Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Apuntes de Lutheria

Cargado por

Cristian TorricoDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Apuntes de Lutheria

Cargado por

Cristian TorricoCopyright:

Formatos disponibles

Resources - How to Set a Sound Post

Introduction: Basic theory of the sound post Part 1: About the soundpost setter, and choosing the wood Part 2: Determining the height and fitting the post Part 3: Positioning and adjusting the post This basic guide will be expanded with time. Email me your questions about this topic, and I will answer in the text of the document. In this way all will benefit.

Introduction: Basic Theory of the Sound Post

This introduction is meant to a guide to those who have little or no knowledge of violin construction, particularly concerning the sound post. Hence it will be largely explained in simple, practical terms. Below is a diagram of a violin cut laterally throught the center that illustrates the position of the sound post in a completed violin.

View of a sound post through the end pin hole at the bottom of the violin. Also seen are The sound post is a small dowel of Spruce that is held by friction some of the cleats which between the top and back plates of a violin (viola, cello, or string bass), reinforce the back seam. situated under the treble side of the bridge. It has both structural and tonal importance. Structurally, it supports the top plate, acting like a pillar under the bridge. Without it, a violin would "cave in" on the treble side. A good violin, however, may not be harmed if it is without a sound post for a short period of time, but an instrument should not be left in this situation for long. Acoustically, the sound post transfers vibrations from the top plate to the back plate of the instrument. It also alters the vibration of the top plate. Its placement, length, thickness, grain orientation, and wood selection influence the tone of an instrument. An instrument without a sound post will sound weak, thin and hollow. On the bass side of an instrument is a "bass bar", a cross section of which can be seen in the illustration above. It has both acoustic and

The sound post can easily be seen through the f-hole on the treble side of the instrument.

structural roles as well.

Part 1: About the Sound Post Setter, and Choosing the Wood A: The Sound Post Setter

The sound post setter is a small metal tool about 23cm/9" long. The sharp point at one end is pressed into the post to hold it for inserting into the instrument. The other end, which looks like a hand, is for moving the post once it has been placed in the instrument. (Sound post setters available here).

B: Selecting the Wood

The post is made of a dowel of spruce, usually about 5.5-6mm in diameter for a full size violin. The post must be small enough to fit through the f-hole at the notches, which is usually the widest point. This is true for all instruments (from the smallest violin to the largest bass). The grain should be fine, straight and even, preferably matching the wood that was used in the top of the instrument. So if the to plate instrument is coarsely grained, use a post with wider grain; if it is filely grained, use a post that has closer growth rings. (Sound post material available here).

Part 2: Determining the Height and Fitting the Post

A: Determining the Height of the Post Once a sound post setter has been obtained, and an appropriate piece of material selected, the next step will be to cut and fit the sound post. There is a tool which is a great help to determining the height of the post, called a sound post gauge, which greatly simplifies this process. Soundpost gauges can be found here. I will also explain here explain how to do it without a guage. A small needle file can be used to ascertain the approximate height for the post.

Insert the file (or other appropriate tool) in the upper 'eye' of the f-hole until it touches the back of the instrument, making sure that the file is perpendicular to the plane of the instrument (parralell with the ribs, or sides). Place your thumb nail on the file to mark the length needed. Mark this length on the sound post. The end grain direction of the sound post must run perpendicular to the grain in the top. This is important to the performance of the instrument. Cut the dowel somewhat longer than what is required for the post With a single-cut file, file the ends at angles to match the arch of the top and the back. B: Inserting and Fitting the Post

To place the post inside the instrument, insert the sharp end of the setter into the post, about 2/3 of the way to the top (picture A) Gently lower the sound post into the instrument (picture B). Once inside the instrument, place the bottom of the soundpost onto the back in the approximate place where it will be. It may be easier to start by placing the soundpost closer to the centre of the instrument, and then pulling it toward the f-hole once it has been placed. Picture A

Picture B

Part 3: Positioning and Adjusting the Post

The correct position of the sound post is behind the bridge foot (toward the tailpiece), as seen in the above diagram. Generally, if the sound post is too short, the upper wing of the f hole will sink with the strings tensioned and the post in the above position. If it is to tall, the wing will protrude. Adjust as necessary.

SOUND POST ADJUSTMENT FOR BEST PERFORMANCE ...The general guide for sound post placement for full sized violins is that the near side of the sound post should be 1/8" behind the back side of the bridge and centered on the right foot of the bridge, or perhaps slightly outboard from this position, but inside the outside border of the right hand bridge foot. ...With the model violin I make I find that a measurement of 0.13" is best (0.13" - 0.125" = 0.005" difference from normal). ...I believe that the entire range of adjustment is in that +/- 0.005" range from the 1/8" standard. See test chart below to see actual test results showing how loudness and tone changes with slight movements of the sound post. ... Along with the relative position to the bridge, the post should be vertical and both ends should closely match the angle of the plate at the contact point. ...Before you move the sound post I recommend that you use a fixture to hold the violin horizontal and which firmly clamps the instrument down so both of your hands are free. It is a very good idea to lessen the string tension to say only 1/4 of normal tension to lessen the pressure on the sound post so that it can be moved easier and to prevent damage to the wood at the contact point, especially to the soft wood of the spruce top plate. ...I use the special flat sound post pliers to move the top of the sound post and a sound post tool to move the bottom end of the 'post. Normally I move the top end of the sound post first until it is in the position I want, and then increase the string tension to about 1/2 tension and then move the bottom end of the post until it is exactly perpendicular (to the plane of the back plate's perimeter edges). ... When I make a sound post, I draw on an arrow in ink showing 'up' and facing the right side of the instrument; that way, at a glance I can see which end of the sound post should be up and be sure that the post has not turned. ...The grain lines of the sound post should be oriented from side to side, that is perpendicular to the grain of the top plate. ...The sound post needs to be a certain length within +/-0.002" of the ideal length. When in position and with no string tension, the sound post should stand in position without falling when the violin is gently tipped. It is the string tension that really clamps the sound post into position. You may want to rub a bit of white blackboard chalk onto the ends of the sound post to help it keep it's position, when installing a new sound post. ...As a practical length, I suggest that you add 0.010" to the ideal centerline length when making your new sound post. This will add a slight preload and make it less likely to shift or fall out of position.

...Here I am measuring the bottom end angle for a new sound post. The angle protractor measurements are written down for future reference. The center-line length of the sound post is also measured at this time. ... Notice that this tool has small wood sound post material epoxied to the ends of a commercially available tool. These fit looselyto begin with and the epoxy mixtured holds them on while inserting through the sound holes and raising into position; then the epoxy sets up with the ends in position, at the correct end angles, in the violin being measured. No guessing anymore! ... Once the sound post top end is installed and put into position, this tool allows measuring to see if the sound post is vertical. The bottom has a cup shape that nestles against the sound post, at which time the top mounted bubble balance is checked for level. You can then see which way the bottom of the sound post needs to be moved in order for the post to become vertical. ...It must be remembered that in all operations involving moving the sound post, no tool must ever come in contact with the wood of the violin around the sound holes. The spruce is very fragile all around the sound hole opening and because cross grain wood this thin can be easily broken off, it must not be touched... thus the importantance of having both hands free to manilupulate the special tools and a fixture that firmly holds the violin in place.

...Sound meter is held in position ( by the pictured metal rod) 14" from the violin's bridge while maximum loudness of the violin's bowed open strings is recorded on chart (as pictured in photo to the left). ...The bottom chart units are in inches behind the bridge back to the back side of the sound post (in hundredths of an inch). The right side chart units are DB of loudness recorded from the sound meter; each 10 DB is double the sound loudness. This chart is typical for a full sized violin. Notice that the maximum loudness increases about 30% when the ideal sound post position is used (and all strings reach a peak at the same point as the tone is maximized (tone impression line is being pointed to with the pen). Once this point is determined and recorded, it becomes the permanent ideal sound post location and need not be concerned about in the future.

...Also note that a change in positon of only +/- 0.020" will be a loss of between 20 and 30% of the total possible power and tone quality. The sound post position is not an arbitrary setting but one that the instrument insists on for proper playing. ...When doing the above test, the sound post must be moved (after first re-installing the holding fixture and losing the string tension) , then the sound post made exactly vertical again in its new position, and then the string tension brought up to concert pitch, bridge straightened up and the maximum loudness bowing test repeated for the next data point. Thus this test can easily consume an hour of time to do properly, but the results are valuable! EXACTLY MEASURING FOR, CUTTING, AND FITTING A SOUND POST... ...Fitting the sound post accurately is made more difficult because both the top and bottom plates of the violin are curved at the contact with the ends of the sound post; besides this, the angle of the end is usually different at the two ends. ...The sound post is approximately 1/4" in diameter and is made of spruce wood. The grain of the sound post is oriented at 90 degrees to the grain of the wood for the top plate... that is, the grain of the one goes across the grain of the other. Normally there should be between five and seven growth rings across the 1/4" width of the sound post. Less grains for a warmer tone and more for a colder tone, is the general rule. ...In this article I will outline my method for carefully measuring the exact length of sound post needed for a particular instrument and how to measure the end angles and accurately cut them, all at the correct overall length (length of the centerline of the sound post). First, I will be helpful if we have some basic sound post tools: Sound post retrieval tool (for when the post is loose inside instrument. Sound post pliers, to manipulate the top end of the sound post Sound post setter, adjustment tool; useful to adjust the bottom position of 'post. Vertical alignment measuring tool Handmade sound post installing tool; or just use the sound post setter's pointed end Twin-layer thin plastic gage for measuring position of sound post through the "ff" hole

...This is the tool that will allow you to tell if the sound post is exactly vertical when inside the violin. The bottom has a shape that 'cups' around the sound post and is parallel to the vertical shaft of the tool. ...The soldered-on brass rod is to allow the tool to be easily turned but is not absolutely necessary. ...On top (out of the picture) is a 'bullseye' level mounted on a wood block that slides over the vertical shaft. (I remove for storage convenience when not in use).

...This tool is commercially available and the inner metal shaft slides up inside the brass tube so that it can measure the centerline length of the sound post that is needed. The thumb screw locks it into the correct length; the tool is then removed from the violin "ff" hole opening and measured. You will notice in this photo that I have added two wooden ends which are tipped to match the inside plate contours...more on this later. ...The plastic post location tool. The two pieces are identical and the end is cut as shown so it can hook around the sound post when it is in position inside the instrument. The end are stapled together for that the two pieces stay in 'registrar'. ...Thus by looking at the outside piece you can tell where the inside piece is compared to the bridge. ...A vernier caliper measures the center-line length of the sound post to the nearest 0.001". be sure to measure in the center of the tipped ends of the wood tips (90 degrees to the tool...not shown)

...This tool measures the end angles of the sound post tool so we know what angles to 'cut' on the sound post ends to accurately fit the instrument. Usually the end angles are different so it is a good idea to put a mark on the sound post as to which way is 'up'...I draw an arrow on the side facing the "ff" hole so it is clearly visible through the sound hole.

...(this is the bottom of the holder fixture) Notice that the top section lifts off the four support feet. This allows you to move the instrument so that you can recapture the sound post after it falls over and is rolling around inside; without having to unclamp the instrument from this holder (saves time and frustration).

...This is the final tool you need to make which allows for the accurate hand sanding of the end angles and which also allows you to exactly control the length of the sound post. ...It is bolted to the mitre gage of my table saw and slides in the slot. The end angle of the post is set on the mitre gage. The sanding disc is flat and the cut is made with by sliding the mitre gage in and out by hand while feeding the motionless sanding disc out (my 'Shop Smith' table saw allows the saw spindle to slide in and out with a lever...perfect for this application.

...These three photos show more details of the sound post tool that allows you to measure how vertical the sound post is once it is installed in the instrument. It fits in through the right hand "ff" hole by turning it sideways.

...Now I will show you the whole process of fitting a new sound post for and instrument from the beginning...

...The first step is to mount two cut off pieces of sound post stock with oversize holes drilled in their center about 70% of the length deep (just larger enough to allow the wood ends to pivot and conform to the shape of the inside of the instrument, when put inside and raised into position). Then some 5 minute epoxy is mixed up and put on the steel shaft ends of the sound post length finding tool. The ends are covered with the two wood 'post ends and then they are gently held in position while they are passed through the right hand "ff" hole. Once inside, the tool is maneuvered so that it is in the position of the sound post and then the tool is lengthened to firmly contact the top and bottom plates and then the thumb screw is firmly locked down. Do this with the tool vertical as shown by the bubble balance. The wood ends tip and conform to the inside plate shape, then the glue sets up. ...It is best to fit the sound post with the instrument lightly strung up with the bridge in proper position and just enough tension in the strings to make them straight. Once the sound post is in position, then the string tension can be brought up to proper tension and that string pressure will hold the sound post firmly in position. ...Here the end angles of the sound post are being measured with the protractor tool (and recorded (of course) for future reference.... ...The needed length of the sound post may change over time but the needed end angles should remain constant.

También podría gustarte

- Violin Making, Second Edition Revised and Expanded: An Illustrated Guide for the AmateurDe EverandViolin Making, Second Edition Revised and Expanded: An Illustrated Guide for the AmateurCalificación: 4.5 de 5 estrellas4.5/5 (2)

- The Violin MakerDocumento157 páginasThe Violin MakerOsvaldo FreixoAún no hay calificaciones

- Ole Bull Plans VIOLINDocumento3 páginasOle Bull Plans VIOLINSamuel SaldañaAún no hay calificaciones

- How Bow Hair Types Influence Sound and FeelDocumento4 páginasHow Bow Hair Types Influence Sound and Feelsalecello2113Aún no hay calificaciones

- A Note On Practical Bridge Tuning For The Violin Maker Carleen M. HutchinsDocumento4 páginasA Note On Practical Bridge Tuning For The Violin Maker Carleen M. HutchinsNikolai BuerginAún no hay calificaciones

- Violin Making 'The Strad' Library, No. IX.De EverandViolin Making 'The Strad' Library, No. IX.Aún no hay calificaciones

- The Violin: Some Account of That Leading Instrument and Its Most Eminent Professors, from Its Earliest Date to the Present Time; with Hints to Amateurs, Anecdotes, etcDe EverandThe Violin: Some Account of That Leading Instrument and Its Most Eminent Professors, from Its Earliest Date to the Present Time; with Hints to Amateurs, Anecdotes, etcAún no hay calificaciones

- Making Transparent Golden Varnish from a Historical RecipeDocumento3 páginasMaking Transparent Golden Varnish from a Historical Recipemarcellomorrone100% (1)

- K The Sound HolesDocumento7 páginasK The Sound HolesTeggy GatiaAún no hay calificaciones

- Achieving Tonal Repeatability in Violins Through Plate Flexural StiffnessDocumento9 páginasAchieving Tonal Repeatability in Violins Through Plate Flexural Stiffnessblancofrank545100% (1)

- Violins and Violin Makers Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the Violin.De EverandViolins and Violin Makers Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the Violin.Aún no hay calificaciones

- A Physicists Quest For The Secrets of StradivariDocumento15 páginasA Physicists Quest For The Secrets of Stradivariyufencha15480% (2)

- A Viol RestorationDocumento31 páginasA Viol RestorationFrancesco Maria MazzoliniAún no hay calificaciones

- ABELE Trad ALWYN The Violin and Its History 1905. IA PDFDocumento156 páginasABELE Trad ALWYN The Violin and Its History 1905. IA PDFAnonymous UivylSA8100% (2)

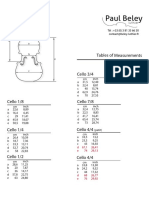

- Tables of Me Sure SP Be Ley CelloDocumento1 páginaTables of Me Sure SP Be Ley CelloPascal DupontAún no hay calificaciones

- Making A Violin NutDocumento33 páginasMaking A Violin NutJuan FernandezAún no hay calificaciones

- Fitting a New Cello BridgeDocumento53 páginasFitting a New Cello BridgeBulbosas de otono100% (1)

- H S Wake - A Strad Model Cello Plans (Luthier-lutherie-Violin-cello) by OganzaDocumento29 páginasH S Wake - A Strad Model Cello Plans (Luthier-lutherie-Violin-cello) by OganzaFábio Daniel Hadad100% (1)

- The Treble Viol - LaBarre - DissertationDocumento93 páginasThe Treble Viol - LaBarre - DissertationThiago EndrigoAún no hay calificaciones

- Violins and Violin Makers: Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the ViolinDe EverandViolins and Violin Makers: Biographical Dictionary of the Great Italian Artistes, their Followers and Imitators, to the present time. With Essays on Important Subjects Connected with the ViolinAún no hay calificaciones

- Antonio Stradivari 1694 'Maria Ex Muir Mackenzie': Description AND Measurements: Roger HargraveDocumento7 páginasAntonio Stradivari 1694 'Maria Ex Muir Mackenzie': Description AND Measurements: Roger HargraveCarlos AlbertoAún no hay calificaciones

- Martin Schleske explores empirical tools in violin makingDocumento15 páginasMartin Schleske explores empirical tools in violin makingFábio Daniel HadadAún no hay calificaciones

- Aaron Rosand On How To Produce A Beautiful ToneDocumento4 páginasAaron Rosand On How To Produce A Beautiful ToneMaria Elena GarciaAún no hay calificaciones

- Working Methods Guarneri Del GesùDocumento10 páginasWorking Methods Guarneri Del GesùhorozimbuAún no hay calificaciones

- Coloring Agents For Varnish: Colors - General OverviewDocumento1 páginaColoring Agents For Varnish: Colors - General Overviewnostromo1979Aún no hay calificaciones

- Unspoiled: To Borman Violins - Additional ArticlesDocumento5 páginasUnspoiled: To Borman Violins - Additional ArticlesmarcellomorroneAún no hay calificaciones

- Brothers AmatiDocumento7 páginasBrothers AmatiPHilNam100% (1)

- Bow Hair QuantityDocumento4 páginasBow Hair Quantitysalecello2113Aún no hay calificaciones

- PollensDocumento13 páginasPollensAdam AcostaAún no hay calificaciones

- Violin Making Guide by Walter H. MaysonDocumento68 páginasViolin Making Guide by Walter H. MaysonBeray Selen100% (1)

- Modernized Violin VarnishesDocumento3 páginasModernized Violin VarnishesMartin AllegroAún no hay calificaciones

- Retuning the plates of a cello to improve toneDocumento1 páginaRetuning the plates of a cello to improve toneAnonymous K8QLiPAún no hay calificaciones

- Gasparo Da SaloDocumento31 páginasGasparo Da SaloFrancesco Maria MazzoliniAún no hay calificaciones

- Guarneri AndreaDocumento163 páginasGuarneri AndreaViolin Ttpc100% (1)

- A Treatise On The Structure and Preservation of The Violin and - Otto Jacob - 1762-1830 Bishop John 1817-1890Documento124 páginasA Treatise On The Structure and Preservation of The Violin and - Otto Jacob - 1762-1830 Bishop John 1817-1890accesosvarios0Aún no hay calificaciones

- TablesofMesuresPBeleyCello PDFDocumento1 páginaTablesofMesuresPBeleyCello PDFClaudio MariniAún no hay calificaciones

- A Brief History of Stradivari and Guarneri del GesùDocumento5 páginasA Brief History of Stradivari and Guarneri del GesùKevinAún no hay calificaciones

- On The Bridge-Hill of The ViolinDocumento18 páginasOn The Bridge-Hill of The Violinuglymutt12335Aún no hay calificaciones

- The 'Betts' Stradivari 1704: A MasterpieceDocumento7 páginasThe 'Betts' Stradivari 1704: A MasterpieceParacelso CelsoAún no hay calificaciones

- Bow Frog RepairDocumento24 páginasBow Frog RepairMario Viola100% (1)

- Sobre Escuelas de ViolínDocumento39 páginasSobre Escuelas de ViolíncontrariomotuAún no hay calificaciones

- Bow (Music)Documento28 páginasBow (Music)JacobNiederhofferAún no hay calificaciones

- Quick Approach To Making A Mold From Strad Posters - ReviseDocumento2 páginasQuick Approach To Making A Mold From Strad Posters - ReviseponbohacopAún no hay calificaciones

- Brb1 IndexDocumento14 páginasBrb1 IndexArnab BhattacharyaAún no hay calificaciones

- A Guide to Violin Varnish - A Selection of Classic Articles on the Development and Qualities of Different Violin Varnishes (Violin Series)De EverandA Guide to Violin Varnish - A Selection of Classic Articles on the Development and Qualities of Different Violin Varnishes (Violin Series)Aún no hay calificaciones

- Fiddle Fanciers GuideDocumento352 páginasFiddle Fanciers GuideGeoff CaplanAún no hay calificaciones

- Plate Tuning PDFDocumento132 páginasPlate Tuning PDFConsuelo FroehnerAún no hay calificaciones

- Cello DimensionDocumento2 páginasCello DimensionChutchawan Ungern100% (1)

- Measuring and tuning a violin bridge's resonance frequencyDocumento8 páginasMeasuring and tuning a violin bridge's resonance frequencyOmid Sharifi100% (1)

- Amati Antonio & Girolamo 134-358Documento225 páginasAmati Antonio & Girolamo 134-358Max RakshaAún no hay calificaciones

- Nicola Amati and The AlardDocumento10 páginasNicola Amati and The AlardPHilNamAún no hay calificaciones

- George Gemünder's Progress in Violin Making: With Interesting Facts Concerning the Art and Its Critics in GeneralDe EverandGeorge Gemünder's Progress in Violin Making: With Interesting Facts Concerning the Art and Its Critics in GeneralAún no hay calificaciones

- VIOLIN Useful Measurements PDFDocumento1 páginaVIOLIN Useful Measurements PDFtotowahidAún no hay calificaciones

- IMSLP407370 PMLP593895 Courv Technicsofviolin EdDocumento142 páginasIMSLP407370 PMLP593895 Courv Technicsofviolin EdThiago PassosAún no hay calificaciones

- Porters StrategyDocumento14 páginasPorters StrategyDeepshikha Goel100% (1)

- Hair Hank AreaDocumento1 páginaHair Hank AreaCristian TorricoAún no hay calificaciones

- Larsen Original ViolaDocumento1 páginaLarsen Original ViolaCristian TorricoAún no hay calificaciones

- Beeswax Wood Finish (For Bare Wood) : Beeswax 1 Beeswax 454 Turpentine Turpentine 473 Linseedoil Linseedoil 473Documento1 páginaBeeswax Wood Finish (For Bare Wood) : Beeswax 1 Beeswax 454 Turpentine Turpentine 473 Linseedoil Linseedoil 473Cristian TorricoAún no hay calificaciones

- Strings Color Identification ChartDocumento9 páginasStrings Color Identification ChartCristian TorricoAún no hay calificaciones

- TRB 2011 Bridge TrafficDocumento17 páginasTRB 2011 Bridge TrafficCristian TorricoAún no hay calificaciones

- Harfield PDFDocumento14 páginasHarfield PDFCristian TorricoAún no hay calificaciones

- Strings Color Identification Chart PDFDocumento9 páginasStrings Color Identification Chart PDFCristian TorricoAún no hay calificaciones

- IMSLP12214-Double Concerto Piano Score PDFDocumento46 páginasIMSLP12214-Double Concerto Piano Score PDFCristian TorricoAún no hay calificaciones

- How To Buy TelescopesDocumento15 páginasHow To Buy TelescopesCristian TorricoAún no hay calificaciones

- Pirastro Violin Evah-Pirazzi 2016-09-15Documento5 páginasPirastro Violin Evah-Pirazzi 2016-09-15Cristian TorricoAún no hay calificaciones

- Soundcompass CelloDocumento1 páginaSoundcompass CelloCristian TorricoAún no hay calificaciones

- Millau - Lifting Temporary Support TowersDocumento3 páginasMillau - Lifting Temporary Support TowersCristian TorricoAún no hay calificaciones

- Laboratory Soils TestingDocumento407 páginasLaboratory Soils Testinglili2000Aún no hay calificaciones

- Creating classical violin forms through edgework and purfling techniquesDocumento4 páginasCreating classical violin forms through edgework and purfling techniquesCristian TorricoAún no hay calificaciones

- Comp Action TestDocumento1 páginaComp Action TestCristian TorricoAún no hay calificaciones

- Manfio Scroll CarvingDocumento62 páginasManfio Scroll CarvingCristian TorricoAún no hay calificaciones

- Ccu 2 Connections March 2005Documento41 páginasCcu 2 Connections March 2005Cristian TorricoAún no hay calificaciones

- Effect of wood removal on vibration frequencies of bridgesDocumento5 páginasEffect of wood removal on vibration frequencies of bridgesCristian TorricoAún no hay calificaciones

- Bow Rehairing - by Lars KirmserDocumento10 páginasBow Rehairing - by Lars KirmserCristian Torrico100% (3)

- Parallel Monitoring of Sound and Dynamic Forces in Bridge-Soundboard Contact of ViolinsDocumento6 páginasParallel Monitoring of Sound and Dynamic Forces in Bridge-Soundboard Contact of ViolinsCristian TorricoAún no hay calificaciones

- PCA-Structures News 1Documento4 páginasPCA-Structures News 1Cristian TorricoAún no hay calificaciones

- Hcaa17 ManualDocumento28 páginasHcaa17 ManualCristian TorricoAún no hay calificaciones

- Cello DimensionDocumento2 páginasCello DimensionChutchawan Ungern100% (1)

- FP03Documento718 páginasFP03John Tejada IIIAún no hay calificaciones

- HAN4400 ManualDocumento48 páginasHAN4400 ManualCristian TorricoAún no hay calificaciones

- CADtools 7 User GuideDocumento91 páginasCADtools 7 User GuideCristian Torrico100% (1)

- Comp Action TestDocumento1 páginaComp Action TestCristian TorricoAún no hay calificaciones

- Malaysian KitesDocumento5 páginasMalaysian KitesMat RoyAún no hay calificaciones

- Music-9 SLM Q1 W3-4 M3-4 V1.0-CC-releasedDocumento27 páginasMusic-9 SLM Q1 W3-4 M3-4 V1.0-CC-releasedVj AleserAún no hay calificaciones

- A Comprehensive Review of The Bookmyshow Website and SystemDocumento6 páginasA Comprehensive Review of The Bookmyshow Website and SystemEbtisam HamedAún no hay calificaciones

- Marc Mcafee CNN Resume 2015Documento1 páginaMarc Mcafee CNN Resume 2015api-278018754Aún no hay calificaciones

- I Could Write Books Zanna Don TDocumento7 páginasI Could Write Books Zanna Don TYan DiazAún no hay calificaciones

- At The Five Spot, Vol. 2 - BookletDocumento6 páginasAt The Five Spot, Vol. 2 - BookletBenjamín Poblete100% (2)

- Prepositions of Time QuizDocumento1 páginaPrepositions of Time Quizthx1138gaAún no hay calificaciones

- Instructions for Operating a TelevisionDocumento7 páginasInstructions for Operating a TelevisionAmbarwaty BilondatuAún no hay calificaciones

- Amos 2 - 3 at 4.0°W - LyngSatDocumento6 páginasAmos 2 - 3 at 4.0°W - LyngSatHassan Mody TotaAún no hay calificaciones

- Addams Audition PrepDocumento4 páginasAddams Audition PrepChristina Johnson100% (5)

- Fixed Wireless Setup GuideDocumento12 páginasFixed Wireless Setup GuidePendekar BlankAún no hay calificaciones

- 19 - RLC Circuits & Resonance PDFDocumento13 páginas19 - RLC Circuits & Resonance PDFRAJESHAún no hay calificaciones

- Em C Am B em C Am: You'Re So Gay-Katy PerryDocumento12 páginasEm C Am B em C Am: You'Re So Gay-Katy PerryBintang Estu AdiAún no hay calificaciones

- Testing Procedure PTDocumento13 páginasTesting Procedure PTashish_2187Aún no hay calificaciones

- Dance History AssignmentDocumento2 páginasDance History AssignmentMaripili RodriguezAún no hay calificaciones

- FTTH BookDocumento197 páginasFTTH BookPrashant Agarwal100% (5)

- Optical Time Domain Reflectometer: Presented by - Payal Prasad - Priya SinhaDocumento9 páginasOptical Time Domain Reflectometer: Presented by - Payal Prasad - Priya Sinhapayalprasad1993Aún no hay calificaciones

- The Importance of Transcribing SolosDocumento5 páginasThe Importance of Transcribing SolosNickBrown100% (1)

- CPAR Reviewer Guide for GAMABA AwardeesDocumento3 páginasCPAR Reviewer Guide for GAMABA AwardeesZennia PorcilloAún no hay calificaciones

- Ukrainian Folk Song MelodyDocumento2 páginasUkrainian Folk Song MelodyGabriela MatcovschiAún no hay calificaciones

- Dreaming of Other - CarpentariaDocumento31 páginasDreaming of Other - CarpentariarewandnAún no hay calificaciones

- Manual Derrick CCTV System - 0991560 PDFDocumento4 páginasManual Derrick CCTV System - 0991560 PDFseanll2563Aún no hay calificaciones

- Future Continuous TenseDocumento17 páginasFuture Continuous TensechangAún no hay calificaciones

- Regaining Wholeness Through The Subtle DimensionsDocumento226 páginasRegaining Wholeness Through The Subtle DimensionsChuy Soto Naranjo100% (4)

- Always With Me DuetDocumento3 páginasAlways With Me DuetHO YONG CHUNG MoeAún no hay calificaciones

- MUSIC Q4 WEEK2-1Documento10 páginasMUSIC Q4 WEEK2-1Maribel CastanedaAún no hay calificaciones

- 30 Day Guitar & Wellness ChallengeDocumento5 páginas30 Day Guitar & Wellness ChallengeBhagat ChawlaAún no hay calificaciones

- Sine Wave GeneratorDocumento5 páginasSine Wave GeneratorSorina LupuAún no hay calificaciones

- Mapeh 6Documento7 páginasMapeh 6Jojo SamaniegoAún no hay calificaciones

- 4.sat SubsystemsDocumento66 páginas4.sat Subsystemsrama krishnaAún no hay calificaciones