Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Cabina Del Operador

Cargado por

Ilarion CiobanuDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Cabina Del Operador

Cargado por

Ilarion CiobanuCopyright:

Formatos disponibles

Maintenance

OPERATORS CAB

GLP/GDP3.5-5.5LJ/MJ (GP/GLP/GDP70-120LJ/MJ) [C813, E813]

PART NO. 524173801

100 YRM 778

SAFETY PRECAUTIONS MAINTENANCE AND REPAIR

When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load. Do not lift heavy parts by hand, use a lifting mechanism. Wear safety glasses. DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks. Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section. Keep the unit clean and the working area clean and orderly. Use the correct tools for the job. Keep the tools clean and in good condition. Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer. Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts. Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs. Be sure to follow the WARNING and CAUTION notes in the instructions. Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems. Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated. NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a condition that can cause immediate death or injury!

CAUTION

Indicates a condition that can cause property damage!

Operators Cab

Table of Contents

TABLE OF CONTENTS

General................................................................................................................................................................ Cab Repair .......................................................................................................................................................... Remove ........................................................................................................................................................... Install............................................................................................................................................................... Switch Panel........................................................................................................................................................ Window Wipers Replacement ............................................................................................................................. Front Wiper Assembly ..................................................................................................................................... Rear Wiper Assembly ..................................................................................................................................... Door Handle Assembly........................................................................................................................................ Fuse Panel .......................................................................................................................................................... Heater Assembly ................................................................................................................................................. Remove ........................................................................................................................................................... Install............................................................................................................................................................... Window Replacement.......................................................................................................................................... Options ................................................................................................................................................................ Rear Strobe Lights .......................................................................................................................................... Heavy-Duty Air Cleaner .................................................................................................................................. Label Replacement.............................................................................................................................................. Electrical Schematics .......................................................................................................................................... This section is for the following models: GLP/GDP3.5-5.5LJ/MJ (GP/GLP/GDP70-120LJ/MJ) [C813, E813] 1 2 2 3 3 4 4 4 6 7 7 7 7 9 11 11 11 12 12

2004 Yale Materials Handling Corp.

100 YRM 778

General

General

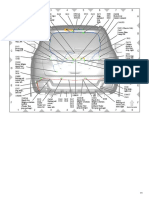

A fully-enclosed operator cab can be installed on the lift truck as an option. See Figure 1. When installed, the cab has doors, windows, window wipers, heater system, and an optional circulation fan. The overhead guard is an integral part of the operator cab. The operator cab is installed on a platform above the main frame members. Step plates on both sides of the lift truck give access to the operator cab. The operator cab is a separate unit and can be removed as a complete unit from the module and frame of the lift truck.

Figure 1. Operator Cab

Cab Repair

100 YRM 778

Cab Repair

REMOVE

To remove the operator cab from the frame, do the following: 1. Remove the retaining screws from the dash and the cowl panel. 2. Lift up the dash and remove the cowl panel. 3. Disconnect the main wiring harness, the front light harness, and the rear light harness between the lift truck and the operator cab. Stow front light harness in the cab leg before removing the cab from the lift truck. 4. Disconnect the water tube and the wiper motor harness connection to the windshield wipers. 5. Disconnect the air filter hose from the lower left corner of the cab frame. 6. Disconnect the water hoses to the heater and disconnect the heater wire harness. 7. Remove the cab front attaching hardware. See Figure 2. 1. 2. 3. 4. 5. FLAT WASHER LOCKWASHER CAPSCREW CAPSCREW LOCKWASHER 6. 7. 8. 9. 10. FLAT WASHER RING WASHER ISOLATOR ISOLATOR ISOLATOR CUP 8. Remove the cab rear attaching hardware (1, 2, and 3, Figure 3).

Figure 3. Rear Attaching Hardware 9. Remove the rear isolator hardware and inspect for wear or damage. Replace if necessary. See Figure 3. 10. To prevent damage to the cab doors, remove them before attaching a lifting device.

WARNING

Make sure that the lifting device has a minimum capacity to lift 500 kg (1100 lb). 11. Connect a lifting device to a spreader bar or lift strap, that is through the door openings at the top of the operator cab (under the overhead guard structure). Put material that will be a cushion at the top of the door openings to prevent damage. Operate the lifting device just enough to correctly position the spreader bar or lift strap on the operator cab.

1. CAPSCREW (2) 2. WASHER (4)

3. SHIM (AS REQUIRED) 4. LEFT FRONT LEG

Figure 2. Front Attaching Hardware

100 YRM 778

Switch Panel 5. Install the rear attaching hardware to the frame and tighten finger-tight only. 6. Install the front attaching hardware. Install the shims as required and bend the tabs as necessary. Tighten finger-tight only. 7. Connect the wiring harnesses and wires to the components in the operator cab. 8. Connect the wiring harness to the heater. 9. Connect the air filter hose to the left rear leg of the cab frame. 10. Tighten the cab mounting bolts as follows: a. Front bolts - 90 Nm (66 lbf) b. Rear bolts - 90 Nm (66 lbf) 11. Connect the water tube and the wiper motor harness connection to the windshield wipers. 12. Connect the main wiring harness and the front and rear light harness between the lift truck and the operator cab. 13. Install the cowl cover. 14. Install the dash over the cowl cover and install the retaining screws. 15. Install the cab doors.

CAUTION

Lift the operator cab carefully. Check that all electrical wires and attachments are disconnected correctly and are not damaged. 12. Carefully lift the cab away from the lift truck. Set the cab assembly in a suitable storage area and put blocks under the unit to make it stable and prevent damage to parts still attached.

INSTALL

If the operator cab was removed for repair or replacement, install it as follows: 1. Connect a lifting device to a spreader bar or lift strap, that is through the door openings at the top of the operator cab (under the overhead guard structure). Put material that will be a cushion at the top of the door openings to prevent damage. Operate the lifting device just enough to correctly position the spreader bar or lift strap on the operator cab. 2. Make sure that the bottom half of the isolators are in place. 3. Install the operator cab on the mounts making sure that the isolator is correctly positioned through the hole in the cab frame mount. See Figure 3. 4. Install the rubber isolators, washers, nuts, and bolts for the mounts. Make sure that the isolators are correctly positioned.

Switch Panel

The switch panel for the front and rear window wipers and the heater fan is located in the upper right rear of the cab. See Figure 4. Gauges and switches that are not an integral part of the cab are covered in Instrument Panel Indicators and Senders 2200 YRM 756.

1. FRONT WIPER/WASHER 2. REAR WIPER/WASHER 3. HEATER FAN Figure 4. Cab Switches

Window Wipers Replacement

100 YRM 778

Window Wipers Replacement

Two window wiper motor assemblies are installed in the operator cab. The front window motor assembly has two wiper arms connected to a single wiper blade. The rear window has a wiper motor assembly that has one wiper arm attached to a single wiper blade. 3. Remove the water tube and disconnect the wiring harness. 4. Repair or replace defective parts and install the front wiper assembly as shown in Figure 5. 5. Install the water tube and connect the wiring harness.

FRONT WIPER ASSEMBLY

1. To replace the front motor assembly, remove the retaining nuts and lockwashers from the wiper arms. Remove the wiper arm and blade from the outside. See Figure 5. 2. Remove the nuts, lockwashers, and flat washers from the two threaded shafts that pass through the metal frame (cowl) of the operator cab.

REAR WIPER ASSEMBLY

1. To replace the rear motor assembly, remove the retaining nut and lockwasher from the wiper arm. Remove the wiper arm and blade from the outside. See Figure 6.

1. 2. 3. 4. 5.

WIPER ARM (2) RETAINING NUT (2) LOCKWASHER (2) NUT (2) LOCK NUT (2)

6. 7. 8. 9. 10.

FLAT WASHER (2) WIPER MOTOR ELECTRICAL CONNECTOR WATER TUBE HEATER

11. COVER 12. CHECK VALVE 13. GROMMET

Figure 5. Front Window Wiper System

100 YRM 778

Window Wipers Replacement

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

MOUNTING STUD WASHER (2) GROMMET (2) GLASS WIPER MOTOR WASHER (2) NUT (2) COVER WATER TUBE CONNECTOR

11. 12. 13. 14. 15. 16. 17. 18. 19. 20.

RESERVOIR SPRAY NOZZLE MOUNTING STUD GROMMET WASHER RETAINER NUT HARDWARE COVER NUT WASHER WIPER ARM

Figure 6. Rear Window Wiper System

Door Handle Assembly 2. Remove the hardware covers, nuts, retainers, and flat washers from the threaded shafts that pass through the glass of the operator cab. 3. Remove the wiper motor cover by pulling backward. The cover is held in place by plastic tabs on the inside of the cover. 4. Remove the water tube and disconnect the wiring harness connector.

100 YRM 778 5. From inside the cab, on the wiper motor, remove the nuts and washers from the mounting studs that pass through the glass from the back side. 6. Repair or replace any defective parts and install the rear wiper assembly as shown in Figure 6. NOTE: One of the mounting studs is also the spray nozzle for the window washer. 7. Install the water tubes and connect the electrical wires harness.

Door Handle Assembly

The door handle assemblies are made up of three components: an outside handle with lock, an inside levertype handle and latch mechanism, and the striker. See Figure 7. The outside door handle is fastened to the door by three screws installed through access holes from the inside of the door. The inside door handle is fastened to the door by a capscrew and washer at the bottom end of the handle and attaching hardware at the mechanism. The handle assembly has a latch mechanism that contacts the striker. The striker is threaded and is installed on the forward door post. Adjust the striker so that it mates with the latch mechanism.

1. DOOR FRAME 2. INSIDE HANDLE 3. COVER

4. STRIKER HARDWARE 5. SEAL 6. OUTSIDE HANDLE

Figure 7. Door Handle Assembly

100 YRM 778

Heater Assembly

Fuse Panel

The fuse panel with the fuses for the window wipers, lights, fan, and heater system are inside the operator cab. This fuse panel is located in the upper right rear corner of the cab. The fuse arrangement is shown in Figure 8. The fuse panel can be pulled away or removed from the mount by loosening two capscrews, then disconnecting the fuse panel from the wire harness.

1. WIPER FRONT/REAR 2. DOMELIGHT

3. FAN/RADIO 4. HEATER/BLOWER

Figure 8. Fuse Panel

Heater Assembly

REMOVE WARNING

If the truck has been run for awhile, the heater hoses will be hot and the water can cause severe burns. Make sure that the hoses are cool before removal. 2. Disconnect the heater electrical connector. 3. Open the right-hand cab door and remove the two screws that fasten the heater duct to the bracket. 4. Remove the four screws that fasten the heater to the bracket and remove the heater assembly.

CAUTION

When the engine heater hoses must be replaced in the cab, make sure to use heater hoses of the correct material and size. Order Yale part number 504323758 for the engine supply hose and 504323755 for the return hose. All hoses must conform to SAE Specification 20R3 Class C or 20R3 Class D-2. NOTE: If the heater fails, replace the heater assembly as a complete unit. 1. Disconnect the two preformed heater hoses from the heater. See Figure 9.

INSTALL

1. Attach the heater assembly to the mounting bracket with four screws and washers. See Figure 9. 2. Attach the heater duct to the mounting bracket with two screws and washers. Make sure that the duct mates with the heater input opening. 3. Make sure that the seal on the door side of the duct is installed correctly. 4. Connect the heater electrical connector. 5. Connect the two preformed heater hoses to the heater. See Figure 9.

Heater Assembly

100 YRM 778

1. 2. 3. 4. 5.

HEAT DUCT SEAL HEATER BRACKET SCREW (4)

6. 7. 8. 9.

WASHER (4) HEATER HOSE CONNECTIONS PREFORMED HEATER HOSE (RETURN) PREFORMED HEATER HOSE (SUPPLY)

Figure 9. Heater Assembly

100 YRM 778

Window Replacement

Window Replacement

WARNING

All windows installed in the cab are made of tempered glass. The overhead skylight is made of Lexan. All replacement windows must be made of the correct material and thickness as the windows furnished with the lift truck. See Table 1 for window specifications. The front window is a single unit held in place by screws through the glass. See Figure 10. The rear and lower door windows are replaced as single units held in the window openings by a rubber seal. The slider windows and frames in the doors must be replaced as a unit. The top window is a single piece of curved Lexan and is fastened by an adhesive. In the event of breakage, cracking, or other damage to any of the cab windows, it is recommended that all windows be repaired or replaced by your Yale dealer or other qualified glazier.

Table 1. Material Specifications for Cab Windows Location of Window Front Rear Doors Upper RH Upper LH Lower, R/L Top 580014007 580014006 524140139 580025892 Tinted Tempered Safety Glass per ANSI Z26.1 AS2 Requirements Tinted Tempered Safety Glass per ANSI Z26.1 AS2 Requirements Tinted Lexan MR 5004-310351 4.5 to 5.0 0.18 to 0.2 Yale Part Number 580014760 580014770 Material Specification mm Tinted Tempered Safety Glass per ANSI Z26.1 AS1 Requirements 5.9 to 7.5 5.6 to 6.8 Thickness inch 0.23 to 0.29 0.22 to 0.27

4.5 to 5.0 3.0

0.18 to 0.2 0.12

Window Replacement

100 YRM 778

1. 2. 3. 4.

FRONT WINDOW SEAL ATTACHING HARDWARE CLAMP WITH HARDWARE

5. 6. 7. 8.

SKYLIGHT REAR WINDOW LOWER DOOR WINDOW UPPER DOOR WINDOW

Figure 10. Operator Cab Assembly Glass

10

100 YRM 778

Options

Options

There are several options available for the cab. See your Yale dealer for the full range of available options.

HEAVY-DUTY AIR CLEANER

In environments with very dirty conditions, the lift truck can be equipped with a heavy-duty air cleaner which precleans the air before it enters the standard air filter. This precleaner is mounted on the rear of the cab in place of the air vent. See Figure 11. Clean or replace the heavy-duty precleaner as necessary. Inspect the canister, the hose, and the molded port for excessive wear, cracks, or damage.

REAR STROBE LIGHTS

In addition to the standard overhead driving lights, the cab can be equipped with a rear-mounted strobe light with either a high or low mounting fixture. See Figure 11. The strobe light is normally configured to operate continuously. It can be optionally configured to activate when the lift truck is put into reverse gear. See Figure 12.

1. LOW MOUNT OR HIGH MOUNT STROBE 2. HEAVY-DUTY AIR CLEANER 3. ADDITIONAL MIRROR Figure 11. Operator Cab Options

11

Electrical Schematics

100 YRM 778

Label Replacement

WARNING

Labels that have WARNINGS or CAUTIONS must be replaced if they are damaged. If a mast of a different size or an accessory carriage is installed, the capacity rating can change. Changes in drive tires can change the capacity rating. See a Yale lift trucks dealer for a replacement nameplate. The nameplate information is a safety item and must be correct for the equipment and configuration of the lift truck. Refer to Frame 100 YRM 726 for label placement.

Electrical Schematics

The electrical schematic for the cab is included in this manual for the users convenience. See Figure 12 and Figure 13. Refer to Diagrams 8000 YRM 757 for the lift truck electrical schematics.

12

100 YRM 778

Electrical Schematics

Figure 12. Cab Light Options Electrical Schematic

13

Electrical Schematics

100 YRM 778

Figure 13. Operator Cab Wiring Schematic

14

Yale Materials Handling Corp. 1400 Sullivan Dr., Greenville, NC 27834-2011

100 YRM 778

6/04 (9/03)(8/02) Printed in U.S.A.

También podría gustarte

- Yale ERC070 HG 8K ManualDocumento46 páginasYale ERC070 HG 8K ManualJavier Silva100% (1)

- Tilt CylindersDocumento14 páginasTilt CylindersJuan Carlos Sanchez Gomez100% (1)

- Yale Reach Truck NR-NDR-DB Specification SheetDocumento6 páginasYale Reach Truck NR-NDR-DB Specification SheetNoelia Brand100% (1)

- Manual de Servicio Hyster Nafta Gas Manutencao Hyster h40 70ft Maintenance Hyster h40 70ftDocumento53 páginasManual de Servicio Hyster Nafta Gas Manutencao Hyster h40 70ft Maintenance Hyster h40 70ftcolive1Aún no hay calificaciones

- Operating Manual: J1.5-2.0XNT (K160)Documento244 páginasOperating Manual: J1.5-2.0XNT (K160)Yan1203Aún no hay calificaciones

- MarooOn Catalog (ENG) 190604Documento45 páginasMarooOn Catalog (ENG) 190604sugar44Aún no hay calificaciones

- Electric C4000 Service Training Pack PDFDocumento28 páginasElectric C4000 Service Training Pack PDFduongpnAún no hay calificaciones

- YALE A284 MPR080VG LIFT TRUCK Service Repair Manual PDFDocumento10 páginasYALE A284 MPR080VG LIFT TRUCK Service Repair Manual PDFsekfsekmdddeAún no hay calificaciones

- 0700yrm1123 (03 2013) Uk enDocumento70 páginas0700yrm1123 (03 2013) Uk enJuan Francisco Canto DiezAún no hay calificaciones

- Arsrepaircatalog Websiteedition Hyster.69192443Documento13 páginasArsrepaircatalog Websiteedition Hyster.69192443MA TotalforkliftAún no hay calificaciones

- Hydraulic SystemDocumento88 páginasHydraulic SystemBaciu NicolaeAún no hay calificaciones

- Metric and Inch (Sae) Fasteners: MaintenanceDocumento22 páginasMetric and Inch (Sae) Fasteners: MaintenanceEsjo100% (1)

- Combilift Sideloader CatalogueDocumento2 páginasCombilift Sideloader CatalogueAulia TiaraAún no hay calificaciones

- ForewordDocumento12 páginasForewordEmadAún no hay calificaciones

- Baoli 3ruote ACDocumento87 páginasBaoli 3ruote ACmirko coppiniAún no hay calificaciones

- Doosan B10 - 13 - 15 - 16R-5 - SB4292E - 18.09Documento494 páginasDoosan B10 - 13 - 15 - 16R-5 - SB4292E - 18.09danielAún no hay calificaciones

- Operator Manual CB en 英语Documento79 páginasOperator Manual CB en 英语Carlos Bernabe Gonzalez100% (2)

- 311345-000 2002 - July PDFDocumento81 páginas311345-000 2002 - July PDFduongpnAún no hay calificaciones

- Mantenimiento Forklift AnchaDocumento106 páginasMantenimiento Forklift AnchaYeisson Agudelo100% (3)

- Electric StakerDocumento18 páginasElectric Stakerrsvti100% (1)

- PDF2D TMPDocumento151 páginasPDF2D TMPRomanAún no hay calificaciones

- Clark Staddle Stacker SM-994 Ssx12!16!18 (Nov-2019) Service Manual - 8120715Documento308 páginasClark Staddle Stacker SM-994 Ssx12!16!18 (Nov-2019) Service Manual - 8120715ALEJOAún no hay calificaciones

- Safety Instructions: EnglishDocumento4 páginasSafety Instructions: EnglishAdrian FerreyraAún no hay calificaciones

- Yale MP040 - Hyster W40ZDocumento12 páginasYale MP040 - Hyster W40ZMAT ALEAún no hay calificaciones

- Century Fuel Products On Material Handling Network MagazineDocumento56 páginasCentury Fuel Products On Material Handling Network MagazineSeth priceAún no hay calificaciones

- 028 FGF 15Documento392 páginas028 FGF 15Mar StawAún no hay calificaciones

- Brakes - PDF t5Documento15 páginasBrakes - PDF t5diego diazAún no hay calificaciones

- Linde Brochure 387-388 DR PDFDocumento12 páginasLinde Brochure 387-388 DR PDFSohailAhmadAún no hay calificaciones

- NC2 Tech YaleDocumento69 páginasNC2 Tech YaleClaudio de PisisAún no hay calificaciones

- Caterpillar Cat GC20N Forklift Lift Trucks Service Repair Manual SN AT90-00011 and Up PDFDocumento50 páginasCaterpillar Cat GC20N Forklift Lift Trucks Service Repair Manual SN AT90-00011 and Up PDFfjkskekmdmmeAún no hay calificaciones

- PDFDocumento6 páginasPDFAmc Forklift Elektrik100% (1)

- Control Electronico Del Motor GM 1Documento100 páginasControl Electronico Del Motor GM 1adelmomouraAún no hay calificaciones

- Cylinder Repair: PART NO. 1580516 2100 SRM 1139Documento30 páginasCylinder Repair: PART NO. 1580516 2100 SRM 1139Fabricio FélixAún no hay calificaciones

- Service Manual Liftstar-2014Documento46 páginasService Manual Liftstar-2014Adam SchwemleinAún no hay calificaciones

- 3 Wheel Electric Forklift Trucks 2,500-3,200 LB PDFDocumento14 páginas3 Wheel Electric Forklift Trucks 2,500-3,200 LB PDFForklift Systems IncorporatedAún no hay calificaciones

- Operation & Service Manual Parts Catalogue: CBD12W Electric Pallet TruckDocumento23 páginasOperation & Service Manual Parts Catalogue: CBD12W Electric Pallet TruckSARAMQRAún no hay calificaciones

- C15-20sL (Lot No 9791,9829)Documento239 páginasC15-20sL (Lot No 9791,9829)Christian BedoyaAún no hay calificaciones

- Vista Mast RepairDocumento28 páginasVista Mast RepairTan JaiAún no hay calificaciones

- Hyster ForklliftDocumento22 páginasHyster ForklliftMohammed Al-hewaimel100% (2)

- BT Serviço Hyster TrilateralDocumento8 páginasBT Serviço Hyster TrilateraltaurusAún no hay calificaciones

- Electrical Diagrams: Ac Motor Control SystemDocumento80 páginasElectrical Diagrams: Ac Motor Control SystemJohn fredy cuervo100% (1)

- 1.5-3.8t X Series IC Forklift TruckDocumento6 páginas1.5-3.8t X Series IC Forklift TruckE Abadt DLAún no hay calificaciones

- Zapi H2 Pump Controller PDFDocumento3 páginasZapi H2 Pump Controller PDFel reyAún no hay calificaciones

- Nobelift PS15 - 15SL - 20-UserManual+partDocumento160 páginasNobelift PS15 - 15SL - 20-UserManual+partAs Salaf Hartanto100% (1)

- 2200SRM0724 (04 2005) Us en PDFDocumento98 páginas2200SRM0724 (04 2005) Us en PDFMayerson AlmaoAún no hay calificaciones

- (C814e) Erp 16-20aaf-Y-Pm-Uk-En - (01-2009)Documento364 páginas(C814e) Erp 16-20aaf-Y-Pm-Uk-En - (01-2009)Slawomir RusinAún no hay calificaciones

- C3000GT PM en 09Documento127 páginasC3000GT PM en 09ForktechAún no hay calificaciones

- Frame: H6.00-7.00XL (H135-155XL) (F006, G006)Documento22 páginasFrame: H6.00-7.00XL (H135-155XL) (F006, G006)michaelquimica9814Aún no hay calificaciones

- Manual Motor Diesel Camiones Mineros 830e 930e Komatsu Partes Funcionamiento Mantenimiento SeguridadDocumento18 páginasManual Motor Diesel Camiones Mineros 830e 930e Komatsu Partes Funcionamiento Mantenimiento SeguridadRamon ArredondoAún no hay calificaciones

- Up-Time Manual - English v2.1Documento68 páginasUp-Time Manual - English v2.1jebtheAún no hay calificaciones

- SC6200Documento50 páginasSC6200Migue Angel Rodríguez CastroAún no hay calificaciones

- Yale PC Service Tool Installation and Use GuideDocumento84 páginasYale PC Service Tool Installation and Use GuideNhàn Nguyễn Thanh100% (1)

- Es10 10es Service ManualDocumento136 páginasEs10 10es Service Manualmohammed100% (1)

- Operation & Maintenance Manual: Zhejiang Noblelift Equipment Joint Stock Co.,LtdDocumento77 páginasOperation & Maintenance Manual: Zhejiang Noblelift Equipment Joint Stock Co.,LtdМикола Попович100% (1)

- YALE (A955) ERP16VF EUROPE FORKLIFT Service Repair Manual PDFDocumento17 páginasYALE (A955) ERP16VF EUROPE FORKLIFT Service Repair Manual PDFfhjskemmd50% (2)

- Sistema HidraulicoDocumento24 páginasSistema HidraulicoCarlos Gomez100% (1)

- SS-SRXN 10-09Documento12 páginasSS-SRXN 10-09Forklift Systems IncorporatedAún no hay calificaciones

- Maintenance and Repair Cab H80XBDocumento20 páginasMaintenance and Repair Cab H80XBvictor lunaAún no hay calificaciones

- Sistema ElectricoDocumento34 páginasSistema ElectricoPlanos MontacargasAún no hay calificaciones

- Main Control Valve: H2.0-3.0XT (H40-60XT) (A380)Documento62 páginasMain Control Valve: H2.0-3.0XT (H40-60XT) (A380)Diego DorowAún no hay calificaciones

- 2954 4650 00 - Qas 600 - enDocumento58 páginas2954 4650 00 - Qas 600 - enIlarion CiobanuAún no hay calificaciones

- 2954 4960 01 - Branded EU Lighting Tower - ENDocumento50 páginas2954 4960 01 - Branded EU Lighting Tower - ENIlarion Ciobanu100% (1)

- Alternador Con ReguladorDocumento26 páginasAlternador Con ReguladorIlarion Ciobanu100% (1)

- Atlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDDocumento36 páginasAtlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDRay Cepeda Mena100% (5)

- 2954 2980 00 - QAS 250 John Deere - ENDocumento52 páginas2954 2980 00 - QAS 250 John Deere - ENIlarion CiobanuAún no hay calificaciones

- 2954 2460 02 - Oah 2-Oav 4 - enDocumento34 páginas2954 2460 02 - Oah 2-Oav 4 - enIlarion CiobanuAún no hay calificaciones

- 2954 2960 03 - Qas 125-150 - enDocumento108 páginas2954 2960 03 - Qas 125-150 - enIlarion CiobanuAún no hay calificaciones

- EC - Engine Control SystemDocumento634 páginasEC - Engine Control SystemIlarion Ciobanu100% (2)

- Gear CalcDocumento2 páginasGear CalcIlarion CiobanuAún no hay calificaciones

- SMJ - Super Multiple JunctionDocumento7 páginasSMJ - Super Multiple JunctionIlarion CiobanuAún no hay calificaciones

- ST - Steering SystemDocumento34 páginasST - Steering SystemIlarion CiobanuAún no hay calificaciones

- HA - Heater & Air ConditionerDocumento210 páginasHA - Heater & Air ConditionerIlarion Ciobanu100% (1)

- CL - ClutchDocumento22 páginasCL - ClutchIlarion CiobanuAún no hay calificaciones

- At - Automatic TransaxelDocumento400 páginasAt - Automatic TransaxelIlarion CiobanuAún no hay calificaciones

- CS 20Documento208 páginasCS 20Ilarion CiobanuAún no hay calificaciones

- General Body Repairs ExteriorDocumento232 páginasGeneral Body Repairs ExteriorergdegAún no hay calificaciones

- Mii000 7 PDFDocumento26 páginasMii000 7 PDFbrane12Aún no hay calificaciones

- Building SSR 2011 12 PDFDocumento403 páginasBuilding SSR 2011 12 PDFRavi KumarAún no hay calificaciones

- Chapter - 2Documento30 páginasChapter - 2Rgirish 1Aún no hay calificaciones

- @airbus: Component Maintenance Manual With Illustrated Part ListDocumento313 páginas@airbus: Component Maintenance Manual With Illustrated Part Listjoker hotAún no hay calificaciones

- Bed Bug Addendum: August 11, 2017Documento18 páginasBed Bug Addendum: August 11, 2017Moise StephaneAún no hay calificaciones

- Taiton Pricelist 23rd Dec 18Documento34 páginasTaiton Pricelist 23rd Dec 18Abhishek Rajput0% (1)

- 10 - 12 Arrow Shed ManualDocumento39 páginas10 - 12 Arrow Shed ManualJason Porter100% (2)

- Schedule of Doors and WindowsDocumento3 páginasSchedule of Doors and WindowsBobby BaybayAún no hay calificaciones

- Dynapac - F1000WDocumento334 páginasDynapac - F1000WFR100% (1)

- Comparison Between Fmvss No. 206 and Ece R11Documento10 páginasComparison Between Fmvss No. 206 and Ece R11MAún no hay calificaciones

- SSP 990493 - The 2019 Audi A8 IntroductionDocumento106 páginasSSP 990493 - The 2019 Audi A8 IntroductionDũng NguyễnAún no hay calificaciones

- The Fortessa Collection 2010Documento36 páginasThe Fortessa Collection 2010monu6006Aún no hay calificaciones

- Godrej Product Price List Wef Jul-21Documento36 páginasGodrej Product Price List Wef Jul-21akkisahAún no hay calificaciones

- Corporación Multi Negocios MG, Fundador Dilan Eduardo Mendez Guerra, Co Fundador Fraterno Vila BetoretDocumento23 páginasCorporación Multi Negocios MG, Fundador Dilan Eduardo Mendez Guerra, Co Fundador Fraterno Vila BetoretEDWARD MGAún no hay calificaciones

- M13 Aircraft StructuresDocumento173 páginasM13 Aircraft Structuresairbuk doeing100% (1)

- @airbus: Airbus S.A.SDocumento402 páginas@airbus: Airbus S.A.Sjoker hotAún no hay calificaciones

- DNV Catalogue - CompressedDocumento28 páginasDNV Catalogue - CompressedCHITRAKAR (ØÑkäR)Aún no hay calificaciones

- Palladio Brochure October 2017 LRDocumento52 páginasPalladio Brochure October 2017 LRpostdarwinAún no hay calificaciones

- Stanley SparePartsManualDocumento53 páginasStanley SparePartsManualjmech455Aún no hay calificaciones

- Component Locator - Door Component ViewsDocumento8 páginasComponent Locator - Door Component ViewsAlfonso BarrantesAún no hay calificaciones

- 04 01 Vlookup Exact Match 1Documento7 páginas04 01 Vlookup Exact Match 1Deepak SinghAún no hay calificaciones

- Section 90 - Cab - Chapter 3Documento36 páginasSection 90 - Cab - Chapter 3Esteban MunaresAún no hay calificaciones

- Simple Machines 1 PDFDocumento9 páginasSimple Machines 1 PDFRavi SinghAún no hay calificaciones

- Catalog D SlidingDocumento26 páginasCatalog D SlidingrubenhuanacuAún no hay calificaciones

- Chery A5 Chapter Three DoorDocumento17 páginasChery A5 Chapter Three DoorAbbode HoraniAún no hay calificaciones

- Front of VehicleDocumento11 páginasFront of VehiclekakaAún no hay calificaciones

- Tesla Door HandlesDocumento7 páginasTesla Door HandlesDunder StoreAún no hay calificaciones

- Shower System AccessoriesDocumento8 páginasShower System AccessoriesJirapong ThailandAún no hay calificaciones

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceDe EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceAún no hay calificaciones

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...De EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Aún no hay calificaciones

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionCalificación: 4.5 de 5 estrellas4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tCalificación: 4.5 de 5 estrellas4.5/5 (27)

- A Mind at Play: How Claude Shannon Invented the Information AgeDe EverandA Mind at Play: How Claude Shannon Invented the Information AgeCalificación: 4 de 5 estrellas4/5 (53)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDe EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeCalificación: 4.5 de 5 estrellas4.5/5 (10)

- Power System Control and ProtectionDe EverandPower System Control and ProtectionB. Don RussellCalificación: 4 de 5 estrellas4/5 (11)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDe Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersCalificación: 5 de 5 estrellas5/5 (1)

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)De EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Calificación: 4 de 5 estrellas4/5 (2)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDe EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesCalificación: 5 de 5 estrellas5/5 (1)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDe EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDe EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonCalificación: 5 de 5 estrellas5/5 (2)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDe EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsCalificación: 3.5 de 5 estrellas3.5/5 (2)

- Digital Transformation: Survive and Thrive in an Era of Mass ExtinctionDe EverandDigital Transformation: Survive and Thrive in an Era of Mass ExtinctionCalificación: 4.5 de 5 estrellas4.5/5 (9)

- Schaum's Outline of Basic Electricity, Second EditionDe EverandSchaum's Outline of Basic Electricity, Second EditionCalificación: 5 de 5 estrellas5/5 (14)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsDe EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsAún no hay calificaciones

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionCalificación: 4 de 5 estrellas4/5 (331)

- Teach Yourself Electricity and Electronics, 6th EditionDe EverandTeach Yourself Electricity and Electronics, 6th EditionCalificación: 3.5 de 5 estrellas3.5/5 (15)

- Build Your Own Electronics WorkshopDe EverandBuild Your Own Electronics WorkshopCalificación: 3.5 de 5 estrellas3.5/5 (3)

- DIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesDe EverandDIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesCalificación: 3.5 de 5 estrellas3.5/5 (3)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignDe EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignAún no hay calificaciones

- Empires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldDe EverandEmpires of Light: Edison, Tesla, Westinghouse, and the Race to Electrify the WorldCalificación: 4 de 5 estrellas4/5 (87)