Documentos de Académico

Documentos de Profesional

Documentos de Cultura

2012 Warman PDF

Cargado por

Mary1014Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

2012 Warman PDF

Cargado por

Mary1014Copyright:

Formatos disponibles

-1-

25th WARMAN DESIGN & BUILD COMPETITION 2012

Weir Minerals and Engineers Australia

Project SILVER: Strategically Innovate for Lateral and Vertical Effected Replenishment

THE CONTEXT: A strategically important Gondwanan observation facility in a hostile environment is to employ a series of tethered balloons. These balloons will require regular but autonomous resupply which needs to be performed accurately and quickly from a remote and protected staging position. Tenders are being called for systems to effect the replenishment using the balloon tether as the connecting pathway from the surface. The Gondwanans have aptly described the project as SILVER. For them it has a high value and a high priority for resolution. THE CHALLENGE: The challenge is to design a prototype system to move the replenishment sphere (payload) from a store to the intended height datum on the balloon tether. Fortunately, teams of engineering students from Earth are about to visit Gondwana as part of their work experience programmes. On 24 previous visits such engineering students have rendered invaluable assistance with solutions to similar engineering problems, and the Gondwanans again are hoping to benefit from the ideas of the innovative budding engineers. To celebrate the assistance from Earth, a special SILVER Anniversary event is planned to coincide with the conclusion of the tender process. Objective The objective is to design, build and prove a prototype system in a laboratory environment that serves to deliver autonomously a supply package to a balloon based observation facility, using the balloon tether to deliver the supply package? In context, can you design the best system to Strategically Innovate for Laterally and Vertically Effected Replenishment? Can you assist in Project SILVER? National Organiser Dr Warren Smith Details follow: Competition Guidelines Competition Rules Frequently Asked Questions Further Competition Details Spirit of the Competition w.smith@adfa.edu.au Phone: 02 6268 8262

Document Control Version 1.0 13/12/2011

Version 1.0

13 December, 2011

-2-

Competition Guidelines

(Version 1 Released: 13/12/2011) ELIGIBILITY G 1. Teams of notionally four first or second-year, nominally mechanical-engineering students, in Australian or New Zealand universities (or other universities by arrangement), may enter the competition. Teams of three or four are strongly recommended. NOTE: It is recognised that some campuses are using the Warman as a 1st Year project and that team sizes may be necessarily forced for logistic reasons to be larger than 4. Both year and size variations are acceptable. SAFETY G 2. Safety is of paramount importance when participating in this competition. All engineers should know that injury and damage to equipment and the environment occurs when the control of energy in a system is lost. G 3. As appropriate, protective clothing, footwear, safety glasses or full face masks should be worn by students working on systems during construction, during testing, and during competitions. G 4. Students are encouraged to carry out a risk assessment for their system prior to campus testing. Students are encouraged to embrace risk management in their own activities and may need to demonstrate safe operation and produce risk assessment documentation in order to compete in either the campus heat or at the National Final. G 5. Compressed gas systems may be used but students must gain local coordinator approval based on a safety assessment. Such systems presented at the National Final will be examined against the following principles and must be acceptable to the National Coordinator. - Home fabricated pressure system components are not to be used unless the pressure is considered to be low. - Commercial components should be used (unions, vessels, cylinders, lines) unless the pressure is low. - Up to 550 kPa (approx 80 psi) may be considered low pressure if such pressure is held inside a plastic drink bottle pressurised by a bike pump. Such a system must be well constrained to prevent projectiles exiting in the event of a failure. For example, an outer, non-pressurised shield shall be included over plastic bottle pressure vessels, to take any sting out of a rupture. - Evidence of proof testing of compressed gas systems shall be provided.

Version 1.0

13 December, 2011

-3-

COMPETITION TRACK, EQUIPMENT AND ENVIRONMENT G 6. The competition track shall be fabricated using primarily two sheets of Medium Density Fibreboard (MDF), each with nominal dimensions 2400 x 1200 x 18 mm, arranged end to end as shown in Figure 1 and Figure 2. The supporting frame for these sheets may be fabricated by any convenient method. NOTE: The MDF sheets as supplied in the ACT are slightly larger than the nominal 2400 x 1200 dimensions. They are 2420 x 1210. They do not need to be cut down. The 12 x 12 DAR fences (see rule G17) on the board extremities are flush with the edge of the as supplied boards. G 7. The two MDF sheets and relevant attached features are identified respectively as track segments 1 and 2 and collectively as the competition track. G 8. The tops of the two primary MDF sheets shall collectively define the competition base plane which is nominally horizontal. The heights of the track segments shall be adjusted so that there is no step between the two track segments. G 9. The competition base plane shall be no less than 200 mm above the supporting floor at the National Final. G 10. Track segment 1 contains the start zone at one end which is representative of a hangar or shed. It presents a rectangular doorway from the start zone modelled by a timber arch. The external surface of the arch is aligned coincident with the centreline of the sheet. An indicative low wall of the start zone will be formed with 90x35 pine timber as shown. G 11. Track segment 2 joins with track segment 1 and at its free end; the balloon tether is arranged vertically, suspended from a gantry or other available structure. G 12. The arrangement for supporting the tether is to provide a rigid support and must not restrict a volume above the base plane of the track defined by a height of 2000 mm and a track side offset of 200. G 13. The tether comprised of 8mm braided polypropylene sash cord will pass through the track base plane and be constrained by the underside of the sheet with a knot in its end. The tether will rise vertically and lead over a pulley system. From the free end of the tether a 4kg mass will be suspended to provide tension. G 14. At a height of 1800 mm above the base plane of the track, the tether will pass through a stop approximately 50mm outside diameter formed from 2 inch OD tube. This stop marks the end of the intended ascent. G 15. An indicative tether support system is shown in Figures 1 and 2. Bracing between the tether support system and the track is recommended but any such bracing is to be well below the base plane of the track. G 16. A 20 litre bucket as depicted in Figure 3 will be modified by removal of the handle and by cutting a hole of 76 mm (3 inch) diameter in the centre of its base. The

Version 1.0

13 December, 2011

-4-

bucket will be constrained by three fixed blocks of 100x90x35 pine timber as shown in Figures 1 and 2 such that the tether passes through the hole in the bucket and is coincident with the axis of the bucket. NOTE: The bucket, available from Bunnings, is a 20 litre heavy duty bucket with handle (black or white) and is identified by a Fine Line Reference Number: 4460449. A sample was purchased in Canberra for $4.50.

FIGURE 1 ISOMETRIC VIEW OF THE PROJECT SILVER COMPETITION TRACK

Version 1.0

13 December, 2011

-5-

FIGURE 2 - PROJECT SILVER COMPETITION TRACK

Version 1.0

13 December, 2011

-6-

FIGURE 3 - PROJECT SILVER BUCKET

G 17. A low wall formed with 90x35 pine timber is positioned transversely at the end of track segment 1 adjacent to the join with track segment 2. It spans half the track G 18. Adjacent to the start zone but outside it as shown in Figures 1 and 2, the longitudinal edges of track segment 1 shall be fenced with 12 x 12 DAR (Dressed All Round) timber strips mounted on the top (track base plane) with their outside edges flush with the sheet edges. The strips will be mounted by countersunk screws (100 mm spacing) on the top surface of the sheets. NOTE: The 12 x 12 DAR fences should be considered as guides rather than barriers built to resist high collision loads. Damaging the fences is considered to be damaging the competition site and will cause a zero run score to be recorded. G 19. All exposed surfaces of the MDF and timber will be brush coated with one coat of Wattyl Water Based Estapol Clear Satin followed by two coats of Wattyl Estapol Matt. G 20. The payload used for the competition will be a regulation 12 inch softball ball.

Version 1.0

13 December, 2011

-7-

NOTE: As defined in the Official Rules of Softball, the completed 30.5cm (12 in) ball shall be between 30.2cm (11 7/8 in) and 30.8cm (12 1/8 in) in circumference, and shall weigh between 178.0g (6 1/4 ounces) and 198.4g (7 ounces). G 21. A Fix-a-Tap sink strainer and table tennis ball will also be integrated with the system and employed as a motion sensor. NOTE: The sink strainer is available in a range of hardware and plumbing supply stores including Bunning.. A sample was purchased in Canberra for $2.00.

FIGURE 4 - PROJECT SILVER SINK STRAINER

G 22. Teams must accept that the presence of bright lighting and photography including flash and infrared systems are part of the competition environment.

Version 1.0

13 December, 2011

-8-

PROTOTYPE SYSTEM G 23. Participating teams shall present a prototype system that serves to transfer a payload on the defined track in accordance with the rules. G 24. The payload, initially located with Subsystem A, is intended to be transferred to another subsystem, Subsystem B, which will then raise the top of the payload to a height of 1800mm above the base plane of the track and hold it indefinitely in that position. G 25. Subsystem A will be initially staged in the start zone and be fully supported by the base plane of the track. G 26. Subsystem B will be initially staged within the bucket and attached to the tether. G 27. Systems that are deemed by the officials and judges to be hazardous will not be permitted to run. Employing any form of combustion is considered hazardous. G 28. Systems that are deemed by the officials and judges to damage or have the capacity to damage the track or its features will not be permitted to run or will be disqualified. G 29. Campus organisers are free to modify the rules and or competition track for their local competition but the guidelines and rules as stated shall be strictly adhered to at the National Final. RULE WORDING G 30. The language of the rules is tiered. Those clauses expressed as SHALL are mandatory and failure to comply will attract penalties which in the extreme could lead to disqualification. Those expressed as SHOULD or MAY reflect some level of discretion and choice.

Version 1.0

13 December, 2011

-9-

Competition Rules

MATERIALS AND MANUFACTURE R 1. Students SHALL manufacture and fabricate their prototype system themselves using commonly available materials, components and methods. NOTE: At the National Final Campus Organisers may be required to confirm that the systems presented have been appropriately manufactured in keeping with the spirit of the competition. R 2. Teams SHALL present a system comprising two Subsystems, A and B.

R 3. One Subsystem at least SHALL be purely mechanical (using no chemical energy (including batteries) and having no functioning electrical or electronic components). The other Subsystem MAY utilise electrical or electronic power and circuitry. PROCEDURE R 4. The mass of the teams system will be measured by an official. The system gross mass SHALL NOT be greater than 8 kilograms. R 5. Contact SHALL NOT be made by team members or their system with the competition track before official setup commences. R 6. The team will be called to the track side and, when ready, an official will signal that the initial setup time has commenced. The team SHALL be allowed a maximum of 120 seconds for initial setup. In this time they are to set up their system (both Subsystem A and Subsystem B). R 7. Contact SHALL only be made by team members or their system with the competition track areas at either end of the track during setup, within the start zone and in close proximity to the bucket and tether. R 8. The tether SHALL NOT be unthreaded in order to attach Subsystem B. However, the pre-tensioning mass MAY be removed and the tether slackened and moved from the vertical if desired. The bucket MAY also be moved. R 9. During setup the team MAY use, for the purposes of setup, additional objects not considered part of the system. R 10. During setup the team SHALL if moved, restore the pre-tensioning mass and bucket. R 11. The team SHALL indicate to the appropriate official when their setup is complete.

Version 1.0

13 December, 2011

- 10 -

R 12. After initial setup and prior to running, everything placed and left on the competition track SHALL be considered to be part of the system. R 13. After initial setup, the system will be subject to volume constraints. For a valid run, Subsystem A SHALL be wholly contained within the start zone as defined by the internal faces of the arch and wall and the track edges. Subsystem B SHALL be wholly contained within the bucket and SHALL NOT project above the bucket rim. The placement and volume conditions will be physically checked by an official. R 14. The payload SHALL then be presented to the team for placement on or in Subsystem A. The payload SHALL NOT be modified in any way and should be clearly visible in order to measure its position as necessary. R 15. A sink strainer and table tennis ball SHALL then also be presented to the team for placement on Subsystem B. Its function is as a motion smoothness sensor. The strainer SHALL be configured with the concavity upward and the table tennis ball SHALL sit in the concavity. The strainer and table tennis ball SHALL NOT be modified in any way and the strainer SHALL only be supported from below. The strainer SHALL NOT be fixed in any way to Subsystem B and no part of Device B SHALL be above the top edge of the strainer. R 16. At this time, the strainer and the table tennis ball MAY project above the rim of the bucket but they SHALL NOT project beyond the internal circumference of the bucket rim. R 17. The free movement of the table tennis ball SHALL NOT be restricted in anyway and there SHALL be clear space horizontally around and above the full circumference of the strainer greater than the diameter of the table tennis ball. R 18. Subsystem B SHALL NOT incorporate any device that is capable of returning the table tennis ball to the strainer should the ball leave the strainer. R 19. The team SHALL be allowed a maximum of 60 seconds for final setup (addition of payload, strainer and table tennis ball). R 20. After final setup and prior to running, the system SHALL be both stationary and satisfy the volume conditions which will again be physically checked by an official. R 21. After set up and prior to running, the system SHALL NOT be held or supported or contacted by anything other than the competition base plane and bucket and tether and it must be ready to start. This prohibits team members from restraining by personal contact a ready-to-release system. Systems should be capable of remaining in the set up condition indefinitely. R 22. On instruction and by a signal from the official starter, the run will commence. A valid run SHALL finish with a run time less than 120 seconds. This will be judged by an official.

Version 1.0

13 December, 2011

- 11 -

R 23. Subsystem A SHALL be started using a single action that does not impart motion or energy to the system. A single-action start may employ a simple instrument not considered part of the system, e.g. using a pair of scissors. R 24. With two exceptions (see following rules), after performing the single-action start, team members SHALL NOT control or touch the system in any way during the run. Wireless control is specifically prohibited. If team members choose to intervene to protect a system that is malfunctioning, a zero score for the run shall be recorded. R 25. The first exception is that if Subsystem A fails to interact autonomously and successfully with Subsystem B, teams will be given a second payload and SHALL trigger Subsystem B by mimicking the intended transfer method manually. If such an intervention is executed, the score recorded will be discounted in accordance with the rules. R 26. The second exception is that if in manually transferring the payload Subsystem B is not triggered, teams SHALL manually trigger Subsystem B by mimicking the intended trigger method. If such an intervention is executed, the score recorded will be discounted in accordance with the rules. R 27. During the run the system SHALL NOT come into contact with anything below the competition base plane or any structures outside the defined clear volume surrounding the track. R 28. During the run, Subsystem A SHALL only operate through the doorway of the start zone. The start zone is to be considered to represent an enclosed hangar or shed. R 29. During the run, the payload SHALL be transferred from Subsystem A to Subsystem B. R 30. Subsystem B SHALL NOT begin movement until it is in possession of the payload. R 31. Subsystem B MAY contact the stop but SHALL NOT grasp it or its supporting structure. R 32. During a valid run, the payload and the table tennis ball SHALL track such that they experience the same motions. The payload and strainer supports SHALL be rigidly connected to mimic linear and rotational accelerations, velocities and displacements. R 33. At the completion of the run and for the run to be valid, all of Subsystem B and the payload SHALL NOT be within or in contact with the bucket. R 34. At the completion of the run and for the run to be valid, Subsystem B and the payload SHALL be fully supported by the tether. R 35. At the completion of the run, if the table tennis ball is not in the strainer or the strainer is not supported in its original position relative to the Subsystem B, the score recorded SHALL be discounted in accordance with the rules.

Version 1.0

13 December, 2011

- 12 -

R 36. At the completion of the run, the overall system SHALL cease both translation on the competition track and gross motion above the competition base plane and remain in this state indefinitely relative to the competition track. Mechanisms and items in the system may continue to move but no further functions can be executed. R 37. The team will indicate to the timekeepers when they declare their run to be complete. However, the time keepers SHALL make the final judgment as to when the system ceases translation, rotation and all functions have ceased. The recorded time may exceed the teams declaration. R 38. The recorded run time MAY be an aggregate of two times if a manual intermediate operation is necessary. Any secondary manual action SHALL be controlled and directed by an official. R 39. The recorded height to the top of the payload SHALL be measured by an official. The payload is to be appropriately visible to make this measurement. R 40. To ensure that judging has been completed teams SHALL NOT retrieve their system or assist in gathering other items until directed by an official. R 41. Subsystem B SHALL be retrieved by removing the pre-tensioning mass providing slackness in the tether, not by standing on the track or by climbing ladders etc. R 42. Systems SHALL NOT damage or contaminate the competition track. Teams presenting systems that damage the track may be disqualified from the competition. EXPLANATORY NOTE: A component of the system left simply on the competition track does not constitute contamination. An example of contamination would be a sticky residue requiring significant effort to remove it, with the possibility of permanent change occurring to the surface finish. R 43. As directed, teams MAY attempt two runs. R 44. The system MAY be modified between runs but the mass, volume and time constraints must be satisfied for a run to achieve a valid non-zero run score. R 45. Violations of procedural rules SHALL result in a zero run score being recorded. R 46. The judges decisions on all matters pertaining to the competition SHALL be final.

Version 1.0

13 December, 2011

- 13 -

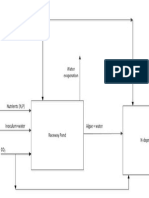

SCORING R 47. Better systems will achieve the objectives of transporting the payload with higher effectiveness whilst adhering to the timing, volume and positioning constraints. A valid run score SHALL be calculated using the following formula and is based on the end state of the payload. The maximum run score is 100. A run and scoring flowchart is shown in Figure 5.

VALID RUN SCORE = DIST 50 TRANS + 1 ACONTROL 400 DEL 1 50 SMOOTH TRIG 1 BCONTROL 150

Calculated to one decimal place, where at the end of the run: ACONTROL = 1 if payload controlled by system at all times up to and including TRANSfer 0 otherwise BCONTROL = 1 if payload controlled by system at all times after TRANSfer 0 otherwise DEL = Distance of payload in cm from vertical datum (max 150)

SMOOTH = 1 if table tennis ball on strainer with Subsystem B 0.7 otherwise TRIG = 1 if Subsystem B autonomously triggered 0.8 otherwise TRANS = 1 if payload autonomously transferred between subsystems 0.98 otherwise TT = Time in seconds for complete run evolution

Recorded if TRANSfer or TRIGgering not autonomous DIST = Distance of payload in cm from bucket rim (max 400) = 0 if payload autonomously transferred between subsystems TA TB TT = Time in seconds for Phase 1 = Time in seconds for Phase 2 = TA+TB

Version 1.0

13 December, 2011

- 14 -

FIGURE 5 - PROJECT SILVER RUN AND SCORING FLOWCHART

R 48. DEL SHALL be measured vertically between the top of the payload and the bottom face of the stop on the tether in cm or part thereof. R 49. DIST SHALL be measured obliquely as the shortest distance between the payload and the rim of the bucket in cm or part thereof. R 50. SMOOTH SHALL be determined by the final position of the table tennis ball. R 51. TT MAY be recorded directly or calculated as an addition of TA and TB R 52. TA SHALL be measured as the time for Subsystem A to cease both translation on the competition track and gross motion above the competition base plane and remain in this state indefinitely relative to the competition track. Mechanisms and items in the subsystem may continue to move but no further functions can be executed. R 53. TB SHALL be measured as the time for Subsystem B to cease both translation on the competition track and gross motion above the competition base plane and remain in this state indefinitely relative to the competition track. Mechanisms and items in the subsystem may continue to move but no further functions can be executed.

Version 1.0

13 December, 2011

- 15 -

R 54. The Warman Competition Score SHALL be the higher score achieved from either run plus half of the score achieved from the other run and the highest Warman Competition Score will be declared the winner. R 55. If equal Warman Competition Scores are recorded by teams, teams tied SHALL be ranked based on the RUNTIME of their highest scoring run. R 56. If the RUNTIMEs of the top ranked teams are within 10 seconds of the fastest, the teams so bracketed SHALL participate in a sudden death run-off to determine the overall places. R 57. In the event of a run-off, each team will make one run. If an equal score is again recorded, each team will make another run. If after a third such run, the score is still equal; the team with the shortest run time in the third run-off run SHALL be declared the winner.

Version 1.0

13 December, 2011

- 16 -

Frequently Asked Questions

(Version 1 Released: 13/12/2011)

1. Does the system have to stay in contact with the competition track at all times? No but the rules do define what can be legally contacted. 2. Can part of a system be discarded off the track without penalty?

No, this would violate the rules and lead to a zero run score. 3. At the end of a run, could a system be supported on the competition track and have a part over the outside edges of the track in plan form projection and not receive a penalty? Yes, you could have a part in space with no competition track component under it as long as nothing other than legal surfaces of the track are contacted by the system. 4. When is a system deemed to be stationary at the completion of the run? The stop instant will be interpreted as the later of when all the contact points between the system and the competition site come to rest and when the functions being performed are observed to have ceased. It must be clear that the system could remain in the end state indefinitely. Some wobbling in the structure is acceptable but gross rotations are not. 5. Autonomous does this mean that the system on the track can not receive input or instructions from a Subsystem off the track (such as a computer)? Or does it mean that the system on the track can receive input from a Subsystem off the track (such as a computer) but that Subsystem (computer) can not be manipulated by a team member during the run? An example of the second would be if the system was controlled by motors that ran to a pre-programmed route transmitted from the computer. Autonomous in this competition implies every control system for the system is to be part of the system on the track and fit within the start volumes. No remote-to-the-track control systems of any sort can be used (manual or pre-programmed, hard wired or wireless). Such configurations would be considered to be part of the system and violate position and volume constraints. 6. Are programmable chips allowed? Yes, you can use a programmable chip, but there is to be no remote communication during the run. 7. What is the allowable voltage and power of any employed electrical systems? There are no restrictions this year but it clearly needs to be safe.

Version 1.0

13 December, 2011

- 17 -

8.

The system mass, SYSMASS, does not influence the scoring. Why is it included?

It is included to validate the maximum mass defined. Failure to comply with the stated maximum mass will result in disqualification. A large mass fundamentally indicates inefficient design. Further, designs needing to be transported to the National Final need to be light and small enough to be accommodated by air travel. 9. Can off-the-shelf items be used? Commonly available components such as toy and machine parts are able to be used. The spirit of the competition is that students manufacture and fabricate their system themselves, meaning that professionals are not engaged to do it for them. It is possible for some assistance to be obtained (eg for a weld) but this should be minimal or where possible be done by the students themselves. The production of major components should not be outsourced.

Version 1.0

13 December, 2011

- 18 -

Further Competition Details

(Version 1 Released: 13/12/2011) NATIONAL FINAL It is planned that the Weir-Warman National Final will be held Friday 28 - Sunday 30 September 2012 in Sydney at a location to be determined. Prizes for Campus Winners and National Podium Places will be awarded at the National Final. A National Final Judges Prize and Design Prize may also be awarded. The planned format will have students gathering on Friday morning in Sydney. A tour of Weir Minerals Ltd will follow. Scrutineering and additional judging will be conducted on Saturday and there will be briefings, presentations and practice sessions held on Saturday. The actual running of the Final and the National Final Dinner will be on Sunday. A team registration form will be available please submit it to Engineers Australia (EA) as early as possible. Travel arrangements are coordinated by EA. Team details are required early August (unless otherwise advised). Teams registering and accepting the invitation and sponsorship to participate at the Final also accept that their names and photographs and video of them can be used for publicity purposes by both EA and Weir Minerals. All team members and attending campus organisers will be required to sign an appropriate authority in relation to this use. In meeting costs, the competition sponsorship funds two students per team. Depending on EA funding, it is hoped that Campus organisers will also be funded. Campuses will be billed for additional students and for people who do not travel but for whom arrangements are made.

Version 1.0

13 December, 2011

- 19 -

Spirit of the Competition

Although the rules may look rigid you will find that they have been written in a way which allows, and in fact encourages, creative and innovative solutions. This is not always the case in real-world engineering projects. In this project and competition, the rules are there because we have tried to be very clear on points which will be important when student groups come together for the National Final. For this reason, it is essential to work with your campus organiser from an early stage, and for the campus organiser to verify decisions with the National Organiser so that everyone has the same understanding of the meaning of the rules. If you think you see a loophole, clear it with your campus organiser before you rely on it in competition. Even if it is accepted at the local level, you might be in for a shock at the national level where the interpretation might be different. Provision will be made for confidentiality, so your idea will not be passed on to other students. It is highly recommended that all students communicate with their campus organiser and that if a ruling is required by the National Organiser; this is sought by the campus organiser. Students SHOULD NOT contact the National Organiser directly for an individual ruling. The competition track will be made with reasonable care but because it is a real engineering object it may well be wrong in various small ways. For example the surface might have a slight longitudinal slope. Your team is expected to consider these possibilities in your design, and develop a system that can function even if the competition track has slight imperfections. In other words, you are not allowed to blame failure of your system on some minor imperfection with the competition track.

A FINAL COMMENT ON SAFETY Please be aware that in 2003 during a campus competition, a student was lucky to escape serious eye injury when a Subsystem went off unexpectedly. While Campus organisers run their own competitions independently, they are strongly encouraged to consider all aspects of safety in relation to the conduct of their competition.

Version 1.0

13 December, 2011

También podría gustarte

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsCalificación: 4 de 5 estrellas4/5 (1)

- 2016 Warman CompetitionDocumento19 páginas2016 Warman CompetitionAndrew WalleyAún no hay calificaciones

- Warman 14 v1 - 0 - FinalDocumento16 páginasWarman 14 v1 - 0 - FinalWingSiangEdwardNgAún no hay calificaciones

- 38mm Flooring: Physical PropertiesDocumento2 páginas38mm Flooring: Physical PropertiesalpogaltreeAún no hay calificaciones

- PG&E Signal Util Connection ReqDocumento14 páginasPG&E Signal Util Connection ReqDonald R Shupp100% (1)

- Kingzip Installation GuideDocumento44 páginasKingzip Installation GuideBuster73108Aún no hay calificaciones

- ADS Corrugated Polyethylene PipeDocumento4 páginasADS Corrugated Polyethylene PipeAzhar PashaAún no hay calificaciones

- Muro - For The Simultaneous Casting of Foundation Beams and The SlabDocumento10 páginasMuro - For The Simultaneous Casting of Foundation Beams and The SlabDaliform GroupAún no hay calificaciones

- Shear Transfer at Engineered Wood FloorsDocumento12 páginasShear Transfer at Engineered Wood FloorsIonFlorentaAún no hay calificaciones

- 063929Documento8 páginas063929hanuAún no hay calificaciones

- Refining Standards & Specifications Communication SP-42-18.2 Accessories For Atmospheric Storage TanksDocumento3 páginasRefining Standards & Specifications Communication SP-42-18.2 Accessories For Atmospheric Storage Tanksviller_lpAún no hay calificaciones

- General Installation Smart DitchDocumento8 páginasGeneral Installation Smart Ditchanon_49687612Aún no hay calificaciones

- Designing A Cable TrayDocumento20 páginasDesigning A Cable TrayTimothy LeonardAún no hay calificaciones

- UntitledyDocumento15 páginasUntitledySàávâñ VàśànthàñAún no hay calificaciones

- ADS 11H Completion Program REV-0Documento32 páginasADS 11H Completion Program REV-0Emmanuel IfedioraAún no hay calificaciones

- Hollow Core Planks Application and Design GuideDocumento46 páginasHollow Core Planks Application and Design Guidemixi1978100% (1)

- Goodman Ductos - Inst OperaciónDocumento8 páginasGoodman Ductos - Inst OperaciónlafsAún no hay calificaciones

- Underground Fuel TanksDocumento24 páginasUnderground Fuel TanksAlupole_AlbertLim100% (1)

- Is - 11855 - Guidelines For Design and Use of Different Types of Rubber Seals For Hydraulic GatesDocumento8 páginasIs - 11855 - Guidelines For Design and Use of Different Types of Rubber Seals For Hydraulic Gateskiranrauniyar100% (1)

- Brochure Railroad N-12 (08-10) PDFDocumento8 páginasBrochure Railroad N-12 (08-10) PDFEnrique Rodulfo GómezAún no hay calificaciones

- Notes For Spreedsheet Calculator SoftwareDocumento8 páginasNotes For Spreedsheet Calculator SoftwareniginpAún no hay calificaciones

- Exothermic Welding System: in This SectionDocumento66 páginasExothermic Welding System: in This Sectionالمهندس مصطفى عبد المجيدAún no hay calificaciones

- Installation - Titan Power Plus-SU2 - Free Standing and Tilt (v2)Documento19 páginasInstallation - Titan Power Plus-SU2 - Free Standing and Tilt (v2)SunMaxx SolarAún no hay calificaciones

- Muro Wall FormworkDocumento10 páginasMuro Wall FormworkDaliform GroupAún no hay calificaciones

- TT 102Documento5 páginasTT 102Osvaldo Marques100% (1)

- Jandy Laminar Jet: Installation and Operation ManualDocumento16 páginasJandy Laminar Jet: Installation and Operation ManualMike Alex Herrera DomínguezAún no hay calificaciones

- Controllogix Chassis-Series B: Installation InstructionsDocumento16 páginasControllogix Chassis-Series B: Installation InstructionsneoflashAún no hay calificaciones

- Jordahl Jva enDocumento48 páginasJordahl Jva engasparAún no hay calificaciones

- GPLamDocumento24 páginasGPLammurdicksAún no hay calificaciones

- Section 233116Documento4 páginasSection 233116Ahmed NabilAún no hay calificaciones

- Riser Flowlines Fpso PartDocumento0 páginasRiser Flowlines Fpso PartspacevibesAún no hay calificaciones

- PERI ACS Method StatementDocumento10 páginasPERI ACS Method StatementvijkingAún no hay calificaciones

- Rope Winches and GearboxesDocumento20 páginasRope Winches and Gearboxesiturcic9100% (1)

- Installation Instructions Hustler 4-Btv, 5-Btv Trap VerticalDocumento14 páginasInstallation Instructions Hustler 4-Btv, 5-Btv Trap VerticalAl SmithermanAún no hay calificaciones

- CG enDocumento24 páginasCG enFederico.IoriAún no hay calificaciones

- DIVISION 2 - Asignment Technical SpecificationsDocumento4 páginasDIVISION 2 - Asignment Technical SpecificationsPatrisha SantosAún no hay calificaciones

- DIVISION 2 - Asignment Technical SpecificationsDocumento4 páginasDIVISION 2 - Asignment Technical SpecificationsPatrisha SantosAún no hay calificaciones

- Installation Guide: Unitray Systems IncDocumento34 páginasInstallation Guide: Unitray Systems IncboltgingerkoppyAún no hay calificaciones

- Cable Tray Load Factor and Spec PDFDocumento7 páginasCable Tray Load Factor and Spec PDFÖmer EmelAún no hay calificaciones

- POLEAS en V - Classical - DrivesDocumento100 páginasPOLEAS en V - Classical - DrivesAriel Linder Ureña MontenegroAún no hay calificaciones

- Grate-Lock Grating: Solid Deck Planking & LAMBDA-LOK™Documento20 páginasGrate-Lock Grating: Solid Deck Planking & LAMBDA-LOK™asifaliabidAún no hay calificaciones

- Standard Slab BridgeDocumento8 páginasStandard Slab BridgeaminjolesAún no hay calificaciones

- Water Motor Alarm F2Documento4 páginasWater Motor Alarm F2Pepes HiuuAún no hay calificaciones

- Installation Instructions Hustler 4-Btv, 5-Btv Trap VerticalDocumento14 páginasInstallation Instructions Hustler 4-Btv, 5-Btv Trap VerticalpartgioAún no hay calificaciones

- BURIED PIPING ANALYSIS - Al Kaye ppdfb07 PDFDocumento58 páginasBURIED PIPING ANALYSIS - Al Kaye ppdfb07 PDFi_tiberius_m8153100% (1)

- Submersible PumpDocumento15 páginasSubmersible Pumpnwright_besterAún no hay calificaciones

- UIG AWWA D103 09std Glass Fused To Steel Bolted Tank Specifications Section 13210 2019r2Documento14 páginasUIG AWWA D103 09std Glass Fused To Steel Bolted Tank Specifications Section 13210 2019r2karunaAún no hay calificaciones

- Pintu KlepDocumento12 páginasPintu KlepAndri KwinAún no hay calificaciones

- Snap-Fit Design ManualDocumento24 páginasSnap-Fit Design ManualrenebbAún no hay calificaciones

- Perform With Precision: Box Culvert TravelerDocumento14 páginasPerform With Precision: Box Culvert Traveler魏雨辰Aún no hay calificaciones

- Ancoraj Zidarie Aparenta Jordahl 40843 Jordahl Jva WebDocumento48 páginasAncoraj Zidarie Aparenta Jordahl 40843 Jordahl Jva WebIulia PetrescuAún no hay calificaciones

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsCalificación: 4.5 de 5 estrellas4.5/5 (10)

- Sewage Disposal Works: Their Design and ConstructionDe EverandSewage Disposal Works: Their Design and ConstructionAún no hay calificaciones

- A Guide to Ship Repair Estimates in Man-hoursDe EverandA Guide to Ship Repair Estimates in Man-hoursCalificación: 4.5 de 5 estrellas4.5/5 (5)

- AlgaeDocumento1 páginaAlgaeMary1014Aún no hay calificaciones

- Microorganism ImageDocumento1 páginaMicroorganism ImageMary1014Aún no hay calificaciones

- DHS Food Safety CertificateDocumento1 páginaDHS Food Safety CertificateMary1014Aún no hay calificaciones

- Engineer Australia Career Expo' Exhibitor List: Swinburne University LabDocumento2 páginasEngineer Australia Career Expo' Exhibitor List: Swinburne University LabMary1014Aún no hay calificaciones

- Falls Creek MealsDocumento1 páginaFalls Creek MealsMary1014Aún no hay calificaciones

- Problem D Tute 5Documento1 páginaProblem D Tute 5Mary1014Aún no hay calificaciones

- PreparationDocumento1 páginaPreparationMary1014Aún no hay calificaciones

- TheDocumento1 páginaTheMary1014Aún no hay calificaciones

- IS 2165 Part2-1965 Ins Coord - Phase To Phase PDFDocumento14 páginasIS 2165 Part2-1965 Ins Coord - Phase To Phase PDFRohit DeraAún no hay calificaciones

- AOP605 Complementary Enhancement Mode Field Effect TransistorDocumento7 páginasAOP605 Complementary Enhancement Mode Field Effect TransistorfrancicciusAún no hay calificaciones

- IS 14697-1999 Edn 1.3Documento35 páginasIS 14697-1999 Edn 1.3prajith555Aún no hay calificaciones

- Cased Charges PDFDocumento10 páginasCased Charges PDFhezigrisaroAún no hay calificaciones

- FRQ Post Nuclear PowerDocumento2 páginasFRQ Post Nuclear Powerdenise solerAún no hay calificaciones

- JM Eagle Blue Brute C900 Onesheet Rev21Documento2 páginasJM Eagle Blue Brute C900 Onesheet Rev21james.sakaiAún no hay calificaciones

- SpittelauDocumento20 páginasSpittelauFranco PiaggioAún no hay calificaciones

- SuperTuff R Tuff R SellSheetDocumento2 páginasSuperTuff R Tuff R SellSheetZainuddinAún no hay calificaciones

- Samsung Frontier WasherDocumento88 páginasSamsung Frontier Washerpetre333Aún no hay calificaciones

- MM Meccalte Mec1275Documento4 páginasMM Meccalte Mec1275HabibAún no hay calificaciones

- Selection and Ranking of Rail Vehicle Components For Optimal Lightweighting Using Composite MaterialsDocumento14 páginasSelection and Ranking of Rail Vehicle Components For Optimal Lightweighting Using Composite MaterialsAwan AJaAún no hay calificaciones

- Opec PDFDocumento30 páginasOpec PDFraina87Aún no hay calificaciones

- Helios Uk Air TreatmentDocumento10 páginasHelios Uk Air TreatmentValentin MalihinAún no hay calificaciones

- Mock Board ReviewDocumento153 páginasMock Board ReviewLovely Rose Dungan TiongsonAún no hay calificaciones

- EcoTech Mp10 Manual ManualDocumento10 páginasEcoTech Mp10 Manual Manualjuanjj100Aún no hay calificaciones

- Literature Review Green MarketingDocumento4 páginasLiterature Review Green Marketingadi2343sh75% (4)

- How I Swapped A 1.9-Liter Turbo Diesel "AAZ" Engine Into A 1982 Volkswagen Vanagon Westfalia DieselDocumento24 páginasHow I Swapped A 1.9-Liter Turbo Diesel "AAZ" Engine Into A 1982 Volkswagen Vanagon Westfalia DieselhamoAún no hay calificaciones

- GE Fluorescent Specification Series Lamps Brochure 12-95Documento8 páginasGE Fluorescent Specification Series Lamps Brochure 12-95Alan MastersAún no hay calificaciones

- Shielding of Power CablesDocumento6 páginasShielding of Power CablesYudo Heru PribadiAún no hay calificaciones

- Checklist Maintenance RobotDocumento4 páginasChecklist Maintenance RobotTrần ĐìnhAún no hay calificaciones

- Ficha Tecnica Sg160 - 200 Kva Data SheetDocumento6 páginasFicha Tecnica Sg160 - 200 Kva Data SheetEduardoAún no hay calificaciones

- Centrifugal Pump Training ManualDocumento28 páginasCentrifugal Pump Training ManualVegeta saiyanAún no hay calificaciones

- Diseño IntercambiadorDocumento9 páginasDiseño IntercambiadorMateo VanegasAún no hay calificaciones

- Rotary EnginesDocumento27 páginasRotary EnginesMuhammad AsifAún no hay calificaciones

- Earthing Transformers For Power SystemsDocumento11 páginasEarthing Transformers For Power Systemsanoopk222100% (1)

- Eagle PERC 72M: 350-370 WattDocumento2 páginasEagle PERC 72M: 350-370 WattHenry Johan Ramirez PereiraAún no hay calificaciones

- 12 220 KV 4400pF CVTDocumento13 páginas12 220 KV 4400pF CVTAshwin SevariaAún no hay calificaciones

- Local Control For EV ChargingDocumento18 páginasLocal Control For EV ChargingNikeshManandharAún no hay calificaciones