Documentos de Académico

Documentos de Profesional

Documentos de Cultura

High Speed Harmonic Drive Gearing

Cargado por

Mohanraj SelvakumarDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

High Speed Harmonic Drive Gearing

Cargado por

Mohanraj SelvakumarCopyright:

Formatos disponibles

High Speed Harmonic Drive Gearing

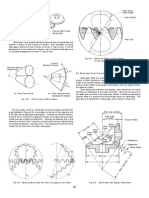

Automation equipment is constantly seeking increased throughput-it's a never ending requirement. For power transmission components, this translates into either higher motor speeds or lower gear ratios. Most applications desire lower gear ratios since life, wear, and noise generally increase with higher speed option. Harmonic drive gearing is a popular choice for many automation applications because of its superior power transmission qualities, which include zero backlash, high torsional stiffness,high positional accuracy, and torque-to-weight ratios. Until recently, however, the lowest gear ratio available has been 50:1. New proprietary tooth design technology has substantially reduced this old limit, making ratios of 30:1 possible. To see how this breakthrough in harmonic drive gearing technology occurs, we'll first need to review the fundamentals of harmonic drive gearing tooth action. Figure 1 shows the three components of harmonic drive gearing: the circular spline, the flexspline, and the elliptical wave generator. Figure 2 shows the operating principle for this mechanism (flexspline deflection is greatly exaggerated for clarity). The gear ratio formula for harmonic drive gearing is; FS GR = (CS-FS) with the tooth differential between the circular spine (CS) and the flexspline (FS) accounting for the gear ratios (GR) achieved. For example, to satisfy the formula, an 80:1 ratio would have 160 teeth on the flexspline and 162 teeth on the circular spline. The two-tooth advance for every revolution of the elliptical generator, or one flexspline advance for every 80 revolutions of the wave generator in this particular example.

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98 Toll Free Fax (877) SERV099 www.electromate.com sales@electromate.com

Harmonic drive gears operate by engaging multiple teeth at the major axes while disengaging them at the minor axes of the wave generator ellipse. To minimize flex stress in the flexspline, our goal is to keep ellipicity to a minimum, which leads us to small tooth height. Achieving a 50:1 ratio, for example, means producing a 100-tooth circular spline. As the number of teeth decreases, their size increases; consequently, ellipicity must increase to provide the required clearance at the minor axis. In older designs, ratios below 80:1 more often than not made use of a four-tooth difference, usually doubling the number of teeth to 200 for a 50:1 ratio in order to reduce the tooth size. Achieving a ratio of approximately 30:1 meant changes in the tooth design were required. HD Systems introduced the "S"-tooth design in 1991. This profile, a departure from the old involute-tooth form, brought many advantages to harmonic drive gearing, such as increased torque capacity, stronger teeth, longer life, and higher torsional stiffness. Figure 3 shows the "S"-tooth profile and the relative motions of the flexspline and circular spline in operation. Developing the new tooth form required significant design analysis, resulting in a profile that lets high numbers of teeth in simultaneous contact share in carrying the load while keeping a low ellipticity. This "S"-tooth profile brought another benefit to harmonic drive gearing by permitting a reduction in ratio down to 50:1, using the two-tooth difference. Nonetheless, getting 30:1 ratios with a two-tooth difference required further profile modifications. In the past, the axisymmetric nature of harmonic drive gearing permitted the use of two-dimensional modeling, which was sufficient to study the kinematics and stress distribution for ratios of 50:1 and higher. However, the demands of 30:1 ratios required a degree of modeling sophistication that two-dimensional models could not deliver. We developed a complex three-dimensional simulation of tooth engagement so that parameters of the "S"-tooth profile could be studied, examined, and modified for optimum engagement and minimum wear. This procedure included detailed finite element analysis of the flexspline toothbed, identifying high stress areas and allowing design modifications for reducing stress to safe and reliable limits.

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98 Toll Free Fax (877) SERV099 www.electromate.com sales@electromate.com

Figure 4 shows the new "S"-tooth (for 30:1) action in the circular-spline/flexspline interface. The result is a new profile that permits 30:1 gear ratios using the two-tooth difference, minimizing ellipticity and maintaining low flexspline stresses. In addition, this new "S"-tooth profile still provides all of the benefits of "S"-tooth harmonic drive gearing. This technology can be incorporated into the complete into the complete range of products, including component sets, gearheads, and servo actuators. With the new lower ratios available, harmonic drive gearing may now be used in applications where planetary or other low-ratio gears might have been used previously, thus allowing a reduction in package size and weight while increasing positional accuracy and achieving zero backlash. This new tooth profile is a major step forward in expanding the range of applications suitable for harmonic drive gearing and in addressing industry's need for increased throughput and accuracy.

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98 Toll Free Fax (877) SERV099 www.electromate.com sales@electromate.com

También podría gustarte

- AGMA Technical PaperDocumento14 páginasAGMA Technical PaperLuis TestaAún no hay calificaciones

- Spiral Bevel Gear - Calculation of StrenghtDocumento28 páginasSpiral Bevel Gear - Calculation of StrenghtCarlo_Filippin85% (13)

- CN101134256ADocumento11 páginasCN101134256ANipun HarshaAún no hay calificaciones

- Engranajes: Diseño y CinemáticaDocumento10 páginasEngranajes: Diseño y CinemáticaOscar SaldivarAún no hay calificaciones

- Long Addendum Gears 1946Documento15 páginasLong Addendum Gears 1946Marco ViniciusAún no hay calificaciones

- Even The Worm Will TurnDocumento2 páginasEven The Worm Will Turnnagaraj.ss@quest-global.comAún no hay calificaciones

- Space Lubrication and Performance of Harmonic Drive GearsDocumento8 páginasSpace Lubrication and Performance of Harmonic Drive GearsyayichangAún no hay calificaciones

- Jabatan Kejuruteraan Mekanikal Jj513Documento12 páginasJabatan Kejuruteraan Mekanikal Jj513Mohd Sabaruddin Mohd SallehAún no hay calificaciones

- Self-Locking Gear - Design and Potential ApplicationsDocumento7 páginasSelf-Locking Gear - Design and Potential ApplicationsVikram BalajiAún no hay calificaciones

- Analysis of ToothDocumento9 páginasAnalysis of ToothvijaykhandgeAún no hay calificaciones

- No Backlash DrivesDocumento28 páginasNo Backlash Drivesmustafa taiforAún no hay calificaciones

- Machine Design 7Documento5 páginasMachine Design 7birhanutaye427Aún no hay calificaciones

- Introduction To Direct Gear DesignDocumento15 páginasIntroduction To Direct Gear DesignburaktuncerAún no hay calificaciones

- Mech - Ijmperd-Design and Finite Element-Nihad Hasan TalibDocumento12 páginasMech - Ijmperd-Design and Finite Element-Nihad Hasan TalibTJPRC PublicationsAún no hay calificaciones

- Gears: Pinion Gear, Step Down DriveDocumento42 páginasGears: Pinion Gear, Step Down DriveIshan VermaAún no hay calificaciones

- Gear DesignDocumento67 páginasGear DesignrobineAún no hay calificaciones

- The Generation Principle and Mathematical Models of A Novel Cosine Gear DriveDocumento14 páginasThe Generation Principle and Mathematical Models of A Novel Cosine Gear DriveRobin MachargAún no hay calificaciones

- 19FTM05. Design of A Double Spiral Bevel Gearset: ISBN: 978-1-64353-044-4Documento1 página19FTM05. Design of A Double Spiral Bevel Gearset: ISBN: 978-1-64353-044-4gioAún no hay calificaciones

- Gear CouplingDocumento4 páginasGear Couplingmartín_suárez_11Aún no hay calificaciones

- Influence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationDocumento7 páginasInfluence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationsamanaveenAún no hay calificaciones

- Gear Geometry For Reduced and Robust Transmission Error and Gearbox NoiseDocumento21 páginasGear Geometry For Reduced and Robust Transmission Error and Gearbox Noiseranim najibAún no hay calificaciones

- Tip ReliefDocumento12 páginasTip ReliefShriyaAgarwalAún no hay calificaciones

- Analysis of A Gear Train Using Finite Element Modelling: Tawanda MushiriDocumento10 páginasAnalysis of A Gear Train Using Finite Element Modelling: Tawanda MushirilitonAún no hay calificaciones

- EoT Study MaterialsDocumento24 páginasEoT Study Materialsishika SHANDILYAAún no hay calificaciones

- Mill Spindle Advanced Gear Design: William R. HerbstrittDocumento5 páginasMill Spindle Advanced Gear Design: William R. HerbstrittTRUNG QUOC LEAún no hay calificaciones

- Ijirt162719 PaperDocumento5 páginasIjirt162719 Paperuday chavanAún no hay calificaciones

- Static and Dynamic Analysis of High Contact Ratio Spur GearDocumento18 páginasStatic and Dynamic Analysis of High Contact Ratio Spur GearTibebu MerideAún no hay calificaciones

- Gear Defect Modeling of A MultipleDocumento12 páginasGear Defect Modeling of A MultipleJose Luis RattiaAún no hay calificaciones

- Bending Load Capacity Enhancement Using Asymmetric Tooth ProfilesDocumento7 páginasBending Load Capacity Enhancement Using Asymmetric Tooth ProfilesJavier Antonio Cardenas OliverosAún no hay calificaciones

- Dynamic Simulation of Meshing Force in Broken Tooth Involute Gear Meshing Process Based On ADAMSDocumento4 páginasDynamic Simulation of Meshing Force in Broken Tooth Involute Gear Meshing Process Based On ADAMSAsha VenkataramAún no hay calificaciones

- Gear CuttingDocumento56 páginasGear Cuttingiyerrahul2679350% (2)

- Gear - New World EncyclopediaDocumento12 páginasGear - New World EncyclopediaNaveen ChakradharAún no hay calificaciones

- 4.0 Gears: Introduction: The Slip and Creep in The Belt or Rope Drives Is A Common Phenomenon, in TheDocumento50 páginas4.0 Gears: Introduction: The Slip and Creep in The Belt or Rope Drives Is A Common Phenomenon, in TheSham SundarAún no hay calificaciones

- Gear System: Shri Balwant Institute of TechnologyDocumento12 páginasGear System: Shri Balwant Institute of TechnologySreejith BabuAún no hay calificaciones

- Effect of Addendum Modification On Root Stress Involute Spur GearsDocumento71 páginasEffect of Addendum Modification On Root Stress Involute Spur GearsAbhishek JoshiAún no hay calificaciones

- GEAR TOOTH PROFILESDocumento5 páginasGEAR TOOTH PROFILESpremnathgopinathanAún no hay calificaciones

- Bevel Gear Transmission AnglesDocumento6 páginasBevel Gear Transmission AnglesNabende UmarAún no hay calificaciones

- Harmonic DriveDocumento3 páginasHarmonic DriveDaniel AndoneguiAún no hay calificaciones

- High Speed Gears-Design and Application by James R. PartridgeDocumento10 páginasHigh Speed Gears-Design and Application by James R. PartridgeAbbasAnsariAún no hay calificaciones

- GearDocumento30 páginasGearsai babuAún no hay calificaciones

- Project Report On Analysis of Propeller ShaftDocumento24 páginasProject Report On Analysis of Propeller ShaftGurpreet Singh50% (8)

- Suspension Paper 5Documento6 páginasSuspension Paper 5Rainier EstradaAún no hay calificaciones

- An Algorithm For Robust Gear Modifications DesignDocumento16 páginasAn Algorithm For Robust Gear Modifications DesignAbhijeet DeshmukhAún no hay calificaciones

- Isma2012 0731Documento12 páginasIsma2012 0731ranim najibAún no hay calificaciones

- Harmonic GearDocumento10 páginasHarmonic GearMaintenance HalolAún no hay calificaciones

- Din 3967-1978 EngDocumento24 páginasDin 3967-1978 EngLatha Pundi100% (4)

- Ijmet: ©iaemeDocumento9 páginasIjmet: ©iaemeIAEME PublicationAún no hay calificaciones

- Back To Iiasics, ... : Design Involute GearDocumento11 páginasBack To Iiasics, ... : Design Involute Gearabdul rachim100% (1)

- MECH 344/M Machine Element DesignDocumento75 páginasMECH 344/M Machine Element DesignlitonAún no hay calificaciones

- 19FTM03. Spline Centering, Piloting, and Toggle: Torsional Stiffness, Shaft Bending, and Centering of Moment LoadsDocumento1 página19FTM03. Spline Centering, Piloting, and Toggle: Torsional Stiffness, Shaft Bending, and Centering of Moment LoadsgioAún no hay calificaciones

- Shaft AnalysisDocumento28 páginasShaft Analysissaravan2015Aún no hay calificaciones

- Analysis of Spur Gear Using Composite MaterialDocumento9 páginasAnalysis of Spur Gear Using Composite MaterialIJRASETPublicationsAún no hay calificaciones

- Traction Control ArticleDocumento8 páginasTraction Control ArticledromakiAún no hay calificaciones

- Asymmetric Cylindrical GearsDocumento6 páginasAsymmetric Cylindrical Gearsकृष्णकुमार दत्तात्रेय जोशीAún no hay calificaciones

- A Crowning Achievement For Automotive ApplicationsDocumento10 páginasA Crowning Achievement For Automotive ApplicationsCan CemreAún no hay calificaciones

- KissSoft Article GearAnalysisAndOptimization PDFDocumento12 páginasKissSoft Article GearAnalysisAndOptimization PDFeng13Aún no hay calificaciones

- ProjectDocumento22 páginasProjectManoj Kumar SarangiAún no hay calificaciones

- Vehicle Gearbox Noise and Vibration: Measurement, Signal Analysis, Signal Processing and Noise Reduction MeasuresDe EverandVehicle Gearbox Noise and Vibration: Measurement, Signal Analysis, Signal Processing and Noise Reduction MeasuresAún no hay calificaciones

- Semi-Active Suspension Control Design for VehiclesDe EverandSemi-Active Suspension Control Design for VehiclesCalificación: 5 de 5 estrellas5/5 (1)

- Carbide Hobs: Pfauter-:Maaig Cutting Tools - .Iud.Documento8 páginasCarbide Hobs: Pfauter-:Maaig Cutting Tools - .Iud.Mohanraj SelvakumarAún no hay calificaciones

- The HMK Guide To Sizing of Servo Motors and AmplifierDocumento23 páginasThe HMK Guide To Sizing of Servo Motors and AmplifierMohanraj SelvakumarAún no hay calificaciones

- Servo FundamentalsDocumento12 páginasServo FundamentalsMohanraj SelvakumarAún no hay calificaciones

- SCARA Robot KinematicsDocumento5 páginasSCARA Robot KinematicsPrasanth Kurapati100% (3)

- A Closed Form Inverse Kinematics of Redundand RobotDocumento26 páginasA Closed Form Inverse Kinematics of Redundand RobotMohanraj SelvakumarAún no hay calificaciones

- Optimal Selection of Motor and Gearhead in Mechatronic ApplicationsDocumento10 páginasOptimal Selection of Motor and Gearhead in Mechatronic ApplicationsMohanraj SelvakumarAún no hay calificaciones

- Basic Brushless Servomotor SizingDocumento4 páginasBasic Brushless Servomotor SizingMohanraj SelvakumarAún no hay calificaciones

- LVDT BasicDocumento4 páginasLVDT Basicวิรัตน์ พ่อไทเกอร์Aún no hay calificaciones

- Introduction To Inverse Kinematics With Jacobian Transpose, Pseudo Inverse and Damped Least Squares MethodsDocumento19 páginasIntroduction To Inverse Kinematics With Jacobian Transpose, Pseudo Inverse and Damped Least Squares MethodsbidibupAún no hay calificaciones

- ME-Paper Code-A GATE 2011: Answer: - (B) ExplanationDocumento22 páginasME-Paper Code-A GATE 2011: Answer: - (B) ExplanationIMLOGANAún no hay calificaciones

- GATE ME 2002 Section A Mock TestDocumento12 páginasGATE ME 2002 Section A Mock TestgopicryoAún no hay calificaciones

- Mechanical Engg-1996 Gate PaperDocumento15 páginasMechanical Engg-1996 Gate PaperAshish KotwalAún no hay calificaciones

- Me 1993Documento4 páginasMe 1993Amit KhatriAún no hay calificaciones

- Mechanical Engineering-1995Documento8 páginasMechanical Engineering-1995நந்த குமார் சம்பத் நாகராஜன்Aún no hay calificaciones

- Test Booklet Primary-1 PDFDocumento53 páginasTest Booklet Primary-1 PDFReynold Morales Libato100% (1)

- Bulletin 13.9.22Documento4 páginasBulletin 13.9.22dbq088sAún no hay calificaciones

- ISO 18794. Café. Análisis Sensorial. Vocabulario. Ingles PDFDocumento16 páginasISO 18794. Café. Análisis Sensorial. Vocabulario. Ingles PDFluigi sanchezAún no hay calificaciones

- I Forgot My Password: LoginDocumento6 páginasI Forgot My Password: LoginMithun ShinghaAún no hay calificaciones

- Mutual FundDocumento40 páginasMutual Fundn kAún no hay calificaciones

- Vacuum Pump Manual (English)Documento12 páginasVacuum Pump Manual (English)nguyen lam An100% (1)

- Stages On The Empirical Program of RelativismDocumento9 páginasStages On The Empirical Program of RelativismJorge Castillo-SepúlvedaAún no hay calificaciones

- Transition Care For ChildrenDocumento19 páginasTransition Care For ChildrenapiresourcesAún no hay calificaciones

- Queueing in The Linux Network StackDocumento5 páginasQueueing in The Linux Network StackusakAún no hay calificaciones

- Lineshaft Turbine Pump 1800 RPM 60 HZDocumento156 páginasLineshaft Turbine Pump 1800 RPM 60 HZFayez Al-ahmadiAún no hay calificaciones

- Family Values, Livelihood Resources and PracticesDocumento285 páginasFamily Values, Livelihood Resources and PracticesRogelio LadieroAún no hay calificaciones

- TPS6 LecturePowerPoint 11.1 DT 043018Documento62 páginasTPS6 LecturePowerPoint 11.1 DT 043018Isabelle TorresAún no hay calificaciones

- Kodak 3D 電腦斷層系統Documento28 páginasKodak 3D 電腦斷層系統fomed_twAún no hay calificaciones

- The Reaction Between Potassium Permanganate and Oxalz'c AcidDocumento3 páginasThe Reaction Between Potassium Permanganate and Oxalz'c AcidNorazwan NorAún no hay calificaciones

- The Grand Landscape - Ian PlantDocumento145 páginasThe Grand Landscape - Ian PlantJohanny Bravo100% (1)

- Assignment On Dam EngineeringDocumento2 páginasAssignment On Dam EngineeringChanako DaneAún no hay calificaciones

- Paul of Aegina LaminectomyDocumento9 páginasPaul of Aegina LaminectomypepepartaolaAún no hay calificaciones

- Fire Resistance Ratings - ANSI/UL 263: Design No. U309Documento4 páginasFire Resistance Ratings - ANSI/UL 263: Design No. U309DavidAún no hay calificaciones

- Testing ReadingDocumento11 páginasTesting ReadingJoan Herbosa100% (1)

- Pageant Questions For Miss IntramuralsDocumento2 páginasPageant Questions For Miss Intramuralsqueen baguinaon86% (29)

- MPP3914 - 36 11 00 05 1Documento24 páginasMPP3914 - 36 11 00 05 1clebersjcAún no hay calificaciones

- Lecture Nsche Engr Mafe SIWESDocumento38 páginasLecture Nsche Engr Mafe SIWESoluomo1Aún no hay calificaciones

- Business Ethics and Social ResponsibilityDocumento16 páginasBusiness Ethics and Social Responsibilitytitan abcdAún no hay calificaciones

- SQL QuestionsDocumento297 páginasSQL Questionskeysp75% (4)

- Crema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketDocumento33 páginasCrema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketTDLemonNhAún no hay calificaciones

- DECIDE ChecklistDocumento2 páginasDECIDE ChecklistGuilioAún no hay calificaciones

- Form 2 Physics HandbookDocumento90 páginasForm 2 Physics Handbookmosomifred29Aún no hay calificaciones

- R 449 PDFDocumento24 páginasR 449 PDFKhaleel KhanAún no hay calificaciones

- Biomed Part-B QuestionsDocumento4 páginasBiomed Part-B QuestionsNirmal KumarAún no hay calificaciones

- Science and Technology Study Material For UPSC IAS Civil Services and State PCS Examinations - WWW - Dhyeyaias.comDocumento28 páginasScience and Technology Study Material For UPSC IAS Civil Services and State PCS Examinations - WWW - Dhyeyaias.comdebjyoti sealAún no hay calificaciones