Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Bearing Design Method A

Cargado por

Dhurai KesavanDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Bearing Design Method A

Cargado por

Dhurai KesavanCopyright:

Formatos disponibles

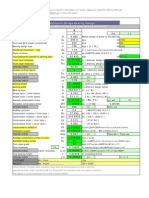

102 kips

122 kips

1.0 in.

0.004 Radians

0.005 Radians (14.4.2.1)

0.009 Radians

Rectangular

yes

18 in.

17 in.

> W

> 17 in.

224 kips

224.00 in.

2

N/A in.

2

*

min

= 13.18 in.

19 in.

L > L

min

>

> N/A

> N/A N/A

323.0 in.

2

*Note - Stress limit increased 10 percent due to prevention of shear deformation per Section 14.7.6.3.2.

1.000 in.

2.000 in.

10.000 in.

= h

ri

= 0.625 in.

Thickness of Top and Bottom Cover Layers (each) 0.250 in.

h

cover

< 0.7h

ri

(14.7.6.1)

0.250 < in. OK

5

3.625 in. *

2.000 in.

12.00 in.

h

rt

> 2s (14.7.6.3.4-1)

3.625 > in. OK

h

rt

> 10s (14.7.6.3.4-2)

N/A > N/A

Calculated Rotation =

Total Unfactored Compressive Load = P

T

=

(n

int

= 0 for PEP and CDP)

2

s

=

0.438

10

s

=

III. SHEAR DEFORMATION (AASHTO LRFD 14.7.6.3.4 )

Number of Interior Elastomeric Layers (Excluding Exterior Layer Allowance) = n

int

=

Total Elastomer Thickness = h

rt

= 2h

cover

+ n

int

h

ri

=

N/A

Maximum Total Shear Deformation of Elastomer at Service Limit =

s

=

0

=

2.00

Elastomeric Layer Thickness

= h

cover

=

For PEP, FGP, and Steel-Reinforced Elastomeric Bearings:

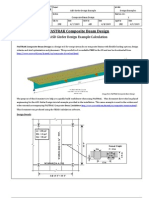

N S B A E L A S T O M E R I C B E A R I N G D E S I G N ( E N G L I S H U N I T S )

M E T H O D A - E L A S T O M E R I C P A D S AND S T E E L - R E I N F O R C E D E L A S T O M E R I C B E A R I N G S - S E C T I O N 1 4 . 7 . 6

I. INITIAL DESIGN INPUTS

Dead Load = P

D

=

Steel-Reinforced Bearing Bearing Type:

A A S H T O L R F D , 3 R D E D . , 2 0 0 4 W I T H 2 0 0 5 I N T E R I M S

The following design program was developed based upon the above-referenced AASHTO LRFD code. The program is applicable to the design of

reinforced pads, the program assumes that interior elastomeric layers are of equal thickness, as are the two exterior elastomeric layers. For fiber-

outlined in articles 14.7.6.3.3 and 14.7.6.4 respectively.

elastomeric pads and steel-reinforced elastomeric bearings, both rectangular and circular in shape. For steel-reinforced elastomeric bearings and fiber-

layer per article 14.7.6.3.1. Compressive deflections and anchorage requirements for bearings are to be verified by the user in accordance with provisions

Live Load = P

LL

=

Flange Width

Rotation Construction Tolerance =

Design Rotation =

s

=

Bearing Shape:

Bearing Subject to Shear Deformation?

reinforced pads, the fiberglass reinforcement comprising h

s

shall be assumed to consist of a double fiberglass layer separated by a 0.125 in. bonding

Horizontal Movement of Bridge Superstructure =

0

=

18 OK

II. BEARING GEOMETRY

Flange Width =

Bearing Width = W =

Based on service limit (14.7.6.3.2)

Minimum Bearing Length = L

Bearing Length = L =

Minimum Required Area of Bearing (shear deformation prevented) = A

min

=

Minimum Required Area of Bearing (shear deformation permitted) = A

min

=

N/A

Bearing Area = A =

19.0 13.18 OK

N/A

N/A

Total Elastomer Thickness of PEP = h

rt

=

Total Elastomer Thickness of CDP = h

rt

= t

p

=

For CDP Elastomeric Bearings:

*Note - Applies to FGP and steel-reinforced elastomeric bearings only.

1 of 4

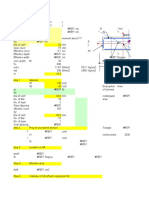

N S B A E L A S T O M E R I C B E A R I N G D E S I G N ( E N G L I S H U N I T S )

M E T H O D A - E L A S T O M E R I C P A D S AND S T E E L - R E I N F O R C E D E L A S T O M E R I C B E A R I N G S - S E C T I O N 1 4 . 7 . 6

A A S H T O L R F D , 3 R D E D . , 2 0 0 4 W I T H 2 0 0 5 I N T E R I M S

The following design program was developed based upon the above-referenced AASHTO LRFD code. The program is applicable to the design of

0.100 ksi

0.08 < < 0.250 ksi (14.7.6.2)

0.08 < < 0.250 ksi N/A

0.08 < < 0.175 ksi

0.08 < < 0.175 ksi OK

0.69 ksi

0.38 ksi

7.18 (14.7.5.1-1)

N/A (14.7.5.1-2)

< 0.80 ksi (14.7.6.3.2-1)

N/A < N/A ksi N/A

s

<1.00GS ksi (14.7.6.3.2-2)

N/A <N/A ksi N/A

<0.80 ksi (14.7.6.3.2-2)

N/A <N/A ksi N/A

< 1.50 ksi (14.7.6.3.2-3)

N/A < N/A ksi N/A

< 1.00 ksi (14.7.6.3.2-4)

0.69 < 1.00 ksi OK

< 1.00GS ksi (14.7.6.3.2-4)

0.69 <0.72 ksi OK

*Note - Stress limit increased 10 percent due to prevention of shear deformation per Section 14.7.6.3.2.

< 0.88 ksi (14.7.6.3.2-1)

N/A < N/A ksi N/A

s

<1.10GS ksi (14.7.6.3.2-2)

N/A <N/A ksi N/A

<0.88 ksi (14.7.6.3.2-2)

N/A <N/A ksi N/A

< 1.65 ksi (14.7.6.3.2-3)

N/A < N/A ksi N/A

<1.10 ksi (14.7.6.3.2-4)

N/A <N/A ksi N/A

<1.10GS ksi (14.7.6.3.2-4)

N/A <N/A ksi N/A

s

s

Bearings Fixed Against Shear Deformation*:

s

PEP:

s

(14.7.6.2) and (14.7.5.2)

Shear Modulus of Elastomer = G =

Circular Shape Factor = S

l

Rectangular Shape Factor = S

l

For Steel-Reinforced Elastomeric Bearings:

Steel Reinforced:

s

IV. COMPRESSIVE STRESS (AASHTO LRFD 14.7.6.3.2)

Bearings Subject to Shear Deformation:

PEP:

Service Average Compressive Stress (Total Load) =

Service Average Compressive Stress (Live Load) =

s

0.100

For PEP, FGP, and CDP Elastomeric Bearings:

G

N/A

G

FGP:

s

CDP:

s

CDP:

s

Steel Reinforced:

FGP:

s

=

+

=

W) (L h

LW

ri

2

= =

A

T

P

s

o

= =

A

P

LL

L

= =

ri

h

D

4

2 of 4

N S B A E L A S T O M E R I C B E A R I N G D E S I G N ( E N G L I S H U N I T S )

M E T H O D A - E L A S T O M E R I C P A D S AND S T E E L - R E I N F O R C E D E L A S T O M E R I C B E A R I N G S - S E C T I O N 1 4 . 7 . 6

A A S H T O L R F D , 3 R D E D . , 2 0 0 4 W I T H 2 0 0 5 I N T E R I M S

The following design program was developed based upon the above-referenced AASHTO LRFD code. The program is applicable to the design of

0.004 radians

0.009 radians

0.003 radians

0.008 radians

(14.7.6.3.5b-1)

> ksi N/A

(14.7.6.3.5b-2)

> ksi N/A

(14.7.6.3.5b-3)

> ksi N/A

(14.7.6.3.5c-1)

> psi N/A

(14.7.6.3.5c-2)

< psi N/A

0 (14.7.6.3.5d)

5

(14.7.6.3.5d-1)

> ksi OK

(14.7.6.3.5d-2)

> ksi OK

(14.7.6.3.5d-3)

> ksi N/A

N/A

N/A

Total Service Rotation About Transverse Axis (with Construction Tolerance) =

s,x

=

Total Service Rotation About Longitudinal Axis (with Construction Tolerance) =

s,z

=

Exterior Layer Allowance = n

ext

=

N/A

PEP:

N/A

Rectangular Pads:

0.69

Circular Pads:

N/A

N/A

N/A

Equivalent Number of Interior Elastomeric Layers = n = n

int

+ n

ext

=

Circular Pads:

N/A

CDP:

V. ROTATION (AASHTO LRFD 14.7.6.3.5)

Service Rotation Due to Total Load About Transverse Axis =

Service Rotation Due to Total Load About Longitudinal Axis =

N/A

Rectangular Pads:

0.69

0.42

0.60

N/A

N/A

FGP and Steel-Reinforced:

N/A

x s

rt

h

L

GS

s ,

2

5 . 0 u o

|

|

.

|

\

|

>

z s

rt

h

W

GS

s ,

2

5 . 0 u o

|

|

.

|

\

|

>

|

|

|

.

|

\

|

s

p

t

L

s s

u o 000 , 6 500 , 1

n h

D

GS

s

ri

s

u

o

2

375 . 0

|

|

.

|

\

|

>

n h

W

GS

z s

ri

s

,

2

5 . 0

u

o

|

|

.

|

\

|

>

n h

L

GS

x s

ri

s

,

2

5 . 0

u

o

|

|

.

|

\

|

>

s

p

t

L

s

u o

|

|

|

.

|

\

|

>

000 , 12

s

rt

h

D

GS

s

u o

2

375 . 0

|

|

.

|

\

|

>

3 of 4

N S B A E L A S T O M E R I C B E A R I N G D E S I G N ( E N G L I S H U N I T S )

M E T H O D A - E L A S T O M E R I C P A D S AND S T E E L - R E I N F O R C E D E L A S T O M E R I C B E A R I N G S - S E C T I O N 1 4 . 7 . 6

A A S H T O L R F D , 3 R D E D . , 2 0 0 4 W I T H 2 0 0 5 I N T E R I M S

The following design program was developed based upon the above-referenced AASHTO LRFD code. The program is applicable to the design of

FGP: Service Limit State

36 ksi

N/A in.

N/A in. (14.7.6.3.1)

Steel-Reinforced: Service Limit State

36 ksi

0.036 in. Controls (14.7.5.3.7-1)

24 ksi (Table 6.6.1.2.5-3)

0.020 in. (14.7.5.3.7-2)

0.036 in.

0.1250 in.

> h

s min

> 0.036 in. OK

6.33 in.

5.67 in. Controls

N/A in.

< W/3

< 5.67 in. OK

17.0 in.

19.0 in.

0.625 in.

0.250 in.

5

3.625 in.

0.1250 in.

4.3750 in.

Reinforcement Thickness = h

s

=

Total Elastomer Thickness = h

rt

=

Number of Interior Elastomeric Layers (Excluding Exterior Layer Allowance) = n

int

=

VII. STABILITY (AASHTO LRFD 14.7.6.3.6)

L/3

D/4

W/3

=

=

Minimum Yield Strength of Fiber Reinforcement = F

yFIBER

=

Total Bearing Thickness = h

rt

+ h

s

(n

int

+1) =

Bearing Length = L =

=

VI. REINFORCEMENT (AASHTO LRFD 14.7.6.3.7)

Minimum Yield Strength of Steel Reinforcement = F

y

=

Steel-Reinforced: Fatigue Limit State

Constant Amplitude Fatigue Threshold = F

TH

=

0.125

Double Fiberglass Layer with 0.125 in. Separation = h

s min total

= 2

hs min

+ 0.125 =

Elastomeric Layer Thickness = h

ri

=

Thickness of top and Bottom Cover Layers (each) = h

cover

=

Required Minimum Reinforcement Thickness = h

s min

=

h

s

Reinforcement Thickness = h

s

=

Total Bearing Thickness = h

rt

+ h

s

(n

int

+1) =

Total Thickness of Bearing Shall Not Exceed the Least of:

4.38

VIII. FINAL DESIGN SUMMARY

Bearing Width = W =

= =

y

s

s

F

h .

h

max

min

0 3

= =

TH

L

s

F

h .

h

max

min

0 2

= =

yFIBER

F

ri

h .

s

h

2 2

min

4 of 4

También podría gustarte

- AASHTO LRFD Bridge Bearing Design SpreadsheetDocumento3 páginasAASHTO LRFD Bridge Bearing Design Spreadsheetramesh_uvAún no hay calificaciones

- Bearing Design Method BDocumento3 páginasBearing Design Method BDhurai KesavanAún no hay calificaciones

- Chapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 EdDocumento5 páginasChapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 Edv pavanAún no hay calificaciones

- 800 LSM Deisgn SheetDocumento5 páginas800 LSM Deisgn SheetArun KunnanchiraAún no hay calificaciones

- Column Strip: E+ve Above Na M+ve SupportDocumento42 páginasColumn Strip: E+ve Above Na M+ve SupportShikha Dubey100% (1)

- Bearing Design PDFDocumento3 páginasBearing Design PDFSushmit SharmaAún no hay calificaciones

- PILES CARRYING CAPACITY ANALYSIS SoftwareDocumento7 páginasPILES CARRYING CAPACITY ANALYSIS SoftwareJhon Anaya VerdeAún no hay calificaciones

- DESIGN OF INTAZE WATER TANKDocumento13 páginasDESIGN OF INTAZE WATER TANKPratikAún no hay calificaciones

- Chapter 2 Design For Serviceability PDFDocumento14 páginasChapter 2 Design For Serviceability PDFChee Fong MakeAún no hay calificaciones

- Shear As 5100 5 MedianPier PierCapDocumento6 páginasShear As 5100 5 MedianPier PierCapSharyn PolleyAún no hay calificaciones

- LRFD Design of Full Height Abutment on Spread FootingDocumento71 páginasLRFD Design of Full Height Abutment on Spread FootingJustinAún no hay calificaciones

- ST DesignDocumento33 páginasST DesignAbdul BariAún no hay calificaciones

- CRACKED BEAM-Prestressed Concrete Bridge Girder Structural Analysis ProgramDocumento3 páginasCRACKED BEAM-Prestressed Concrete Bridge Girder Structural Analysis ProgramNurLelyHardiantiZendratoAún no hay calificaciones

- Substructure DesignADocumento53 páginasSubstructure DesignACharisse Ann Arado BadoriaAún no hay calificaciones

- Angle Seat Detail AllowableDocumento4 páginasAngle Seat Detail AllowablepiziyuAún no hay calificaciones

- Box Culver 1 X 4 X 3Documento97 páginasBox Culver 1 X 4 X 3Bilal Ahmed BarbhuiyaAún no hay calificaciones

- Thumb Rules For Steel DesignDocumento3 páginasThumb Rules For Steel Designpranit_rai100% (1)

- UB UC Steel SectionsDocumento10 páginasUB UC Steel SectionsMuhammad HasanAún no hay calificaciones

- 0.5 Ton-CraneDocumento20 páginas0.5 Ton-CraneILYAS HUSSAINAún no hay calificaciones

- Long and Short Column Design BasisDocumento2 páginasLong and Short Column Design BasisMUTHUKKUMARAMAún no hay calificaciones

- AISC (LRFD) Shear Connection - Cleat AngleDocumento14 páginasAISC (LRFD) Shear Connection - Cleat AngleMANOJAún no hay calificaciones

- Design of Base Slab of UGTDocumento5 páginasDesign of Base Slab of UGTAamir SuhailAún no hay calificaciones

- Chute Design Part 1Documento11 páginasChute Design Part 1Anorld WalkerAún no hay calificaciones

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Documento9 páginasCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDAún no hay calificaciones

- Design of Slab Bs-2 Calculation of Crack WidthDocumento2 páginasDesign of Slab Bs-2 Calculation of Crack WidthD SRINIVASAún no hay calificaciones

- Design Example ASD GirderDocumento12 páginasDesign Example ASD GirderEdward van MartinoAún no hay calificaciones

- Upgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectDocumento14 páginasUpgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectkuttakhaoAún no hay calificaciones

- AASHTO Shear Calculator, No Stirrups: Code Values of Beta and ThetaDocumento6 páginasAASHTO Shear Calculator, No Stirrups: Code Values of Beta and ThetaNuttasak AriyapurkAún no hay calificaciones

- Discrete Element Method to Model 3D Continuous MaterialsDe EverandDiscrete Element Method to Model 3D Continuous MaterialsAún no hay calificaciones

- 17.7. Spectrum AnalysisDocumento34 páginas17.7. Spectrum AnalysisFeras Temimi100% (1)

- Rectangular BasePlate DesignDocumento13 páginasRectangular BasePlate DesignMuhammad HasanAún no hay calificaciones

- Bearing Load CalculationDocumento16 páginasBearing Load CalculationmhsalihAún no hay calificaciones

- Garg, Aamod. 'Gantry Girders in India' - IJCMES PDFDocumento5 páginasGarg, Aamod. 'Gantry Girders in India' - IJCMES PDFAamod GargAún no hay calificaciones

- Hollow Box Girder Bridge Structural Design ModelsDocumento1 páginaHollow Box Girder Bridge Structural Design ModelsJeerawatAún no hay calificaciones

- Dyke Wall DesignDocumento20 páginasDyke Wall DesignBasitAún no hay calificaciones

- Elastomeric Bearing 13-09-13Documento27 páginasElastomeric Bearing 13-09-13bulganinganguliAún no hay calificaciones

- Reinf - conc.Beams-Design Torsional&Axially LoadedDocumento1 páginaReinf - conc.Beams-Design Torsional&Axially LoadedHermogenesGerardoIII OcanaAún no hay calificaciones

- Two Way Slabs PDFDocumento5 páginasTwo Way Slabs PDFmathuAún no hay calificaciones

- CraneBeam v1 1Documento39 páginasCraneBeam v1 1satya_jayantiAún no hay calificaciones

- Pile Foundation Design: Dr. Magdi ZumrawiDocumento20 páginasPile Foundation Design: Dr. Magdi Zumrawitemesgen yohannesAún no hay calificaciones

- SteelGirder Design ExampleDocumento59 páginasSteelGirder Design ExampleFranco VasquezAún no hay calificaciones

- Anchor Design for 219mm Pole SupportDocumento1 páginaAnchor Design for 219mm Pole SupportS A K ClostreAún no hay calificaciones

- STEEL BEAM WEB STIFFENER ANALYSISDocumento7 páginasSTEEL BEAM WEB STIFFENER ANALYSISNEOAún no hay calificaciones

- Risa Base Examples PDFDocumento7 páginasRisa Base Examples PDFAamirShabbirAún no hay calificaciones

- Plate GirderDocumento7 páginasPlate GirderAnonymous sfkedkymAún no hay calificaciones

- 19 - Bearing Capacity - Eccentric LoadingDocumento5 páginas19 - Bearing Capacity - Eccentric LoadinghiyeonAún no hay calificaciones

- Design Steel Reinforced Elastomeric Bridge BearingsDocumento27 páginasDesign Steel Reinforced Elastomeric Bridge BearingsRupchanda BarmanAún no hay calificaciones

- III- Design of Bridges Reinforced Concrete Slab CulvertDocumento9 páginasIII- Design of Bridges Reinforced Concrete Slab CulvertVinayagamoorthy ChithambaramAún no hay calificaciones

- HEC 18 Contraction ScourDocumento5 páginasHEC 18 Contraction Scourjibendra mishraAún no hay calificaciones

- AASHTO Elastomeric Bearing Design Program SummaryDocumento38 páginasAASHTO Elastomeric Bearing Design Program SummaryxyztaaAún no hay calificaciones

- Elastomeric Bearing Design Method BDocumento3 páginasElastomeric Bearing Design Method BYauri HugoAún no hay calificaciones

- Background To Design Rules - Issue of EN13445 EN1591 Part PDFDocumento19 páginasBackground To Design Rules - Issue of EN13445 EN1591 Part PDFBenoit LabreAún no hay calificaciones

- Spreadsheet For Design of Bridge BearingsDocumento8 páginasSpreadsheet For Design of Bridge BearingsAli Akbar100% (1)

- CA-3513GN-SS-014 (Rev. 1D)Documento38 páginasCA-3513GN-SS-014 (Rev. 1D)Bekro SitepuAún no hay calificaciones

- Notes On Anchor Bolt Design (ACI 318-08 APP D)Documento6 páginasNotes On Anchor Bolt Design (ACI 318-08 APP D)Kai LeeAún no hay calificaciones

- 05 - A Software Solution To Help Design Steel Beam To Column Connection PDFDocumento11 páginas05 - A Software Solution To Help Design Steel Beam To Column Connection PDFSwati KulkarniAún no hay calificaciones

- 006-A Software Solution To Help Design Steel Beam To Column Connection PDFDocumento11 páginas006-A Software Solution To Help Design Steel Beam To Column Connection PDFSwati KulkarniAún no hay calificaciones

- Stiffening Ring Cal For Exteneral Press.Documento11 páginasStiffening Ring Cal For Exteneral Press.inspectormhp100% (1)

- CNP 6SD Sub MotorDocumento2 páginasCNP 6SD Sub Motormuhammadirsyad230793Aún no hay calificaciones

- Slender Web I Section Design - Staad Verification ProblemDocumento14 páginasSlender Web I Section Design - Staad Verification ProblemGuessss..........!!!!!100% (1)

- Earthquake at Port GrabenDocumento1 páginaEarthquake at Port GrabenDhurai Kesavan100% (1)

- Structural Mechanics Ii Tutorial Sheet #2Documento1 páginaStructural Mechanics Ii Tutorial Sheet #2Dhurai KesavanAún no hay calificaciones

- Example II.A-12 All-Bolted Unstiffened Seated Connection (Beam-To-Column Web)Documento12 páginasExample II.A-12 All-Bolted Unstiffened Seated Connection (Beam-To-Column Web)mohdnazirAún no hay calificaciones

- 3 Hinged ArchDocumento17 páginas3 Hinged Archsatyakam87453980% (10)

- Ce717abutment - CalcDocumento18 páginasCe717abutment - CalcDhurai KesavanAún no hay calificaciones

- Statics: Vector Mechanics For EngineersDocumento28 páginasStatics: Vector Mechanics For Engineersganesh_withucadAún no hay calificaciones

- Notes 2 Forces & MomentsDocumento15 páginasNotes 2 Forces & MomentsDhurai KesavanAún no hay calificaciones

- Trig Identities & FormulasDocumento2 páginasTrig Identities & FormulasSergio CabreraAún no hay calificaciones

- Structural Strength vs StiffnessDocumento1 páginaStructural Strength vs StiffnessDhurai KesavanAún no hay calificaciones

- Splice LRFD-LFD DesignDocumento23 páginasSplice LRFD-LFD DesignDhurai KesavanAún no hay calificaciones

- Introduction To Natural HazardsDocumento2 páginasIntroduction To Natural HazardsDhurai KesavanAún no hay calificaciones

- Load Combination and Stress Checks for Bridge DesignDocumento14 páginasLoad Combination and Stress Checks for Bridge DesignDhurai KesavanAún no hay calificaciones

- Pcef Prop TemplateDocumento4 páginasPcef Prop TemplateDhurai KesavanAún no hay calificaciones

- Cambering Steel BeamsDocumento2 páginasCambering Steel BeamsFernando PizarroAún no hay calificaciones

- Seismic Conn 1Documento6 páginasSeismic Conn 1Dhurai KesavanAún no hay calificaciones

- 10 Tips For Designing With Steel JoistsDocumento2 páginas10 Tips For Designing With Steel JoistsjavyusfAún no hay calificaciones

- Load Combination and Stress Checks for Bridge DesignDocumento14 páginasLoad Combination and Stress Checks for Bridge DesignDhurai KesavanAún no hay calificaciones

- Condition ASD LRFD Related Info: W-Shapes - S-Shapes - C-And MC-ShapesDocumento4 páginasCondition ASD LRFD Related Info: W-Shapes - S-Shapes - C-And MC-Shapesanand77ininAún no hay calificaciones

- AISC ExamI1&2&3Documento11 páginasAISC ExamI1&2&3Dhurai KesavanAún no hay calificaciones

- The History of Stiffness-MethodDocumento9 páginasThe History of Stiffness-MethodStella GibsonAún no hay calificaciones

- Calculation of AISC - PryingActionDocumento5 páginasCalculation of AISC - PryingActionYoshua YangAún no hay calificaciones

- Ho 1Documento2 páginasHo 1Dhurai KesavanAún no hay calificaciones

- AISC ChaphDocumento4 páginasAISC ChaphDhurai KesavanAún no hay calificaciones

- CE 317 Structural Mechanics II Tutorial Sheet #8 Axial Forces in Trusses from Temperature Change and Member Length ErrorsDocumento1 páginaCE 317 Structural Mechanics II Tutorial Sheet #8 Axial Forces in Trusses from Temperature Change and Member Length ErrorsDhurai KesavanAún no hay calificaciones

- Ts 09Documento1 páginaTs 09Dhurai KesavanAún no hay calificaciones

- I Sem - Curr & SyllDocumento13 páginasI Sem - Curr & SyllAstronaut KennedyAún no hay calificaciones

- Ts 06Documento1 páginaTs 06Dhurai KesavanAún no hay calificaciones

- CE 317 Structural Mechanics II Handout #2 Fixed End MomentsDocumento2 páginasCE 317 Structural Mechanics II Handout #2 Fixed End Momentsprabhu81Aún no hay calificaciones

- Test Report OD63mm PN12.5 PE100Documento6 páginasTest Report OD63mm PN12.5 PE100Im ChinithAún no hay calificaciones

- Auditor General Insurance Regulation Dec 2011Documento23 páginasAuditor General Insurance Regulation Dec 2011Omar Ha-RedeyeAún no hay calificaciones

- Alok ResumeDocumento3 páginasAlok Resumealok choudharyAún no hay calificaciones

- HVDC BasicDocumento36 páginasHVDC BasicAshok KumarAún no hay calificaciones

- Elem. Reading PracticeDocumento10 páginasElem. Reading PracticeElissa Janquil RussellAún no hay calificaciones

- December - Cost of Goods Sold (Journal)Documento14 páginasDecember - Cost of Goods Sold (Journal)kuro hanabusaAún no hay calificaciones

- RA8485 Animal Welfare Act (Carabao Slaughter)Documento2 páginasRA8485 Animal Welfare Act (Carabao Slaughter)Jazreth Gaile100% (1)

- GCSDocumento20 páginasGCSnicole aligno100% (2)

- To The OneDocumento8 páginasTo The OnePizzaCowAún no hay calificaciones

- Aphasia PDFDocumento4 páginasAphasia PDFRehab Wahsh100% (1)

- Farid Jafarov ENG Project FinanceDocumento27 páginasFarid Jafarov ENG Project FinanceSky walkingAún no hay calificaciones

- LH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionsDocumento304 páginasLH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionshadensandorAún no hay calificaciones

- Forest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundDocumento4 páginasForest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundAnonymous 6iFFjEpzYjAún no hay calificaciones

- Dimensional Data: For Valves and ActuatorsDocumento52 páginasDimensional Data: For Valves and ActuatorsPaulAún no hay calificaciones

- English Financial Assistance ApplicationDocumento4 páginasEnglish Financial Assistance ApplicationAlyssa JenningsAún no hay calificaciones

- 01 - 01 - SK10 - JXNipponDocumento1 página01 - 01 - SK10 - JXNipponredevils86Aún no hay calificaciones

- DR - Hawary Revision TableDocumento3 páginasDR - Hawary Revision TableAseel ALshareefAún no hay calificaciones

- Grab Go Porter S 5 ForcesDocumento2 páginasGrab Go Porter S 5 ForcesUtkarsh SharmaAún no hay calificaciones

- Myth and Realism in The Play A Long Day's Journey Into Night of Eugene O'neillDocumento4 páginasMyth and Realism in The Play A Long Day's Journey Into Night of Eugene O'neillFaisal JahangeerAún no hay calificaciones

- 2020-11 HBG Digital EditionDocumento116 páginas2020-11 HBG Digital EditionHawaii Beverage GuideAún no hay calificaciones

- AZ ATTR Concept Test Clean SCREENERDocumento9 páginasAZ ATTR Concept Test Clean SCREENEREdwin BennyAún no hay calificaciones

- Female Reproductive System Histology IDocumento5 páginasFemale Reproductive System Histology ISolomon Seth SallforsAún no hay calificaciones

- MLS 321 Aubf M6u2 Other Metabolic Diseases V2122Documento7 páginasMLS 321 Aubf M6u2 Other Metabolic Diseases V2122proximusAún no hay calificaciones

- Abstract - Tropen Tag 2011 PDFDocumento634 páginasAbstract - Tropen Tag 2011 PDFzmoghesAún no hay calificaciones

- Model Fs CatalogDocumento4 páginasModel Fs CatalogThomas StempienAún no hay calificaciones

- Nursing Care PlansDocumento10 páginasNursing Care PlansGracie S. Vergara100% (1)

- FB77 Fish HatcheriesDocumento6 páginasFB77 Fish HatcheriesFlorida Fish and Wildlife Conservation CommissionAún no hay calificaciones

- Grade Eleven Test 2019 Social StudiesDocumento6 páginasGrade Eleven Test 2019 Social StudiesClair VickerieAún no hay calificaciones

- Case Report on Right Knee FuruncleDocumento47 páginasCase Report on Right Knee Furuncle馮宥忻Aún no hay calificaciones

- Life Overseas 7 ThesisDocumento20 páginasLife Overseas 7 ThesisRene Jr MalangAún no hay calificaciones