Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Modelling of A Hybrid Solar Panel With Solar Concentration

Cargado por

SEP-PublisherTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Modelling of A Hybrid Solar Panel With Solar Concentration

Cargado por

SEP-PublisherCopyright:

Formatos disponibles

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013 www.seipub.

org/eer

35

Modelling of a Hybrid Solar Panel with Solar

Concentration

Olena Iurevych

*1

, Sergii Gubin

2

, Michel Dudeck

3

Jean le Rond dAlembert Institute, Pierre and Marie Curie University / National Aerospace University Kharkiv

Aviation Institute

4 place Jussieu 75005 Paris, France /17, Tchkalova st, 61070 Kharkiv, Ukraine

*1

yurevi.elena@yandex.ru;

2

gubinsv@d4.khai.edu;

3

michel.dudeck@upmc.fr

Abstract

A hybrid solar installation equipped with a holographic

concentrator allows converting the solar radiation into

thermal energy and photovoltaic energy. A modeling of the

different energy transfers and efficiencies is presented in

order to estimate the influence on the collected energy of the

parameters such as solar radiation, environmental

temperature and characteristics of the various elements

making up the sensor. The obtained efficiency of the hybrid

solar panel is 63%. This analysis is the first step before the

realization of an experimental facility and before a more

detailed modelling.

Keywords

Hybrid Solar Panel; Photovoltaic Panel; Holographic Concentrator

I nt r oduc t i on

The more convenient and promising system to

generate electricity at the surface of Earth from the

solar energy is the photovoltaic method using a direct

transformation by solar panels. Currently, only 5% of

the energy in Ukraine is produced by photovoltaic

transformation because of its high cost, but it's an

interesting solution for places distant of the

distribution lines of electricity. However, the

photovoltaic conversion is regarded worldwide as a

way forward among the possible non-fossil energy

resources. Intensive research is being conducted to

increase the efficiency of photovoltaic cells. Although

high efficiencies were obtained in the laboratory for

space applications (40.8% Boeing-Spectrolab in 2008,

39.7% Full Spectrum, and 41% European FP-7 program

Hiper 2009-2011), marketed solar panels have an

efficiency only 19-20%. Nowadays, the radiation of the

Sun to warm domestic water is currently used.

The solar panel previously developed in USA uses a

separation of the solar flux by a holographic sheet to

produce electricity by a photovoltaic panel. However,

this solar panel does not use the thermal sun energy.

Other hybrid panels with thermal and electric

productions are currently proposed but without

holographic separation. The originality of the

presented research on a hybrid panel is found in the

association of thermal and electric productions with

holographic film.

In the studied solar system, the concentration of the

radiation is performed by a holographic film set

between two layers of polycarbonate. The solar

radiation in the visible range (380nm-700nm) is

partially reflected by the holographic film and after

multiple surface reflections this radiation falls on the

photovoltaic cells. The device combines the

photoelectric cell and a heat exchanger that uses heat

from the heating of solar cells and solar radiation that

passes through the holographic film. The combined

device offers the possibility to use the density of solar

radiation per square meter with high efficiency. The

steady state of the installation was modeled by

introducing the intensity of solar flux, its reflection on

the surface of the collector, the transmission in the

polycarbonate, the properties of the holographic film,

photovoltaic cell and heat exchanger. This simple

model allows us to estimate the electrical and thermal

performances of the installation. It is the starting point

for a detailed analysis of this complex system. It will

contribute to defining a final optimized system. The

study will involve the definition of an optimal

operating point of the solar panel for different

conditions of solar flux, lighting change and

temperature, taking into account the effect of partial

shading. The modeling of current-voltage

characteristics of the solar panel is necessary to

optimize its design and is essential for the estimation

of the performances according to its operating

conditions.

www.seipub.org/eer Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

36

Set up

The spectrum in the visible range of the solar radiation

is reflected on the holographic film and on the inner

surface of the outer layer of polycarbonate monolith

until it falls on the photovoltaic cell that produces

electricity. The holographic film and the inner surface

of the outer layer of polycarbonate monolith play the

role in waveguides making a total internal reflection.

The thermal radiation (IR range) crosses the

holographic film and arrives on the thermal converter

(absorber). A heat transfer fluid circulates in the tubes

set in the absorber.

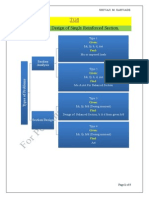

The main elements of the solar panel are a

concentrator of solar energy (holographic film), a

photovoltaic panel, and a thermal converter (FIG. 1).

FIG. 1 HYBRID SOLAR SYSTEM

1. POLYCARBONATE MONOLITH 2. CONCENTRATOR OF

SOLAR RADIATION HOLOGRAPHIC FILM 3. PHOTOVOLTAIC

CELLS 4. HEAT CONDUCTING GREASE 5. ABSORBER 6. HEAT

TRANSFER FLUID 7. INSULATION 8. BODY

A thermal grease is necessary to deflect the heat

energy arriving on photovoltaic cells in order to

reduce the temperature of the photovoltaic cells and to

increase its electric efficiency. The absorber is

insulated to reduce heat losses to its external

environment.

1 2 : VISIBLE SPECTRAL RANGE OF THE SOLAR RADIATION

3 : THERMAL SPECTRAL RANGE OF THE SOLAR

RADIATION

FIG. 2 TRANSMISSION OF THE SOLAR RADIATION

Holographic Film

The used hologram is a medium with a three-

dimensional holographic reflection that can restore the

amplitude, phase and spectral composition of the

object wave (Denisyuk hologram). Illuminated by a

white light, it re-emits a radiation in a narrow range of

wavelength which is close to that of the recording and

which forms a holographic image. The radiation

having a different frequency crosses the hologram

without effect. The three-dimensional hologram

effectively restores the image when it is illuminated

with an angle adaptive to the wavelength used for

recording. The brightness of the reconstructed image

is maximum if the incident wave is illuminating the

hologram with a Bragg angle which is a function of

incident wavelength and the geometry of the

registration system. A change in the wavelength

modifies the angle at which all the reflected waves are

added in phase. The three-dimensional hologram is

obtained when the 3D interference figure is recorded

and uses the entire depth of the recording layer. It is

formed in the mass of the gelatine film as the systems

of strata that the wavelengths used. The 3D hologram

separates the solar radiation arriving on hybrid sensor

into two spectral ranges: the visible range and the

infrared range. This hologram serves as concentrator

of the visible spectrum which reduces the amount of

used photovoltaic cells.

The holographic film is composed of polyethylene-

terephthalate and gelatin. It is covered with ethylene-

vinyl -acetate (polymer glue).

Photovoltaic Cells

The modeling was done considering AsGa solar cells

from Spectrolab.

Polycarbonate Monolith

Monolithic polycarbonate is used as protective cover

instead of glass because of its mechanical properties

which increases the lifespan of the installation because

the monolith polycarbonate presents a resistance 250

times greater than glass. The polycarbonate monolith

leaves from 88 to 93% of incident radiation (90-92% for

the glass). Another advantage of the monolithic

polycarbonate compared to glass is its density 50%

lighter than glass, reducing the weight when the

installation is placed on the roof of a house.

The polycarbonate is used as a waveguide for the

transport of radiation which is reflected several times

between the film and the polycarbonate-air interface

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013 www.seipub.org/eer

37

until it arrives on the surface of the photovoltaic cell,

placed between the films. The critical angle of

reflection between the monolithic polycarbonate

(n=1.52) and air (n=1) is 39. A total internal reflection

requires an incidence lower than 39 .

Model i ng

The different relations describing the behavior of the

all sub-elements are briefly presented. The efficiency

of the coupled thermal-voltaic solar device has been

calculated to illustrate its advantages with the use of a

set of parameters of holographic concentrator,

photovoltaic and thermal device retained as an

example to illustrate the advantages of the solar

hybrid with holographic concentrator. The used model

requires some assumptions as for the description of

current-voltage relation of the photovoltaic cells, for

the absence of heat transfer from the metallic box to

the ambient atmosphere, for the values of the different

heat exchanges parameters and for the use of a 1D

description for the heat transfer (instead of 2D or 3D

description). However, the presented model includes

the main transfer to perform a first description of a

hybrid solar captor.

Energy on the Photovoltaic Converter

The solar radiation

) / (

2

m W E

s

arrives on the surface of

the captor and due to a reflection from this surface of

the U.V. radiation, only

) / (

2

0

m W E

enters in the solid

polycarbonate layer (waveguide) and after it arrives on

the holographic film with only a density per unit

surface of

) / (

2

0

m W E k

op

(kop is the optical coefficient of

transmission of the polycarbonate layer). Then, the

holographic film re-emits the energy

h op h h

S E k k W E

0

) (

= where kh is the coefficient of

emission of the holographic film having a surface

h

S ).

FIG. 3 ENERGETIC TRANSFERS IN THE SOLAR PANEL

The photovoltaic converter (surface SPEC) receives the

energy

) (W E

h

reflected by the holographic film and the

direct solar flux:

PEC op h op h PEC

S E k S E k k W E

0 0

) (

+ = .

Taking into account the concentration coefficient kc

related to the ratio of surfaces of the holographic film

to the photovoltaic converter

PEC

h

c

S

S

k =

, the density of

radiation of energy ) / (

2

m W E

PEC

influencing the

surface of the photovoltaic converter (PEC) is:

) 1 ( ) / (

0

2

c h op PEC

k k E k m W E + =

(1)

The different transfers of energy are shown on FIG 3.

Photovoltaic Current-voltage

The characteristic voltage-current curve of the

photovoltaic system is deduced from usual and simple

relations describing the physical processes.

FIG. 4 SCHEMA OF THE ELECTRIC CIRCUIT EQUIVALENT TO A

PHOTOVOLTAIC CELL

The photovoltaic system is described with the use of

an equivalent schematic circuit which includes a

resistance Rs in series, a resistance Rsh in parallel

(shunt), a diode crossed by a current Id, and a photo-

current Ipht. Then, the characteristic current-voltage

Ich-Uch curve of photovoltaic system is written as,

sh

s ch ch s ch ch

pht

R

R I U

T

I U q

I I I

+

|

.

|

\

|

+

= ) 1

) R (

(exp

0 ch

(2)

here Id is the diode current which is expressed

as ) 1 e ( I I

0

d

V

U

0 d

= , Ud is the diode voltage as , I0) is

the reverse saturation current which is temperature

dependent and V0 is a diode parameter expressed as a

function of the diode parameter A by

e

AkT

V

0

= (k is

the constant of Boltzmann, T is the temperature and

e > 0 is the charge of electron). If one assumes that the

www.seipub.org/eer Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

38

shunt resistance is large enough to neglect the last

term in the relation (2), the current Ich becomes:

) 1

T

) R I U ( q

(exp I I

) 1 e ( I I I

s ch ch

0 pht

V

U

0 pht ch

0

d

|

.

|

\

|

+

=

= =

(3)

where the photovoltaic current Ipht is the function of

temperature T by the relation:

) )( ( ) (

* 0

* 0 * 0

T T

E

E

dI

E

E

I I

PEC

t

PEC

cc pht

=

(4)

The current Icc corresponds to nominal conditions with

a density of solar flux ) m / W ( E

2

* 0

at the

temperature

* 0

T (short-circuit current), and dIt is a

thermal parameter for the current. The relation

between photovoltaic current and photovoltaic voltage

is function of the solar radiation and temperature, and

a set of parameters describing the behavior of the

photovoltaic system (

t * 0 * 0 cc

dI , E , T , A , R , I

). In this

ideal model of Shockley, the diode parameters can be

determined as on a basis of semiconductor structure

voltage Uit (which is the voltage when the photovoltaic

circuit is opened Ich =0, Uch = Ui) as a function of

temperature is expressed as:

) (

* 0

T T dU U U

t i it

+ =

(5)

where dUt is a voltage temperature coefficient and Ui

is the floating voltage under the standard temperature

T0* (K) and illumination changing. Ui is depending on

Iopt and Io,

|

|

.

|

\

|

+ = 1 ln

0

I

I

e

Akt

U

opt

i

. This relation

allows us to calculate the parameter A from the values

of parameters Ui, Iopt, Io given by the manufacturer.

From the physical characteristic (p-n junction), the

resistance Rs in series is given by:

d t

PEC

opt

t opt

s

r T T dI

E

E

I

T T dU U

R

(

(

|

|

.

|

\

|

+

=

) (

) (

* 0

* 0

* 0

(6)

where rd = dU/dI is a differential resistance at the

beginning of illumination and Uopt is a voltage at the

optimal point. The reverse saturation current is

temperature-dependent and deduced from the short-

circuit condition

|

.

|

\

|

=

T k A

U e

exp

I

I

it

pht

0

where T is the environmental temperature. The power

delivered by solar energy plant is

PEC PEC PEC PEC u

S N E P = where

PEC

E is a month-

average, daily-average value of the energy of the solar

radiation influencing the PECs surface density (W/m

2

),

where

PEC

is the electric efficiency of the

photoconverter, NPEC is the number of cells per unit of

surface. The maximum power is given by

opt opt max

I U P =

.

Energy on the Thermal Converter

The IR solar radiation arriving on the surface of the

holographic film is

h op r

S E k k

0

where the coefficient

r

k defines the IR energy in the solar radiation (

r

k =

0.47). If one assumes that this energy is transferred to

the thermal converter, the energy ) (

1

W E

th

on the

thermal system is

h 0 op r

1

th

S E k k E

= . It is necessary to

add the energy coming from the photovoltaic system.

This energy is equal to the collected energy minus the

energy converted in electricity is written as:

) 1 )( 1 (

0

2

PEC c h PEC op th

k k S E k E + =

The total energy on the thermal system is:

) 1 )( 1 (

0 0

2 1

PEC c h PEC op h op r th th th

k k S E k S E k k E E E + + = + =

giving the following density of energy ) / (

2

m W E

th

:

| | ) 1 )( 1 (

2 1 0 PEC c h s r s op th

k k k k k E k E + + =

(7)

where

th

h

s

S

S

k =

1

and

th

PEC

s

S

S

k =

2

are ratios between the

surfaces related to the surface of the thermal converter.

A schematic description can be used to describe the

balance energy of the absorber. The received energy

from the thermal converter is

th th

S E

0

if

0

is the

optical efficiency of the converter. Moreover, this

energy is not completely given to the fluid due to the

size of the calorific fluid circuit with a factor of

exchange F. The thermal energy ) (W Q

r

received by

the fluid is

th th r

E FS Q

0

= . For the user, a loss of

thermal energy is appearing in raison of the difference

of temperature between the temperature of the fluid at

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013 www.seipub.org/eer

39

the exit of the solar captor and the ambient

temperature T. This effect can be described by a loss of

thermal energy as ) ( T T FS Q

f th l

= where

f

T is

the mean temperature of the fluid at the thermal

converter enter. Then, the user receives the thermal

energy:

| | ) (

0

T T E FS Q Q Q

f th th l r

= + =

(8)

Resul t s f or a Test Case

By way of example, numerical results are presented

for a test case in order to illustrate the advantages

combined receiver of solar radiation. The previous

relations clearly indicate that the operating conditions

of the captor are depending on many parameters:

intensity of the solar radiation, sizes of the different

elements, and their physical parameters. Typical

values are retained.

The surface of the combined receiver is 1 m

2

and the

surface of the photoconverter is 0.127 m

2

. The incident

solar radiation

0

E

is 1000 W/m

2

giving a density of

energy

PEC

E

on the photoconverter of 7648 W/m

2

from the relation (1) with kop=0.87 and kh=0.97 and a

density of energy

th

E

for the thermal conversion of 438

W/m

2

from the relation (7) with kr=0.47, ks1=0.873,

ks2=0.127, PEC=19% .

TABLE 1 PARAMETRE OF THE SOLQR CELL

siz

e

Ui Icc Uopt Iopt dIt dUt dP

t

PEC

M V A V A A/

degree

V/

degree

%

0

.

0

7

x

0

.

0

7

1

.

0

2

5

1

.

4

9

4

5

0

.

9

1

.

4

0

1

4

0

.

0

0

0

9

8

0

.

0

0

1

8

0

.

4

8

1

9

a)

b)

FIG. 5 CHARACTERISTICS OF THE PHOTOVOVERTER UNDER

DIFFERENT SOLAR RADIATIONS

) / (

2

0

m W E

EQUAL TO

200-400-600-800-1000 W/M

2

A) CURRENT-VOLTAGE B) POWER-

VOLTAGE

The electric power delivered by the photoconverter is

235 W and the heat productivity of the solar collector

is 388 W. However, the calorific fluid crossing the

thermal converter will receive a lower energy due to

loss of energy in the converter.

The characteristic curves voltage Uch - current Ich and

voltage Uch - power P= Uch. Ich of the photoconverter are

presented on FIG. 5 for different values of the density

of energy

0

E

from 200W/m

2

to 1000W/m

2

. These

curves present the classic behaviour of a photovoltaic

converter with a quasi-constant value of the intensity

as a function of the voltage Uch up a value of Uch

independent on the energy and a fall to 0 for 2.7V for

the used values of the parameters. The electric power

P presents a maximum for 22V which is independent

on the solar energy.

FIG. 6 EFFICIENCY OF THE PHOTOVOLTAIC SYSTEM

The collected thermal energy Q has been estimated

with 9 . 0 = F ,

2

1m S

th

= , 87 . 0

0

= , 5 = , K 288 T , K 301 T

f

= = ,

2

th

m / W 438 87 E =

(FIG. 7). This energy is increasing

www.seipub.org/eer Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

40

from 130W to 390W with a linear variation.

FIG. 7 THERMAL ENERGY AS A FONCTION OF SOLAR ENERGY

The photovoltaic cells have an electric efficiency

written PEC and another efficiency

el

is defined. It is

related to the global solar captor as

s sc

el

E S

P

=

where

Ssc is the surface of the solar captor. The electric

efficiency

el

is a linear function of the energy and

varying from 4% to 18% (FIG. 6).

The efficiency of the solar thermal converter is defined

as

th sc

th

E S

Q

=

. This efficiency is a linear function of

the energy and varies from 13% to 39% (FIG. 8).

FIG. 8 EFFICIENCY OF THE THERMAL SYSTEM

The efficiency of the hybrid solar panel is:

% 63

el th ph

= + =

Conc l usi on

The modeling of the voltage-current and the voltage-

power characteristic module determines the optimal

operating point when the sun lighting and ambient

temperature change. The characteristics of the hybrid

solar system were deduced from the parameters of the

solar cells from Spectrolab. The thermal heat delivered

by the heat converter has been evaluated. The hybrid

solar system provides electricity and heating. Such a

system allows using solar radiation with a high

efficiency, to reduce the size and weight. The

proposed solar system can be used for solar homes.

It is obvious that the presented modeling of the

thermal and electric transfers of energy is strongly

depending on many parameters and requires an

experimental validation, which is the next step of this

study.

REFERENCES

Andreeva, O. V., Applicative holography [Text]: Schoolbook

/ O. V. Andreeva SPb: SPbUITMO, 2008. -184p.

Bezruchko, K. V., Autonomous ground electric power

installations on renewable sources [Text]: schoolbook /

K. V. Bezruchko, S. V. Gubin Kharkov: National

Aerospace University Kharkov aviation institute, 2007.

300 p.

Bordina, N. M., The simulation of volt-amps diagrams of

edge-illuminated solar cells and solar batteries [Text]/

N.M. Bordina, V.A. Letin M.: Informelectro, 1986 62p.

Iurevych, O., Gubin, O., Dudeck, M., Concentrateur pour

un capteur solaire hybride, Second International

Conference on Renewable Energy, 15-16 Avril 2012, Bejaia,

Algeria.

Iurevych, O., Gubin, S., Dudeck, M., Combined receiver of

solar radiation with holographic planar concentrator, 1

st

International Symposium on electrical Arc and Thermal

Plasma in Africa, 17-22 oct. 2011.

Iurevych, O., Gubin, S., Modlisation mathmatique des

installations solaires combines avec concentrateurs du

rayonnement solaire, Congrs Franais de Thermique,

Perpignan, France, 24-27 May 2011.

Ouagadougou, Burkina-Faso, IOP Conference Series:

Materials Science and Engineering Physics 29 (2012)

012016.

Patent number : US 5,877,874 Date of Patent : Mar. 2, 1999

Device for concentrating optical radiation Invertor :

Glenn A. Rosenberg, Tucson, AZ (US).

Patent number : US 6,274,860 B1 Date of Patent : Aug. 14,

2001 Device for concentrating optical radiation Invertor:

Glenn A. Rosenberg, Tucson, AZ (US).

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013 www.seipub.org/eer

41

Products-Space-Cells-Single Junction Solar Cells-GaAs/Ge

Single Junction Solar Cells [Electronic asset]

mode:http://www.spectrolab.com.20.11.2009.

Olena Iurevych was born July 30, 1988 in Kharkiv (Ukraine).

Secondary school (1995-2003). Aerospace lyceum of

National Aerospace University Kharkiv Aviation Institut.

School leaving certificate. She has mastered a program of

elective courses Basis for Aerospace Technology (2003-

2005). Diploma Bachelor Energetics of National Aerospace

University Kharkiv Aviation Institut, qualification power

engineering specialist engineer (2009). Diploma Master

Renewable energy of National Aerospace University

Kharkiv Aviation Institut, qualification research engineer

(2010). Participate in the conferences scientific of National

Aerospace University Kharkiv Aviation Institut and of

The National Aerospace Educational Center of Youth

(2009-2010). Study course in National Aerospace University

Kharkiv Aviation Institut (2010). Participate in the

conference Socit franaise de physique, Perpignan, France,

24-27 may, Modeling of renewable energy installations

combined for energy production with solar concentrator

Iurevych Olena, Gubin Sergii (2011). Jointly supervised

doctoral thesis. Ph.D. thesis preparation under supervision

between the University Pierre et Marie Curie, PARIS VI

(France), hereinafter referred to as UPMC and National

Aerospace University Kharkiv Aviation Institute,

hereinafter referred as KhAI (Ukraine) (2011). Patent in

Ukraine 2010 06698 31.05.10 Combined solar installation

patent owners: Olena Iurevych, Sergii Gubin (2012).

Sergii Gubin was born December 5, 1958 in Kharkiv

(Ukraine). Bachelor degree, specialist in Kharkiv State

College of Ration Enginnering (1978). Masters degree,

Electromechanical in National aerospace University KhAI

(1984). Ph.D in National aerospace University KhAI

(1998). He is Head of Department of Thrusters and Power

Systems of Spacecrafts of the National Aerospace University

"KhAI" and also is an associate professor of this department.

He specializes in structures of autonomous and assured

power supply systems, modeling of the processes in power

supply systems of spacecrafts and plants of assured power

supply, photovoltaic transformation of energy,

electrochemical accumulation of energy, research of the

processes in energy converters and accumulators. He has

lectured over ten years at the National Aerospace

University"Kharkiv Aviation Institute". In addition to

working for the National Aerospace University, Sergey

Gubin has participated in several research projects on

demand of companies and industry leading enterprises of

Ukraine and nearby countries, such as Central Specialized

Design Office, Samara, Russia, Research-and-Production

Complex Saturn, Krasnodar, Russia, Design Office

Department of Production Association Kharkiv electrical

equipment plant, Kharkiv, Ukraine, State Design Office

Yuzhnoye, Dnepropetrovsk, Ukraine, Institute of

Semiconductor Physics of National Academy of Sciences,

Kiev, Ukraine, Research Technological Institute of

Instrument, Kharkiv, Ukraine. He has participated in the

international research project TEMPUS/TACIS.

Michel Dudeck was born August 9, 1945 in Paris. He

obtained two PhD (1972 at the University Pierre and Marie

Curie (UPMC) at Paris: Study of boundary layers in fluid

mechanics, 1982 at the UPMC at Paris: State doctorate on

Thermodynamics) and a Habilitation in 1987 at the UPMC.

He is a professor at the University Pierre and Marie Curie

(Paris 6) since 1988 and Assistant Professor from 1969 to

1988. He teaches Fluid Mechanics, Thermodynamics and

Thermal systems. He was director of the French research

group CNRS/CNES/SNECMA/Universities Propulsion

Spatiale par plasma " from 1996 to 2011. His research activity

is carried out at the Jean Le Rond d'Alembert Institute at the

University Pierre and Marie Curie. His research concerns the

propulsion of satellites by Hall effect plasma thruster,

plasma reentry in planetary atmospheres and

thermodynamics of energetic systems (reverse osmosis, solar

panels). Prof. Dudeck is member of the Societe Francaise de

Physique (SFP) and the Association dAronautique et

dAstronautique de France (AAAF).

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Handbook5 PDFDocumento257 páginasHandbook5 PDFZAKROUNAún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Virtual Work 3rd Year Structural EngineeringDocumento129 páginasVirtual Work 3rd Year Structural EngineeringStefano Martin PorciunculaAún no hay calificaciones

- Centrifugal CastingDocumento266 páginasCentrifugal Castinguzairmetallurgist100% (2)

- Maintenance of Mining MachineryDocumento22 páginasMaintenance of Mining Machineryjorgeluis2000100% (1)

- International Chemistry Olympiad Problems Volume 03 (2009-2013)Documento291 páginasInternational Chemistry Olympiad Problems Volume 03 (2009-2013)Science Olympiad Blog75% (4)

- Tensile Strength of Mass Concrete 913-938 PDFDocumento28 páginasTensile Strength of Mass Concrete 913-938 PDFchutton681Aún no hay calificaciones

- Physics: Pearson EdexcelDocumento16 páginasPhysics: Pearson EdexcelRichard Davidson12100% (1)

- Mill's Critique of Bentham's UtilitarianismDocumento9 páginasMill's Critique of Bentham's UtilitarianismSEP-PublisherAún no hay calificaciones

- Redesign of Scott Bicycle Frame AnalysisDocumento11 páginasRedesign of Scott Bicycle Frame Analysisraghunath670743Aún no hay calificaciones

- PCAB List of Licensed Contractors For CFY 2017-2018 As of 19 Sep 2017 - Web2Documento175 páginasPCAB List of Licensed Contractors For CFY 2017-2018 As of 19 Sep 2017 - Web2Paige Lim76% (21)

- Extrusion Press PDFDocumento2 páginasExtrusion Press PDFRobert25% (4)

- Thermal Analysis of Albendazole Investigated by HSM, DSC and FTIRDocumento8 páginasThermal Analysis of Albendazole Investigated by HSM, DSC and FTIRElvina iskandarAún no hay calificaciones

- Contact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentDocumento7 páginasContact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentSEP-PublisherAún no hay calificaciones

- Improving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesDocumento5 páginasImproving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesSEP-PublisherAún no hay calificaciones

- Influence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearDocumento13 páginasInfluence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearSEP-PublisherAún no hay calificaciones

- Experimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesDocumento8 páginasExperimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesSEP-PublisherAún no hay calificaciones

- Device For Checking The Surface Finish of Substrates by Tribometry MethodDocumento5 páginasDevice For Checking The Surface Finish of Substrates by Tribometry MethodSEP-PublisherAún no hay calificaciones

- FWR008Documento5 páginasFWR008sreejith2786Aún no hay calificaciones

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocumento5 páginasMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherAún no hay calificaciones

- Enhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentDocumento6 páginasEnhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentSEP-PublisherAún no hay calificaciones

- Effect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesDocumento11 páginasEffect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesSEP-PublisherAún no hay calificaciones

- Reaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesDocumento9 páginasReaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesSEP-PublisherAún no hay calificaciones

- Microstructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesDocumento7 páginasMicrostructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesSEP-PublisherAún no hay calificaciones

- Mindfulness and Happiness: The Empirical FoundationDocumento7 páginasMindfulness and Happiness: The Empirical FoundationSEP-PublisherAún no hay calificaciones

- Delightful: The Saturation Spirit Energy DistributionDocumento4 páginasDelightful: The Saturation Spirit Energy DistributionSEP-PublisherAún no hay calificaciones

- Enhanced Causation For DesignDocumento14 páginasEnhanced Causation For DesignSEP-PublisherAún no hay calificaciones

- Ontology-Based Testing System For Evaluation of Student's KnowledgeDocumento8 páginasOntology-Based Testing System For Evaluation of Student's KnowledgeSEP-PublisherAún no hay calificaciones

- Quantum Meditation: The Self-Spirit ProjectionDocumento8 páginasQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherAún no hay calificaciones

- Isage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophyDocumento8 páginasIsage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophySEP-PublisherAún no hay calificaciones

- Cold Mind: The Released Suffering StabilityDocumento3 páginasCold Mind: The Released Suffering StabilitySEP-PublisherAún no hay calificaciones

- A Tentative Study On The View of Marxist Philosophy of Human NatureDocumento4 páginasA Tentative Study On The View of Marxist Philosophy of Human NatureSEP-PublisherAún no hay calificaciones

- Legal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialDocumento4 páginasLegal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialSEP-PublisherAún no hay calificaciones

- Social Conflicts in Virtual Reality of Computer GamesDocumento5 páginasSocial Conflicts in Virtual Reality of Computer GamesSEP-PublisherAún no hay calificaciones

- Technological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsDocumento9 páginasTechnological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsSEP-PublisherAún no hay calificaciones

- Architectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldDocumento5 páginasArchitectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldSEP-PublisherAún no hay calificaciones

- Metaphysics of AdvertisingDocumento10 páginasMetaphysics of AdvertisingSEP-PublisherAún no hay calificaciones

- Computational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpDocumento6 páginasComputational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpSEP-PublisherAún no hay calificaciones

- Damage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationDocumento10 páginasDamage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationSEP-PublisherAún no hay calificaciones

- The Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateDocumento8 páginasThe Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateSEP-PublisherAún no hay calificaciones

- Phet ReflectionDocumento3 páginasPhet Reflectionapi-260335088Aún no hay calificaciones

- Chapter 4Documento36 páginasChapter 4Sumedh KakdeAún no hay calificaciones

- Static Mixers for Solid-Solid MixingDocumento8 páginasStatic Mixers for Solid-Solid MixingSalsa_Picante_BabyAún no hay calificaciones

- Numericals - RajasthanUniversity - Papers End Sem ChemDocumento20 páginasNumericals - RajasthanUniversity - Papers End Sem ChemJanmendraAún no hay calificaciones

- KIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITDocumento2 páginasKIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITSorinAún no hay calificaciones

- MIT2 080JF13 Lecture2 PDFDocumento26 páginasMIT2 080JF13 Lecture2 PDFAbhilashJanaAún no hay calificaciones

- Modeling Arterial Blood Flow With Navier-StokesDocumento15 páginasModeling Arterial Blood Flow With Navier-Stokesapi-358127907100% (1)

- ROCKYDocumento4 páginasROCKYNelson Alexander Aponte SimbronAún no hay calificaciones

- Metalic AsDocumento16 páginasMetalic AsKarencita Genesis LapibaAún no hay calificaciones

- SOAL ElmesDocumento16 páginasSOAL ElmesNurul HanifahAún no hay calificaciones

- How Does DCPIP WorkDocumento3 páginasHow Does DCPIP WorkIsaac LeeAún no hay calificaciones

- Vibration assignment on 3DOF cantilever beam systemDocumento5 páginasVibration assignment on 3DOF cantilever beam systemIzzah 'AtirahAún no hay calificaciones

- Soil Testing Procedures For Calcareous SoilsDocumento5 páginasSoil Testing Procedures For Calcareous SoilsDoThanhTungAún no hay calificaciones

- Egee 101 Reflective Essay 1Documento3 páginasEgee 101 Reflective Essay 1api-142590237Aún no hay calificaciones

- Marking Scheme Physics Trial SPM SBP 2016 Paper 3Documento6 páginasMarking Scheme Physics Trial SPM SBP 2016 Paper 3Anonymous UypCttWAún no hay calificaciones

- Mapua Institute of Technology: Field Work 1 Pacing On Level GroundDocumento7 páginasMapua Institute of Technology: Field Work 1 Pacing On Level GroundIan Ag-aDoctorAún no hay calificaciones

- Mechanics WorksheetDocumento64 páginasMechanics WorksheetyeosiewliAún no hay calificaciones

- Notes Singly RF BeamDocumento5 páginasNotes Singly RF Beamshivaji_sarvadeAún no hay calificaciones

- Electrostatic Discharge Ignition of Energetic MaterialsDocumento9 páginasElectrostatic Discharge Ignition of Energetic Materialspamos1111Aún no hay calificaciones