Documentos de Académico

Documentos de Profesional

Documentos de Cultura

VBENBR1004

Cargado por

VidyasenDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

VBENBR1004

Cargado por

VidyasenCopyright:

Formatos disponibles

For Information

on Valbart

Specialized valves,

please refer

to the following

leaflets:

2011 Valbart Srl - All Rights Reserved. - VBENBR1004

Double block and bleed valves

Via delle Industrie, 9/5 - 20883 Mezzago (MB) ITALY

valbartsales@flowserve.com

Phone: +39 039 624111 - Fax: +39 039 6241178

www.valbart.com

Double block and bleed valves

Double block and bleed valves

Available in the

following size

2- 48

150# - 600#

2 - 36

900# - 1500#

2 - 24

2500#

* Larger size available

upon request

The Double Block and Bleed Isolation Philosophy requires two in-line isolation valves and a

bleed valve, used to drain or vent trapped fluid between the two closure elements in order to

safely isolate safely the downstream pipe. This feature can be achieved with one single valves

c/w a bleed port between the obturators.

MAIN APPLICATIONS

Offshore oil & gas production

Gas & oil terminals

Chemical & Petrochemical

Refining

ADVANTAGES

CHARACTERISTICS

Space and weight saving

Anti blow out/low emission stems

Cost saving (product & installation)

Fire safe & anti-static design

Minimized leak paths

Independent ball and stem

Increased line structural integrity

Self aligning trims

ESDV+MOV or ESDV+XV

configurations

Self relieving/ Double piston effect

floating seats

Increasesd reliability of the system

Soft or metal seated

Fiscal Metering Skid Manufacturing

LNG gas carrier

Process/ Power industry

contractors

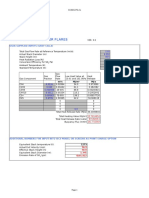

* Length C does not include the length of the bleed plug

CLASS # 600

CLASS # 1500

SIZE

(in)

W (Kg)

W (Kg)

W (Kg)

49

49

165

102

98

528

47

49

49

216

104

103

584

82

49

49

216

106

104

584

95

3x2

74

49

210

102

98

587

47

74

49

241

103

102

574

88

74

49

267

104

103

660

129

74

74

210

165

128

627

93

74

74

241

163

132

643

94

74

74

267

167

128

660

184

4x3

100

74

373

165

128

703

117

100

74

292

166

127

719

152

100

74

311

166

128

787

207

100

100

273

210

160

679

170

100

100

292

211

169

734

232

100

100

311

179

170

787

356

6x4

150

100

356

210

160

806

225

150

100

381

208

163

857

328

144

100

394

213

168

944

485

150

150

356

250

200

873

380

150

150

381

259

213

924

576

144

144

394

260

233

1010

816

8x6

201

150

419

250

200

975

438

201

150

470

263

213

1051

660

192

144

483

265

229

1140

906

201

201

419

288

255

1020

728

201

201

470

297

264

1096

928

192

192

483

304

290

1194 1312

10x8

252

201

510

288

255

1147

880

252

201

545

294

269

1197 1035

239

192

585

297

287

1353 1431

10

252

252

510

330

308

1264 1137

252

252

545

342

333

1314 1515

239

239

585

363

352

1435 2250

12x10 303

252

560

330

308

1314 1379

303

252

610

348

328

1441 1733

287

239

709

360

347

1581 2288

12

303

303

575

378

348

1380 1601

303

303

610

384

379

1507 2114

287

287

709

417

425

1664 3150

14

334

334

628

394

360

1494 1516

334

334

640

398

368

1640 2175

315

315

765

437

426

1854 3990

16x12 385

334

686

378

348

1533 1887

385

334

705

400

382

1679 2422

360

315

848

424

422

1925 3640

16

385

385

700

430

410

1644 2135

385

385

710

436

437

1790 3225

360

360

848

475

493

2042 5698

18

436

436

774

467

430

1790 2933

436

436

800

484

497

2017 4230

405

405

980

563

608

2184 8673

20x16 487

436

815

430

410

1850 3128

487

436

790

439

442

1850 3738

455

405

1015

484

502

2161 6676

487

487

865

500

492

1985 3693

487

487

890

532

503

2109 6300

455

455

1015

617

645

2450 11798

24x20 589

487

940

500

492

2192 4547

589

487

1040

534

500

2240 7020

530

455

1293

624

643

2575 14138

589

1028

594

570

2207 6630

589

589

1059

617

633

2368 8840

530

530

1293

698

724

2720 18564

20

Design is available in side entry, (bolted, welded body) and for onshore, offshore (top side) or sub-sea configurations.

CLASS # 900

24

589

Bleed/Vent system can be provided with Globe, Gate or Ball valves as per customers requirement.

All dimensions except where other wise specified are in mm.

Weight figures are relevant to flanged end valves.

Note: For dimensions and weights in larger sizes consult the factory.

Dimensions C, D, E, and weights are subject to change

without notice.

Face-to-face dimensions not listed in industry standards

are subject to change without notice.

También podría gustarte

- Did You Know: The Only Thing You Should Be Doing When You'Re Driving Is DrivingDocumento1 páginaDid You Know: The Only Thing You Should Be Doing When You'Re Driving Is DrivingVidyasenAún no hay calificaciones

- Copper-Nickel - Seawater System Design - GuidelinesDocumento15 páginasCopper-Nickel - Seawater System Design - GuidelinesVidyasenAún no hay calificaciones

- Pamplate PDFDocumento2 páginasPamplate PDFVidyasenAún no hay calificaciones

- HSE SMHeatDocumento1 páginaHSE SMHeatVidyasenAún no hay calificaciones

- 02 Self Contained Fire Suppression Foam Units Rev 5 04Documento2 páginas02 Self Contained Fire Suppression Foam Units Rev 5 04VidyasenAún no hay calificaciones

- Block and Bleed ValvesDocumento25 páginasBlock and Bleed ValvesVidyasenAún no hay calificaciones

- Thiruvasagam - SivapuranamDocumento4 páginasThiruvasagam - SivapuranamVidyasenAún no hay calificaciones

- Check ValveDocumento2 páginasCheck ValveVidyasenAún no hay calificaciones

- CPI SeparatorDocumento77 páginasCPI SeparatorVidyasen100% (1)

- Peak Oil TheoryDocumento21 páginasPeak Oil TheoryVidyasenAún no hay calificaciones

- Fuel Filters Vessels Cartridges Hydrocarbon FiltrationDocumento21 páginasFuel Filters Vessels Cartridges Hydrocarbon FiltrationVidyasenAún no hay calificaciones

- Separator NadobyDocumento15 páginasSeparator NadobyVidyasenAún no hay calificaciones

- Agricultural Solid Waste Management: Basic Strategies: National Dairy Research InstituteDocumento14 páginasAgricultural Solid Waste Management: Basic Strategies: National Dairy Research InstituteVidyasenAún no hay calificaciones

- MTGDocumento17 páginasMTGVidyasenAún no hay calificaciones

- Api/Ei (Ip) 5 Edition: Horizontal Coalescer Separator VesselDocumento2 páginasApi/Ei (Ip) 5 Edition: Horizontal Coalescer Separator VesselVidyasenAún no hay calificaciones

- Calculation Sheet For Flares: User Supplied Inputs (Grey Cells)Documento1 páginaCalculation Sheet For Flares: User Supplied Inputs (Grey Cells)VidyasenAún no hay calificaciones

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)