Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Sample Cooler

Cargado por

kingathur26681Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Sample Cooler

Cargado por

kingathur26681Copyright:

Formatos disponibles

KARRASCH & ECKERT ECKERT

Gesellschaft fr Wassertechnologie mbH

Sample Cooler Operation Manual

page 1/3

Sample Cooler

1 Description

A proper steam boiler operation requires regular monitoring of the water chemistry. The sample cooler described in this manual serves for easy, safe and accurate sampling and cooling of condensate, boiler feed water and boiler water. The sample cooler consists of a vessel with inner cooling loop and welded on collecting cup with discharge, connections for cooling and sampling water, a shut off valve for cooling water and a throttling valve for sample water. For cooling, the sample water within the cooling loop flows through the cooling water within the vessel, in countercurrent direction.

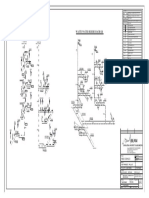

Picture: sample cooler with cation exchanger and connection for conductivity measurement (not included in the standard design)

2 Intended Use

The device described in this manual exclusively serves for cooling of boiler feed water, boiler water and condensate samples within the described limitations. Any other kind of use is not permitted.

3 Safety Advice

3.1 Temperature During operation, hot water flows through the device. WARNING: Danger of burns and scalding due to hot water and hot device parts! Sample taking is only permitted if cooling water is fully flowing through the device. Before maintenance or repair works, the device needs to be shut-off and cooled down. 3.2 Pressure The device operates at over-pressure. WARNING: In case of opening or de-assembling of pressure-loaded device parts, there is the danger of injuries as well as damage to the device! Before maintenance or repair works, the device needs to be shut-off and relieved of pressure.

Status: 09/11/2009

Subject to change without notice.

http://www.karrasch-eckert.de/

KARRASCH & ECKERT ECKERT

Gesellschaft fr Wassertechnologie mbH

Sample Cooler Operation Manual

page 2/3

4 Technical Data

4.2 Type 80-300 hot water temperature, max. . 150 C primary hot water pressure, , max. 10 bar sample water flow rate, max. 40 l/h sample water outlet temperature 25 / 45 C (amount and temperature of cooling water varies) diameter cylindrical casing height total height hot water connection cooling water connection waste water connection 88.9 300 500 DN 6 R R mm mm mm

Material: casing, cooling loop, p, collecting cup completely made of stainless steel 1.4571 Accessories: or hot water, for connection to pipe 8x1, made of stainless steel 1 throttling valve DN 6 for 1 shut-off ball valve R 1/2 fo or cooling water, made of brass 4.3 Type 80-500 , max. 250 C hot water temperature, primary hot water pressure, max. 40 bar sample water flow rate, max. 40 l/h sample water outlet temperature 25 / 45 C (amount and temperature of cooling water varies) diameter cylindrical casing height total height hot water connection cooling water connection waste water connection 88.9 500 750 DN 6 R R mm mm mm

Material: casing, cooling loop, op, collecting cup completely made of stainless steel 1.4571 Accessories: or hot water, for connection to pipe 8x1, made of stainless steel 1 throttling valve DN 6 for 1 shut-off ball valve R 1/2 fo or cooling water, made of brass

Status: 09/11/2009

Subject to change without notice.

http://www.karrasch http://www.karrasch-eckert.de/

KARRASCH & ECKERT ECKERT

Gesellschaft fr Wassertechnologie mbH

Sample Cooler Operation Manual

page 3/3

5 Installation

The sample cooler is equipped with mountings for installation of fastening clips, or for fixation at a wall. The hot water or sample water line respectively is connected to the hot water throttling valve via a male stud coupling. The inlet and outlet line for the cooling water are each connected to the device with a threaded connection.

6 Operation

6.1 Manual Sample Taking In order to take a water sample, the cooling water valve needs to be opened slowly until it is fully opened. As soon as cooling water is flowing through the entire cooling vessel, the hot water throttling valve is to be slowly opened until the sample water exits as a thin jet of water. The sample vessel, for example an Erlenmeyer flask, now needs to be flushed with sample water a few times. After wards, the sample water can be taken in the required amount. Excess sample water is drained off through the collecting cup. 6.2 Continuous Sample Taking For continuous sample taking, the sample water flow through the device needs to be adjusted during commissioning, as described in 6.1.

7 Maintenance

In order to prevent sedimentation and corrosion, only soft water or demineralised water free of iron and chlorine may be used as cooling water. Should hardness sedimentation occur despite, the device can be cleaned with citric acid. To this end, the complete sample cooler needs to be inserted into a 5% citric acid dilution for about 8 hours.

8 Manufacturer Contact Data

Address:

KARRASCH & ECKERT

Gesellschaft fr Wassertechnologie mbH

Viehtrift 1 D-29308 Winsen/Aller Germany Tel.: Fax: E-Mail: Website: +49 (0)5143 93513 +49 (0)5143 93514 info@karrasch-eckert.de http://www.karrasch-eckert.de

Status: 09/11/2009

Subject to change without notice.

http://www.karrasch-eckert.de/

También podría gustarte

- Pipe Index: Ta Chen International, Inc.Documento10 páginasPipe Index: Ta Chen International, Inc.kingathur26681Aún no hay calificaciones

- Pipe Index: Ta Chen International, Inc.Documento10 páginasPipe Index: Ta Chen International, Inc.kingathur26681Aún no hay calificaciones

- Pipe Index: Ta Chen International, Inc.Documento10 páginasPipe Index: Ta Chen International, Inc.kingathur26681Aún no hay calificaciones

- Heat Transfer Technology 1010 03-10-2009 GBDocumento8 páginasHeat Transfer Technology 1010 03-10-2009 GBkingathur26681Aún no hay calificaciones

- Panwater PET 300 & 400 FC Series Cooling Towers PDFDocumento4 páginasPanwater PET 300 & 400 FC Series Cooling Towers PDFkingathur26681Aún no hay calificaciones

- Office (Eng)Documento31 páginasOffice (Eng)kingathur26681Aún no hay calificaciones

- TPM Administration PillarsDocumento53 páginasTPM Administration Pillarskingathur26681Aún no hay calificaciones

- Heat Exchanger Oil and Gas 1216 01-04-2012 GBDocumento12 páginasHeat Exchanger Oil and Gas 1216 01-04-2012 GBkingathur26681Aún no hay calificaciones

- PROFILL35 GDocumento9 páginasPROFILL35 Gkingathur26681Aún no hay calificaciones

- Brosur Belt InabecDocumento16 páginasBrosur Belt Inabeckingathur26681Aún no hay calificaciones

- Compressor ValvesDocumento9 páginasCompressor Valvesleading_aliAún no hay calificaciones

- APV Hybrid - Welded Heat ExchangerDocumento8 páginasAPV Hybrid - Welded Heat Exchangerkingathur26681Aún no hay calificaciones

- Victorindo General Products Catalog PDFDocumento8 páginasVictorindo General Products Catalog PDFkingathur26681Aún no hay calificaciones

- E SF 504 PDFDocumento33 páginasE SF 504 PDFAmirhosein605334Aún no hay calificaciones

- High Precision GearheadsDocumento32 páginasHigh Precision Gearheadskingathur26681Aún no hay calificaciones

- Ship Unloader LargepneumaticDocumento10 páginasShip Unloader LargepneumaticTaufik SinggihAún no hay calificaciones

- Panwater PCF Series Cooling Tower PDFDocumento28 páginasPanwater PCF Series Cooling Tower PDFkingathur26681Aún no hay calificaciones

- Twinro Leaflet PDFDocumento7 páginasTwinro Leaflet PDFkingathur26681Aún no hay calificaciones

- Bolted Bin SystemsDocumento8 páginasBolted Bin Systemskingathur26681Aún no hay calificaciones

- Heavy Duty Side Entry Mixers Technical ManualDocumento24 páginasHeavy Duty Side Entry Mixers Technical Manualkingathur26681100% (1)

- Marine and Offshore Insulation PDFDocumento0 páginasMarine and Offshore Insulation PDFkingathur26681Aún no hay calificaciones

- Triro Leaflet PDFDocumento5 páginasTriro Leaflet PDFkingathur26681Aún no hay calificaciones

- Distributors: Engineered Material Handling SolutionsDocumento1 páginaDistributors: Engineered Material Handling Solutionskingathur26681Aún no hay calificaciones

- Automatic SamplersDocumento6 páginasAutomatic Samplerskingathur26681Aún no hay calificaciones

- Bulk WeighersDocumento8 páginasBulk Weigherskingathur26681Aún no hay calificaciones

- The Process Pigging System Introduced by Pigs UnlimitedDocumento22 páginasThe Process Pigging System Introduced by Pigs Unlimitedkingathur26681100% (1)

- Bucket ElevatorsDocumento6 páginasBucket Elevatorskingathur26681Aún no hay calificaciones

- Polly Pigs ImageDocumento1 páginaPolly Pigs Imagekingathur26681Aún no hay calificaciones

- Pneumatic ConveyorDocumento5 páginasPneumatic ConveyorAhom CKAún no hay calificaciones

- Pipeline Integrity MGT Period 9 & 10 Difficult To Pig PipelinesDocumento158 páginasPipeline Integrity MGT Period 9 & 10 Difficult To Pig Pipelinesluisbazan7055100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Dayliff Water MetersDocumento2 páginasDayliff Water MetersEdward MainaAún no hay calificaciones

- Radial Flow For Unconfined AquiferDocumento4 páginasRadial Flow For Unconfined Aquifertom meeteiAún no hay calificaciones

- Cscro VIII HR Training Center Building - Phase 1 Plans PDFDocumento10 páginasCscro VIII HR Training Center Building - Phase 1 Plans PDFJohn Laurence Crucena VillaAún no hay calificaciones

- Water Supply Riser Diagram Waste Water Riser Diagram: ResidenceDocumento1 páginaWater Supply Riser Diagram Waste Water Riser Diagram: ResidenceAbebe MuluyeAún no hay calificaciones

- Control valve cross reference guide Flomatic OCV Singer Bermad Cla-Val Ross G/A WattsDocumento1 páginaControl valve cross reference guide Flomatic OCV Singer Bermad Cla-Val Ross G/A WattskaustavAún no hay calificaciones

- Model 375AST: Reduced Pressure Principle AssemblyDocumento2 páginasModel 375AST: Reduced Pressure Principle AssemblyGaurangAún no hay calificaciones

- Rain Water Storage & Pipe Gutter CalculationDocumento17 páginasRain Water Storage & Pipe Gutter Calculationhera4u2Aún no hay calificaciones

- BOMBA TAPERED HB 3 - Presentation - Harris - Pumping Flumping WellsDocumento22 páginasBOMBA TAPERED HB 3 - Presentation - Harris - Pumping Flumping WellsrolandoAún no hay calificaciones

- Reinforcement Drawings Exemples PDFDocumento27 páginasReinforcement Drawings Exemples PDFbasilecoqAún no hay calificaciones

- Toto CatalogueDocumento20 páginasToto CatalogueHerdiyantoAún no hay calificaciones

- Plano Hyd 994F PDFDocumento23 páginasPlano Hyd 994F PDFAlcanfred Cte BtoAún no hay calificaciones

- 22.water and Wastewater Treatment Plant HydraulicsDocumento127 páginas22.water and Wastewater Treatment Plant HydraulicsPuerto Parra Plan Aguas SantanderAún no hay calificaciones

- Test - Project Assistant - WASH - Sana'aDocumento7 páginasTest - Project Assistant - WASH - Sana'aMhalbanaAún no hay calificaciones

- UP 22sept08Documento44 páginasUP 22sept08api-3786544Aún no hay calificaciones

- PCAB Classification S-2017Documento2 páginasPCAB Classification S-2017rachelAún no hay calificaciones

- Series 825Y Specification SheetDocumento2 páginasSeries 825Y Specification SheetFEBCOAún no hay calificaciones

- ProjectDocumento16 páginasProjectMegha NagarajAún no hay calificaciones

- Sanitary Drainage System Design RequirementsDocumento50 páginasSanitary Drainage System Design RequirementsNilu BishiAún no hay calificaciones

- Pipe Wall Thickness Calculation-ASME B31.3Documento4 páginasPipe Wall Thickness Calculation-ASME B31.3Rajul MuraliAún no hay calificaciones

- Matrix For Piping Work - ITP - Final - PK3Documento4 páginasMatrix For Piping Work - ITP - Final - PK3Trương Ngọc SơnAún no hay calificaciones

- HepvO PIC Aug2003Condensate DrainDocumento2 páginasHepvO PIC Aug2003Condensate DrainAhmed TahaAún no hay calificaciones

- REVERSE OSMOSIS TECHNOLOGY FOR WATER TREATMENTDocumento73 páginasREVERSE OSMOSIS TECHNOLOGY FOR WATER TREATMENTAkhil ShrivastavAún no hay calificaciones

- ME 326: Experiment No. 1Documento32 páginasME 326: Experiment No. 1parvejAún no hay calificaciones

- DSUMPS-ReliableSubmersiblePumpsforSump,Effluent,WastewaterandSewageDocumento10 páginasDSUMPS-ReliableSubmersiblePumpsforSump,Effluent,WastewaterandSewageAri WijayaAún no hay calificaciones

- R.O. Watermaker - 200,000 Liters/Day: Leader in Reverse Osmosis TechnologyDocumento1 páginaR.O. Watermaker - 200,000 Liters/Day: Leader in Reverse Osmosis TechnologyHerik AziziAún no hay calificaciones

- An 775 An 776 An 777 An 778 An 840 An 842 An 838 An 844Documento1 páginaAn 775 An 776 An 777 An 778 An 840 An 842 An 838 An 844blackhawkAún no hay calificaciones

- SanipackDocumento2 páginasSanipackJose C. Pachas100% (1)

- Basic Hydraulics - JR - L&TDocumento188 páginasBasic Hydraulics - JR - L&TArul SankaranAún no hay calificaciones

- May Thuy Khi Cau Hoi On Tap NewDocumento29 páginasMay Thuy Khi Cau Hoi On Tap NewKhang DangAún no hay calificaciones

- Techno-Commercial Offer For 600 KLD STP MBBRDocumento9 páginasTechno-Commercial Offer For 600 KLD STP MBBRTech MongerAún no hay calificaciones