Documentos de Académico

Documentos de Profesional

Documentos de Cultura

ASME17-1 - Wire Rope Replacement Criteria

Cargado por

egyinspectoryahooTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

ASME17-1 - Wire Rope Replacement Criteria

Cargado por

egyinspectoryahooCopyright:

Formatos disponibles

Rope Replacement Criteria

ASME 17.1 Wire Rope Replacement Criteria

Please find below, reprinted from ASME17.1-2007/CSA-B44-07 by permission of The American Society of Mechanical Engineers (All rights reserved) Sections 8.6.3.2 thru 8.6.3.2.6, Section 8.6.3.3 and 8.6.3.3.1, Section 8.11.2.1.3(CC) and Table 8.11.2.1.3(cc). These excerpts provide useful guidance for those examining wire ropes and outline the key replacement criteria for ropes on inspection. They establish the conditions under which ropes can be retired safely. These fall broadly into three categories: 1 Crown Wire Breaks Those that contact the sheave directly and are prone to wear or break. 2 Valley Breaks Those that are situated between adjacent strands; they make no contact with the sheave but are still subject to wear by fatigue. ASME 17.1 sets the criterion for the acceptable number of breaks in both. 3 Rope Diameter Reduction Irrespective of an acceptable number of Crown or Valley Wire Breaks, rope stretches, its length and tension are adjusted and over time the wire rope diameter is reduced. ASME 17.1 specifies the diameter reductions at which point the rope should be retired

8.6.3.2 - Replacement of a Single Suspension Rope

If one rope of a set is worn or damaged and requires replacement, the entire set of ropes shall be replaced, except where one rope has been damaged during installation or acceptance testing prior to being subjected to elevator service, it shall be permissible to replace a single damaged rope with a new rope, provided that the requirements of 8.6.3.2.1 through 8.6.3.2.6 are met. 8.6.3.2.1 The wire rope data for the replacement rope must correspond to the wire rope data specified in 2.20.2.2(a), (b), (c), (f), and (g) for the other ropes. 8.6.3.2.2 The replacement rope shall be provided with a wire rope data tag conforming to 2.20.2.2 8.6.3.2.3 The suspension ropes, including the damaged ropes, shall not have been shortened since their original installation. 8.6.3.2.4 The diameter of any of the remaining ropes shall not be less than the nominal diameter minus 0.4mm (0.015 in.) 8.6.3.2.5 The tension of the new replacement rope shall be checked and adjusted as necessary at semi-monthly intervals over a period of not less than two months after installation. If proper equalization of rope tension cannot be maintained after six months, the entire set of hoist roes shall be replace. 8.6.3.2.6 The replacement rope shall be provided with the same type of suspension rope fastening used with the other ropes.

8.6.3.3 - Replacement of Ropes Other than Governor Ropes

8.6.3.3.1 Replacement of all ropes, except governor ropes (see 8.6.3.4) shall conform to the following: (a) (b) (c) (d) (e) Replacement ropes shall be as specified by the original elevator manufacturer or be at least equivalent in strength, weight, and design. Ropes that have been previously used in another installation shall not be reused. When replacing suspension, compensation, and car or drum counterweight ropes, all ropes in a set shall be replaced, except as permitted by 8.6.3.2 The ropes in the set shall be new, all from the same manufacturer, and of the same material, grade, construction, and diameter.

NOTE: It does not state that the ropes be from the same master reel.

(f)

Data tags conforming to 2.20.2.2 shall be applied. Suspension, car, and drum counterweight rope fastenings shall conform to 2.20.9.

DRUCEGROVE Ltd, Unit 12 Abbey Mead Industrial Park, Brooker Road, Waltham Abbey, Essex, EN9 1HU Phone: +44 (0) 1992 650486 Fax: +44 (0) 1992 652226 sales@drucegrove.com www.drucegrove.com

Rope Replacement Criteria

ASME 17.1 Wire Rope Replacement Criteria 8.11.2.1.3(CC) - Wire Suspension and Compensating Ropes

8.11.2.1.3(cc)(1) Wire suspension and compensating ropes shall be replaced: (a) (b) (c) (d) if the broken wires are equally distributed among the strands, when the number of broken wires per rope lay in the worst section of the rope exceeds the values shown in column A of Table 8.11.2.1.3(cc)(1); or if the distribution of the broken wires is unequal, and the broken wires predominate in one or two strand, when the number of broken wires per rope lay in the worst section of the rope exceeds the values shown in column B of Table 8.11.2.1.3(cc)(1); or if four or five wires, side by side, are broken across the crown of any strand, when the number of broken wires per rope lay in the worst section of rope exceeds values shown in column C of Table 8.11.2.1.3(cc)(1); or if in the judgment of the inspector, any unfavourable condition, such as fretting corrosion (red dust or rouge), excessive wear of individual wires in the strands, unequal tension, poor sheave grooves, etc, exists, the criteria for broken wires will be reduced by 50% of the values indicated in Table 8.11.2.1.3(cc)(1) for any of the three conditions described above; or if there is more than one valley break per rope lay.

(e)

Table 8.11.2.1.3(cc)(1)

Types of Wire Ropes 6x19 class (6 strands w/ 16-26 wires/strand) 8x19 class (8 strands w/ 16-26 wires/strand) A 24-30* 32-40* B 8-12* 10-16* C 12-20* 16-24*

8.11.2.1.3(cc)(2) On winding drum machines, the ropes shall be replaced: (a) (b) (c) if the broken wires are equally distributed among the strands, when the number of broken wires per rope lay in the worst section of the rope exceeds 12 to 18; or if wire breaks predominate in one or two strand, when the number of broken wires per rope lay in the worst section of rope exceeds 6 to 12: or if there is more than one valley break per rope lay.

8.11.2.1.3(cc)(3) On any type of elevator, the suspension, compensation and governor ropes shall be replaced when their actual diameter is reduced below the value shown in Table 8.11.2.1.3(cc)(3)

Table 8.11.2.1.3(cc)(3)

Nominal Size

(inches)

Maximum Reduced Diameter

(inches decimal inches)

3/8 7/16 1/2 9/16 5/8 11/16 3/4 1

11/32 0.344 13/32 0.406 15/32 0.469 17/32 0.531 37/64 0.578 41/64 0.640 45/64 0.703 15/16 0.938

Reprinted from ASME A17.1-2007/CSA-B44-07 by permission of The American Society of Mechanical Engineers All rights reserved http://catalog.asme.org/Codes/PrintBook/A171CSA_B44_2007_Safety_Code.cfm

DRUCEGROVE Ltd, Unit 12 Abbey Mead Industrial Park, Brooker Road, Waltham Abbey, Essex, EN9 1HU Phone: +44 (0) 1992 650486 Fax: +44 (0) 1992 652226 sales@drucegrove.com www.drucegrove.com

También podría gustarte

- Load Testing of LiftsDocumento4 páginasLoad Testing of LiftsahmedAún no hay calificaciones

- Alloy Steel D ShacklesDocumento2 páginasAlloy Steel D ShacklesPradipta LenkaAún no hay calificaciones

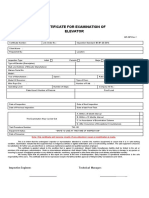

- Acceptance Checklist: Elevator Machine Room And/or Control SpaceDocumento4 páginasAcceptance Checklist: Elevator Machine Room And/or Control SpaceImran KhanAún no hay calificaciones

- Ve Chklist Lift Inspect-1Documento2 páginasVe Chklist Lift Inspect-1RajaDurai Ramakrishnan0% (1)

- Ladder Safety ChecklistDocumento3 páginasLadder Safety ChecklistzulfactAún no hay calificaciones

- Mechanical Lift Categorization: Risk Questions Yes NoDocumento1 páginaMechanical Lift Categorization: Risk Questions Yes NomohammedAún no hay calificaciones

- Lifts and Hoists Maintenance TasksDocumento19 páginasLifts and Hoists Maintenance TasksMachineryengAún no hay calificaciones

- JKJ 167 Checklist of Initial Inspection For EscalatorDocumento3 páginasJKJ 167 Checklist of Initial Inspection For EscalatorHong Leong KuAún no hay calificaciones

- Lifts and Hoists Maintenance Tasks PDFDocumento19 páginasLifts and Hoists Maintenance Tasks PDFMachineryengAún no hay calificaciones

- Installation and Operating Instructions Overspeed Governor Type 7/8/9Documento16 páginasInstallation and Operating Instructions Overspeed Governor Type 7/8/9RuiAún no hay calificaciones

- LIFTING POINT Color Code Requirements in PR-1708 PDFDocumento2 páginasLIFTING POINT Color Code Requirements in PR-1708 PDFNibin OdukkathilAún no hay calificaciones

- General Contractor's Passenger and Freight Elevator Pre-Inspection ChecklistDocumento4 páginasGeneral Contractor's Passenger and Freight Elevator Pre-Inspection ChecklistEngr. Jeremiah BadanaAún no hay calificaciones

- Elevator Violation CodesDocumento31 páginasElevator Violation CodesAnonymous YzSzB0rpNKAún no hay calificaciones

- Eot Crane ChecklistDocumento1 páginaEot Crane ChecklistMohammad Abubakar Siddiq75% (8)

- CEN TC10 Presentation - 20 - 50Documento92 páginasCEN TC10 Presentation - 20 - 50bugseAún no hay calificaciones

- Elevator Final ChecklistDocumento3 páginasElevator Final ChecklistYasser Fathi100% (2)

- Elevator Inspection Records Quality Control (QC) Dept.: Pt. Ife Jaya IndonesiaDocumento8 páginasElevator Inspection Records Quality Control (QC) Dept.: Pt. Ife Jaya IndonesiaNaseh Ya NasehAún no hay calificaciones

- Method Statement For The Installation of Minispace Lifts - The RenaissanceDocumento13 páginasMethod Statement For The Installation of Minispace Lifts - The Renaissancemanuel chang100% (1)

- Tirak: For Man-RidingDocumento36 páginasTirak: For Man-RidingBismo Anggoro80% (5)

- 8689-2018 Sixco Chain SlingDocumento2 páginas8689-2018 Sixco Chain SlingAnonymous wuugFvOBjZAún no hay calificaciones

- Checklist For Inspection of Escalators PDFDocumento1 páginaChecklist For Inspection of Escalators PDFAry Putra100% (1)

- Passenger & Freight Elevator Pre-Inspection Checklist 2014 - FinalDocumento3 páginasPassenger & Freight Elevator Pre-Inspection Checklist 2014 - FinalMostafa MohmmedAún no hay calificaciones

- Year Full Load Test Elevator Contractor SOWDocumento2 páginasYear Full Load Test Elevator Contractor SOWJoseAún no hay calificaciones

- Elevator Rope Tension Gauage - Equator - 99.9% ArticleDocumento4 páginasElevator Rope Tension Gauage - Equator - 99.9% ArticleSubiiah Panneer SelvamAún no hay calificaciones

- Hitachi Hoist - ManualDocumento156 páginasHitachi Hoist - ManualMetCESAún no hay calificaciones

- Loading Test Method Statement FinalDocumento10 páginasLoading Test Method Statement FinalBOUZAIDAAún no hay calificaciones

- Process For Load Hook TestingDocumento14 páginasProcess For Load Hook TestingAli DiabAún no hay calificaciones

- SR ElevatorDocumento1 páginaSR ElevatorAbdurachman100% (1)

- Elevator (MR) Certificate Standard FormatDocumento2 páginasElevator (MR) Certificate Standard FormatAkhil100% (2)

- 2023 Escalator Pre Inspection Checklist 20230110fillableDocumento3 páginas2023 Escalator Pre Inspection Checklist 20230110fillablevikrant9870% (1)

- IGD20 Complete ManualDocumento39 páginasIGD20 Complete ManualFERNSAún no hay calificaciones

- Crane Sheave - Early FailuresDocumento14 páginasCrane Sheave - Early FailuresMichael WoodAún no hay calificaciones

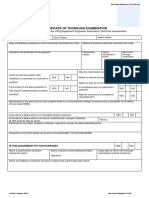

- Elevator Five Year Safety Test FormDocumento2 páginasElevator Five Year Safety Test FormTaufiq Omar HasanAún no hay calificaciones

- Lift Rope Inspection PDFDocumento2 páginasLift Rope Inspection PDFcarlosorizaba100% (1)

- Elevator RescueDocumento1 páginaElevator Rescueeliasox123Aún no hay calificaciones

- EIAC Requirements TrainingDocumento52 páginasEIAC Requirements TrainingFarrukh AhmedAún no hay calificaciones

- Elevator ChecklistDocumento3 páginasElevator ChecklistNguyễn Thế PhongAún no hay calificaciones

- Lubrication and Elevator RopesDocumento7 páginasLubrication and Elevator RopesRui Miguel Salvador100% (1)

- Desc. Técnica ALIMAKDocumento103 páginasDesc. Técnica ALIMAKFran jimenezAún no hay calificaciones

- 0503 Geda Hoist InstructionsDocumento6 páginas0503 Geda Hoist InstructionsBoruida MachineryAún no hay calificaciones

- Guide D'Utilisation: Operating ManualDocumento16 páginasGuide D'Utilisation: Operating ManualnameAún no hay calificaciones

- LEEA Certificate of Thorough ExaminationDocumento1 páginaLEEA Certificate of Thorough Examinationengmuhmud100% (1)

- Elevator MSRADocumento74 páginasElevator MSRAsajin0% (1)

- User Manual Wire Rope SlingDocumento4 páginasUser Manual Wire Rope SlingRashid GhaniAún no hay calificaciones

- Accii LR2Documento4 páginasAccii LR2pnsanatAún no hay calificaciones

- Elevator Violation CodesDocumento31 páginasElevator Violation Codeshossam hassanAún no hay calificaciones

- Material Hoist - Spare Parts ManualDocumento42 páginasMaterial Hoist - Spare Parts ManualRajesh PanchalAún no hay calificaciones

- Overhead Crane Operator Inspection ChecklistDocumento2 páginasOverhead Crane Operator Inspection ChecklistYousef Wally83% (6)

- EMMARDocumento5 páginasEMMARNisar DeenAún no hay calificaciones

- Checklist For Escalator Inspection PDFDocumento1 páginaChecklist For Escalator Inspection PDFthanggimme.phanAún no hay calificaciones

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionDocumento31 páginasPR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionAdnanAún no hay calificaciones

- Steel Wire Rope Handling & MaintenanceDocumento23 páginasSteel Wire Rope Handling & MaintenanceRahul100% (1)

- Overhead CraneDocumento4 páginasOverhead Craneahmedzizo_2Aún no hay calificaciones

- Wire Rope Manual PDFDocumento35 páginasWire Rope Manual PDFMuhammad Vaudzan N SumadiputraAún no hay calificaciones

- OTIS Elevator Weekly Inspection Checklist Revision 28 December 2019.Documento2 páginasOTIS Elevator Weekly Inspection Checklist Revision 28 December 2019.JayJayAún no hay calificaciones

- Qcs 2010 Section 21 Part 20 Elevators & EscalatorsDocumento14 páginasQcs 2010 Section 21 Part 20 Elevators & Escalatorsbryanpastor106Aún no hay calificaciones

- 03-17-V1risk Assessment (Wire Rope Replacement) v1Documento4 páginas03-17-V1risk Assessment (Wire Rope Replacement) v1Mohamed ElnagdyAún no hay calificaciones

- Escalator Checklist DS022Documento1 páginaEscalator Checklist DS022Tian Fung WangAún no hay calificaciones

- 14 2400 Hydraulic ElevatorsDocumento12 páginas14 2400 Hydraulic ElevatorsPercy GoitsemangAún no hay calificaciones

- Tech Tip 2 PDFDocumento5 páginasTech Tip 2 PDFaziez_rahmawanAún no hay calificaciones

- Drilling RigsDocumento18 páginasDrilling RigsegyinspectoryahooAún no hay calificaciones

- GangwayDocumento26 páginasGangwayegyinspectoryahoo100% (2)

- Masts/Derricks/Substructures: Api RP 4GDocumento12 páginasMasts/Derricks/Substructures: Api RP 4GegyinspectoryahooAún no hay calificaciones

- Hand Operated Chain Lever HoistsDocumento2 páginasHand Operated Chain Lever HoistsegyinspectoryahooAún no hay calificaciones

- LEEA-059-5 Documentation and Marking - Part 5 Lifting Accessories, Slings PDFDocumento13 páginasLEEA-059-5 Documentation and Marking - Part 5 Lifting Accessories, Slings PDFJason RobertsAún no hay calificaciones

- Position Paper Of: Fédération Européenne de La Manutention Product GroupDocumento3 páginasPosition Paper Of: Fédération Européenne de La Manutention Product GroupegyinspectoryahooAún no hay calificaciones

- Instructions For The Safe Use Of: EyeboltsDocumento2 páginasInstructions For The Safe Use Of: Eyeboltsdsn_sarmaAún no hay calificaciones

- List of FEM Documents 2012 PDFDocumento5 páginasList of FEM Documents 2012 PDFluigimarlone100% (1)

- Wits 2010Documento3 páginasWits 2010egyinspectoryahooAún no hay calificaciones

- Examination SchemesDocumento2 páginasExamination SchemesegyinspectoryahooAún no hay calificaciones

- N460-WITS Fact Sheet 2012 FEM Corr2Documento3 páginasN460-WITS Fact Sheet 2012 FEM Corr2egyinspectoryahooAún no hay calificaciones

- FEM Facts Europe 2010Documento1 páginaFEM Facts Europe 2010egyinspectoryahooAún no hay calificaciones

- Seatrax Hydraulic OptionsDocumento2 páginasSeatrax Hydraulic OptionsegyinspectoryahooAún no hay calificaciones

- N 0284 FEM Postionpaper Lifting Person Final 2011-05-04Documento2 páginasN 0284 FEM Postionpaper Lifting Person Final 2011-05-04egyinspectoryahooAún no hay calificaciones

- FEM Facts Europe 2007Documento1 páginaFEM Facts Europe 2007egyinspectoryahooAún no hay calificaciones

- FEM Facts Europe 2006Documento1 páginaFEM Facts Europe 2006egyinspectoryahooAún no hay calificaciones

- FEM Facts Europe 2009Documento1 páginaFEM Facts Europe 2009egyinspectoryahooAún no hay calificaciones

- FEM Overload Testing of Mobile Cranes PDFDocumento2 páginasFEM Overload Testing of Mobile Cranes PDFegyinspectoryahooAún no hay calificaciones

- FEM Facts Europe 2005Documento1 páginaFEM Facts Europe 2005egyinspectoryahooAún no hay calificaciones

- Main Return Line Filter PackageDocumento1 páginaMain Return Line Filter PackageegyinspectoryahooAún no hay calificaciones

- Closed Vs Open Loop SafetyDocumento5 páginasClosed Vs Open Loop SafetyRyanAún no hay calificaciones

- Operation: Follower Boat DeckDocumento1 páginaOperation: Follower Boat DeckegyinspectoryahooAún no hay calificaciones

- Study GuideMobile CraneDocumento30 páginasStudy GuideMobile CraneegyinspectoryahooAún no hay calificaciones

- Swifty Loudspeaker KitDocumento5 páginasSwifty Loudspeaker KitTNAún no hay calificaciones

- Course Add Drop Form For Ug Course 1718T2 PDFDocumento1 páginaCourse Add Drop Form For Ug Course 1718T2 PDFArtyomAún no hay calificaciones

- PresentationDocumento67 páginasPresentationNagarjuna Reddy MAún no hay calificaciones

- Eaturing: To Smaller Recording Performance Speakers: - The GuideDocumento76 páginasEaturing: To Smaller Recording Performance Speakers: - The GuideMatthew WalkerAún no hay calificaciones

- For Calibration List - OrginalDocumento62 páginasFor Calibration List - Orginaluttam khatriAún no hay calificaciones

- Environmental Education Through Art PDFDocumento27 páginasEnvironmental Education Through Art PDFCeci_SunshineAún no hay calificaciones

- Mohit Soni ReportDocumento104 páginasMohit Soni ReportMohitAún no hay calificaciones

- Technical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Documento4 páginasTechnical Service Bulletin 6.7L - Illuminated Mil With Dtcs P1291, P1292, P0191 And/Or P06A6 - Engine Harness Chafe 19-2231Yaniss AlgeriaAún no hay calificaciones

- Draw 224-1Documento8 páginasDraw 224-1Alther Dabon33% (3)

- American Woodworker 163 2012-2013 PDFDocumento76 páginasAmerican Woodworker 163 2012-2013 PDFkaskdos100% (1)

- Aiwa RM-77 Service ManualDocumento9 páginasAiwa RM-77 Service Manualcristianhumberto_reyesaguileraAún no hay calificaciones

- Fee ChallanDocumento1 páginaFee ChallanMuhammad UsmanAún no hay calificaciones

- BS en 00480-6-2005 PDFDocumento8 páginasBS en 00480-6-2005 PDFShan Sandaruwan AbeywardeneAún no hay calificaciones

- Vacuum Gauges 45Documento20 páginasVacuum Gauges 45Sameeksha AnandAún no hay calificaciones

- Hatch Cover Maintenance PlanDocumento5 páginasHatch Cover Maintenance Planvinay3972Aún no hay calificaciones

- Gardenia RedddDocumento44 páginasGardenia RedddYasmin Yvonne De Chavez100% (1)

- Tech Datasheet AXTT 2VDocumento2 páginasTech Datasheet AXTT 2VALEX MATHEUS DA SILVA FERRAZAún no hay calificaciones

- Analysis and Design of Bridge Substructures PDFDocumento195 páginasAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)

- Chapter 5e ch05 HallDocumento9 páginasChapter 5e ch05 HallGlorden Mae Ibañez SalandananAún no hay calificaciones

- Contamination ControlDocumento5 páginasContamination ControlPadmanabhan DhanasekaranAún no hay calificaciones

- 7.sieve Analysis AhmedDocumento9 páginas7.sieve Analysis AhmedJin AhmedAún no hay calificaciones

- Cembrit Patina Design Line - LowresDocumento11 páginasCembrit Patina Design Line - LowresRaul AntonieAún no hay calificaciones

- Lab 1: Basic Cisco Device Configuration: Topology DiagramDocumento17 páginasLab 1: Basic Cisco Device Configuration: Topology DiagramnhiAún no hay calificaciones

- Fingerstyle Guitar - Fingerpicking Patterns and ExercisesDocumento42 páginasFingerstyle Guitar - Fingerpicking Patterns and ExercisesSeminario Lipa100% (6)

- Honda Fit Timing ChainDocumento14 páginasHonda Fit Timing ChainJorge Rodríguez75% (4)

- Realizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsDocumento7 páginasRealizing Higher Productivity by Implementing Air Drilling Tech For Drilling Hard Top Hole Sections in Vindhyan FieldsLok Bahadur RanaAún no hay calificaciones

- TCE BE EEE RulesandRegulationsDocumento509 páginasTCE BE EEE RulesandRegulationsAplieAún no hay calificaciones

- Invisible EyeDocumento16 páginasInvisible EyeSushmita Paul0% (1)

- IJV MARLEY AutomotiveDocumento6 páginasIJV MARLEY AutomotiveUmer HamidAún no hay calificaciones

- 1 1 6 Blood Splatter Analysis Experimental DesignDocumento4 páginas1 1 6 Blood Splatter Analysis Experimental Designapi-343751193100% (1)