302 - Service Manual PDFDocumento40 páginasTK3302 - Service Manual PDFsil182Aún no hay calificaciones

- Case Adhesives BrochureDocumento6 páginasCase Adhesives BrochureChanakyaAún no hay calificaciones

- 1.ar-315 BC&BL Lighting & IlluminationDocumento28 páginas1.ar-315 BC&BL Lighting & IlluminationUsha Sri GAún no hay calificaciones

- K.analysis of The Articulated Robotic Arm (TITLE DEFENCE)Documento22 páginasK.analysis of The Articulated Robotic Arm (TITLE DEFENCE)sky4sterAún no hay calificaciones

- Caterpillar 990H BrochureDocumento20 páginasCaterpillar 990H BrochureEugene MalinowskiAún no hay calificaciones

- Autovue IntegrationDocumento4 páginasAutovue IntegrationmansrallyAún no hay calificaciones

- 08 Sep-603b Thol Ret 670Documento9 páginas08 Sep-603b Thol Ret 670m khAún no hay calificaciones

- Work at Height Questions For Height PassDocumento3 páginasWork at Height Questions For Height PassPravash Mohanty100% (1)

- Day 1 Borehole Geophysics WDocumento21 páginasDay 1 Borehole Geophysics Waliy2k4uAún no hay calificaciones

- Report Specification ExampleDocumento19 páginasReport Specification ExampleGarry RamirezAún no hay calificaciones

- Computation For Concrete Mix 120221Documento3 páginasComputation For Concrete Mix 120221MASGRO BUILDERSAún no hay calificaciones

- ProeDocumento160 páginasProejohn100% (1)

- B200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10Documento4 páginasB200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10George P ReynoldsAún no hay calificaciones

- 2014 03 Istanbul PDFDocumento3 páginas2014 03 Istanbul PDFFaraj DividAún no hay calificaciones

- Excel ExercisesDocumento37 páginasExcel ExercisesBERNIELLE DAVE FALDASAún no hay calificaciones

- Inspection & Maintenance of Dams: Dam Safety GuidelinesDocumento79 páginasInspection & Maintenance of Dams: Dam Safety Guidelinesvishu1909100% (1)

- Astm D 7070-04Documento6 páginasAstm D 7070-04Pamela SanabriaAún no hay calificaciones

- Nokia c7-00 Rm-675 Rm-691 Service Manual-12 v6Documento32 páginasNokia c7-00 Rm-675 Rm-691 Service Manual-12 v6sasquatch69Aún no hay calificaciones

- Columns: Advance of Computation Since These Codes FallDocumento2 páginasColumns: Advance of Computation Since These Codes FallAbhimanyu RavindranathAún no hay calificaciones