Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PCS Multi-Stage Plunger Lift

Cargado por

Miguel Urzagaste CruzDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

PCS Multi-Stage Plunger Lift

Cargado por

Miguel Urzagaste CruzCopyright:

Formatos disponibles

Multi-Stage Plunger Lift:

An Economical Alternative to Pumping Units

Conventional Plunger Lift Overview Performs best in wells:

Producing primarily gas Producing at or near critical flow rate Accumulating large amounts of solids Producing light oil, condensate or water That are low volume or marginal That have tubing irregularities

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Plunger Lift Advantages

Efficiently removes accumulated liquids Can extend production to economic depletion Increases BHP drawdown to increase production Utilizes wells own energy; no power source needed Controls solid and hydrate buildup Performs well in deviations Low capital and operating costs

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Plunger Lift Limitations

GLR requirements and adequate associated gas: typically 4 Mcf to 1 Bbl ratio of gas to liquid needed Limited fluid removal volume Fall time is prohibitive in deep wells

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Other Potential Lift Methods Pump Jack/Beam Lift

Advantages Large fluid volumes Greater depths Requires little intervention Familiar to operators Disadvantages High capital cost High operating cost Gas locking Challenging in horizontals

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Soap Injection

Advantages Low capital cost Easy implementation Familiar to operators Disadvantages High operating cost Not effective in oil

www.pcslift.com

How Multi-Stage Plunger Lift Compares

Can operate in GLRs nearing 1 Mcf to 1 Bbl gas to liquid Lower installation and maintenance costs (works with existing plunger lift equipment) Entirely mechanical; no power or fuel requirement Less expensive than pump jack; conservatively less than one-tenth of the cost Good performance in horizontal wells Better at removing solids and preventing buildup

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

The Multi-Stage Tool

Bumper spring absorbs impact of arriving plunger Collar stop holds the tool in place in the tubing Seal element (pack off) ensures oneway flow of liquids and prevents slippage Locking mechanism holds tool in Open position until set Ball and seat (flow cage) and holds liquids for transfer to the upper plunger, which lifts and removes them

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

How Multi-Stage Lift Works

Bottom assembly and plunger are installed. Tool is placed by wireline about 40-70% down the tubing, above the bottom plunger. First cycle: Bottom plunger carries fluids up to the tool. Tool holds the fluids above it. Top plunger is installed; it descends and lands at the tool. Next cycle: Top plunger delivers its fluids to surface. Bottom plunger delivers more fluids up to the tool. Plungers travel in tandem in subsequent cycles, delivering fluids first to the tool, then to the surface.

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Pressure Vs. Delta Time

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Case History A

Well A: Challenges

Frequently loading up; no longer able to lift fluids on its own Plunger lift installed, but large amounts of liquids required long shut-in times When the plunger could run, tubing pressure often knocked down the separator Plunger was not able to cycle consistently Pump jack was considered, but cost was prohibitive

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Case History A Results

Multi-Stage Tool and upper plunger installed over existing plunger lift system Gas production increased from 17 to 124 Mcf/day After a few cycles, separator was able to function and consistent production was achieved

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Case History B

Well B: Challenges

Inhibited by high production of frac sand and wax Plunger would not cycle consistently; well shut-in most of the time Pump jack installation and soap injection were considered

Feb. 27 - Mar. 2, 2011

2011 Gas Well Deliquification Workshop

Property of Production Control Services. All content is confidential to PCS and its respective partners. Denver, Colorado

12 www.pcslift.com

Case History B Results

Multi-Stage Tool and upper plunger lift installed over existing plunger lift system After cleaning the tubing, sand production decreased Plungers began to cycle consistently and well was able to produce

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Comparison of Lift Options

Options Advantages Disadvantages

Multi-Stage Low capital cost Can be labor intensive Plunger Lift Easy installation Familiar to operators Pump Jack Familiar to operators High capital cost Best reservoir Intervention often costly drawdown Challenging on horizontals Low capital cost Expensive to operate Easy installation Technology often not Familiar to operators applied

Soap Injection

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Conclusion

Multi-Stage Plunger Lift can cost-effectively increase production of gas and oil Extends range of plunger lift applications; possible in wells approaching 1 Mcf : 1 Bbl gas-to-liquid ratio Much more economical than pump unit (beam lift); installation and maintenance costs are significantly lower than beam pumping More effective in oil-rich environments than soaping

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

Contact PCS to Learn More

Click here or email information@pcslift.com to learn more about multi-stage plunger lift.

www.pcslift.com

Property of Production Control Services. All content is confidential to PCS and its respective partners.

También podría gustarte

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Example of Annual Audit Planning Work ProgramDocumento2 páginasExample of Annual Audit Planning Work Programrindwa100% (1)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- English Vs Romanian SyntaxDocumento7 páginasEnglish Vs Romanian SyntaxAna Maria Chirea-Stoica100% (1)

- Chapter 4 Calculations ANSWERSDocumento2 páginasChapter 4 Calculations ANSWERSmollicksoham2907Aún no hay calificaciones

- S&S PDFDocumento224 páginasS&S PDFMohammed MateenAún no hay calificaciones

- Philippine Ecd Checklist Class Summary (Post-Test) SY: 2022-2023Documento5 páginasPhilippine Ecd Checklist Class Summary (Post-Test) SY: 2022-2023UltravioletHeartAún no hay calificaciones

- Section A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentDocumento22 páginasSection A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentThanh PhongAún no hay calificaciones

- MgF2 SolGelDocumento8 páginasMgF2 SolGelumut bayAún no hay calificaciones

- VRV Heat Recovery REYQ-XDocumento20 páginasVRV Heat Recovery REYQ-XFrancisco LinaresAún no hay calificaciones

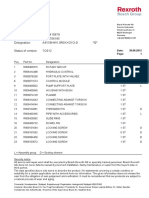

- A4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Documento25 páginasA4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Alonso TabordaAún no hay calificaciones

- Current Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Documento11 páginasCurrent Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Manoj Digi Loans100% (1)

- Airsprings - TroubleshootingDocumento4 páginasAirsprings - TroubleshootingCihan CantaşAún no hay calificaciones

- Course Syllabus Template For BSED 1Documento2 páginasCourse Syllabus Template For BSED 1Rosalyn MauricioAún no hay calificaciones

- 01 Agile Challenge-Does Anyone Have A PencilDocumento13 páginas01 Agile Challenge-Does Anyone Have A PencilAbhisek MukherjeeAún no hay calificaciones

- Title DefenseDocumento3 páginasTitle DefenseLiezl Sabado100% (1)

- The Impact of Employees' Commitment Towards Food Safety at Ayana Resort, BaliDocumento58 páginasThe Impact of Employees' Commitment Towards Food Safety at Ayana Resort, Balirachelle agathaAún no hay calificaciones

- Collaboration Proposal FormDocumento4 páginasCollaboration Proposal FormGabriel TecuceanuAún no hay calificaciones

- Deck Manual PDFDocumento217 páginasDeck Manual PDFBozidar TomasevicAún no hay calificaciones

- CreditCardStatement3665658 - 2087 - 02-Mar-21Documento2 páginasCreditCardStatement3665658 - 2087 - 02-Mar-21Aamir MushtaqAún no hay calificaciones

- 40rua 40rusDocumento68 páginas40rua 40rusfua2011live.comAún no hay calificaciones

- Vedic Astrology - Marriage Star Matching Compatibility For Pooraadam Girl and Aayilyam BoyDocumento1 páginaVedic Astrology - Marriage Star Matching Compatibility For Pooraadam Girl and Aayilyam BoyRam GopalAún no hay calificaciones

- Spectatorship Affect and Liveness in Contemporary British Performance PDFDocumento358 páginasSpectatorship Affect and Liveness in Contemporary British Performance PDFShivansh Tuli100% (1)

- AI Coming For LawyersDocumento4 páginasAI Coming For LawyersbashiAún no hay calificaciones

- ASN PyariViswamResumeDocumento3 páginasASN PyariViswamResumeapi-27019513100% (2)

- Artikel Jurnal Siti Tsuwaibatul ADocumento11 páginasArtikel Jurnal Siti Tsuwaibatul Aaslamiyah1024Aún no hay calificaciones

- 335 Model DDX-LP Dry Pipe Valve SystemDocumento8 páginas335 Model DDX-LP Dry Pipe Valve SystemM Kumar MarimuthuAún no hay calificaciones

- Proper Storage of Instruments2Documento20 páginasProper Storage of Instruments2Pierre Vincent PorrasAún no hay calificaciones

- LED Lighting Applications Design GuideDocumento20 páginasLED Lighting Applications Design GuideBank100% (3)

- Learning Activity Sheet in Science-9: Week 7-Quarter 3Documento5 páginasLearning Activity Sheet in Science-9: Week 7-Quarter 3theinvaderAún no hay calificaciones

- Implications of PropTechDocumento107 páginasImplications of PropTechAnsar FarooqiAún no hay calificaciones

- Guidelines For The Oral Presentation Bands Singers e MusicDocumento2 páginasGuidelines For The Oral Presentation Bands Singers e Musicjuliusdelazare100% (1)