Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Solar Energy To Drive Half Effect

Cargado por

PaneendraBhatDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Solar Energy To Drive Half Effect

Cargado por

PaneendraBhatCopyright:

Formatos disponibles

Int. J.

of Thermal & Environmental Engineering

Volume 1, No. 1 (2010) 1-8

*

Corresponding author. Tel.: +664317045

Fax: +9876543210; E-mail: rabahgomri@yahoo.fr

2010 International Association for Sharing Knowledge and Sustainability

DOI: 10.5383/ijtee.01.01.001

1

Solar Energy to Drive Half-Effect Absorption Cooling System

Rabah GOMRI

*

Laboratory of Gnie Climatique, Engineering Faculty, Department of Gnie Climatique

25000, Constantine, Algeria

Abstract

This paper presents the simulation results and an overview of the performance of low capacity two stage half-effect

absorption cooling system (10kW), suitable for residential and small building applications. The primary heat source is

solar energy supplied from flat plate collectors. The complete system (solar collectors-absorption cooling system) was

simulated using a developed software program. The energy and exergy analysis is carried out for each component of the

system. All exergy destructed that exist in this solar cooling system is calculated. Critical temperatures which are the

minimum allowable hot water inlet temperatures are determined. This system has shown promising characteristics.

When the condenser temperature is fixed at 28C, 32C and 36C it can be concluded that between time of day 10 and

14 solar collector provides about 96%, 95% and 91% heating energy required respectively with a cover of about 100%

between time of day 11 and 13 which correspond to a maximum of solar radiation. The daily cover is about 71%, 70%

and 65% respectively.

Keywords: Absorption cooling system; Performance; Solar energy; Two stage; Half-effect system.

1. Introduction

Nowadays world is marked with an intensive use of energy,

cooling and air conditioning remains having the large share of

energy consumption. Besides the energy consumption, climatic

changes have become an international issue that was treated in

many international summits (the last one was the United

Nations Climate Change Conference Copenhagen December

2009). In this context, solar chilled water production through

absorption cycles energy may be considered one of the most

desirable applications to reduce energy consumption and CO

2

gas emissions. The use of solar energy to drive cooling cycles

for air conditioning is an attractive concept because of the

coincidence of peak cooling loads with the available solar

power.

Algeria, as well as most of other Arab countries, enjoys of

solar radiations. During the summer, the demand for electricity

greatly increases because of the use of vapour compression air

conditioning system, which increases the peak electric load,

and major problems in the countrys electric supply arise. Solar

energy can be used for cooling as it can assist in providing the

heating energy for absorption cooling systems.

Two types of the absorption chillers, the single effect and half

effect cycles, can operate using low temperature hot water. By

using a two stage half-effect LiBr absorption chiller instead of

single effect chiller, it is possible to decrease the required

generator temperature of the chiller and this allowed the use of

simple flat plate collectors to produce hot water to be used as

the hot source for absorption chiller.

The principle of the half-effect cycle is that it has two lifts.

The term lift is used to represent a concentration difference

between the generator and absorber. This concentration

difference is what drives or gives the potential for mass to flow

into the absorber. With the single effect there is only one lift.

Many researchers have reported works on half-effect cycles.

Ma and Deng [1] have reported preliminary results of an

experimental investigation on a 6 kW vapour absorption

system working on half-effect cycle with H

2

O-LiBr as the

working fluids. With hot water temperature requirement of

around 85C, a chilled water temperature of 7C has been

reached in their experiment. Sumathy et al. [2] have tested

solar cooling and heating system with a 100 kW half-effect

absorption chiller working on the same cycle. The system has

been used successfully with generation temperatures in the

range of 6575C to achieve a chilled water temperature of

9C. Arivazhagan et al. [3] presented a simulation studies

conducted on a half-effect vapour absorption cycle using

R134a-DMAC as the refrigerant-absorbent pair with low

Gomri / Int. J. of Thermal & Environmental Engineering, 1 (2010) 1-8

2

temperature heat sources for cold storage applications.

Arivazhagan et al. [4] presented experimental studies on the

performance of a two-stage half eeffect vapour absorption

cooling system. The prototype was designed for 1 kW cooling

capacity using HFC based working fluids (R134a as refrigerant

and DMAC as absorbent).

In the paper presently considered, it is planed to use solar two-

stage half-effect vapour absorption cooling machine to produce

chilled water for air conditioning. This study aims at assessing

the feasibility of solar powered absorption cooling systems

under Algerian conditions. The system proposed to provide

cooling in summer (June, July August and September) for a

building located in Constantine, east of Algeria (longitude

6.62 E, latitude 36.28N and altitude of 689m). The results

presented in this paper were for 1-day period operation (21

st

of

July).

2. Simulation of the Performance

2.1. Solar collector system

The various relations that are required in order to determine the

useful energy collected and interaction of the various

constructural parameters on the performance of a collector

are taken from [5-10].

The energy balance equation of the solar collector can be

written as follows [5]:

stg loss u c G

Q Q Q A . I + + = (1)

Where I

G

is the instantaneous solar radiation incident on the

collector per unit area, A

C

is the collector surface area, Q

loss

is

the heat loss from the collector and Q

u

is the useful energy

transferred from the absorber to the fluid flowing through the

tubes of the collector. Q

stg

is the energy stored in the collector

(Q

stg

=0: the solar thermal system is considered at steady state

conditions).

The useful energy gain of the flat plate collectors is calculated

by:

( ) ( ) | |

a fi L G R c u

T T . U I . . . F . A Q = (2)

Where A

C

is the collector area, F

R

is the collector heat removal

factor, ( ) o t. is the transmittance-absorptance products, U

L

is

the collector overall loss coefficient, T

a

is the ambient air

temperature and T

fi

is the fluid temperature at the inlet to the

collector.

The Collector heat removal factor (F

R

) is the ratio of useful

heat obtained in collector to the heat collected by collector

when the absorber surface temperature is equal to fluid entire

temperature on every point of the collector surface.

( )

(

(

(

=

p

L c

C . m

' F . U . A

L c

p

R

e 1

U . A

C . m

F (3)

Where m is the mass flow rate of water, C

p

is the specific heat

of water and F is the collector efficiency factor. F represents

the ratio of the actual useful energy gain to the useful energy

gain that would result if the collector absorbing surface had

been at local fluid temperature.

The collector overall heat loss coefficient (U

L

) is the sum of

the top (U

T

, bottom U

B

and edge U

E

heat loss coefficient. It

means that:

E B T L

U U U U + + = (4)

The first law efficiency (thermal efficiency) of the solar

collectors is the ratio of useful energy obtained in collector to

solar radiation incoming to collector. It can be formulated as:

c G

u

FPC - th

.A I

Q

= (5)

The prediction of collector performance requires knowledge of

the absorbed solar energy by collector absorber plate. The solar

energy incident on a tilted collector consists of three different

distributions: beam radiation, diffuse radiation, and ground

reflected radiation. The details of the calculation depend on

which diffuse sky model is used. For estimating sky diffuse

solar radiations several models have been developed [11-15].

They vary mainly in the ways that treat the three components

of the sky diffuse radiation, i.e. the isotropic, circumsolar and

horizon radiation streams. In this study the absorbed radiation

on the absorber plate is calculated by Perezs model [16].

For the estimation of the ground reflected radiation an average

value of the ground albedo of 0.2 is used.

2.2. Half-effect effect absorption cooling system

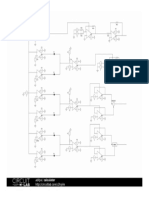

The two stage half-effect absorption refrigeration system as

shown in Fig. 1 consists of condenser, evaporator, two

generators, two absorbers, two pumps, two solution heat

exchangers, two solution reducing valves and a refrigerant

expansion valve. In the system operation, the evaporator and

low pressure absorber operate at low pressure (evaporation

pressure P

ev

). The low pressure generator (LPG) and high

absorber operate at intermediate pressure (P

i

) and the high

pressure generator (HPG) and the condenser operate at high

pressure (condenser pressure, P

cd

). Both generators (LPG and

HPG) can be supplied with heat at the same temperature.

The refrigerant vapour from the evaporator is absorbed by the

strong solution in the low absorber. The weak solution from

the low absorber is pumped to the low generator through the

low solution heat exchanger. The strong solution in the low

generator is returned to the low absorber through the low

solution heat exchanger. The refrigerant vapour from the low

generator is absorbed by the strong solution in the high

absorber. The weak solution from the high absorber is pumped

to the high generator through the high solution heat exchanger.

The strong solution in the high generator is returned to the high

absorber through the high solution heat exchanger. In both heat

exchangers, the weak solution from the absorber is heated by

the strong solution from the generator. The refrigerant is boiled

out of the solution in the high generator and circulated to the

condenser. The liquid refrigerant from the condenser is

returned to the evaporator through an expansion valve.

Gomri / Int. J. of Thermal & Environmental Engineering, 1 (2010) 1-8

3

HEX-2

Evaporator

Low

Absorber

Low

Generator

Condenser

High

Absorberr

High

Generator

HEX-1

Flate plate

solar collectors

Auxliary

heater

Collectors

pump

14

2

3

Pump

P2

13

15

17

11

16

12

5

8 6

7

1

10

4

9

Pump

P1

Reducing

valve V1

Reducing

valve V2

Fig. 1. The schematic illustration of solar two stage half-effect absorption cooling system

The half-effect effect absorption cooling system is simulated

assuming the following conditions:

- The analysis is made under steady conditions.

- The refrigerant (water) at the outlet of the condenser is

saturated liquid.

- The refrigerant (water) at the outlet of the evaporator is

saturated vapour.

- The Lithium bromide solution at the absorber outlet is a

strong solution and it is at the absorber temperature

- The outlet temperatures from the absorbers and from

generators correspond to equilibrium conditions of the

mixing and separation respectively.

- Pressure losses in the pipelines and all heat exchangers

are negligible.

Gomri / Int. J. of Thermal & Environmental Engineering, 1 (2010) 1-8

4

- Heat exchange between the system and surroundings,

other than in that prescribed by heat transfer at the HPG,

evaporator, condenser and absorber, does not occur

- The reference environmental state for the system is water

at an environment temperature T

0

of 25C and 1

atmospheric pressure (P

0

)

- The system produce chilled water, and generators are

driven by hot water.

- The system rejects heat to cooling water at the condenser

and absorbers.

- Both generators are supplied with heat at the same

temperature.

- The refrigerant flow rate leaving the low temperature

generator is equal to the refrigerant flow rate leaving the

high temperature generator.

Simulations are carried out for a constant refrigeration

capacity Q

ev

=10kW, Pump efficiency

P

=85%, Heat

exchangers effectiveness c

I

=c

II

=70%, condensation

temperature is equal to the absorber temperature T

cd

=T

ab

.

Condensation temperature is varied in the following range:

T

cd

=28C to 36C. The outlet temperature of cooling water has

been assumed at T

cd

-3 and the inlet temperature of cooling

water has been assumed at T

cd

-8. Evaporation temperature is

maintained at T

ev

=5C. The outlet temperature of chilled water

has been assumed at T

ev

+3 and the inlet temperature of chilled

water has been assumed at T

ev

+8. Generation temperature T

g

is varied from 42C to 62C. The outlet temperature of hot

water has been assumed at T

g

+8 and the inlet temperature of

hot water has been assumed at T

g

+21.

In this analysis, the thermal-physical properties of the working

fluids have to be known as analytic functions. A set of

computationally efficient formulations of thermodynamic

properties of lithium bromide/water solution and liquid water

developed by Patek and Klomfar [17] are used in this work.

The equations for the thermal properties of steam are obtained

from correlation provided by Patek and Klomfar [18].

For the thermodynamic analysis of the absorption system the

principles of mass conservation and first law of

thermodynamic are applied to each component of the system

(see Fig. 1).

Mass Conservation: Mass conservation includes the mass

balance of total mass and each material of the solution. The

governing equations of mass and type of material conservation

for a steady state and steady flow system are:

0 m m

0 i

= (6)

= 0 x . m x . m

0 0 i i

(7)

Where m is the mass flow rate and x is de mass fraction of

LiBr in the solution. The mass fraction of the mixture at

different points of the system (Fig.1) is calculated using the

corresponding temperature and pressure data.

The mass flow rate of refrigerant is obtained by energy balance

at evaporator and is given as,

( )

3 2

ev

3

h h

Q

m

=

(8)

Energy analysis: The first law of thermodynamics yields the

energy balance of each component of the absorption cooling

system as follows:

( ) ( ) 0 W Q Q h . m h . m

0 i 0 0 i i

= + +

(9)

The thermal efficiency (coefficient of performance) of the

absorption cooling system is obtained by

( )

2 p 1 p LPG HPG

ev

W W Q Q

Q

COP

+ + +

= (10)

Exergy analysis: Exergy analysis is the combination of the

first and second law of thermodynamics and is defined as the

maximum amount of work, which can be produced by a stream

or system as it is brought into equilibrium with a reference

environment and can be thought of as a measure of the

usefulness or quality of energy [19]. According to Bejan et al.

[20] the exergetic balance applied to a fixed control volume is

given by the following equation:

W Ex ex . m ex . m Ex

j heat

out

i

i i

in

i

i i d

|

|

.

|

\

|

|

|

.

|

\

|

=

(11)

Where Ex

d

is rate of exergy destruction. Ex

heat

is the net exergy

transfer by heat at temperature T, which is given by

i

j

j

0

heat

Q .

T

T

1 Ex

|

|

.

|

\

|

= (12)

W is the mechanical work transfer to or from the system.

The specific exergy of flow is:

( ) ( )

0 0 0

s s T h h ex = (13)

m is the mass flow rate of the fluid stream, h is the enthalpy, s

is the entropy and the subscripts 0 stands for the restricted

dead state.

The exergetic efficiency (rational efficiency) can be calculated

as the ratio between the net exergy produced by the evaporator

(exergy desired output) and the input exergy to the generator

(exergy used) plus the mechanical work of the solution pumps:

Gomri / Int. J. of Thermal & Environmental Engineering, 1 (2010) 1-8

5

( ) ( )

(

(

+ +

|

|

.

|

\

|

+

|

|

.

|

\

|

=

2 p 1 p

h

0

gL gH

b

0

ev

exergy

W W

T

T

1 . Q Q

T

T

1 . Q

(14)

T

b

and T

h

are the mean temperature of the cold source (in the

evaporator) and the hot source (in the generator) respectively.

Q

gH

is the heat supplied to the HPG and Q

gL

is the heat

supplied to the LPG.

2.3. Mathematical model for the global system

For this part, the mathematical model is based on the following

assumptions:

- The solar collector loop is chosen without a storage

tank.

- An auxiliary heat source is provided, so that the hot

water is supplied to generators when solar energy is

not sufficient to heat the water to the required

temperature level needed by the generators

- The overall thermal efficiency of the complete solar

absorption cooling system

overall

is the product of

COP and solar efficiency

th-FPC

[21] :

FPC - th overall

. COP = (15)

aux u gL gH

Q Q Q Q + = + (16)

Q

aux

is the auxiliary heating load.

3. Results and Discussion

The energy and exergy analysis was carried out on 21

st

of July

in Constantine (East of Algeria; Latitude 36.28N, Longitude

6.62E). A computer program was written for thermodynamic

analysis. The program was based on the energy balance,

exergy balance and thermodynamic properties for each

reference point. The initial conditions are given into the

program including the ambient conditions, the solar energy

collector parameter specification, the component temperatures,

pumps efficiencies, effectiveness of heat exchangers and

evaporator load. With the given parameters, the

thermodynamic properties at all reference points in the system

were calculated. The results obtained from the present study

may be presented as follows.

Fig. 2 shows the effects of the generator, and condenser

temperature on the coefficient of performance (COP).

The high values of COP are obtained at high generator and low

condenser temperatures. For a given evaporator and condenser

temperature, there is a minimum generator temperature which

corresponds to a maximum COP. It should be noted that the

COP initially exhibits significant increase with an increase of

generator temperature, and then the slope of the COP curves

become almost flat. In other words, increasing the generator

temperature higher than a certain value does not provide much

improvement for the COP.

0.0

0.1

0.2

0.3

0.4

0.5

40 45 50 55 60 65

Generator temperature [C]

C

o

e

f

f

i

c

i

e

n

t

o

f

p

e

r

f

o

r

m

a

n

c

e

-

C

O

P

[

-

]

Tcd=28C

Tcd=32C

Tcd=36C

Fig.2. Coefficient of performance versus generator temperature

'Tg' and condenser temperature 'Tcd' (Tev=5C)

The variation of exergetic efficiency with generator

temperature for two stage half-effect cooling system at

different condenser temperatures is shown in Fig. 3. Exergetic

efficiency increase with an increase in the generator

temperature up to a certain generator temperature (for a given

evaporator, absorber and condenser temperature, there is a

minimum generator temperature which corresponds to a

maximum exergy efficiency) and then decrease.

0

5

10

15

20

25

40 45 50 55 60 65

Generator temperature [C]

E

x

e

r

g

y

e

f

f

i

c

i

e

n

c

y

[

%

]

Tcd=28C

Tcd=32C

Tcd=36C

Fig.3. Exergy efficiency versus generator temperature 'Tg' and

condenser temperature 'Tcd' (Tev=5C)

The variation of total exergy loss with generator temperature

for cooling at different condenser temperatures is shown in

Fig. 4. The total exergy loss of the absorption cooling system

drops sharply to a minimum value with an increase of

generator temperature and then increases further. For each

condenser temperature there is a generator temperature at

which the total exergy loss of the absorption cooling system is

minimum which corresponds to a maximum value of exergy

efficiency and COP. In this study When the evaporator

temperature is maintained constant at 5C and condenser

temperature is varied from 28C and 36C and generators

temperatures are varied from 42 to 62 C the maximum COP

is 0.44 and the maximum exergetic efficiency is about 21%

Gomri / Int. J. of Thermal & Environmental Engineering, 1 (2010) 1-8

6

0

1

2

3

4

5

40 45 50 55 60 65

Generator temperature [C]

E

x

e

r

y

d

e

s

t

r

u

c

t

e

d

[

k

W

]

Tcd=28C

Tcd=32C

Tcd=36C

Fig.4. Exergy destructed versus generator temperature 'Tg' and

condenser temperature 'Tcd' (Tev=5C)

Fig. 5 shows the variation of heat supplied to the two

generators (Qg) versus the generator temperature for different

value of condenser temperature. It is clear that for a given

condenser temperature there is a minimum generator

temperature for which the Qg is minimum. This optimum

generator temperature corresponds to the generator temperature

giving the maximum COP and exergetic efficiency of the

absorption cooling system. It should be noted that the Qg

initially exhibits a significant decrease with an increase of

generator temperature, and then the slope of the Qg curves

become almost flat. At higher generator temperature the values

of Qg became almost the same for the different condenser

temperatures.

20

22

24

26

28

30

40 45 50 55 60 65

Generator temperature [C]

H

e

a

t

s

u

p

p

l

i

e

d

t

o

t

h

e

t

w

o

g

e

n

e

r

a

t

o

r

s

(

Q

g

)

[

k

W

]

Tcd=28C

Tcd=32C

Tcd=36C

Fig.5. Heat supplied to the two generators versus generator

temperature 'Tg' and condenser temperature 'Tcd' (Tev=5C)

Fig. 6 shows the variation of the number of flat plate solar

collector (N

FPC

) during the peak solar gain hour on 21

st

of July

versus the generator temperature for different value of

condenser temperature. For a given condenser temperature

there is an optimum generator temperature for which the N

FPC

is minimum. This optimum generator temperature corresponds

to the generator temperature giving the maximum COP and the

maximum exergetic efficiency of the absorption cooling

system.

20

22

24

26

28

30

32

34

36

38

40

40 45 50 55 60 65

Generator temperature Tg [C]

N

u

m

b

e

r

o

f

F

P

C

'

N

F

P

C

'

Tcd=28C

Tcd=32C

Tcd=36C

Fig.6. Variation of the number of FPC 'N

FPC

' versus generator

temperature 'Tg' and condenser temperature (Ac=2.03m

2

)

Figs. 7, 8 and 9 show the variation of energy efficiency of

solar flat plate collectors (solar collector thermal efficiency,

th-FPC

), against time of day for different generator and

condenser temperatures. It can be seen that the instantaneous

collector efficiency is slightly higher after 12h and then

decreases gradually at the shut off of operation hour. We note

the existence of a maximum value of roughly 0.6

corresponding to the maximum incident radiation (also a

minimum generator temperature of 42C and a minimum

condenser temperature of 28C).

The COP of the absorption cooling system is a constant value

during all the day then and as can be seen from (Eq.1) the

thermal efficiency of the global system will decrease with an

increase of the generator temperature and condenser

temperature

0

0.1

0.2

0.3

0.4

0.5

0.6

7 8 9 10 11 12 13 14 15 16 17 18

Time of day [h]

S

o

l

a

r

c

o

l

l

e

c

t

o

r

s

e

f

f

i

c

i

e

n

c

y

Tg=42c

Tg=46c

Tg=50c

Tg=54c

Tg=58c

Tg=62c

Fig.7. Variation solar collectors thermal efficiency versus time of

day and generator temperature 'Tg' (Tcd=28C)

0

0.1

0.2

0.3

0.4

0.5

0.6

7 8 9 10 11 12 13 14 15 16 17 18

Time of day [h]

S

o

l

a

r

c

o

l

l

e

c

t

o

r

s

e

f

f

i

c

i

e

n

c

y

Tg=42c

Tg=46c

Tg=50c

Tg=54c

Tg=58c

Tg=62c

Fig.8. Variation solar collectors thermal efficiency versus time of

day and generator temperature 'Tg' (Tcd=32C)

Gomri / Int. J. of Thermal & Environmental Engineering, 1 (2010) 1-8

7

0

0.1

0.2

0.3

0.4

0.5

0.6

7 8 9 10 11 12 13 14 15 16 17 18

Time of day [h]

S

o

l

a

r

c

o

l

l

e

c

t

o

r

s

e

f

f

i

c

i

e

n

c

y

Tg=54c

Tg=56c

Tg=58c

Tg=60c

Tg=62c

Fig.9. Variation solar collectors thermal efficiency versus time of

day and generator temperature 'Tg' (Tcd=36C)

Figs. 10, 11 and 12 show the variation of energy delivered to

the two generators (LPG and HPG) and the contribution

percentage of solar energy and auxiliary heating load. When

the condenser temperature is fixed at 28C, 32C and 36C it

can be seen that between time of day 10 and 14 solar collector

provides about 96%, 95% and 91% heating energy required

respectively with a cover of about 100% between time of day

11 and 13 which correspond to a maximum of solar radiation.

The daily cover is about 71%, 70% and 65% respectively.

Then, a high value of condenser temperature influence

negatively the rate of solar energy provided. The low solar

radiation values early in the morning and later in the afternoon

hours cause a significant increase in required auxiliary heating.

0

5

10

15

20

25

E

n

e

r

g

y

r

a

t

e

[

k

W

]

8 9 10 11 12 13 14 15 16

Time of day [h]

Solar Energy

Auxiliary heat

Fig. 10 Contribution percentage of solar energy and auxiliary

heating load (Tcd=28C, Tg=48C)

0

5

10

15

20

25

E

n

e

r

g

y

r

a

t

e

[

k

W

]

8 9 10 11 12 13 14 15 16

Time of day [h]

Solar Energy

Auxiliary heat

Fig. 11 Contribution percentage of solar energy and auxiliary

heating load (Tcd=32C, Tg=50C)

0

5

10

15

20

25

E

n

e

r

g

y

r

a

t

e

[

k

W

]

8 9 10 11 12 13 14 15 16

Time of day [h]

Solar Energy

Auxiliary heat

Fig. 12 Contribution percentage of solar energy and auxiliary

heating load (Tcd=36C, Tg=60C)

3. Conclusion

In this paper, an attempt has been made to study the

combination: flat plate solar collectors and a two stage

absorption cooling system. The main results obtained are

concluded below:

- When the evaporator temperature is maintained

constant at 5C and condenser temperature is varied

from 28C and 36C and generators temperatures are

varied from 42 to 62 C the maximum COP is 0.44

and the maximum exergetic efficiency is about 21%

- For a given condenser temperature there is an

optimum generator temperature for which the N

FPC

is

minimum. This optimum generator temperature

corresponds to the generator temperature giving the

maximum COP and exergetic efficiency of the

absorption cooling system.

- We note the existence of a maximum value of solar

collector thermal efficiency,

th-FPC

of roughly 0.6.

- The thermal efficiency of the global system will

decrease with an increase of the generator

temperature and condenser temperature

References

[1] Ma WB, Deng SM. Theoretical analysis of low temperature

hot source driven two stage LiBr-H

2

O absorption refrigeration

system. International Journal of refrigeration 1996; 19(2):

141-146. http.dx.doi.org/10.1016/0140-7007(95)00054-2

[2] Sumathy K, Huang ZC, Li ZF. Solar absorption cooling with

low grade heat source - A strategy of development in South

China. Solar Energy 2000; 72 (2): 155-165.

http.dx.doi.org/10.1016/S0038-092X(01)00098-6

[3] Arivazhagan S, Murugesan SN, Saravanan R,

Renganarayanan S. Simulation studies on R134a-DMAC

based half effect absorption cold storage systems. Energy

Conversion and Management 2005;46(11-12):17031713.

http.dx.doi.org/10.1016/j.enconman.2004.10.006

[4] Arivazhagan S, Saravanan R, Renganarayanan R.

Experimental studies on HFC based two-stage half effect

vapour absorption cooling system. Applied Thermal

Engineering 2006; 26 (14-15): 1455-1462.

http.dx.doi.org/10.1016/j.applthermaleng.2005.12.014

Gomri / Int. J. of Thermal & Environmental Engineering, 1 (2010) 1-8

8

[5] Frederick FS. Flat plate solar collector performance

evaluation with a solar simulator as a basis for collector

selection and performance prediction. Solar Energy 1976;

18(5) : 451466. http.dx.doi.org/10.1016/0038-

092X(76)90012-8

[6] Kalogirou SA. Solar thermal collectors and applications.

Progress in energy and combustion science 2004;30(3): 231-

295. http.dx.doi.org/10.1016/j.pecs.2004.02.001

[7] Uca A, Inalli M. thermo-economical optimization of a

domestic solar heating plant with seasonal storage. Applied

Thermal Engineering 2007; 27 (2-3): 450456.

http.dx.doi.org/10.1016/j.applthermaleng.2006.06.010

[8] Karatasou S, Santamouris M, Geros V. On the calculation of

solar utilizability for south oriented flat plate collectors tilted

to an angle equal to the local latitude. Solar energy 2006;

80(12):1600-1610.

http.dx.doi.org/10.1016/j.solener.2005.12.003

[9] Akhtara N, Mullick SC. Computation of glass-cover

temperatures and top heat loss coefficient of flat-plate solar

collectors with double glazing. Energy 2007; 32 (7): 1067-

1074. http.dx.doi.org/10.1016/j.energy.2006.07.007

[10] Sartori E. Convection coefficient equations for forced air flow

over flat surfaces. Solar Energy 2006;80(9):10631071.

http.dx.doi.org/10.1016/j.solener.2005.11.001

[11] Bugler JW. The determination of hourly insolation on an

inclined plane using a diffuse irradiance model based on

hourly measured global horizontal insolation. Solar Energy

1977;19(5):477491. http.dx.doi.org/10.1016/0038-

092X(77)90103-7

[12] Klucher T. Evaluation of models to predict insolation on tilted

surfaces. Solar Energy 1979;23(2):111114.

http.dx.doi.org/10.1016/0038-092X(79)90110-5

[13] Gueymard C. An isotropic solar irradiance model for tilted

surfaces and its comparison with selected engineering

algorithms. Solar Energy 1987; 38 (5): 367386.

http.dx.doi.org/10.1016/0038-092X(87)90009-0

[14] Reindl DT, Beckman DA, Duffie JA. Evaluation of hourly

tilted surface radiation models. Solar Energy 1990;45(1): 9

17, 1990.

[15] Perez R, Ineichen P, Seals R. Modelling daylight availability

and irradiance components from direct and global irradiance.

Solar Energy 1990; 44(5): 271289.

http.dx.doi.org/10.1016/0038-092X(90)90055-H

[16] Elminir K H, Ghitas AE., El-Hussainy F., Hamid R., Beheary

MM, Abdel-Moneim KM. Optimum solar flat-plate collector

slope: Case study for Helwan, Egypt. Energy Conversion and

Management 2006; 47 (5): 624637.

http.dx.doi.org/10.1016/j.enconman.2005.05.015

[17] Patek J, Klomfar J. Computationally effective formulation of

the thermodynamic properties of LiBr-H

2

O solution from 273

to 500K over full composition range. International Journal of

Refrigeration 2006; 29 (4): 566-578.

http.dx.doi.org/10.1016/j.ijrefrig.2005.10.007

[18] Patek J, Klomfar J. A simple formulation for thermodynamic

properties of steam from 273 to 523 K, explicit in temperature

and pressure. International Journal of Refrigeration 2009; 32

(5): 1123-1125, 2009.

http.dx.doi.org/10.1016/j.ijrefrig.2008.12.010

[19] J.T. Kotas, The exergy method of thermal plant Analysis.

Lavoisier: Paris, 1987.

[20] A. Bejan, G. Tsatsaronis G and M. Moran M. Thermal design

and optimization. Wiley: New York, 1996.

[21] Ortega O, Garcia O, Best R, Gomez VH. Two-phase flow

modeling of a solar concentrator applied as ammonia vapor

generator in an absorption refrigerator. Renewable Energy

2008;33(9):20642076.

http.dx.doi.org/10.1016/j.renene.2007.11.016

Nomenclature

A

C

Collector surface area, m

2

COP Thermal efficiency (coefficient of performance) of

the absorption cooling system

C

p

Specific heat of water, kJ/kg.K

Ex Exergy, kW

F Collector efficiency factor.

F

R

Collector heat removal factor

H Enthalpy, kJ/kg

HPG High pressure generator

I

G

Instantaneous solar radiation incident, kW/m

2

LPG Low pressure generator

M Mass flow rate of the fluid stream,

Q Heat (Energy), kW

S Entropy, kJ/kg.K

T Temperature, K

U

L

collector overall loss coefficient, kW/m

2

.K

W Mechanical work transfer to or from the system, kW

T Temperature of the jet, K

Greek Symbols

Efficiency

( ) o t. is the transmittance-absorptance products

Subscripts

0 Reference value

A Ambient

Aux Auxiliary

B Cold source

Cd Condenser

D Destruction

Ev Evaporator

Fi The fluid at the inlet to the collector.

FPC Flat plate collectors

G Generator

gH High pressure generator

gL Low pressure generator

H Hot source

P Pump

Th Thermal

U Useful

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- 01 Installation Guide AtmelStudio6Documento16 páginas01 Installation Guide AtmelStudio6sameer7868Aún no hay calificaciones

- MC PaperDocumento15 páginasMC PaperPaneendraBhatAún no hay calificaciones

- Computing Distance FunctionsDocumento17 páginasComputing Distance FunctionsPaneendraBhatAún no hay calificaciones

- 03 Installing and Using BootloaderDocumento12 páginas03 Installing and Using BootloaderPaneendraBhatAún no hay calificaciones

- Burger's EquationDocumento10 páginasBurger's EquationPaneendraBhatAún no hay calificaciones

- Fundamentals - of - Signals - and - Systems - Using - Web - and - Matlab SolutionsDocumento433 páginasFundamentals - of - Signals - and - Systems - Using - Web - and - Matlab SolutionsMeseret BeyeneAún no hay calificaciones

- Read MeDocumento4 páginasRead Meconnect2nsAún no hay calificaciones

- 01 Installation Guide AtmelStudio6Documento16 páginas01 Installation Guide AtmelStudio6sameer7868Aún no hay calificaciones

- Read MeDocumento4 páginasRead Meconnect2nsAún no hay calificaciones

- Simple Analog CalculatorDocumento1 páginaSimple Analog CalculatorPaneendraBhatAún no hay calificaciones

- Cargo Aligning RulebookDocumento14 páginasCargo Aligning RulebookSailesh SahuAún no hay calificaciones

- Soft Robotic Manipulation of Onions & Artichokes in Food IndustryDocumento21 páginasSoft Robotic Manipulation of Onions & Artichokes in Food IndustryPaneendraBhat100% (1)

- First ScriptDocumento1 páginaFirst ScriptPaneendraBhatAún no hay calificaciones

- Physical Research LaboratoryDocumento2 páginasPhysical Research LaboratoryPaneendraBhatAún no hay calificaciones

- Sem Engine ReportDocumento3 páginasSem Engine ReportPaneendraBhatAún no hay calificaciones

- Analysis of CrapDocumento1 páginaAnalysis of CrapPaneendraBhatAún no hay calificaciones

- 4207 13730 4 PBDocumento9 páginas4207 13730 4 PBPaneendraBhatAún no hay calificaciones

- Ansys Fluent TutorialDocumento5 páginasAnsys Fluent TutorialPaneendraBhatAún no hay calificaciones

- MEMS Based Pressure SensorsDocumento15 páginasMEMS Based Pressure SensorsPaneendraBhatAún no hay calificaciones

- Design, Fabrication, and Characterization of A Solenoid System To Generate Magnetic Field For An ECR Proton SourceDocumento8 páginasDesign, Fabrication, and Characterization of A Solenoid System To Generate Magnetic Field For An ECR Proton SourceaaooprvAún no hay calificaciones

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Manual de Operacion y Mantnimiento PDFDocumento106 páginasManual de Operacion y Mantnimiento PDFBrando pabloAún no hay calificaciones

- Operation 490BDocumento60 páginasOperation 490BYe Min Htike100% (1)

- Modern Automotive Technology Flyer and Order FormDocumento2 páginasModern Automotive Technology Flyer and Order FormDarmawan Putranto0% (1)

- Asl Ga37-55 VSD MK5Documento67 páginasAsl Ga37-55 VSD MK5Ramraj Enterprises100% (1)

- Eq Generacion Electrica Iluminacion Olympian GEP150Documento5 páginasEq Generacion Electrica Iluminacion Olympian GEP150Franz JW MontezaAún no hay calificaciones

- 352 KW Doosan Generator D440 IvDocumento5 páginas352 KW Doosan Generator D440 IvRodolfoGarciaAún no hay calificaciones

- Apd NG450Documento5 páginasApd NG450Magaly PeraltaAún no hay calificaciones

- Dongfeng: Technical SpecificationsDocumento2 páginasDongfeng: Technical Specificationsเสกสรรค์ จันทร์สุขปลูกAún no hay calificaciones

- BJB BKC Bru Bls Bxe BXF BXJ Engine EngDocumento207 páginasBJB BKC Bru Bls Bxe BXF BXJ Engine EngMihai Lungu50% (2)

- KKS Kody EN DE PDFDocumento58 páginasKKS Kody EN DE PDFHoai Nam TaAún no hay calificaciones

- Hand Cranked Engine: Zero-Point FuelDocumento37 páginasHand Cranked Engine: Zero-Point FuelEngineering ProjectAún no hay calificaciones

- E2876Documento3 páginasE2876criveraAún no hay calificaciones

- DGW201M: Owner'S and Operator'S ManualDocumento32 páginasDGW201M: Owner'S and Operator'S ManualthuanAún no hay calificaciones

- 12 Perhitungan Rem IIIDocumento11 páginas12 Perhitungan Rem IIIReza BagusAún no hay calificaciones

- Restore /restore Plus Heavy-Duty Coolant Cleaners: The Safe and Efficient Way To Clean Heavy-Duty Cooling SystemsDocumento2 páginasRestore /restore Plus Heavy-Duty Coolant Cleaners: The Safe and Efficient Way To Clean Heavy-Duty Cooling SystemsemezibAún no hay calificaciones

- Caterpilar C175-16 - Project Guide - LEBW0010-00 PDFDocumento83 páginasCaterpilar C175-16 - Project Guide - LEBW0010-00 PDFsfdsdfsf50% (2)

- MDD Series Service ManualDocumento206 páginasMDD Series Service Manualwilson chaconAún no hay calificaciones

- Important Information: Operator's Manual D14 DC14 DI14Documento50 páginasImportant Information: Operator's Manual D14 DC14 DI14steynhen100% (2)

- Cooling Systems in Automobiles & Cars: Gogineni. Prudhvi, Gada - Vinay, G.Suresh BabuDocumento9 páginasCooling Systems in Automobiles & Cars: Gogineni. Prudhvi, Gada - Vinay, G.Suresh Babupankaj645924Aún no hay calificaciones

- Cat 2012 PDFDocumento1 páginaCat 2012 PDFابو عمر الغزيAún no hay calificaciones

- MAY 13 Complete Catalogue - DotxDocumento65 páginasMAY 13 Complete Catalogue - DotxCommercial AndPlantAún no hay calificaciones

- Manual Skoda Octavia 1,9 66kWDocumento140 páginasManual Skoda Octavia 1,9 66kWCornea Horatiu SebastianAún no hay calificaciones

- DDC SVC MAN 0074 2007.application and Instalation S60Documento348 páginasDDC SVC MAN 0074 2007.application and Instalation S60Antony MorenoAún no hay calificaciones

- Caterpillar 950HDocumento717 páginasCaterpillar 950HThiago Henrique100% (18)

- Air Cooled Heat Exchanger Preliminary SelectionDocumento4 páginasAir Cooled Heat Exchanger Preliminary SelectionAA GGAún no hay calificaciones

- 7 Series: Model 709Documento4 páginas7 Series: Model 709Dark CenobiteAún no hay calificaciones

- Lubrication & Maintenance Chart TLB Case (Andy)Documento3 páginasLubrication & Maintenance Chart TLB Case (Andy)Zakhele MpofuAún no hay calificaciones

- Operation and Maintenance Manual Motores P158LE P180LE P222LE Daewoo DoosanDocumento165 páginasOperation and Maintenance Manual Motores P158LE P180LE P222LE Daewoo Doosanvictorhernandezrega60% (5)

- Combined SM32Documento488 páginasCombined SM32jijikoko100% (4)