Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Mig 15

Cargado por

Riadh FantarDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Mig 15

Cargado por

Riadh FantarCopyright:

Formatos disponibles

M i k o y a n - G u r e v i c h

F l y i n g Pa p e r A i r p l a n e

!

!

!

Launch with a rubber band for extra long flights!

Aerodynamic design will produce exciting barrel

rolls and loops.

Simple constructions techniques get you flying

with a sturdy plane that can take a beating.

1999 KittyHawk Software, Inc.

H

o

r

i

z

o

n

t

a

l

S

t

a

b

i

l

i

z

e

r

Canopy

Wing

Rubber Band

Launcher

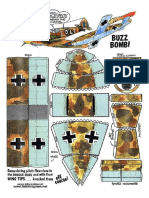

Print on 80 pound card stock paper.

Design Page 1 of 2

Always be careful of people around

you when flying your plane.

Mikoyan-Gurevich MiG-15

Flying Paper Airplane Model

1999 KittyHawk Software, Inc.

Score & Fold

Score & Fold

Score & Fold

Score & Fold

Score & Fold

Cut

Score & Fold

S

c

o

r

e

&

F

o

l

d

C

u

t

o

u

t

b

l

a

c

k

a

r

e

a

2

1

11

10

Cut out

black area

Cut out

black area

Nose Weight

Nose Weight

Nose

Fuselage

Front

Vertical

Stabilizer

Fuselage

Rear

Main

Fuselage

Glue a penny

behind this part.

G

l

u

e

C

a

n

o

p

y

H

e

r

e

C

u

t

&

B

e

n

d

D

o

w

n

C

u

t

&

B

e

n

d

D

o

w

n

Score & Fold

Print on 80 pound card stock paper.

Design Page 2 of 2

Always be careful of people around

you when flying your plane.

Mikoyan-Gurevich MiG-15

Flying Paper Airplane Model

1999 KittyHawk Software, Inc.

9

5

6

4

3

8

7

R

u

b

b

e

r

b

a

n

d

l

a

u

n

c

h

e

r

R

u

b

b

e

r

b

a

n

d

l

a

u

n

c

h

e

r

1

2

3

5

6

8

9

10

11

7

4

Assembly Instructions

Tools: Scissors, White Glue, Ruler, "Dead" Pen (no ink left) & Hobby Knife.

1. Begin by printing the two design (pattern) pages on 65#-80# cover weight card stock. This is important

because your plane will not fly if printed on too heavy or too light paper. You can usually find this type of

paper at an office supply store. Check your printer's instructions for printing on heavy paper.

2. Using your "dead" pen & ruler, score all of the blue dashed lines on both design pages. Try to score as

accurately as possible to ensure you plane goes together properly.

3. Cut out part number 1. This is the wing for your plane. Fold the part along all of the score lines. The

tabs on the back and bottom of the wing are folded over flat. Run a line of glue along the tab and wingtip

areas. Fold the top of the wing over and down on top of the glue areas. Carefully line the edges of the

wing halves. You'll notice the top of the wing has a crease and is slightly raised above the bottom wing,

this is to add strength to the wing. Repeat this on the other side of the wing.

Fold the tab on the center front of the wing down flat. Run a line of glue along the white areas of the two

wing halves and tab and fold the center section over. Before the glue dries, make sure the bottom of the

wing is flat and not twisted. This makes a big difference in the performance of your plane. Set the wing

aside.

4. Cut out part number 2. This is the horizontal stabilizer. Don't forget to cut the black slit in

the front of the stabilizer. Fold the two bottom halves of the

stabilizer over. Fold the four tabs attached to the halves back

(these will attach the stabilizer to the vertical stabilizer later).

Run a line of glue around the edges of the stabilizer making

sure the top and bottom half edges are lined up. Set the

horizontal stabilizer aside.

5. Cut out parts number 3-6. These will become the

nose of your plane. Form part number 3 into a

cone and glue. Glue a penny on the back of part

number 4 and fold the triangular shaped tabs

down. Put a line of glue around the

triangular shaped tabs on part 4 and insert

it into the nose section (part #3) until it

is flush with the front. Roll parts 5

then 6 into cones and glue them

inside part number 3. This adds

strength to the nose of your

plane.

6. Cut out part number

7. This will be the

rear end of the

Tip: Cut out the parts as they are needed so you don't loose track of which part is which.

1999 KittyHawk Software, Inc.

fuselage. Form the part into a cone and glue.

7. Cut out part number 8. This will be the main section of the fuselage. Don't forget to cut the two red lines

on each side for the wing. Form the part into a tube and glue.

8. Glue part 7 (fuselage rear) into the back of part number 8 (nearest the red stars). Make sure you line up

the seams on the bottom of the two parts.

9. Glue the nose section on the front of the fuselage. Make sure you line up the seams on the bottom of the

parts.

10. Cut out part number 9. Don't forget to cut out the black slits on the top of the part. This is the vertical

stabilizer. Fold the four tabs up, then fold the part in half. Run a line of glue around the top and back edges.

Do not put any glue along the tab edges as the part will need to open up slightly like an envelope.

11. Stick a pencil or pen up inside part 9 to spread it apart slightly. Glue part number 9 (vertical stabilizer)

tabs to the top rear of the fuselage on the white areas. By spreading the stabilizer apart slightly, it is much

sturdier and will stand up straight.

12. Glue the horizontal stabilizer (part 2) to the vertical stabilizer. The two parts will interlock with the slits

cut earlier. The tabs are glued to the white areas on the vertical stabilizer.

13. Fold the two tabs on each side of the fuselage down and insert the wing. Line the wing up so it is

centered in the fuselage. Put a little glue on each tab to hold the wing in place.

14. Cut out part number 10. This is the canopy. Form the part into a half circle and glue. Fold the two tabs

on the sides up and glue the canopy into place on the top of the fuselage. The front of the canopy will be

right at the seam between the main fuselage and nose section.

15. Cut out part number 11. This is the attachment point for your rubber band launcher. Fold in half along

the center crease and the two side panels back. Put some glue on the triangular shaped center section and

glue together. Put some glue on the two tabs and glue to the bottom of the fuselage in the area indicated.

Congratulation! Your plane is now done.

Making a rubber band launcher.

1. Lay the rubber band flat on the table with a stick or

pencil on top.

2. Take one end of the rubber band over the stick and feed

it through the loop on the other end of the rubber band.

3. Pull the rubber band tight so that it does not slip on the

stick.

To make a longer launcher, follow the same steps on the end of the first rubber band with a second and third

rubber band so you have a launcher with longer rubber band.

1 2 3

1999 KittyHawk Software, Inc.

For more paper model fun, visit:

www.paperparadise.com

Flying Tips and Adjustments

Are you having troubles getting your plane to fly? First, look at the plane with the nose towards you. Make sure

the fuselage (body of the plane), wings and tail are not warped and the wing and fuselage are perpendicular (at right

angles) to each other. If the pieces are made well, then pay close attention to what the plane is doing and you

should be able to correct it. There are four basic problems your plane can have: Dive, Stall, Fade and Spin. Here

are some tips for correcting them:

Dive: If your plane consistently dives toward the ground when you throw it,

try to bend the elevators, the back edges of the horizontal stabilizer, up just a

little until it stops.

Stall: If your plane consistently wants to climb upward then runs out of

airspeed and tumbles to the ground, then try to bend the elevators, the back

edges of the horizontal stabilizer, down just a little until it stops.

Turn and roll: If your plane constantly turns to the right or left when you

throw it, then bend the aileron, the rear edge of the wing, to the side it is

fading to down slightly. So if your plane keeps fading off to the right, then

bend the rear most edge of the right wing, down slightly.

Launching Your Plane

Once you have made a few hand tosses and have the plane flying straight and level, you are ready for a rubber band launch.

When launching your plane with the rubber band, the plane leaves your hands at a high rate of speed. It is so fast

that someone near you will not be able to get out of the way in time to not get hit. So make sure all people near you are far enough away

and aware that you are preparing to launch your plane.

Never use the rubber band launcher indoors or near a busy street. Many of these planes can fly up to 50 feet high and over 60 yards when

launched with the rubber band.

When launching, you first need to determine which direction the wind is blowing. To determine the direction of the wind, look around for a

flag or at the trees. If you are still unsure, pick up a pinch of dirt or grass and toss it into the air. Watch what direction the dust or grass

float down.

Your plane is a glider so the wind will greatly determine where it is going to go. Make sure that the wind will not take your plane and sail it

over in a direction that is not desirable, like your neighbors roof or in your swimming pool.

You will have the best flights when you launch perpendicular to the wind. Depending upon the wind speed you may also want to try and

launch directly into the wind. If you are near a building or trees, the wind may be swirling. Try to get away from the swirling wind.

Now, with your rubber band launcher in one hand, hook the rubber band on the launching point on the plane. Hold on to the rubber band

where it goes around the launching point on the plane (pinch it between your thumb and index finger). Pull back and extend your hand

holding the stick forward. Make sure the plane and stick are clear of your body. Aim up at approximately 45 degrees and let go!

Safety is always first.

To stop dive, bend up

To stop stall, bend down

To stop left turn, bend down

1999 KittyHawk Software, Inc.

KittyHawk Software, Inc.

P.O. Box 64189

Tucson, AZ 85728

United States

(520)622-2200

Fax: (520)622-3700

Email: info@khs.com

También podría gustarte

- RFFS-100 Micro Pitts SpecialDocumento6 páginasRFFS-100 Micro Pitts Specialmam73Aún no hay calificaciones

- T-38 Park Jet Construction GuideDocumento16 páginasT-38 Park Jet Construction Guidemam73Aún no hay calificaciones

- Bob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Documento16 páginasBob's Card Models: Fairchild C-119G 'Flying Boxcar" (1:72)Luiz Fernando MibachAún no hay calificaciones

- F-107 Instructions FullDocumento20 páginasF-107 Instructions Fullmam73Aún no hay calificaciones

- Paper Plane (STREAM-CX) : Pattern: Vertical Fin Wing FilletDocumento2 páginasPaper Plane (STREAM-CX) : Pattern: Vertical Fin Wing FilletFransiskus OrganisAún no hay calificaciones

- AMEDEO Glider Instructions&Template-CardboardDocumento5 páginasAMEDEO Glider Instructions&Template-CardboardNoldy S L LohoAún no hay calificaciones

- F 15 ManualDocumento17 páginasF 15 Manualscimionetta0% (1)

- Free Sample PlaneDocumento6 páginasFree Sample PlaneArvind N LakshmananAún no hay calificaciones

- Avro Shackleton MR Mk 2 Model KitDocumento15 páginasAvro Shackleton MR Mk 2 Model KitSkyrest OrtizAún no hay calificaciones

- CAP Piper Cub Paper Airplane 2Documento2 páginasCAP Piper Cub Paper Airplane 2paskasevaAún no hay calificaciones

- BN-2 Islander Paper Model Guide for Britten-Norman Twin Engine Regional AirlinerDocumento11 páginasBN-2 Islander Paper Model Guide for Britten-Norman Twin Engine Regional AirlinerLuiz Fernando MibachAún no hay calificaciones

- Bob's Card Models: Douglas DC-6B 1:72Documento18 páginasBob's Card Models: Douglas DC-6B 1:72Luiz Fernando MibachAún no hay calificaciones

- (Digital Navy) - DN IJN YamatoDocumento62 páginas(Digital Navy) - DN IJN YamatoDenis Villagomez Fernandez100% (1)

- Bob's Card Models: Douglas DC-3 "Dakota" (Scale 1:50)Documento15 páginasBob's Card Models: Douglas DC-3 "Dakota" (Scale 1:50)erik gomezAún no hay calificaciones

- Boomerang: Assembly Instructions: Assembling The Zebra, Command Four, and Star BoomerangsDocumento3 páginasBoomerang: Assembly Instructions: Assembling The Zebra, Command Four, and Star Boomerangsdwi widodoAún no hay calificaciones

- (Paper Model-ABC Magazine Special) Jules Vernes Part 2Documento33 páginas(Paper Model-ABC Magazine Special) Jules Vernes Part 2Dym Gogosu100% (6)

- TOTAL TrackerDocumento11 páginasTOTAL TrackerLuiz Fernando MibachAún no hay calificaciones

- Blue AngelsDocumento11 páginasBlue AngelsJovan Veličković75% (4)

- Grumman S-2 Tracker Model Features Authentic US Navy DecalsDocumento11 páginasGrumman S-2 Tracker Model Features Authentic US Navy DecalsLuiz Fernando MibachAún no hay calificaciones

- Paper Craft - Paper Model - Building - AirportDocumento6 páginasPaper Craft - Paper Model - Building - AirportKaren Müller100% (1)

- Bob's Card Models: Martin Mars Water Bomber (1:72)Documento21 páginasBob's Card Models: Martin Mars Water Bomber (1:72)Luiz Fernando MibachAún no hay calificaciones

- SU-47 Parts 6mm Depron PDFDocumento19 páginasSU-47 Parts 6mm Depron PDFAlejandro LabléeAún no hay calificaciones

- TOTAL TrackerDocumento11 páginasTOTAL TrackerLuiz Fernando MibachAún no hay calificaciones

- Supermarine Spitfire MK VIII - BetaDocumento4 páginasSupermarine Spitfire MK VIII - Betamrpalaces100% (1)

- ARES Paper ModelDocumento1 páginaARES Paper ModelHany ElGezawyAún no hay calificaciones

- Bob's Card Models: and (Resources)Documento19 páginasBob's Card Models: and (Resources)Luiz Fernando MibachAún no hay calificaciones

- Your Files: Coca-Cola Paper F-15 #005004Documento2 páginasYour Files: Coca-Cola Paper F-15 #005004Hina Saadia AkmalAún no hay calificaciones

- Mercedes Benz I e LTR (1) QDocumento6 páginasMercedes Benz I e LTR (1) QAugusto Manuel Inga SánchezAún no hay calificaciones

- Contraseña Paper-Replika - Com CORSAIR 2Documento29 páginasContraseña Paper-Replika - Com CORSAIR 2ClaudioAlfredoSpoto100% (2)

- Total Dc3 SwissDocumento16 páginasTotal Dc3 SwissLuiz Fernando MibachAún no hay calificaciones

- Yzf r1 07 Assembly FullDocumento20 páginasYzf r1 07 Assembly FullChoky Masih TopiazAún no hay calificaciones

- Assembly InstructionsDocumento27 páginasAssembly InstructionsLorenzo Martinez ValenzuelaAún no hay calificaciones

- Pipejet: Piper Pa-47 PiperjetDocumento7 páginasPipejet: Piper Pa-47 PiperjetFikri NakhlaAún no hay calificaciones

- Bulldozer Bulldozer: Special Vehicle Series: 03Documento10 páginasBulldozer Bulldozer: Special Vehicle Series: 03Ronald ChavezAún no hay calificaciones

- Build a 1:72 scale model of the C-54 "Candy BomberDocumento13 páginasBuild a 1:72 scale model of the C-54 "Candy BomberLuiz Fernando MibachAún no hay calificaciones

- US Missile Truck (Paper Models)Documento3 páginasUS Missile Truck (Paper Models)Dym Gogosu100% (1)

- Su-37 Park Jet Plans (Assembly Drawing Tiled)Documento2 páginasSu-37 Park Jet Plans (Assembly Drawing Tiled)coloAún no hay calificaciones

- Plugin Yz450fm Assembly01Documento4 páginasPlugin Yz450fm Assembly01wahidnursalimAún no hay calificaciones

- Racer 539 Hawk: Pattern: Dihedral Angle GaugeDocumento3 páginasRacer 539 Hawk: Pattern: Dihedral Angle GaugeNELXON2010Aún no hay calificaciones

- TC Midget: Classic Car Series: 05Documento6 páginasTC Midget: Classic Car Series: 05Felixz GiatamaAún no hay calificaciones

- AeroModeller - 1957-01 - Albatros - DVDocumento3 páginasAeroModeller - 1957-01 - Albatros - DVKevin WilliamsAún no hay calificaciones

- (Paper Model) (Ship) (GPM 030) - Aircraft Carrier USS Enterprise (CVN 65)Documento57 páginas(Paper Model) (Ship) (GPM 030) - Aircraft Carrier USS Enterprise (CVN 65)Dym Gogosu78% (18)

- Snice Mirage 2000 Plan v2 FinalDocumento1 páginaSnice Mirage 2000 Plan v2 FinalLalith Kumar100% (1)

- Bonanza JA3907-Flyable EditionDocumento1 páginaBonanza JA3907-Flyable EditionSilvia Cristina100% (2)

- ForestsDocumento2 páginasForestsMorgdah GravesAún no hay calificaciones

- Bob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Documento9 páginasBob's Card Models: Junkers Ju 52 ("Tante Ju" - "Iron Annie") 1:72Luiz Fernando MibachAún no hay calificaciones

- Front and side views of an Airbus A320 paper modelDocumento20 páginasFront and side views of an Airbus A320 paper modelDaniel433Aún no hay calificaciones

- Planes DadDocumento16 páginasPlanes DadhgeileenAún no hay calificaciones

- F15D2D Fold3DDocumento1 páginaF15D2D Fold3Dsilviakill762100% (1)

- Aeronca Chief TandemDocumento7 páginasAeronca Chief TandemAviation/Space History Library100% (1)

- Fokker DR 1paper Model V 2 0 by Rubenandres77-D3hukhtDocumento20 páginasFokker DR 1paper Model V 2 0 by Rubenandres77-D3hukhtluccamantiniAún no hay calificaciones

- Flying 3D Paper Airplane Construction Manual (Cutout Nets Included!)Documento12 páginasFlying 3D Paper Airplane Construction Manual (Cutout Nets Included!)danylomalyuta67% (3)

- (Paper Model-ABC Magazine Special) Jules Vernes Part 1Documento40 páginas(Paper Model-ABC Magazine Special) Jules Vernes Part 1Dym Gogosu100% (6)

- (Paper Model) Paper Card Models (Marek) Aviatik BergDocumento2 páginas(Paper Model) Paper Card Models (Marek) Aviatik BergPablo Arbelaez100% (1)

- Medieval Trebuchet (Papermodel) PDFDocumento21 páginasMedieval Trebuchet (Papermodel) PDFKuschelAún no hay calificaciones

- Science of Flight-White WingsDocumento14 páginasScience of Flight-White WingsMtzCarlosAún no hay calificaciones

- BD 5 InstructionsDocumento13 páginasBD 5 InstructionskokiskoAún no hay calificaciones

- AeroModelTemp 2014Documento31 páginasAeroModelTemp 2014Aditya TejaswiAún no hay calificaciones

- Paper AirplaneDocumento7 páginasPaper Airplaneazukick80% (5)

- Supercool Paper Airplanes Ebook: 12 Paper Airplanes; Assembled in Under a Minute: Includes Instruction Book with Downloadable Plane TemplatesDe EverandSupercool Paper Airplanes Ebook: 12 Paper Airplanes; Assembled in Under a Minute: Includes Instruction Book with Downloadable Plane TemplatesCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Il-2, Death To The Fascist Occupiers! V-VS, 210th ShAP, Red 2, Flown by N.A.Zub, Hero of The S.U.Documento2 páginasIl-2, Death To The Fascist Occupiers! V-VS, 210th ShAP, Red 2, Flown by N.A.Zub, Hero of The S.U.Khillhing100% (1)

- Il-2 Sturmovik Spacer Model Design Started 8/2009 InstructionsDocumento24 páginasIl-2 Sturmovik Spacer Model Design Started 8/2009 InstructionsKhillhingAún no hay calificaciones

- Fokker DR 1paper Model V 2 0 by Rubenandres77-D3hukht PDFDocumento20 páginasFokker DR 1paper Model V 2 0 by Rubenandres77-D3hukht PDFJuan RamónAún no hay calificaciones

- F 117 NighthawkDocumento1 páginaF 117 NighthawkKhillhingAún no hay calificaciones

- V-1 MissileDocumento1 páginaV-1 MissileKhillhingAún no hay calificaciones

- Hercules Model Low ResDocumento8 páginasHercules Model Low ResGeorge DrambAún no hay calificaciones

- Osprey - Men at Arms 226 - The American War 1812-1814Documento51 páginasOsprey - Men at Arms 226 - The American War 1812-1814Khillhing93% (15)