Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PCS7 With Profibus

Cargado por

Raj ChavanDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

PCS7 With Profibus

Cargado por

Raj ChavanCopyright:

Formatos disponibles

Field Automation with PROFIBUS and SIMATIC PCS 7

Product Brief April 2003

PROFIBUS

Distributed automation solutions on the basis of open fieldbuses are currently the standard in many sectors of the production and process engineering industries. Only fieldbuses permit full use of the functional advantages of digital communication such as improved resolution of measured values, diagnostics facilities and remote parameterization. PROFIBUS is currently the most successful open fieldbus with a large installed basis for a wide range of applications. The IEC 61158 / EN 50170 standard guarantees future compatibility of your investments. PROFIBUS is suitable for fast communication with distributed I/Os (PROFIBUS DP) in production automation, and for communications tasks in process automation (PROFIBUS PA). It is the first fieldbus system which covers the requirements of both sectors using identical communications services. The transmission method of PROFIBUS PA is tailored to the requirements of the process industry. The standardized communications services guarantee interoperability between field devices from different vendors and remote modification of field device parameters during operation. With SIMATIC PDM (Process Device Manager), an integrated and cross-vendor tool for configuring, parameterization, commissioning and diagnostics of intelligent process devices on the PROFIBUS, it is possible to configure a large number of process devices from different vendors using one uniform graphical user interface. Theory of operation PROFIBUS PA is the expansion of PROFIBUS DP with process-oriented components for direct connection of actuators and sensors. The RS 485 transmission system used for PROFIBUS DP has been replaced for PROFIBUS PA by the transmission system according to IEC 61158. This system is internationally standardized and can also be used for intrinsicallysafe applications.

highlights

Advantages of distributed field automation with PROFIBUS PA: Totally integrated modular system Fast, fault-free installation from sensor up to the management Low servicing costs thanks to simlevel opens up new plant concepts pler cabling and plant structure, as Problem-free interchanging of field well as comprehensive diagnostics devices from different vendors facilities which comply with the standard Greatly reduced commission costs profile as result of simplified loop check Connection of transmitters, valves, Scaling/digitization of measured actuators etc. to the network values already carried out in field Implementation of intrinsically-safe device; thus no conversion required applications with use of fieldbus in in SIMATIC PCS 7. potentially explosive atmospheres This results in: Easy installation with two-wire cable for common power supply and data Lower hardware costs transmission Shorter startup time Problem-free maintenance Reduced cabling costs as result of Low-cost software engineering savings in material and routing Higher operational reliability. Reduced configuring costs resulting from simple, centralized engineering of field devices (PROFIBUS PA and HART with SIMATIC PDM, also cross-vendor)

PROFIBUS PA uses the same communications protocol as PROFIBUS DP; the communications services and telegrams are identical. With PROFIBUS PA, information and the power supply to the field devices can be transmitted on one two-wire cable. PROFIBUS PA can be used in standard environments just as in potentially explosive atmospheres. When using in potentially explosive atmospheres, the PROFIBUS PA and all connected devices must be designed with the type of protection Ex [i]. The uniform protocol of PROFIBUS DP and PROFIBUS PA permits the connection of the networks and thus the combination of processing performance and intrinsically-safe transmission.

PROFIBUS International The conformity and interoperability tests carried out by laboratories authorized by PROFIBUS International (PNO) together with the PNO device certification guarantee that the quality and functionality are also provided in multi-vendor installations. You can find further information on PROFIBUS in the PNO product catalog. The PNO supports the further technical development, standardization and worldwide marketing of PROFIBUS. The catalog provides a summary of a wide range of products and services associated with PROFIBUS. It represents the offers from suppliers worldwide, and is available online on the Internet at: www.profibus.com

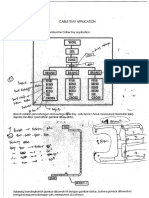

PROFIBUS PA in the SIMATIC PCS 7 environment SIMATIC PCS 7 is the process control system in the Siemens automation network "Totally Integrated Automation" (TIA). It uses standard hardware and software components from the TIA family such as controllers, PCs, communications functions and distributed I/Os. The uniform data management, communication and configuration capabilities of TIA offer an open platform for advanced, future-oriented and economical automation solutions in all sectors of the process industry, manufacturing industry and hybrid industries. The use of worldwide standards means that the system is open and flexible in many respects. At the field level, a wide range of standardized field devices (PROFIBUS DP/PA, HART) can be integrated. The adjacent Fig. shows the integration of PROFIBUS PA in SIMATIC PCS 7. The most important features of the configuration are the optimized communication throughout all hierarchical levels and central engineering for all components. Communication between the automation system and field devices on PROFIBUS PA takes place via representative blocks in the CPU. There are five representative blocks (analog input/output, digital input/output, totalizer) with which all field devices are covered. The inputs and outputs of these blocks "represent" the field devices in the CPU to facilitate access to the operator system via the plant bus. The blocks are configured in the central engineering system. The configuration data are also generated there and loaded during commissioning into the DP/PA link and the field devices. The SIMATIC PDM parameterization software is used for commissioning and diagnostics of the field devices. It is executed in the engineering system and can communicate directly with field devices via the communication levels.

Up to 10 DP lines can be used per CPU for access to the field level. Since all field components are connected together on the PROFIBUS DP, it is easy to adapt the field instrumentation to the physical characteristics of the plant, e.g. one DP line per subsystem. Safe communication with PROFIBUS DP (PROFISafe) Now that PROFIBUS DP has extended the total integration of distributed automation to the process environment by means of the PROFIBUS PA version (IEC 1158-2), the PROFISafe profile expands the PROFIBUS DP communication between CPU and process I/O by safety-related functions for the protection of persons, plants and the environment. PROFISafe permits coverage of the extremely fast response times in the production sector on the one hand and the extremely low-power instrument mode in the process sector on the other by one totally integrated solution. A safety bus implemented with PROFISafe is one of the open systems. The defined interfaces and procedures permit use of a permanently increasing number of safety devices (F hosts and F slaves) and systems with a flexible constellation. Both standard and safetyoriented communication are carried out

on one single cable, which not only results in enormous saving of cabling requirements and stocking of parts, but also provides the advantage of retrofitting. Both standard and safety-oriented communication can also be distributed on different PROFIBUS lines if required. The safety measures are encapsulated in the communication stations. This encapsulation means that the useful load of standard PROFIBUS telegrams is extended by a few bytes of information which guarantee safe communication. The PROFISafe profile supports fail-safe communication for applications up to safety class SIL 3 according to IEC 61508, up to requirement class AK 6 according to DIN V 19250/DIN V VDE 0801, and up to category 4 according to EN 954-1. Availability is an important factor with safety systems, and can be increased using a redundant design of the complete system. This was taken into consideration right from the beginning of the PROFISafe development.

SIMATIC PDM

SIMATIC PDM (Process Device Manager) is a totally integrated and cross-vendor tool for configuring, parameterization, commissioning and diagnostics of intelligent field devices and components. SIMATIC PDM enables the configuring of a large number of process devices from different vendors using one software and one uniform user interface. This results in surety and significantly saves costs for investments, training and follow-up costs. SIMATIC PDM can be used in two manners: As an integral tool in STEP 7, and thus as an integral component of the SIMATIC PCS 7 engineering system. Independent of system suppliers on a PC/programming device with Windows 95/98/ME and Windows NT/2000/XP. The display of device parameters and functions is uniform for all supported process devices, and independent of their communications link, e.g. via PROFIBUS DP/PA or the HART protocol. The core functions of SIMATIC PDM include the setting and modifications of device parameters, comparison of correct and actual parameter settings, testing for plausibility of inputs, simulation, diagnostics, administration, and commissioning functions, e.g. testing of the signal loops of process device data. In addition, SIMATIC PDM enables online monitoring of process values, alarms and status signals of the device.

Hardware view in HW Config

Lifelist with detailed and diagnostics information on the field devices

Parameter view Configuring of process devices: user interface of SIMATIC PDM

User interface The graphical user interface of SIMATIC PDM complies with the VDI/VDE GMA 2187 and IEC 65/349/CD regulations. Even devices with several hundred parameters can be processed clearly and rapidly. SIMATIC PDM can be used for extremely simple navigation in highly complex stations such as remote I/Os up to the connected field devices. Several views are available to operators: Hardware project view (integrated in SIMATIC PCS 7) Process devices are configured within STEP 7 / SIMATIC PCS 7 using HWConfig and displayed graphically or in tabular form. Process device plant view a tagbased view that includes display of diagnostics information The devices configured in HWConfig or in the process device network view are also automatically created in the process device plant view.

Parameter view for parameterization

of process devices The parameters of a selected process device can be displayed, modified and saved here. Communication to the device is also established here. This parameter display is started following double clicking on a process device in one of the other views. Lifelist view for identification/diagnostics as well as for online parameterization of the process devices Process device network view (for stand-alone application) The hierarchical structure of networks, communications components up to process devices can be configured here. When integrating in STEP 7 / PCS 7, these data can be imported, thus avoiding double inputs.

Central device operation The overview display shows the possible connection points of SIMATIC PDM in a system. The engineering stations on which SIMATIC PDM is installed are connected on the plant bus. Working on one project database using different stations is possible via the LAN. Devices can be connected in different manners in the field: PROFIBUS PA devices to DP/PA couplers and links, or HART devices to the HART analog input/output modules of the ET 200M or ET 200iS. HART devices can also be connected to conventional analog input/output modules. A HART multiplexer is shown on the right via which all connected HART devices can be accessed.

SIMATIC PDM

The SIPART DR controllers and the SIMOCODE are representatives of PROFIBUS DP devices in the Fig. on page 5. The PROFIBUS DP is connected here to a SIMATIC S7-400 automation system. The S7-400 permits connection of several DP segments. Routing Routing allows access from a central location commonly from the engineering station to device parameters and to the status of any process device that is part of an installation. Reconnection of the DP interface of the PC to the correct DP segment in each case is superfluous, thus eliminating a possible source of faults. It is then possible to: Read diagnostics information from the field devices Modify device settings Calibrate and adjust field devices Monitor process values Generate simulation values in the field device Modify the field device parameters.

Communication SIMATIC PDM supports several communications protocols and components for communication with the following devices: Devices with PROFIBUS DP interface These are connected directly on the PROFIBUS DP. An example is the SIPART DR20 process controller. Devices with PROFIBUS PA interface e.g. the SITRANS P transmitter Remote I/O stations, e.g. ET 200M The PROFIBUS PA devices supported by SIMATIC PDM are connected to the PROFIBUS DP segment via a DP/PA link or DP/PA coupler. The fully integrated PROFIBUS devices can be parameterized, as well as almost all PROFIBUS devices with the following PA profiles of versions 2.0 and 3.0: - Pressure and temperature - Level and flow - Actuators - Discrete I/Os - Analyzers (only PA profile version 3.0) Devices with HART interface These devices can be connected in different manners: - Via the SIMATIC ET 200M distributed I/O station with the HART modules - Via the ET 200iS distributed I/O station with HART on PROFIBUS according to PNO - Via a HART modem with which a point-to-point connection is established between a PC or engineering station and the HART device - Via HART multiplexers present in the HART server of the HCF (HART Communication Foundation). Further HART devices can be parameterized in addition to the fully-integrated, HART-compatible devices. Controllers with serial SIPART DR communication via RS 232 / RS 485 Controllers from the SIPART range can be parameterized via the so-called SIPART DR network.

Device Description Language SIMATIC PDM supports field devices conforming to the PROFIBUS PA profile descriptions provided by PROFIBUS International (PNO), as well as field devices which are supported by an Electronic Device Description (EDD) and HART Device Description (HART-DD). The design and functions of the field devices are described by the Electronic Device Description Language EDDL specified by the PNO. SIMATIC PDM automatically creates its GUI with the corresponding field device information using these descriptions. The HART field devices described by HART-DDL are integrated into SIMATIC PDM using the HCF catalog (Hart Communication Foundation). HART-DDL is a widely accepted standard and is strongly supported by device vendors. Additional field devices from Siemens as well as devices from other vendors can be simply integrated into SIMATIC PDM by importing their device descriptions (EDD, GSD). Access protection SIMATIC PDM supports two different groups of users: specialists and maintenance engineers. The maintenance engineer can modify the operating data, the specialist can access all parameters and functions. A password can be assigned as required as access protection for specialists.

Diagnostics with PROFIBUS PA and SIMATIC PCS 7

Diagnostics display (left) on the operator station with plant topology. One field device is faulty (red symbol) on the PROFIBUS PA line. The associated message "Deviation" is displayed in the message line. Clicking the faulty field device displays a process view (right) in which an operator can recognize that the inlet valve has been closed and can no longer be opened. SIMATIC PDM can be used if required to read further detailed information from the field device.

Status information from PROFIBUS PA devices Each PROFIBUS PA device delivers a status together with each measured value. This status contains a variety of diagnostics information on the measured value delivered by the device, in accordance with the profile definition of PROFIBUS International (PNO). The standard diagnostics information delivered by the PROFIBUS PA devices includes e.g.: Device faults, Maintenance requests, Operating mode (automatic or local operation) of a positioner, Configuration fault etc. Compression of information using standard SIMATIC PCS 7 function blocks The status information can be interpreted, compressed or output as alphanumeric messages in SIMATIC PCS 7 using standard CFC blocks, always based on the PNO profile definition.

Practice-oriented PCS 7 diagnostics blocks for Siemens field devices In addition to this, practice-oriented diagnostics blocks are available which are specially tuned to Siemens field devices and are ready to use. These blocks provide precise message texts optimally matched to the respective device which are more comprehensive than those of the standard defined in the profile. Examples include: "Deviation fault" (SIPART PS2), e.g. resulting from compressed air failure (also see Fig. above) "Function check" (ULTRAMAT/OXYMAT). Furthermore, the diagnostics blocks provide evaluation of the status with respect to time, e.g. by the message "Continuous overload". For specific field devices, the diagnostics blocks also have an interface for user functions which would otherwise have to be configured in addition, e.g. autocalibration for gas analyzers. This increased degree of convenience is offered for the following PROFIBUS PA field devices from Siemens, e.g. SITRANS P, SITRANS T, SITRANS F US, SITRANS LR, SIPART PS2, ULTRAMAT, OXYMAT or SIPAN.

The diagnostics messages permit operators to react more rapidly, and to inform the maintenance personnel more exactly. Operators know, for example, that a device has to be replaced in the near future, or that a device is currently being configured or calibrated and thus cannot carry out any measurements. These messages are displayed on the operator station (OS), and are saved in the OS message archive together with a time stamp and the tag number. Specific maintenance information using SIMATIC PDM Detailed information which is exceptionally appropriate as a decision basis for further actions can be called from field devices using SIMATIC PDM, e.g. whether the device is positioned in an unsuitable location resulting in an excessively high temperature for the measuring electronics, or whether it has to be tested and repaired by a maintenance engineer. Thus service measures can be planned before a device fails. Integration in MES systems If required, the diagnostics messages can also be evaluated by host computers via the standard interfaces of SIMATIC PCS 7, e.g. via the OPC interface.

DP/PA coupler and DP/PA link

PROFIBUS-DP/PA transition To guarantee a problem-free transition between PROFIBUS DP and PROFIBUS PA with their different transmission systems, the SIMATIC range provides the DP/PA coupler and DP/PA link as gateways. Their respective application depends on the plant size, the required performance, and the automation system used: The DP/PA coupler is used for small quantity breakdowns (signal quantities) and low timing requirements The DP/PA link is used for large quantity breakdowns and high timing requirements. DP/PA link Application The DP/PA link is a very simple gateway that links PROFIBUS DP and PROFIBUS PA together in a manner whereby data transmission decoupling is retained. PROFIBUS DP and PROFIBUS PA can thus be combined without influencing the processing performance of PROFIBUS DP. The DP/PA link permits the design of large systems with extensive address volumes and demanding requirements with respect to cycle time. It can be operated on standard PROFIBUS DP masters. Mode of operation The DP/PA link functions as a slave on the PROFIBUS DP and as a master on the PROFIBUS PA. From the viewpoint of the automation system or process control system, the DP/PA link is a modular slave. The individual modules of this slave are the field devices connected to the lower-level PROFIBUS PA system. The field devices are addressed indirectly via the DP/PA link. Thanks to data transmission decoupling, the maximum transmission rate of up to 12 Mbits/s can be utilized on the PROFIBUS DP side. The addressing capacity of the system is considerably increased due to the fact that up to 31 field devices can be connected to a DP/PA link, but the DP/PA link only reserves one PROFIBUS DP address.

Design The DP/PA link is of modular design according to the S7-300 format. It comprises the IM 157 interface module and one or more DP/PA couplers in the versions either for hazardous or non-hazardous applications. Use of active bus modules as the backplane bus permits the hot swapping of individual modules during operation as well as a redundant design for the PROFIBUS DP interface. High-availability applications are therefore possible together with the AS 414H/AS 417H automation systems.

Versions of the DP/PA link for hazardous or non-hazardous applications are also configurable by combination of the IM 157 with hazardous or non-hazardous versions of the DP/PA coupler. This modular system can be extended to up to 5 PROFIBUS PA lines per DP connection. These lines are physically isolated as far as the power supply is concerned, but constitute one bus system for communications aspects.

Intelligent PROFIBUS-compatible field devices

Siemens offers a complete range of intelligent field devices for use with the SIMATIC PCS 7 process control system that allow automation and control at the field level: Process devices Analyzers Weighing systems Panel instruments Drives

PDM

SITRANS T

The field devices identified by this symbol can be parameterized using SIMATIC PDM.

Process devices The process devices are available as either PROFIBUS or HART compliant versions. Further technical data and ordering information on these process devices are available at: www.siemens.com/fielddevices

SITRANS P

SITRANS F US

SITRANS F M

Transmitters for pressure measurements PDM The SITRANS P transmitters are suitable for flow, pressure and level measurements of corrosive and non-corrosive gases, vapors and liquids. Various measuring cells are used for the different requirements and permit optimum accuracy for the respective task. With a completely welded measuring cell, the SITRANS P is vacuum-tight, has an exceptional over-pressure tolerance capability, resulting in a long service life with unmatched operating performance. These transmitters are designed for absolute and differential pressures from 1 mbar to 400 bar.

Flow measurements PDM The SITRANS F US ultrasonic flowmeter with the patented helical passage of sound is used to measure flow of conductive and non-conductive liquids, e.g. solvents, organic liquids and condensates. In addition to the signal for the flow, the device delivers additional data from which information can also be derived on the product quality. The main advantages are the high measuring accuracy, the flow without pressure losses, the wide dynamic range, the multi-sensor properties, and the low maintenance costs since no moving parts are present. The SITRANS F M electromagnetic flowmeter measures the flow of electrically conductive media above 0.008 S/cm. Homogeneous liquids can be measured, including flowing media with solid particles such as slurries, pastes and sludges. Flow velocities up to 12 m/s are permissible. Nominal diameters from DN 2 to DN 2000 are available, together with flanges according to DIN, ANSI and further standards. Liners are available with soft and hard rubber, with NOVOLAK for corrosive media up to 130 C, and with PTFE for temperatures up to 180 C.

Temperature measurements PDM SITRANS T is used to measure temperatures. Its universal input stage provides flexibility such that all common temperature sensors and DC voltage sources can be connected: Pt 100 resistance thermometers, Thermocouples, Resistance-based sensors/potentiometers from 24 to 6000 and DC voltage sources with spans from 17 mV to 1120 mV. The complete standardized temperature range can be measured for the various sensors. The characteristics of all sensors are linearized.

Intelligent PROFIBUS-compatible field devices

Level measurements PDM SITRANS LR 400 is a high-frequency radar level meter for the process industry, featuring high accuracy and wide measuring ranges. SITRANS LR 300 is a level meter that operates per the Siemens patented microwave pulse technology, and provides exceptional measurement reliability even under difficult operating conditions. The device can be used on pressurized vessels, in explosive or nonexplosive media, in applications where large amounts of steam or dust are present, and in high temperature applications. Besides these two level instruments, Siemens portfolio also includes various ultrasonic level meters for a variety of applications. These include compact devices for measuring liquid, solid or sludge levels, and a system for monitoring and controlling pump stations. Meters for capacitive level measurements SITRANS LC 500 is an ideal capacitive level meter for use under extreme temperature and pressure conditions. The Siemens patented active shield technology protects it from dirt, deposits, steam and condensation. The SITRANS LS level switches are used to determine predefined levels of bulk materials, sludges or interfaces. The measurement is based on the non-contact ultrasonic principle or using highlysensitive capacitive electrodes. A wide range of different versions is available, including those for use at high pressures and temperatures or sanitary versions for the food and drink industry or the pharmaceutical industry.

SIPART PS2 SITRANS LR

capacitive level measurements

Analyzers

Intelligent positioner for pneumatic control valves PDM The SIPART PS2 electropneumatic positioner is used with linear or quarterturn control valves and air-operated dampers. The positioner ensures that the control valve performs as commanded by the control system and also provides feedback to the control system regarding the actual valve position at all times. The SIPART PS2 positioner is available in PROFIBUS and HART compliant versions. The user is able to configure many advanced functionalities such as a min-stop position, a fail-safe position, etc. via a comprehensive choice of configurable parameters in the positioner. SIPART PS2 is also available for use in hazardous areas.

Analyzers Liquid analysis PDM Siemens liquid analyzers under the brand SIPAN are available for measurement of pH, conductivity and dissolved oxygen. These analyzers are PROFIBUS PA compliant and are powered over the bus. Intrinsically-safe versions are available for applications in electrically hazardous areas. Gas analyzers PDM ULTRAMAT 6 operates on the dual beam NDIR principle, and continuously and selectively measures IR-active gases such as CO/NO/SO2, CO2, N2O and CH4. OXYMAT 6 operates according to the paramagnetic alternating pressure principle, and is used to measure oxygen in gases. CALOMAT 6 measures the specific thermal conductivity to determine the concentration of hydrogen and noble gases. FIDAMAT gas analyzers have a flame ionization detector to measure hydrocarbons. The measurement is component-specific, and not just class-specific. As a first approximation, the result is proportional to the number of C atoms in the respective molecule.

10

Weighing systems Weighing modules Net weight and proportioning scales for industrial processes can be configured quickly and efficiently using predefined scales blocks. For SIMATIC PCS 7, Siemens offers configuration packages with blocks for the SIWAREX M and SIWAREX U weighing modules as add-on products. These blocks permit simple linking of the weighing modules into the engineering system, and also easy operation of the scales from the operator system. The scales faceplate in the operator system also provides important diagnostics information for the operating personnel. Integral message response and maintenance functions such as the reading or writing of all weighing parameters provide a high level of system availability, and thus short down times. Siemens-Milltronics weighing systems The range comprises: Precision and torque scales for reliable and continuous weighing of bulk materials High-performance conveyor scales for measuring ranges from 45 kg/h up to 725 t/h Low-maintenance bulk flow meter with high reliability and repeatability (even for difficult mixing and batch functions) Panel instruments Process controllers PDM The SIPART DR19 and DR21 process controllers designed for general process control provide a single-loop control solution at an affordable price. These offer a wide range of preconfigured functions for process control which can be deployed by users without any programming knowledge or engineering effort. The built-in self-tuning algorithms in the SIPART DR19 and DR21 makes the task of commissioning these controllers even easier. These two process controllers are connected to the SIMATIC PCS 7 automaSIPART DR

SIPART DR

SIMOCODE-DP

MASTERDRIVES Weighing systems MICROMASTER

tion systems via PROFIBUS DP. The SIPART DR19/21 function blocks are available as add-on products for SIMATIC PCS 7. Each function block has its associated OS faceplate which shows the control and display elements of the corresponding process controller. Drives Motor management PDM The SIMOCODE-DP motor protection and control device is primary used in the motor control centers (MCC) of process industry plants. It offers the following functions: Comprehensive motor protection and motor feeder monitoring Integral, software-based control programs for all typical, switched motor applications Detailed motor and plant diagnostics Integral PROFIBUS DP interface In particular for applications in the chemical industry, SIMOCODE-DP provides safe isolation and complies with the NAMUR regulations. SIMOCODE-DP can be integrated simply into the SIMATIC PCS 7 process control system using the PCS 7 function block SIMOCODE-DP offered as an add-on product, and visualized in the operator

station using the associated OS faceplate. Variable Frequency Drives The MASTERDRIVES range is universal and modular. The power range extends from 0.55 up to 2300 kW. All common international power supplies from 200 to 690 V are covered. The MICROMASTER drive is a standard frequency converter in the power range from 0.12 up to 90 kW, and can be used for numerous drive applications with variable speeds. The converter is particularly suitable for applications with pumps, fans and conveying equipment. The add-on product "Drive ES PCS 7" can be used to control, operate and monitor the drives using the SIMATIC PCS 7 process control system. Parameterization, commissioning and diagnostics of the drives can be carried out with the addon product "Drive ES Basic" which can be integrated in the SIMATIC Manager.

11

Technical specifications

Technical specification Function

DP/PA coupler Bus coupling of PROFIBUS DP (45.45 kbits/s) and PROFIBUS PA (31.25 kbits/s)

IM 157 (for DP/PA link) Bus coupling of PROFIBUS DP (9.6 kbits/s to 12 Mbits/s, slave functions) and PROFIBUS PA Implementation of the DP/PA link function together with one or more DP/PA couplers

HART modules For coupling HART devices to PROFIBUS DP

Power supply Supply Mains backup Mechanical design Current consumption

24 V DC 20 ms 4-pole screw terminal max. 400 mA (Ex version) max. 750 mA (Non-Ex version) approx. 7 W (Ex- and Non-Ex version) max. 100 mA (in DP/PA link) max. 200 mA (in Y-link) approx. 2 W (in DP/PA link) approx. 4 W (in Y-link)

24 V DC

Power loss

PROFIBUS DP connection PROFIBUS-PA connection Intrinsically-safe version

9-pin Sub-D plug, electrically isolated and floating 2-pole screw terminal, permanently integrated terminating resistor, [EEx ia]: output current max. 110 mA 4-pole screw terminal, selectable terminating resistor, output current max. 400 mA

Via IM 153-2 interface module (ET 200M)

Non-intrinsically-safe version

Transmitter connection

2-wire connection (HART, 4...20 mA) 4-wire connection (0...20 mA) Common fault LED (red) Channel-specific fault (red) HART status (green) Input 10+sign/13+sign/15+sign Output 12+sign Output up to 650

Displays

DP bus active (yellow) PA bus active (yellow) 24 V DC(green)

System fault (red) DP bus fault (red) PA bus fault (red) 24 V DC(green)

Parameterizable resolution (bits+sign) Load impedance Temperature range

[EEx ia]: 0...+60 C [EEx ib]: -25...+60 C Non-Ex: -25...+60 C S7-300 format, double-width module (80 mm), mounting on S7-300 rail Ex version [EEx ia] II C 80 x 125 x 130

-25...+60 C

0...+60 C

Packaging system

S7-300 format, single-width module (40 mm), mounting on S7-300 rail 40 x 125 x 130 Ex version [EEx ib] II C 40 x 125 x 120

Type of protection Dimensions (W x H x D) in mm

Siemens AG Automation and Drives Industrial Automation Systems D-76181 Karlsruhe

www.siemens.com/simatic-pcs7

Order No. E86060-A4678-A121-A2-7600 Printed in the Federal Republic of Germany 315148 KB 0403 5.0 SR En

Siemens AG 2003 Subject to change without prior notice

The information provided in this brochure contains merely general descriptions or characteristics of performance which in case of actual use do not always apply as described or which may change as a result of further development of the

products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract. Availability and technical specifications are subject to change without notice.

También podría gustarte

- PCS 7 Logic MatrixDocumento134 páginasPCS 7 Logic Matrixtan_bkAún no hay calificaciones

- Open PCS7 PDFDocumento114 páginasOpen PCS7 PDFpatytigreraAún no hay calificaciones

- Setting up PCS7 Projects with IEADocumento6 páginasSetting up PCS7 Projects with IEAmoxlindeAún no hay calificaciones

- Pcs7 Create Own Block Icons v8x enDocumento33 páginasPcs7 Create Own Block Icons v8x enHhaabbde SybaritzAún no hay calificaciones

- DCS PCS 7Documento2 páginasDCS PCS 7eman71Aún no hay calificaciones

- PR WinCC OA V315 Technical Features enDocumento252 páginasPR WinCC OA V315 Technical Features enKijo Supic100% (1)

- CPU 410 en-US en-USDocumento422 páginasCPU 410 en-US en-USSergio PastellettoAún no hay calificaciones

- MatrikonOPC Server For Siemens PLCs Driver User ManualDocumento177 páginasMatrikonOPC Server For Siemens PLCs Driver User ManualRamirez ManuelAún no hay calificaciones

- Siemens Sample Configurations - IEtoPB Link - June03Documento15 páginasSiemens Sample Configurations - IEtoPB Link - June03Hhaabbde SybaritzAún no hay calificaciones

- Training CatalogDocumento16 páginasTraining Catalogsmartdev29Aún no hay calificaciones

- PHB PCS7 eDocumento528 páginasPHB PCS7 eSaad BroAún no hay calificaciones

- PLC ProgrammingDocumento86 páginasPLC ProgrammingMuhammad BilalAún no hay calificaciones

- Simatic PDMDocumento16 páginasSimatic PDMmkdo82Aún no hay calificaciones

- PCS7 PH Installation enDocumento94 páginasPCS7 PH Installation enjjccmmaaAún no hay calificaciones

- Simatic Pcs 7 Guiding You Through Change: Your Trusted Partner For Lifecycle InnovationDocumento28 páginasSimatic Pcs 7 Guiding You Through Change: Your Trusted Partner For Lifecycle Innovationmfonseca31Aún no hay calificaciones

- SCE EN 020-011 R1404 Startup S7-1500 V13Documento79 páginasSCE EN 020-011 R1404 Startup S7-1500 V13Yoga AdiAún no hay calificaciones

- ABB Industrial 800xaDocumento12 páginasABB Industrial 800xaUjjwal GhoshAún no hay calificaciones

- PLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING, - PID Control in SIEMENS S7 PLC PDFDocumento4 páginasPLC, PLC LADDER, PLC EBOOK, PLC PROGRAMMING, - PID Control in SIEMENS S7 PLC PDFfeyyazkurtAún no hay calificaciones

- PDS S-Series ProfibusDP IODocumento6 páginasPDS S-Series ProfibusDP IOKarthik SelvaAún no hay calificaciones

- Vijeo Citect V70 Getting StartedDocumento94 páginasVijeo Citect V70 Getting StartednharchelloAún no hay calificaciones

- Simatic HmiDocumento324 páginasSimatic HmiAyman ElotaifyAún no hay calificaciones

- PCS7 PROFINET Engineering enDocumento41 páginasPCS7 PROFINET Engineering enAbez FiveAún no hay calificaciones

- PLC23 001B Introduction S7-200Documento18 páginasPLC23 001B Introduction S7-200hassanaagib100% (1)

- SIMATIC PROFINET System Description PDFDocumento182 páginasSIMATIC PROFINET System Description PDFChen CYAún no hay calificaciones

- 3BDD011932-111 A en Freelance Operation Guide Freelance OperationsDocumento351 páginas3BDD011932-111 A en Freelance Operation Guide Freelance OperationsMathias MolleAún no hay calificaciones

- Data Connect: Using Xlreporter With Kepserverex - DaDocumento4 páginasData Connect: Using Xlreporter With Kepserverex - DaAnas Bin AhmadAún no hay calificaciones

- PCS7 LicenseDocumento28 páginasPCS7 LicenseSreedhar Rakesh Vellanki100% (1)

- 1A - P L C - Allen BradleyDocumento45 páginas1A - P L C - Allen BradleyMystic AamirAún no hay calificaciones

- WinCC V7.5 WinCC: General Information and InstallationDocumento266 páginasWinCC V7.5 WinCC: General Information and InstallationAbdullah SeliemAún no hay calificaciones

- What Is OPCDocumento3 páginasWhat Is OPCnamhtsAún no hay calificaciones

- Safety Integrated For Process AutomationDocumento40 páginasSafety Integrated For Process AutomationSerge RINAUDOAún no hay calificaciones

- SCADA - CitectSCADA ConfigurationDocumento2 páginasSCADA - CitectSCADA Configurationmoeen2006Aún no hay calificaciones

- How Set Historian PCS7 PDFDocumento3 páginasHow Set Historian PCS7 PDFHeber Alejandro Gahona JeriaAún no hay calificaciones

- PCS7 Create Own Block Icons V90 enDocumento33 páginasPCS7 Create Own Block Icons V90 enEmerson KleemAún no hay calificaciones

- Simatic Pcs7 BoxDocumento4 páginasSimatic Pcs7 BoxRaj ChavanAún no hay calificaciones

- Simatic pcs7 Traing Course PDFDocumento34 páginasSimatic pcs7 Traing Course PDFmiraAún no hay calificaciones

- hc900 OpcserverDocumento12 páginashc900 Opcservermanu2020Aún no hay calificaciones

- Application Examples Overview enDocumento26 páginasApplication Examples Overview enArunagiriAún no hay calificaciones

- Troubleshooting ProfibusDocumento5 páginasTroubleshooting Profibussteam100deg8229Aún no hay calificaciones

- PCS7 v8.2Documento29 páginasPCS7 v8.2nelle69Aún no hay calificaciones

- PCS7 Project Adaption AdvESDocumento40 páginasPCS7 Project Adaption AdvESAbez FiveAún no hay calificaciones

- GH Cp343-1ex30 76Documento67 páginasGH Cp343-1ex30 76KoertBAún no hay calificaciones

- WinCC V70 OS Antivirus Compatibility ListDocumento2 páginasWinCC V70 OS Antivirus Compatibility ListnithinvnAún no hay calificaciones

- WinCC Communication en-US en-US PDFDocumento528 páginasWinCC Communication en-US en-US PDFAhmed Mohamed BardiniAún no hay calificaciones

- Kepserverex Manual PDFDocumento280 páginasKepserverex Manual PDFnew2trackAún no hay calificaciones

- Positioning of The Modular S7 Controllers ........................................................... 1-2Documento16 páginasPositioning of The Modular S7 Controllers ........................................................... 1-2MiguelGonzalezAún no hay calificaciones

- WinCC V72 Compatibility List eDocumento2 páginasWinCC V72 Compatibility List ejjccmmaaAún no hay calificaciones

- WinCC TagLogging AlarmloggingDocumento3 páginasWinCC TagLogging AlarmloggingcbaliveAún no hay calificaciones

- Vijeo Citect Installation GuideDocumento76 páginasVijeo Citect Installation GuideRafael GadbemAún no hay calificaciones

- Configuracion Sinamics PCS7 PDFDocumento21 páginasConfiguracion Sinamics PCS7 PDFAlvaro AvilaAún no hay calificaciones

- CitectSCADA v7 End User PresentationDocumento25 páginasCitectSCADA v7 End User PresentationSaikat SahaAún no hay calificaciones

- Modicon PremiumDocumento459 páginasModicon Premiumsalmo83:18Aún no hay calificaciones

- Simatic Step 7 DownloadDocumento3 páginasSimatic Step 7 DownloadZdravko PeranAún no hay calificaciones

- Security and Wincc OaDocumento24 páginasSecurity and Wincc OaKijo SupicAún no hay calificaciones

- L01 - Introduction To Studio 5000 Logix DesignerDocumento11 páginasL01 - Introduction To Studio 5000 Logix DesignerjaysonlkhAún no hay calificaciones

- Profibus PDFDocumento12 páginasProfibus PDFchochoroyAún no hay calificaciones

- Profibus Pa: Profibus Pa Profibus PA Profibus PA Profibus PaDocumento4 páginasProfibus Pa: Profibus Pa Profibus PA Profibus PA Profibus PamandaremAún no hay calificaciones

- An Open Electronic Marshalling SolutionDocumento4 páginasAn Open Electronic Marshalling Solutionmanuelsantos2007Aún no hay calificaciones

- Profinet PDFDocumento36 páginasProfinet PDFstgpereiraAún no hay calificaciones

- Networked Control System: Fundamentals and ApplicationsDe EverandNetworked Control System: Fundamentals and ApplicationsAún no hay calificaciones

- Annexure For Pressure GaugeDocumento2 páginasAnnexure For Pressure GaugeRaj ChavanAún no hay calificaciones

- Pdms Cable TrayDocumento10 páginasPdms Cable TrayRaj ChavanAún no hay calificaciones

- XFDocumento1 páginaXFRaj ChavanAún no hay calificaciones

- His AtlDocumento7 páginasHis AtlRaj ChavanAún no hay calificaciones

- Drak A Mog CatalogDocumento376 páginasDrak A Mog Catalogdadok999Aún no hay calificaciones

- Proline Prosonic Flow 93W: Technical InformationDocumento32 páginasProline Prosonic Flow 93W: Technical InformationRaj ChavanAún no hay calificaciones

- Cs01304den 0112Documento2 páginasCs01304den 0112Raj ChavanAún no hay calificaciones

- Instrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Documento88 páginasInstrumentation Cables: BS 5308, Part 1 BS 5308, Part 2 and Gen. To BS 5308, Part 1Raj ChavanAún no hay calificaciones

- SU-FMO Fire Alarm System Basics Presentation To Building Managers 7-28-2014Documento30 páginasSU-FMO Fire Alarm System Basics Presentation To Building Managers 7-28-2014Ahmed MohamedAún no hay calificaciones

- PL-2303 Windows XP Driver UpdateDocumento1 páginaPL-2303 Windows XP Driver UpdatePolo AlvarezAún no hay calificaciones

- What Does NAMUR NE 43 Do ForDocumento1 páginaWhat Does NAMUR NE 43 Do ForRaj ChavanAún no hay calificaciones

- DVR Vs NVRDocumento3 páginasDVR Vs NVRGvds SastryAún no hay calificaciones

- Why Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Documento2 páginasWhy Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Raj ChavanAún no hay calificaciones

- Marine Electrical KnowledgeDocumento53 páginasMarine Electrical KnowledgeRhn RhnAún no hay calificaciones

- NEMA Motor Manual Section on AccessoriesDocumento16 páginasNEMA Motor Manual Section on AccessoriesDelfinshAún no hay calificaciones

- and 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFDocumento8 páginasand 330425 Accelerometer Acceleration Transducers - Datasheet - 141638 - Cda - 000 PDFdialixhAún no hay calificaciones

- Schneider Electric - Overload Relay Trip CurvesDocumento84 páginasSchneider Electric - Overload Relay Trip CurvesMichael Parohinog GregasAún no hay calificaciones

- Chapter 18 FiltrationDocumento18 páginasChapter 18 FiltrationGMDGMD11Aún no hay calificaciones

- His AtlDocumento7 páginasHis AtlRaj ChavanAún no hay calificaciones

- Unit 6: Project EvaluationDocumento12 páginasUnit 6: Project EvaluationRaj ChavanAún no hay calificaciones

- Surge Protec IIDocumento14 páginasSurge Protec IIRaj ChavanAún no hay calificaciones

- Area Classification: (IEC/EN 60529)Documento1 páginaArea Classification: (IEC/EN 60529)nestkwt1Aún no hay calificaciones

- One NoteDocumento11 páginasOne NoteRaj ChavanAún no hay calificaciones

- Chem Earth PointsDocumento65 páginasChem Earth PointsRaj ChavanAún no hay calificaciones

- EINTH012Documento32 páginasEINTH012Raj ChavanAún no hay calificaciones

- Why Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Documento2 páginasWhy Has 4-20 Ma Gained So Much Acceptance and Survived So Long?Raj ChavanAún no hay calificaciones

- Cost Estimation Techniques for Uncertain ProjectsDocumento7 páginasCost Estimation Techniques for Uncertain ProjectsRaj ChavanAún no hay calificaciones

- Unitronics IdntolvurDocumento24 páginasUnitronics IdntolvurRaj ChavanAún no hay calificaciones

- BN330500dt PDFDocumento19 páginasBN330500dt PDFvvAún no hay calificaciones

- ProffieBoard TeensySaber User Manual v1.5 13Documento52 páginasProffieBoard TeensySaber User Manual v1.5 13Jason SAún no hay calificaciones

- Restrict References PragmaDocumento2 páginasRestrict References PragmabskrbvkrAún no hay calificaciones

- Oftware Equirements Pecification: Ndroid LatformDocumento10 páginasOftware Equirements Pecification: Ndroid Latformtanay9bhargavaAún no hay calificaciones

- Overview of The QuantStudio® 3 System - Rev2 - LA19507Documento50 páginasOverview of The QuantStudio® 3 System - Rev2 - LA19507Michael OkekeAún no hay calificaciones

- Lab - 10 - Sequence Detector Using FSMDocumento3 páginasLab - 10 - Sequence Detector Using FSMTalha KhalidAún no hay calificaciones

- 2024 DHC 2698, Ericsson v Lava InternationalDocumento476 páginas2024 DHC 2698, Ericsson v Lava InternationalkenzaelkabiriAún no hay calificaciones

- Cyberpulse Computing Fact Sheet: IT Hardware DistributorDocumento1 páginaCyberpulse Computing Fact Sheet: IT Hardware DistributorKagiso Arthur JonahAún no hay calificaciones

- BOOK Laptop Motherboard Fault FinderDocumento85 páginasBOOK Laptop Motherboard Fault FinderServis Accu80% (5)

- VTP Interview Questions and Answers (VLAN Trunking Protocol) - Networker InterviewDocumento2 páginasVTP Interview Questions and Answers (VLAN Trunking Protocol) - Networker InterviewBhanu SainiAún no hay calificaciones

- Mobile Banking FaqDocumento4 páginasMobile Banking FaqSenthil KumarAún no hay calificaciones

- Dsi 403Documento176 páginasDsi 403Vitaly SavenkovAún no hay calificaciones

- IBM Watson Defeats Humans on JeopardyDocumento18 páginasIBM Watson Defeats Humans on JeopardyPraveen NairAún no hay calificaciones

- Zigbee Based Wireless Tyre Pressure Monitoring SystemDocumento1 páginaZigbee Based Wireless Tyre Pressure Monitoring SystemojenikohAún no hay calificaciones

- Fault-Tolerant Routing in Mobile Ad Hoc NetworksDocumento1 páginaFault-Tolerant Routing in Mobile Ad Hoc NetworksAshwin SangemAún no hay calificaciones

- Packet Tracer ACL ChallengeDocumento3 páginasPacket Tracer ACL ChallengeBilegdemberel TugbaatarAún no hay calificaciones

- A10 DS 15100 en PDFDocumento12 páginasA10 DS 15100 en PDForellana160Aún no hay calificaciones

- Wireless Bank Security System Using Sensors SynopsisDocumento7 páginasWireless Bank Security System Using Sensors SynopsisHamza HebAún no hay calificaciones

- Office file format standardization processDocumento2 páginasOffice file format standardization processSatine SatineAún no hay calificaciones

- Kumpulan 31: Iot Based Object Counting and Colour DetectionDocumento8 páginasKumpulan 31: Iot Based Object Counting and Colour DetectionAFiqah Nazirah JailaniAún no hay calificaciones

- 3GPP TS 23.040Documento219 páginas3GPP TS 23.040Derek YangAún no hay calificaciones

- FMC Flow Management Computer: FeaturesDocumento4 páginasFMC Flow Management Computer: Featurescacalot93Aún no hay calificaciones

- Your First iOS Application: GeneralDocumento54 páginasYour First iOS Application: Generalvijay19882710Aún no hay calificaciones

- CamHi 4G IP Camera Quick Start GuideDocumento11 páginasCamHi 4G IP Camera Quick Start GuiderbokisAún no hay calificaciones

- Automatic-Book-Scanner 4 PDFDocumento5 páginasAutomatic-Book-Scanner 4 PDFpolikarpaAún no hay calificaciones

- Kat PickleDocumento3 páginasKat PickleKiagus M. Roihan A.Aún no hay calificaciones

- Lab Workbook: Analysis and Design of AlgorithmsDocumento38 páginasLab Workbook: Analysis and Design of AlgorithmsSahil GandhiAún no hay calificaciones

- Sasatel EVDO Wifi RouterDocumento2 páginasSasatel EVDO Wifi Routersoud98Aún no hay calificaciones

- (Video Title) : FPGA Design For Embedded SystemsDocumento13 páginas(Video Title) : FPGA Design For Embedded SystemsAl AminAún no hay calificaciones

- ASP-NET The Complete Reference Matthew MacDonaldDocumento67 páginasASP-NET The Complete Reference Matthew MacDonaldonlyviki60% (5)

- Manuale DunazipDocumento9 páginasManuale DunazipErre DiAún no hay calificaciones