Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Internship ReportInternship Report

Cargado por

Hemanth KumarTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Internship ReportInternship Report

Cargado por

Hemanth KumarCopyright:

Formatos disponibles

JK TYRE & INDUSTRIES LTD.

, VTP MYSORE

INTRODUCTION

INDUSTRY PROFILE

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

INTRODUCTION The world rubber industry had made its beginning in the year 1887 with the invention of the rubber vulcanization process by Mr. Charles Goodyear. However, the growth of the industry received a big boost towards the end of the century when Mr. John Boyd Dunlop succeeds in the making vulcanized rubber in to inflatable pneumatic tyre in1888. Since then the tyre industry has continued to be a major segment of rubber industry all over the world. Even in India, automobile tyre & tubes account for a major part of Indian rubber product industry. HISTORY OF TYRE INDUSTRY The following chronicles development of the tyre industry as we know it today. Mr. R W Thomson invented & patented the pneumatic tyre in 1845. In his first design used a number of thin inflated tubes inside a leather cover. This helped in the later development in the tyre design. Mr. Dunlop first advertised his tyres in December 1888 in The Irish Cyclist, & attracted major attention in the following years. A Belfast cycle won the race on the pneumatic rubber tyres & gained attraction of the public. But unfortunately the original tyre has its own drawbacks. The inner tube was difficult to place inside the tyre & also it stuck to the wheel. In 1890 Mr. C K Welsh patented the design of a wheel rim & outer cover with inextensible lip. By now we had the basics for todays tyres. Over the years, the tyre has been developed in to todays high technology offerings by considering two of the most important technical development include Michelins creation of the redid tyre with its vastly superior grip in 1948,& the developments made by when Dunlop did away with the inner tube on car tyres in1972. Over the increase in technology aspects, the tyre has many features includes high speed racing, such as formula one to deliver a comfortable ride, have a relative puncture resistance, wear & tear resistance. Tyre industry in India

AL-AMEEN Institute of Management Studies, Bangalore 2

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Indian was about 60 years old. It becomes one of the core industry sectors in India which comes under Essential commodities Act. The history of the Indian tyre industry could be divided in to following periods: 1920 to 1935 (multinational trading in tyre) 1935 to 1960 (multinational manufacturing era) 1961 to 1974 (broadening of production base) 1975 onwards Broadening of production bases

Trading tyres in India was first started in 1920 by Firestone at Mumbai, followed by Goodyear in 1922 & later by Dunlop in 1926.Dunlop set up the first tyre factory at saharganj, West Bengal in the year 1936..At present there are 20 licensed companies & 24 factories which included 11 large companies manufacturing the full range of tyres & tubes. The Indian tyre companies are having collaboration with tyres companies of U.S.A, U.K, West Germany & Japan. Significant changes occurred in the tyre manufacturing process, change over from rayon to nylon & introduction of radial tyres of both steel belt & fiber glass are most important. The large Tyre units are Apollo, Bombay Tyres International, Ceat, Dunlop, Goodyear, J.K Modi, M.R.F, and Premier, TCI, VTL, and Birla Tyres. The company which manufactures tyres primarily for two and three wheelers are Metro tyres, Sri Chakra, Falcon, stallion, Transport, S.kumars. The production of tubes by the large & medium sector is 80% of the tyre production. The tubes are manufactured from natural rubber as well as from imported butyl rubber. Tyre inner tubes are covered under packaged commodities Act. The government has set up various committees in 1955 includes tariff commission whose function is to decentralization of the tyre industry. Between 1974 & 1985 the government set up the Bureau of industry cost & price (BICP) to study the cost & price of tyre industry, but the study report of

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

BICP were not made public. In May 1974 the government set up a committee on the tyre industry with Mr. M Satyapal as chairman. The committee submitted its report to the government in 1985. Report has not been published. MRF, Ceat, Dunlop, Apollo & Modi rubber dominates the industry together accounting for much as 60% of total output. Among individual companies, MRF is moving in to aircraft tyre manufacturing in collaboration with Royal Goodrich Company. The total capacity of Ceat has gone up to 45 lacks tyres with the commence of Walaj plant & has plans to manufacture nylon cord tyres. Vikrant tyres with a new all steel radial tyre plant & have plans to manufacture nylon cord tyres. A Vikrant tyre with a new all steel radial tyre plant for trucks and buses is the only company modernizing the existing plant and manufacturing and new technological tyres of international standards and acceptability, Indian tyre industry is all set to capture a major share in export market & increase its share export of various countries. The tyre industry is a raw material intensive industry. Raw materials account for about 55% of the production cost. The major raw materials used in the tyre making i.e., nylon fabric cord & synthetic rubber are petroleum based derivatives. In India the ratio of the synthetic rubber to the natural in the profile of the raw materials consumption is approximately 20:80, which stands in contrast to the ratio of 70:30 for developed countries. The natural rubber is more resistant & is there fore more suitable to Indian roads. PRESENT STATUS OF TYRE INDUSTRIES Automotive tyre manufactures association (ATMA) set up in 1975 as a representative body of automotive tyre industry in India. The association constitutes of companies manufacturing tyres ranging from animal driven vehicles to aero tyres for defense applications. The association represents approx. 90% of the tyre production in the country. The association forms the bridge between government and tyre industries. According to ATMA demand for tyres for estimated at 242 lakh tyres in 1991 and 1992 against installed capacity of 296 lakhs tyres and demand estimate for the year 1994 to 1995 where 287.16

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

lakhs tyres against the production of 308 lakhs and still growing at a very rapid pace. Among the individual companies MRF is moving into aircraft tyres and formula racing tyres manufacturing in collaboration with uniroyal good rich. The total capacity of Ceat tyres has gone up to 45 lakhs with commencement of nylon cord tyres. Modi rubber tyre industry ahs modernized the modipuram plant and modinagar plan is under implementation. Vikrant tyres with a new plant for all steel radial tyre for trucks and busses fare the first company in India with such a state of art technology, Vikrant tyres after taken over by JK tyres are having a major supplier of tyres to various countries and are no way short of foreign companies in terms of quality and quantity. INPUTS FOR TYRE INDUSTRIES The major raw materials and there weightage in the total raw material structure are as follows SL no. 1 2 3 4 (Remaining chemicals) NATURAL RUBBER It is the most important rubber material used in the manufacture of tyres, natural rubber accounts for about 10%(by requirement in the production of the tyres. The productivity of natural rubber in India is one of the highest in the world, but still India is facing shortage of the natural rubber. The tyre industry consumes about 48% of the natural rubber produced in the country. Till in the year 1988, the government controls the price of the natural rubber. Where as now the government fixes based on the bench mark price which helps the small weight) of the total raw material RAW MATERIALS PERCENTAGE

Natural rubber 25% Synthetic rubber 14% Carbon black 13% Nylon Fabric cord 34% share of raw materials of 14% approx. is accounted by rubber

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

farmers to maintain the margins. There is no ceiling on the maximum price. Due to the above prices of natural rubber has been fluctuating from time to time. SYNTHETIC RUBBER Styrene Butadiene Rubber (SBR) manufactured from petroleum feed stock mainly used for passenger car, jeep and LCV tyres. POLY Butadiene Rubber (PBR), also manufactured from petroleum feed stock mainly used in heavy duty truck tyres. BUTYL RUBBER is a synthetic rubber mainly used for making inner tubes used in the tyres. Entire quantum of 24000 MT of this variety of the tube is consumed in 1996 to 1997 was imported as no company in Indian manufactures this kind of the synthetic rubber. The VTL consumed approx. of total 16679 MT of natural and synthetic rubber during 1999 to 2000 for a capacity utilization level of 62% approx. and the cost of the above quantum is RS.6096.58 lakhs. CARBON BLACK It is petroleum based inorganic chemical in a form of quasi graphite powder of extreme fineness and with high surface area composed of elemental carbon. The main inputs required in the manufactures of carbon black are carbon black feed stock (CBFS) and furnace oil. Carbon black is divided into two grades viz., soft and hard grades. Soft grade carbon black is used inside the ply. For the coating of fabric and treads in the tyres the hard grade is used about 60% of carbon black produced in India are of soft variety. VTL has consumed carbon black amounting to 7324 MT of the total raw materials consumed during the 2005 to 2006. NYLON YARN/FABRIC/TYRE CORD It is an essential reinforcement material. The nylon tyre yarn in terms of cost of raw materials is account of about 27%. Caprolactum is a major raw material used in the manufacture of nylon tyre cord. It imparts strength and tenacity to the tyre. It also reduces the ware and tear of the tyre. The tyre cord is placed below the tyre tread, which is in contact with the road.

AL-AMEEN Institute of Management Studies, Bangalore 6

JK TYRE & INDUSTRIES LTD., VTP MYSORE

FUNCTION OF TYRES Tyre provides steering response. Durable and easy to drive. Has load carrying capacity. Provides cushioning ability. Cooler running and gives more mileage. Passenger safety. Supplies load holding ability.

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

JK PROFILE

JK TYRE INDUSTRIES A BRIEF PROFILE COMPANY PROFILE NAME ADDRESS : JK Tyre &Industries ltd : JK Tyre & Industries ltd VIKRANT TYRE PLANT KRS road, metagalli,

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Mysore-570002. CONSTITUTION DATE OF INCORPORATION PRODUCT REGISTERED OFFICE : Limited Company : October 3, 1973 : AUTOMOBILE tyres, flaps :VIKRANT HOUSE NO.4, first main road V.V mohalla, mysore-02 COMMUNICATION LINKS GRAMES E-mail FAX: TELEPHONE NO. : Vikrant Tyres : hrd@vikrant.com :( 0821)2582404 :( 0821) 2511540, 2582954

COMMENCEMENT OF BUSINESS : October 11, 1973

JK organization owes its name to late Lala Juggilal Singhania, a dynamic personality with broad vision. Inspired by the cause of the Swadeshi movement of Mahatma Gandhi, & driven by the zeal to set up an Indian enterprise, Lala Kamlapat Singhania founded JK organization in the 19 th century ushering in new industrial era in India. The process of industrialization & diversification was worthily & successfully carried on by Lala kamlapats three illustrious sons- Sir Padampat, Lala Kailashpat & Lala Lakshmipat. Excellence comes not from mere words or procedures. It comes from an urge to strive and deliver the best. A mindset that says, when it is good enough, improve it. It is a way of thinking that comes only from a power within." H.S SHINGHANIA JK Tyre & Industries Ltd. is the flagship company under the umbrella of JK Organization The advent of JK Organization on the industrial landscape of India almost synchronizes with the beginning of an era of industrial awareness - an endeavor

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

for self reliance and the setting up of a dynamic Indian industry. This was way back in the middle of the 19th century. CORE VALUES JK Organization has been a forerunner in the economic and social advancement of India. It always aimed at creating job opportunities for a multitude of countrymen and to provide high quality products. It has striven to make India self reliant by pioneering the production of a number of industrial and consumer products, by adopting the latest technology as well as developing its own know-how. It has also undertaken industrial ventures in several other countries. JK Organization is an association of industrial and commercial companies and charitable trusts. Its member companies, employing nearly 50,000 persons are engaged in the manufacture of a variety of products and in diverse fields of commerce Trusts are devoted to promoting industrial, technical and medical research, education, religious values and providing better living and recreational facilities. With the spirit of social consciousness uppermost in mind, J.K. Organization is committed to the cause of human advancement. Today JK Organization, an association of Industrial and commercial companies and charitable trusts, continues to grow to greater heights under the stewardship of its President, Shri Hari Shankar Singhania. The Principal business of the JK Organization includes Tyre, Paper, Cement, Drugs & Pharmaceuticals, Agri Genetics, Dairy and Food Products, Audio Magnetic Tapes, Sugar, Cosmetics, Woolen Textiles, Steel, Engineering Files, International Trading, Hybrid Seeds, Industrial Rubber Products, Material Handling System etc The group besides having a consistent record of growth and diversification has created a reputation for quality for all its products and most of its products enjoy a leadership status in their respective market segments. BEYOND BUSINESS

AL-AMEEN Institute of Management Studies, Bangalore

10

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Identifying with social issues and contributing to the society has been a philosophy, which has been carried on from the founding fathers. Various institutions set up by the group throughout India in diverse fields of social welfare stand testimony to this philosophy. HEALTH CARE ACTIVITIES Involved with the diverse array of medical and health services, the organization has set up a number of pioneering institutes all over the country including super specialty hospitals. Pushpawati Research Institute, New Delhi for Liver, Renal and Digestive Diseases is the first of its kind in India. HASETRI (Hari Shankar Singhania Elastomer and Tyre Research Institute) JK Tyre attaches tremendous value to R&D in its efforts to maintain the high quality of its products and lead the field in innovation. HASETRI, a world class research and development centre is a symbol of this. The Hari Shankar Singhania Elastomer & Tyre Research Institute (HASETRI) is the very first of its kind in India. Established in October 1991, HASETRI has already been recognized under SIRO (Scientific and Industrial Research Organization) by the Department of Scientific & Industrial Research (SDIR), Govt. of India. And has been acknowledged by the Indian Institutes of Technology (IITs) and other universities for registration leading to higher studies. HASETRI fulfills the research requirements for services related to the Elastomer and Tyre industry

LIBRARY AND INFORMATION CENTRE HASETRI is a data repository par excellence where up-to-date information can be accessed on related disciplines. Numerous national and international journals, periodicals, books, technical reports, standards on the latest developmental work are available. As a member of these institutes, HASETRI can source literature from the Indian National Scientific Documentation Centre

AL-AMEEN Institute of Management Studies, Bangalore

11

JK TYRE & INDUSTRIES LTD., VTP MYSORE

(INSDOC) unit of the Centre for Scientific and Industrial Research (CSIR) and the Foundation of Innovation and Technology Transfer (FITT), Indian Institute of Technology (IIT), New Delhi. ACADEMIC ASSOCIATIONS HASETRI acts as a bridge between academia and industrial circles and promotes better interaction between the two. Some areas where HASETRI is involved are: Jointly running a Diploma Course in Polymer Science and Rubber Technology with Mohanlal Sukhadia University, Udaipur Technical manpower development through the Indian Rubber Institute (IRI); organizing refresher courses for industrial personnel Sponsored Research Programmes with the Indian Institutes of Technology (IITs) and other universities are leading to an M.Tech and Ph.D. degrees. Jointly sponsored National/International Rubber Conferences/Seminars Associated with BIS and ISO for standardization of specification and test methods for raw material and finished products related with rubber and allied industries.

MEMBERSHIPS Department of Scientific and Industrial Research(DSIR) Bureau of Indian Standards (BIS) Indian National Scientific Documentation Centre (INSDOC) Foundation for Innovation and Technology Transfer (FITT), Indian Institute of Technology (IIT), New Delhi.

AL-AMEEN Institute of Management Studies, Bangalore 12

JK TYRE & INDUSTRIES LTD., VTP MYSORE

JK TYRES PLANTS Kankoli Banmore Mysore plant-I (VTP) Mysore plant-I (VTP Radial) :Rajasthan :Madhya Pradesh :Karnataka :Karnataka

MILESTONES OF J.K.INDUSTRIES LTD

AL-AMEEN Institute of Management Studies, Bangalore

13

JK TYRE & INDUSTRIES LTD., VTP MYSORE

1933 1940

First in the India to manufactures calico princes-Juggilal Kamlapat Cotton Spinning and Weaving Mils Co., Kanpur. First in India to manufacture steel bailing hoops for jute and cotton and to make the country self sufficient by meeting the entire demand J.K.Iron and Steel Co.,Ltd., Kanpur First in India to produce Aluminum virgin metal from Indian Bauxite Aluminum Corporation of India Ltd., Jaykaynagar.

1944 1949 1959 1960

First in India to manufacture Engineering Files -J.K.Engineers Files, Bombay.

First in India to set up a continuous process Rayon plant. First to manufacture a Hydraulically operated cane crushing mill for Khandsari Sugar Plant and completed 100 ton plant- J.K.Iron and Steel Co. Ltd., Kanpur. First in world to set up a plant for production of Hydrosulphite of Soda by Sodium Amalgam process-J.K.Chemicals Ltd., Bombay. First in India to produce Nylon-6 with its own polymerized raw material-J.K.Synthetics Ltd., Kota. First to produce Sodium Sulphoxylate Formaldehyde (Rangolite c of Formosul) in India J.K.Synthetics Ltd., Kota. First to manufacture TV sets in India-J.K.Electronics, Kanpur. First to manufacture Metallic. Cops for Synthetic Filament yarn industrial in India-Syntax tube works, Kanpur First in India to license Synthetic Fiber Technology to third party as well as the first to manufacture Synthetic Filament yarn industrial in India-Syntax tube works, Kanpur. First in India to produce Steel Belted Radial Tyres fro passenger cars, trucks and buses-J.K. Tyre Plant, Kankoli.

1961 1962 1965 1968

1973

1976

AL-AMEEN Institute of Management Studies, Bangalore

14

JK TYRE & INDUSTRIES LTD., VTP MYSORE

1980 1984 1985

First in world to make Steel Belted Radial Tyres for passenger cars, trucks and buses-J.K.Tyre Plant, Kankoli. First in India to produce White Cement through dry processJ.K.White Cement, Gotan. First to India to produce Cathonic Dyeable Polyester Fiber J.K.Synthetics Ltd., Kota. First in India to produce Nylon Tyre cord base on Spin Draw Technology- J.K.Synthesis Ltd., Kota. First to India to produce Magnetic Tapes with Cobalt Technology J.K.Magnetics, Surpajpur. Banmore Tyre Plant (BTP)set up with a capacity of 5.7 lakhs tyres p.a. R & D Centre set up at HASTERI. Indias first T-Rated tyre launched BANMORE Tyre Plant (BTP) crossed 100TPD. Mercedes Benz launched on J.K.STEEL RADIALS First tyre manufacturer in the world to get ISO 9001. Awarded the National Export Award for 1996-97 Vikrant Tyres (VTL) acquired. Indias firs H rated tyre launched. Only tyre manufactures to getE mark certification. HASETRI becomes the first research institute in Asia to get ISO 9002. Indias first dual contact high traction Steel Radial aqua sonic Launched. Introduces Steel Wheels. First tyre manufacturer in the world to get Qs 9000. Awarded CAPEXILs highest export award for 1997-98 Synergy with VTL in procurement, marketing and production flexibility. Completion of Stat of the art modernization of truck radials. J.K.Tyres ranked 1st largest Tyre Company in the world. ISA-14000 accredition for environment and safety. J.K. introduced National Go-karting Champion slips. J.K. industrial received FOCUS LAC export award for he year 1999-2000.

1989 1991 1992 1994 1995 1997

1996 1998 1999

2000 2001

VIKRANT TYRES LIMITED- AN OVERVIEW

AL-AMEEN Institute of Management Studies, Bangalore 15

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Vikrant Tyres ltd (VTL), the company is situated in the area of 53 acres in mysore.VTL is a major tyre manufacturing company & one of the most successful industrial ventures in the state of Karnataka. In the year 1970 this company was become joint venture by the participation of the South Indian Export Company Pvt Ltd., Madras with Karnataka State Industrial Investment & Development Corporation Ltd., (KSIIDC). For establishing an automobile tyres & tubes manufacturing unit Metagalli industrial area Mysore. In 1977 the management was controlled by the government of Karnataka through Karnataka State Industrial Investment & Development Corporation Ltd., (KSIIDC). The commercial production started from 19th may 1980. During 1985 a pilot plant was set up for manufacturing of radial tyres. Commercial production of radial tyres was started in Feb 1991 at the new radial tyre plant. J.K. Industries acquired Vikrant Tyres Limited, Mysore in 1997 because To keep pace with the market demand as well as technological leadership in Indian market.JK industries & Vikrant Tyres Limited are the only tyre companies in India to have received all three ISO 9001, QS 9000 and ISO 14001 certificates. The company is now racing ahead by focusing on exports & the synergy in sales & marketing operations with JK Tyre has enabled VTL to expand its distribution network. It is now exporting truck tyres to over 55 countries across 6 continents including North, Central and South America, and the Middle East and South East Asia. New markets are being continuously explored to expand the multi brand international sale. MILESTONES OF VIKRANT TYRES LIMITED Joint Venture by SIEC Pvt. Ltd., and KSIIDC conceived to 1970 1973 1977 manufacture Automotive Tyres and Tubes at Mysore. Incorporated as a joint venture company by KSSIDC and SIEC Pvt. Ltd., Madras(Chennai) Taken Over by Government OF Karnataka through KSIIDC

16

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

1980 1982 1985 1989 1991 1992 1994 1997 1999

Commercial Production Commenced Collaboration with M/s AVON Tyres UK. T-Pilot plant setup for manufacturing of truck Radial Tyre Plant. Construction of new Truck Radial Tyre Plant. Commercial Production of all steel Truck Radial Tyre. First against OTR tyre rolled out. Certified to IS 9001: 1994 quality management systems. JKIL inducted as strategic Alliance Partner (SAP) by government of Karnataka Certified to QS 9007:1998 QMS and also 14001:1996 Ems. Turnaround under JK management within 10 months and declared divided after a gap of 6 years. Massive modernization and up gradation investing Rs. 224.13 Crores. March Bias plant Rs. 73.16 Crores. December Truck Radial plan Rs .150.97 Crores. Merged with JKIL. Certified to ISO/RS 16949:2002 process based QMS. First Indian tyre company to adopt process based management through Business Process Re-Engineering (BPR)

2000 2003 2004

INFRASTRUCTURAL FACILITIES IN VIKRANT 1) CANTEEN According to the section 48(1) it is obligatory on the part of every factory to provide canteen facility where in more than 200 employees are employed and hence Vikrant also provides canteen facility for its employees, which is well constructed, furnished with good furniture, equipments and also with good accommodation. Here 100% subsidy is provided for meals, coffee and tea, snacks is supplied with subsidy up to Rs.300 per month. 2) GROUP HOSPITALIZATION SCHEMES This scheme covers employee, spouse and two children. The workers whose salary is more than 7500 per month are covered under ESI and they are paid through ESI. But the ESI exempted employees are covered for a sum of

AL-AMEEN Institute of Management Studies, Bangalore

17

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Rs. 20,000 per annum. Spouse and 2 children are covered for Rs. 15,000/- each per annum. One time financial assistance is provided to spouse and any 2 children suffering from the illness of serious nature and requiring prolonged treatment in respect of Heart/blood related illness. Brain related illnesses Kidney problems All types of cancerous diseases.

The assistance is restricted to 50% of the expenses incurred by them towards hospitalization expenses, diagnostic, and consultative charges subject to a maximum of forty thousand rupees only. 3) GROUP GRATUITY SCHEME Gratuity is paid to the dependents for the future service of the deceased employee if he had continued in service gratuity is calculated as compulsory 5 months salary for the left years of service or 5 months salary for the years of service rendered.

4) ASSISTANCE FOR THE FAMILY OF DECEASED EMPLOYEE Assistance of Rs.50, 000/- is contributed from the management to the family of the decreased employee. 5) BENEVOLENT FUND Both the employee and the employer contribute towards benevolent fund. Employee contributes Rs.5 per month and employer contribution is Rs.10 per month.Through benevolent fund Rs. 50,000/- is paid to the deceased employees family, Rs.75,000 towards major illness Rs.40,000 to spouse 2 children and refundable advances is given up to father/mother of employee. 6) FAMILY PLANNING Rs.20,000 in case of serious illness to

AL-AMEEN Institute of Management Studies, Bangalore

18

JK TYRE & INDUSTRIES LTD., VTP MYSORE

If the employee undergoes family planning the management will pay RS.300/- Cash incentive and also provides 7 days leave. 7) INTEREST SUBSIDY ON HOUSING LOAN Housing loan is provided by the company. The maximum amount paid is three lakhs of over and above 9% interest. 8) CONSUMER CO-OPERATIVE SOCIETY There is a separate building for this society. Working capital is provided by the company. Consumers Co-operative Society is run by workers or Management Representative on no-profit, no loss basis. Election is held every year to appoint the office bearers of this society. Here credit facility is provided to its members 9) INCREMENTS FOR ACQUIRING QUALIFICATIONS To encourage employees to pursue studies, additional increment is given to those who acquire additional qualifications . 10)COUNSELING FOR EMPLOYEES SPOUSE AND CHILDRENS Outside experts is hired to conduct counseling sessions on carrier guidance to employee childrens and health care tips to all. 11) SPORTS AND CULTURAL ACTIVITIES Sports and cultural activities are conducted every year on Kannada RajyothUthsava Day for employees, their spouses and children. This is conducted in order to provide recreational facility to the employees and their family. 12) SAFETY Management is providing its employees with ear plugs, goggles, gloves, fire extinguishes, etc as safety measure. Training on safety is also given to every employee. Every year mock drill regarding the safety action is conducted. 13) VOLUNTARY RETIREMENT SCHEME Voluntary retirement is given to employees if they are willing to have. When the employees go for VRS hey are given with 3 months salary for every completed year of service or 3, 75,000 or salary for the balance period of service which ever is less.

AL-AMEEN Institute of Management Studies, Bangalore

19

JK TYRE & INDUSTRIES LTD., VTP MYSORE

14) ACCIDENTAL INSURANCE SCHEME The employees who come under ESI will pay the accidental insurance if they met any accidents. For other employees company will pay the hospital expenses. 15) MATERNITY BENEFIT Both pre maternal leave and post maternal leave is given to the women employees with pay. 16)TRADE UNION SUPPORT In order to encourage trade union activities the 7 offices bearer who are elected are given only with general shifts. 17) FIRST-AID APPLIANCES Whenever the accident occurs, the worker will be taken to the health center which is inside the plant. The entire minor and first- aid is done here itself and when there is major accident first aid is done in the health center and then they are taken to the hospital. Every day at least 2 ambulances will be inside the plant which will be kept ready to carry the injured person when ever there is an emergency.

18) REST ROOMS In J.K. Industries rest room is provided to all departments. During the interval time the employees can go there and take relax for few minutes. 19) BONUS Every year bonus is paid to the employees. The bonus amount depends on the turnover or profit of that year. 20) PROHIBITION OF OVERLAPPING SHIFT SHIFT TIMINGS First Shift Second Shift Third Shift : 07.00 A.M. to 03.00 P.M : 03.00 A.M to 11.00 P.M : 11.00 AM to 07.00 PM

AL-AMEEN Institute of Management Studies, Bangalore

20

JK TYRE & INDUSTRIES LTD., VTP MYSORE

General Shift

: 08.45 AM to 05.00 PM

In order to avoid overlapping of shifts the shift timing of employees is changed once in a week after his weekly off. 21) EXTRA WAGES FOR OVER TIMES When ever there is a shortage of workers or production is more the management provides over time to their workers & pays double wages to the employees. BOARD OF DIRECTORS OF JK INDUSTRIES: Chairman Vice Chairman & Managing Director Directors : Hari Shankar Singhania : Raghupathi Singhania : Arvind Narottam Lalbhania Arvind Singh Mewar Bhakul Jain Managing Director Dy.Managing Director : Bharath Hari Singhania : Vikrampati Singhania

BANKS ASSISTING TO VTL Corporation bank Indian bank Punjab national bank State bank of India State bank of Mysore Syndicate bank

AREA OF OPERATIONS The head office at Mysore is connected with various Regional offices, District office, Branch office and Forwarding Agents throughout the company.

AL-AMEEN Institute of Management Studies, Bangalore

21

JK TYRE & INDUSTRIES LTD., VTP MYSORE

The common marketing Organization (CMO) manages the marketing of Nylon Bias Tyres. The head of the CMO is at New Delhi. The Truck Radial Group (TRG) manages the marketing of all steel truck radial tyres. The head office of TRG is situated at Bangalore

PRODUCT PROFILE

AL-AMEEN Institute of Management Studies, Bangalore

22

JK TYRE & INDUSTRIES LTD., VTP MYSORE

PRODUCT PROFILE The products are sold under different brand names Track Tyres Jet rib Vikrant track king Star lug Super track king Hi life Jet star Track plus J T classic Jet track Sand cum hiway J T king

Light Truck Tyres Jet rib Star jug Fleet king Track king

O.T.R (Of The Road) JK tubes Vikrant tubes Tube V EX

AL-AMEEN Institute of Management Studies, Bangalore

23

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Flaps JK flaps JK RD flaps JK EXP flaps

PRODUCT RANGE INTERNATIONAL JK Tyre is a leading exporter of tyres from India and roughly accounts for about 26% of the total tyre exports from India (along with its associate Vikrant Tyres Limited). It is the first and only tyre manufacture in the world to receive the QS 9000 for multilocation operations: World's first tyre manufacture to receive the ISO 9000 for all its operations in one go. Also J.K Tyres is the first tyre company in India to receive ISO 14001 in recognisition of its environmental management systems. Today, JK Tyre's products compete with the best international players in the premium international bias market in more than 55 countries in 6 continents. The exports operate through a strong and dedicated distribution network, and our distributors are fully supported by the company's technical team in terms of continued product development to meet specific market needs. JK Tyre had obtained international accreditation for its products in the US, Europe, South America and the Middle East. J.K Tyre has been the recipient of various awards for exports for the last many years for its commitment to offer superior performance standards & path -breaking innovations. Recently, it was honored with ' The Special Export Award 2000-2001' from Capexil, making it its fourth consecutive award from India's premier industrial association. JK Tyre has also been recently recognized by Indian Trade Promotion Organization (ITPO) for being the largest tyre exporter to Latin America markets and is the proud recipient of first-ever FOCUS LAC Award for the year 1999-2000. J.K Tyres constant endeavor to deliver superior value to its customers and a sound marketing strategy forms the foundation of this

AL-AMEEN Institute of Management Studies, Bangalore

24

JK TYRE & INDUSTRIES LTD., VTP MYSORE

spectacularly consistent performance on the international front. While JK Tyre has maintained its consistency in its marketing and distribution strategies for the export markets, it has also actively pursued development of new superior products to adapt to specific requirements of the different markets. The credit goes to the India's biggest in-house R&D centre, HASETRI (Hari Shankar Singhania Elastomer and Tyre Research Institute) . This Centre for Rubber and Allied Technology was established at Jaykaygram, ISO/IEC Guide 25 & EN 45001. Equipped with advanced testing facilities, it pursues excellence by evolving technologies for superior product performance to reduce waste and pre-empt consumer needs. DOMESTIC J.K. Tyre has been at the forefront of the radial revolution in India. Since inception, we have been regularly releasing high quality, high technology products, which have withstood the test of time and are forerunners in the industry today. Our leadership position in the industry can be attributed to the mantra of offering high technology products and services to the customer. In J.K. Tyre, it is our philosophy to continuously anticipate and understand the customer requirements, convert them into performance standards for our products and services, and meet these standards every time. This has resulted in development of many innovative products from the most modern, technologically advanced production facilities, some of which are listed below :

First manufacturer to launch "T" rated tyres in 1994-Ultima. First manufacturer to launch "H" rated tyres in 1996-97-Ultima 210 H. First manufacturer to launch Dual Contact High Traction Steel radialsAqua sonic First manufacturer to introduce India's first range of eco-friendly colored tyres. First manufacturer to introduce V-rated uni-directional tyre in 2006 First manufacturer to produce special application Z-rated motorsports tyre in 2006

AL-AMEEN Institute of Management Studies, Bangalore

25

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Maruti SX-4, Maruti Swift and Mahindra Renault Logan Rides exclusively on JKTyres.

ACHIEVEMENT/AWARDS JK TYRES ranked 16TH largest tyre company in the world. ISO-14001 accreditation for environment & safety. Indias first T-rated tyre launched. The only tyre manufacturing company got E-marks certification. Awarded by CAPEXILS highest export award for 1997-98. Certified by ISO 9001:1994 quality managements systems. First Indian Tyre Company to adopt Business Process Re-Engineering It has ranked number one in customer satisfaction by the JD power Asia pacific study.

(BPR).

COMPETITORS JK tyre is in no. 2 position in Indian market where its market share is about The main competitors of JK tyres in National market are MRF,

21%. GOODYEAR, CEAT, and APOLLO. The main competitors of JK tyres in international markets are BRIDGESTONE, MICHELIN, COPPER, PIRELLI & SUMITOMO.

AL-AMEEN Institute of Management Studies, Bangalore

26

JK TYRE & INDUSTRIES LTD., VTP MYSORE

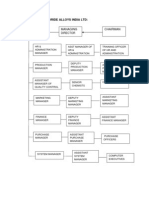

ORGANIZATIONAL CHART

AL-AMEEN Institute of Management Studies, Bangalore 27

JK TYRE & INDUSTRIES LTD., VTP MYSORE

UNIT HEAD

BUSINESS UNITS

G M (OTR)

G M (EXPORT)

SHARE SERVICE UNITS

BU-1 HEAD SUPPLIES

SSU-1 ENIGEERING SERVICES PLANT SSU-3 HEAD

SSU-6 HEAD MS

SSU-6 HEAD MS VP WORKS

BU-2 HEAD STOCK

COMMERCIAL

SSU-4 HEAD

BU-3 HEAD TYRE CURING SSU-4 HEAD-QA SSU-6 PLANT SHIFT INCHARGE BU-4 & SSU-2 HEAD TRUCK RADIAL AL-AMEEN Institute of Management Studies, Bangalore 28 SSU-6 PLANT SHIFT INCHARGE

SSU-4 HEAD-HR

JK TYRE & INDUSTRIES LTD., VTP MYSORE

BU-5 OUTPUT MANAGEMENT

SSU-4 HEAD

SSU-6 PLANT SHIFT INCHARGE

INFORMATION

SSU-5 HEAD PEOPLE SERVICE

SSU-6 PLANT SHIFT INCHARGE

DEPARTMENTS

AL-AMEEN Institute of Management Studies, Bangalore 29

JK TYRE & INDUSTRIES LTD., VTP MYSORE

FUNCTIONAL DEPARTMENTS OF JK INDUSTRIES There are the functional departments at JK Industries (Vikrant type plant) [JK] (VIP) and they are follows. 1) Materials 2) Production 3) Engineering 4) Technical 5) Quality Assurance 6) Human Resource Management 7) Production Planning 8) Personal & Administration Secretarial 9) Internal audit 10) Electronic Data Processing (EDP) 11) Industrial Engineering 12) Finance 13) Marketing 14) Technical services. Due to time constraint, only the basic departments such as production, marketing, Human Resources and Finance, quality assurance have been studies. 1. MATERIALS STORES DEPARTMENT: There are the three stores in JK industries (Vikrant tyre plant); Raw materials stores

30

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Engineering stores Finished goods stores

The function of raw materials stores and finished goods stores are centralized in the Head Office itself. For all 4 plants of JK industries the Head Office itself controls purchase decisions and supply of raw materials.

RAW MATERIALS STORES In JK industries (Vikrant Tyre plant) follows First in First Out method for inventories. Everything is controlled by the head of the department. Some of the raw materials accumulated in stores are Natural rubber, Synthetic rubber, Chemicals (Sulphur, Zinc oxide), Carbon and so on ENGINEERING STORES In the stores, materials like spare parts of machineries are needed for the purpose of production. The ordering level is fixed for each material, when the material reaches the reordering level computer itself identifies it and keeps purchase request to purchase department. Some of the raw materials accumulated in stores are Bearings, gears, motors, valves etc. The reordering level is calculated on the basis of lead time. Buffer stock is also maintained to meet present requirement. FINISHED GOODS STORES The finished goods are stored & preserved in finished goods stores in order to protect it from rain, dust & water. The duty of FGS head to distribute the finished goods directed by the supply chain management. Supply chain management decides the day to day distribution. All the finished goods after the final inspection are kept at the transferring area. A finished goods transfer note is prepared in triplicate copies. The note contains details about material description & quantity. The original copy is sent to central excise wing & duplicate to production

AL-AMEEN Institute of Management Studies, Bangalore

31

JK TYRE & INDUSTRIES LTD., VTP MYSORE

department & another copy to production & planning control (PPC) department. The current status of the stock can be checked by using transfer notes. If the finished goods require packaging then it transfers to packing area. If not it is send to storage area.

WORK FLOW MODEL

AL-AMEEN Institute of Management Studies, Bangalore 32

JK TYRE & INDUSTRIES LTD., VTP MYSORE

AL-AMEEN Institute of Management Studies, Bangalore

33

JK TYRE & INDUSTRIES LTD., VTP MYSORE

2. PRODUCTION DEPARTMENT The production department has 1532 workers who are looking after production of tyres & Flaps at VTP. VTP presently has a production capacity of 10.30 lakhs tyres per annum. It has entered into a collaboration agreement with M/S continental tyres, Germany in 1998 for technology up gradation Basic requirements of a Tyre Load carrying capacity ( Vehicle + Load) Transmit Driving / Breaking Torque High durability and Length Low rolling resistance Mileage Fatigue resistance Good appearance Weather resistance

Other requirement of Tyre

STAGES IN TYRE MANUFACTURING PROCESS 1. COMPUND AT BANBURY Compounding is the process of mixing the necessary raw materials with selected Elastomer in the banbury. Banbury is an internal mixer, which consists of a completely enclosed mixing chamber with two spiral shaped rotors. There is a hoper to feed the ingredients & door to discharge the mix. The rubber ingredients like chemicals are weighted as mentioned in specification file & fed into the hoper. Then the mixing process takes place. Required mixing time is fixed to get better quality mixing. 2. EXTRUDER The main function of an Extruder is to produce tread & side wall, bead, apex.

AL-AMEEN Institute of Management Studies, Bangalore 34

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Extrusion is a process of forcing the mixed compound by means of screw, which rotates inside the barrel. There are two types of extruder a. Screw extruder b. Ram extruder Screw extruder In screw extruder the screw is rotated by means of a motor through reduction gears. The extruder consists of hoper, dye-hard, barrel & dyes. There are two types of screw extruder Cold feed extruder Hot feed extruder In cold feed extruder the feeding compound is in cold condition while in hot feed extrusion the feeding compound is in hot or warm condition. Screw extruder is commonly used because it can obtain continuous extrusion as compared from ram extruder. The extruder temperatures are about to 100 to 200 degree Celsius. 3. ZELL PLANT The dipping process takes place in a Zell plant. Here rayon, nylon, polyesters are dipped in a solution containing normally a latex based resorcinol formaldehyde to improve adhesive properties. Then the fabric is dried at a temperature of about 280 to 300 Celsius & it stretches to about 015%. 4. CALENDARING Calendar is machine, consists of number of rolls held in a frame work used to produce the rubber sheets of required strength & lengths. To get a better quality calendared fabric with uniform gauges, viscosity plays an important role & required temperature is about 110 to 137 degree Celsius. 5. BIAS CUTTER It is a machine used to make the plys or the rubber coated fabrics at a required width & angle. Which are used in the production of tyres. Bias angle is the angle of cords in tyres w r t the central line. Based on the ideal curved

AL-AMEEN Institute of Management Studies, Bangalore

35

JK TYRE & INDUSTRIES LTD., VTP MYSORE

angle which is required type, size & pattern. Bias angle is calculated for a particular drum. If the angle is not as per the specification, it will affect the performance of the tyre. In general the angle 45 degree & the width of the sheet is 100 to 137 mm. 6. POCKET MAKING It is process of making the pocket from the angle cutter fabrics. In pocket making section, three types of pockets are constructed. They are first, second, third pocket. The plys used for the first & second pocket are known as inner ply & those used for third pocket are known as outer ply, pockets are made for easy building of heavy vehicle tyres. 7. BLADDER Butyl rubber compound is used for making the bladder. As first butyl rubber is mixed with specified chemicals properly & then it enters the extruder section by the use of the extruder, a specific length & width of slug is extruded. Then the edges of the slug are cut into specified angle for joining purpose. BLADDER PRESS There are two types of Bladder presses namely 400 tons & 800 tons presses. These presses operate with hydraulic pressure. At first the bladder drum is lowered & the slug is loaded & the lower portion of the mould is then raised to touch the upper patterns. After the sufficient curing time the mould is automatically opened & the bladder is released. It is then trimmed to remove the excess materials. Some of the possible defects that occurs during the manufacturing of bladders are a. Splice opening: This is due to improper joining caused by fluctuating pressure. b. Porosity: This is due to the high extrusion temperature.

AL-AMEEN Institute of Management Studies, Bangalore

36

JK TYRE & INDUSTRIES LTD., VTP MYSORE

8. BEAD MAKING Bronze plated steel wire is coated with layer of rubber compounds to form a bead. 9. BEAD FLIPPING A Filtering compound called apex is provided over the bead. A strip fabric is used to bind the apex with the bead and the bed with the tyre. It is called flipper bead, which is another component of tyre. 10. GREEN TYRE BUILDING All the above components (Pocket, Bead, Flipper, Tread & Chaffer) are assembled, during the tyre building to form Green Tyre. 11. AWLING Green tyres are then sent for awling where air traps are removed by randomly piercing the green tyres using awling gun. 12. TYRE CURING It is a process of cross linking the rubber compounds through heat & pressure. For the process of curing tyres presses are used. These presses are pre warmed before loading of green tyre is done in top ring raise condition with vacuum. Shaping is done by centering the green tyre correctly. Bladders are used for tyre curing. 13. POST CURE INFLATION Cured tyre are loaded onto post cure inflation units to cool pressure, this is done to avoid shrinking of the nylon fabric. 14. TYRE MOULDING Before moulding operations, the green tyre has to be made ready for painting with inner lubricants inside the tyre for easy release from the bladder & the side walls are to be coated with blemish paints. Blemish paints contains carbon black, naphtha, styrene butadiene rubber components & this enables easy flow of compounds while curing in the mould pattern. The blemish paint helps in minimizing the surface flow marks. As a whole to obtain better results,

AL-AMEEN Institute of Management Studies, Bangalore

37

JK TYRE & INDUSTRIES LTD., VTP MYSORE

green tyre should not touch the floor & there should no any contamination on the tyre surfaces. Tyre moulding is a complex type of compression moulding normally cured in presses. The raw tyre has to be placed over a bladder. Then the bladder & tyre expands together due to steam pressure & simultaneously the tyre gets compressed between two moulds in closed position. In this, the operation cycle time, pressure, temperature has to be maintained properly to get optimum vulcanization during moulding process of the tyre. 15. TYRE FINISHING & INSPECTION After curing, the tyres obtained are further finished by trimming of the projection on the tyres surfaces & are checked for defects. Thus the process of removing excess materials on the tyre after curing is called finishing. The finishing process is done either by buffing or trimming method. Buffing is done using emery paper wrapped on a cylindrical rubber press. Thus all tyres are inspected in systematized process. If any defects are found it has to be separated & remaining can be stored in warehouse. 16. TYRE TESTING There are two types of tests Non destructive tests Destructive tests Non destructive tests This the test carried out with any destructing or damaging the product to check the sidewall surface defects, blows blisters, flow cracks under cure, flaws & so on. MAIN MOTTO OF PRODUCTION To obtain high quality products. To be customer oriented company To minimize the cost in the process To reduce the idle time of the machines. To increase the productivity

AL-AMEEN Institute of Management Studies, Bangalore 38

JK TYRE & INDUSTRIES LTD., VTP MYSORE

To increase the performance of the both machine & the employees. 3. QUALITY ASSURANCE DEPARTMENT

QUALITY ASSURANCE-HEAD

QUALITY ASSURANCE-MANAGER

EMS (ENVIRONAMENTAL MANAGEMENT SERVICES) &SAFETY MANAGER

QUALITY MAINTANENCE SERVICE - MANAGER

The People of JK tyres are very much committed to quality in every thing what they do. They continuously anticipate and understand customers requirement, convert these into performance standards for there products and services and meet these standards every time. Customer satisfaction both internally and externally is the main motto of the company. PROCESS OR ACTIVITIES OF QUALITY ASSURANCE DEPARTMENT Super Audit (process Audit): Checking the process as per the Standards of Technical Specification. PPAP co-ordination: Production part approval process. The organization shall conform to a product and manufacturing process approval procedure recognized by the customer.

AL-AMEEN Institute of Management Studies, Bangalore

39

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Capability study: This is applying statistical technique to the process and studying the process capability. Customer complaint handing: It is a process of handing customer complaint in an organized and structured manner. Cut Tyre /Flap Rating: Monthly Checking the product as per determined specification. Unit level MRMC Management Review Rating: Once in a 3 months review of Business plans, quality, status, customer complaints. Continual Improvement: Conducting reviews, preparing minutes & follow up activities for CI projects. Some of Certificates of Quality obtained by JK Tyre

ISO 9001 QS 9000 Environment Management System (ISO 14001) E-MARK DOT (Department of Transport) INMETRO (Institute National de Materiologia Brazil)

AL-AMEEN Institute of Management Studies, Bangalore

40

JK TYRE & INDUSTRIES LTD., VTP MYSORE

4. HUMAN RESOURCES DEPARTMENT

PRESIDENT & DIRECTOR

DEPUTY GENERAL MANAGER

DEPUTY MANAGER

OFFICER HUMAN RESOURCE MANAGEMENT The main functions of HR Dept- of JK Tyre Industries at VTP is Recruitment and Selection Training & Development Performance Appraisal Implementing Incentive Schemes Coordinating among different departments Maintenance of Industrial Relationship.

HRD COMMITTEE MEETING HRD committee consists of senior executives, who meet once in six months under the chairmanship of president & Director. Meeting is arranged by HR department. Matter concerning to HRD are discussed in the meeting. The minutes of the meeting are prepared and circulated to all concerned.

AL-AMEEN Institute of Management Studies, Bangalore

41

JK TYRE & INDUSTRIES LTD., VTP MYSORE

COMMUNICATION MEETING A minimum of six- communication meetings will be conducted in a year under the chairmanship of president and director. The meeting is organized by HR Department. Selected executives from various departments are invited to attend the meeting which is basically to facilitate direct communication between CEO and all levels of executives in the organization. TRAINING SYSTEM IN JK INDUSTRIES LTD (VIKRANT TYRE PLANT) OBJECTIVE To establish the training procedures of identifying the training needs and impart training to support organizational objectives of enhancing knowledge skill and effective utilization of human resources. JK Industries is a production-oriented company & has a majority of work force that is technically oriented and also comprises management executives. Training becomes a part and parcel of the inputs given by the company to its employees. So it is of great importance to know the training system in Vikrant. Training records helps to measure effectiveness in sending various persons on training and to send those who really need help & improvements to perform a particular task. It has been rightly said If you plan for a year, plant corn; If you plan for a decade, plant trees; But if you plan for a century, plant man. This is the Philosophy, which the company follows to guides their employees at JK tyres. WORK CULTURE JK Tyre provides an enabling work culture with a clear sense of vision; mission and strategies in which people work with clear goals and thereby achieve more & perform effectively. Goals are set participative and performance is reviewed transparently, starting with self assessment. Merit is recognized through proportionate rewards and growth opportunities. The companys aspiration of being a global player known for its excellence provides opportunities to stretch for the potential of people.

AL-AMEEN Institute of Management Studies, Bangalore

42

JK TYRE & INDUSTRIES LTD., VTP MYSORE

DEVELOPMENT The company systematically plans for the developments of every individual through training and job rotation opportunities. Participation in crossfunctional teams provides opportunities for contribution as well as new learning. In this environment even the so-called ordinary are able to do the extraordinary i.e. the company introduced a concept of Business Process Re-Engineering (BPR). DUTIES & RESPONSIBILITY OF H.R. DEPARTMENT Responsible for man power planning & recruitment. Responsible for all H.R.D. activities Responsible for employee relations & welfare. Compliance with all labor laws. Responsible for general administration. Responsible for monitoring performance appraisals Responsible for all aspects of personal management Ensure good inter personal relations-promote positive discipline & disciplinary actions. Campus interviews & keeping a live register of job seekers. Giving advertisement in the print Medias, referring to employment exchanges consultancy firms & temporary help agencies PROFESSIONAL CAREERS IN JK TYRE Sales, marketing & exports. Manufacturing operations. Engineering and production services. R & D and product development. Materials Management and Logistics. Finance, Accounting and Commercial Management. Human Resource Management.

AL-AMEEN Institute of Management Studies, Bangalore

43

JK TYRE & INDUSTRIES LTD., VTP MYSORE

5. MARKETING DEPARTMENT VICE PRESIDENT

GENERAL MANAGER

DEPUTY GENERAL MANAGER

DEPUTY MANAGER

TERRITORY MANAGER

OFFICER

OFFICER

STAFF FUNCTIONS OF MARKETING DEPARTMENT

STAFF

Marketing is a process by which goods and services are delivered to the customers. Marketing is one of the activities for maximization of profits and wealth. So marketing is an activity, which plays an important role in the organization to achieve its objectives.

AL-AMEEN Institute of Management Studies, Bangalore

44

JK TYRE & INDUSTRIES LTD., VTP MYSORE

It satisfies the customer needs, it is available throughout the world. It collects the feed back from the customers and provides the proper service according to their needs, it works for the customers satisfaction, it collects the information regarding current market condition for their products, to maximize the awareness of the products it give prominence to the promotional activities. Products of J.K. Tyre have good acceptance both in domestic and international markets. Broadly, the customers are categorized into & segments like: Original Equipment manufacturers (Domestic & Exports) Overseas Markets Institutional sales & Replacement Markets. The company supplies the tyres for VOLVO, ASHOK Leyland and Tata Motors. It is the largest exporter from India accounting 26% of the total quantity exported. DUTIES & RESPONSIBILITIES Sales and marketing overseas Customer Interaction. Sales Planning, Forecast & Targeting. Interaction with Head Office (Ho) & other parties. Regular monitoring with production department. Monitor CHA (customer House Agent) activities. Co-ordinate with export team for smooth work flow. Timely dispatch to ensure scheduled shipping of tyres to customers. About 60% of the product goes to Original Equipment manufacturers (OEM) market. There are about 200 C&F (clearing and forwarding agency) spread all over India.

MARKETING IN JK TYRE

AL-AMEEN Institute of Management Studies, Bangalore

45

JK TYRE & INDUSTRIES LTD., VTP MYSORE

38% of the production goes to replacement market. 26% of the production goes to export.

FINANCE FOR THEIR BANKING TRANSACTIONS Purchase for advance licenses DEPB (Duty Entitlement Pass Book) benefits. Production for meeting the customers requirements. CHA for interaction with customer. Export Inspection agency for inspection of he cargo (export). Shipping companies like Maersk, ALP (American president Lines) for A document after the cargo is shipped. Head office at Mysore connected with various regional offices. District offices, Brach offices and carrying and forwarding agents through out the country. Common marketing organization (CMO) manages the marketing of NYLON Bias tyres of JK industries. The head of CMO is at New Delhi. The marketing of all steel truck radial tyres is managed by Truck radial group (TRG) which is residing in Bangalore. EXPORTS JK industries are exported to over 55 countries. Major countries include United States of America, Australia, United Kingdom New Zealand, Hong Kong Netherlands and most of Middle East, Africa and Asian countries. MAIN PROBLEMS IN EXPORT The exporter is fully geared up to meet the expectations of the customer; he has no authority or control for a lot of other aspects, which are beyond his control. Some of the problems that are common to the exporter are Availability of container ships. Delay of departure of ships.

MARKETING NETWORK

AL-AMEEN Institute of Management Studies, Bangalore

46

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Delay by the concerned people in inspection agencies. Port strike and other disturbances. Customs authority.

MARKETING STRATEGY J. K. Tyres has adopted Total control campaign beginning with print campaign, which will focus on the companys research and development; the total control campaign will further evolve into a five part television commercial which will address JK Tyres physical strength as well as its role in a persons life. The Company has targeted 17 top cities which accounts for more than 60 percent of radial tyre sales for its outdoor media involving billboards and double Decker buses in Mumbai. For joint promotions, JK Tyre joins the hands with Maruti Udyog Ltd Brands, Tata India & Fiat for cars & Ashok Leyland & Tata for trucks,with others. Moreover, it will intensely pursue customer contact program and organize goCarting events in 13 cities like Delhi, Indore, and Ahmedabad & Hyderabad .

AL-AMEEN Institute of Management Studies, Bangalore

47

JK TYRE & INDUSTRIES LTD., VTP MYSORE

6. FINANCE DEPARTMENT

Unit head Head Commercial Commerc ial Manager I Capital equipme nt] Commerc ial Manager II Finance manage r Account s Financ e manag er Bill passin g Financ e manag er [MIS] Financ e manag er Import s &expor Financ e manag er Costin g

Coordina tion & license Finance manage r Bank & treasur y

Commercial Services Accounts Costing Banking & Treasury Purchase capital Equipment Contracts

Customer co- coordinator & Licenses

48

AL-AMEEN Institute of Management Studies, Bangalore

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Procurement of capital Equipments/ Spares is done coordinating with Head Office commercial for placement of orders, vendor rating for capital/imported spares related parties. Customs co-coordinator and license, Application and Reconciliation of customer and carry and forward services related activities and co-ordination for imports. DUTIES & RESPONSIBILITY OF FINANCE DEPARTMENT Preparation of MIS(Management Information System) & BRR (Business Review Report) Finalization of monthly, quarterly, half-yearly and annual reports of the company. Co-ordination with statutory auditors & tax auditors Finalization of cost accounts. Cost reduction and cost of quality report. Review of books of accounts Preparation of trial balance Overhead position of BRR. To lay down policy guidelines & procedures for maintenance of accounting systems of the company including in the case where the company is promoter. budgetary plans. To have overall cash flow management & submit the same to the top management from time to time Investment of short terms surplus funds & optimize the return there on. To workout working capital requirements for submission of proposal to Banks/consortium Banks for sanction & documentation there of. To handle depreciation, investment allowance if any, tax planning & for any change in maintenance of statutory all units. To guide & get short terms & long term budgets. To get monthly profit & loss accounts prepared & compare the same with

AL-AMEEN Institute of Management Studies, Bangalore

49

JK TYRE & INDUSTRIES LTD., VTP MYSORE

To compile, consolidate & prepare corporate accounts at defined periodicity. To ensure timely preparation & printing of annual reports & assist in holding of annual general meetings. To look after overall taxation management. To handle costing last reduction/ controls. To ensure accurate & reliable MIS. Head Office unit reconciliation, prepaid & OSL review support for

preparation of overhead budget, assisting for finalization of accounts and statutory audit. Factory budget and monitoring standard costing, up gradation of special changes for standard costing, valuation of monthly work in progress and closing stock, OMC (outside Mixing center) stock reconciliation, Monitoring daily bank balances and inter bank bend transferring, bank payment & reconciliation, co-ordination with financial institutions and banks, creation of securities, Public deposit Scheme and its related references, correspondence and reports, maintenance of fixed asset records (addition deletion & depreciation), bank books & cash book. Bill passing of raw materials, stores and spares and contracts of all kinds, review of parts ledgers. Issue of PFC forms and Tax Deducted at Source (TDS) certificates, OMC and freight payments, entry tax details. Miscellaneous MIS for raw materials, Sundry creditors and freight. Bill passing for imported items. Accounting of exports sales. Exports bill discounting- Export debtors monitoring, Monthly FOREX report of import and export, CHA bills payments for exports and imports. Payments of salary and wage. Payments under workmen compensation Act. Employees reimbursement Viz, traveling, conveyance, medical, LTA, etc/ Finalization of provident fund, benevolent fund (both employees and executives) & superannuating trust accounts, employees TDS. All insurance related activities including Media-claim.

AL-AMEEN Institute of Management Studies, Bangalore

50

JK TYRE & INDUSTRIES LTD., VTP MYSORE

VISION & MISSION

AL-AMEEN Institute of Management Studies, Bangalore

51

JK TYRE & INDUSTRIES LTD., VTP MYSORE

VISION TO BE AMONGST THE MOST ADMIRED COMPANIES IN INDIA COMMITED TO EXCELENCE. MISSION To be the No.1 position in Truck & bus segment. To make Truck/Bus radial operations profitable & to retain leadership in the passenger radial market. To be the largest Indian tyre exporter, continue to be a significant player in the world in truck & Bias market. To be a customer obsessed company. To enhance value to shareholders & service to all stake holders. To develop a highly motivated team with a sense of ANANDA. To excel as a values driven organization. To be the most preferred Tyre Brand in India. To be the largest & most profitable tyre company in India. Customer satisfaction. Produce high quality of products. TO be the No. 1 Tyre company in India. Profit Maximization. To be the large Tyre Export Company in India. To be a customer obsessed company. TO enhance value to share holders and services to all stakeholders. To attain global standard though continuous improvement in the products and services in order to maintain market leadership.

OBJECTIVES OF THE COMPANY

AL-AMEEN Institute of Management Studies, Bangalore

52

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Accidents free safe production In order to demonstrate its commitment towards quality, JK tyre has made

QUALITY POLICY never ending efforts to make all its products of world class quality. We the people of JK tyre will have an organization committed to quality in everything we do we will continuously anticipate and understand our customers requirements convert these into performance standards for our products and services and meet these standards every time. Full customer satisfaction-both internal and external is our motto. QUALITY MANAGEMENT ISO 9001: JK Tyre worlds first tyre company to receive ISO 9001 certification for its entire operations in 1995 in one go our quality management system is completely integrated into al aspects of our operations. QS 9000: JK Tyre the worlds first Tyre Company to receive quality management system certification QS 9000. In 1998 for multi location operations, we are using QS 9000 system as a tool for continuous incremental improvement. Environment Management System [ISO 14001]: JK Tyre recognizes the impact that our business has on the environment and takes over responsibilities for maintaining harmony with nature. We are the first tyre company in India to receive ISO 14001 certification for multi location operations 1999. E-MARK: JK Tyre is the only tyre company in India having E-mark certification on their products, a mandatory requirement for exporting tyres to European Markets. DOT (Department of Transport) : JK Tyre has to DOT certification on its products, a mandatory requirement for exporting tyres to US market. INMETRO (Institute National De Materiologia- Brazil):

AL-AMEEN Institute of Management Studies, Bangalore

53

JK TYRE & INDUSTRIES LTD., VTP MYSORE

We also have the certification for INMETRO a mandatory requirement for exporting tyre to Brazil (South America). This is a product as well as a system certification. Also this is a proof of superior quality of JK Tyre and our ability to meet stringent international standards.

AL-AMEEN Institute of Management Studies, Bangalore

54

JK TYRE & INDUSTRIES LTD., VTP MYSORE

TOTAL PRODUCTIVE MAINTENANCE [TPM]

TOTAL PRODUCTIVE MAINTENANCE Vikrant Tyre plant is implementing Total Productive Maintenance (TPM) in step by step process to face the competition in the market. This is the only thing that stands between success and total failure of the company. It has been proven to be a program that works. It can be adapted to work not only in industrial plants, but in construction, building maintenance, transportation, and in a variety of other situations. Employees must be educated and convinced that TPM is not just another "program of the month" and that management is totally committed to the program and the extended time frame necessary for full implementation. If everyone involved in a TPM program does his or her part, an unusually high rate of return compared to resources invested may be expected. BRIEF INTRODUCTION OF TPM DEFINITION

AL-AMEEN Institute of Management Studies, Bangalore

55

JK TYRE & INDUSTRIES LTD., VTP MYSORE

Total Productive Maintenance (TPM) is a maintenance program which involves a newly defined concept for maintaining plants and equipment. The goal of the TPM program is to markedly increase production while, at the same time, increasing employee morale and job satisfaction. TPM brings maintenance into focus as a necessary and vitally important part of the business. It is no longer regarded as a non-profit activity. Down time for maintenance is scheduled as a part of the manufacturing day and, in some cases, as an integral part of the manufacturing process. The goal is to hold emergency and unscheduled maintenance to a minimum. TPM - HISTORY TPM is an innovative Japanese concept. The origin of TPM can be traced back to 1951 when preventive maintenance was introduced in Japan. However the concept of preventive maintenance was taken from USA. Nippondenso was the first company to introduce plant wide preventive maintenance in 1960. Preventive maintenance is the concept wherein, operators produced goods using machines and the maintenance group was dedicated with work of maintaining those machines, however with the automation of Nippondenso, maintenance became a problem as more maintenance personnel were required. So the management decided that the routine maintenance of equipment would be carried out by the operators. (This is Autonomous maintenance, one of the features of TPM). Maintenance group took up only essential maintenance works. Thus Nippondenso which already followed preventive maintenance also added Autonomous maintenance done by production operators. The maintenance crew went in the equipment modification for improving reliability. The modifications were made or incorporated in new equipment. This lead to maintenance prevention. Thus preventive maintenance along with Maintenance prevention and Maintainability Improvement gave birth to Productive maintenance. The aim of productive maintenance was to maximize plant and equipment effectiveness to achieve optimum life cycle cost of production equipment.

AL-AMEEN Institute of Management Studies, Bangalore

56

JK TYRE & INDUSTRIES LTD., VTP MYSORE

By then Nippon Denso had made quality circles, involving the employees participation. Thus all employees took part in implementing Productive maintenance. Based on these developments Nippondenso was awarded the distinguished plant prize for developing and implementing TPM, by the Japanese Institute of Plant Engineers (JIPE). Thus Nippondenso of the Toyota group became the first company to obtain the TPM certification. TYPES OF MAINTENANCE 1. Breakdown maintenance It means that people waits until equipment fails and repair it. Such a thing could be used when the equipment failure does not significantly affect the operation or production or generate any significant loss other than repair cost. 2. Preventive maintenance (1951) It is a daily maintenance (cleaning, inspection, oiling and re-tightening), design to retain the healthy condition of equipment and prevent failure through the prevention of deterioration, periodic inspection or equipment condition diagnosis, to measure deterioration. It is further divided into periodic maintenance and predictive maintenance. Just like human life is extended by preventive medicine, the equipment service life can be prolonged by doing preventive maintenance. 2a. Periodic maintenance (Time based maintenance - TBM) Time based maintenance consists of periodically inspecting, servicing and cleaning equipment and replacing parts to prevent sudden failure and process problems. 2b. Predictive maintenance This is a method in which the service life of important part is predicted based on inspection or diagnosis, in order to use the parts to the limit of their service life. Compared to periodic maintenance, predictive maintenance is condition based maintenance. It manages trend values, by measuring and analyzing data about deterioration and employs a surveillance system, designed to monitor conditions through an on-line system.

AL-AMEEN Institute of Management Studies, Bangalore

57

JK TYRE & INDUSTRIES LTD., VTP MYSORE

3. Corrective maintenance (1957) It improves equipment and its components so that preventive maintenance can be carried out reliably. Equipment with design weakness must be redesigned to improve reliability or improving maintainability 4. Maintenance prevention (1960) It indicates the design of new equipment. Weakness of current machines are sufficiently studied (on site information leading to failure prevention, easier maintenance and prevents of defects, safety and ease of manufacturing) and are incorporated before commissioning a new equipment. WHY TPM? TPM was introduced to achieve the following objectives. The important ones are listed

Avoid wastage in a quickly changing economic environment. Producing goods without reducing product quality. Reduce cost. Produce a low batch quantity at the earliest possible time. Goods send to the customers must be non defective.

Steps in introduction of TPM in an organization Step A - PREPARATORY STAGE STEP 1 - Announcement by Management to all about TPM introduction in the organization Proper understanding, commitment and active involvement of the top management in needed for this step. Senior management should have awareness programmes, after which announcement is made to all. Publish it in the house magazine and put it in the notice board. Send a letter to all concerned individuals if required. STEP 2 - Initial education and propaganda for TPM Training is to be done based on the need. Some need intensive training and some just an awareness. Take people who matters to places where TPM already successfully implemented.

AL-AMEEN Institute of Management Studies, Bangalore

58

JK TYRE & INDUSTRIES LTD., VTP MYSORE

STEP 3 - Setting up TPM and departmental committees TPM includes improvement, autonomous maintenance, quality maintenance etc., as part of it. When committees are set up it should take care of all those needs. STEP 4 - Establishing the TPM working system and target Now each area is benchmarked and fix up a target for achievement. STEP 5 - A master plan for institutionalizing Next step is implementation leading to institutionalizing wherein TPM becomes an organizational culture. Achieving PM award is the proof of reaching a satisfactory level. STEP B - INTRODUCTION STAGE This is a ceremony and we should invite all. Suppliers as they should know that we want quality supply from them. Related companies and affiliated companies who can be our customers, sisters concerns etc. Some may learn from us and some can help us and customers will get the communication from us that we care for quality output. STAGE C - IMPLEMENTATION In this stage eight activities are carried which are called eight pillars in the development of TPM activity. Of these four activities are for establishing the system for production efficiency, one for initial control system of new products and equipment, one for improving the efficiency of administration and are for control of safety, sanitation as working environment. STAGE D - INSTITUTIONALISING STAGE By all there activities one would has reached maturity stage. Now is the time for applying for PM award. Also think of challenging level to which you can take this movement. PILLARS OF TPM PILLAR 1 - 5S

AL-AMEEN Institute of Management Studies, Bangalore

59

JK TYRE & INDUSTRIES LTD., VTP MYSORE

TPM starts with 5S. Problems cannot be clearly seen when the work place is unorganized. Cleaning and organizing the workplace helps the team to uncover problems. Making problems visible is the first step of improvement. JAPANESE TERM Seiri Seiton Seiso Seiketsu Shitsuke SEIRI - Sort out English Translation Organization Tidiness Cleaning Standardization Discipline Equivalent 'S' term Sort Systematize Sweep Standardize Self - Discipline

This means sorting and organizing the items as critical, important, frequently used items, useless, or items that are not need as of now. Unwanted items can be salvaged. Critical items should be kept for use nearby and items that are not be used in near future, should be stored in some place.

.SEITON - Organize

AL-AMEEN Institute of Management Studies, Bangalore

60

JK TYRE & INDUSTRIES LTD., VTP MYSORE

The concept here is that "Each item has a place and only one place ". The items should be placed back after usage at the same place. To identify items easily, name plates and colored tags has to be used. Vertical racks can be used for this purpose, and heavy items occupy the bottom position in the racks. SEISO - Shine the workplace This involves cleaning the work place free of burrs, grease, oil, waste, scrap etc. No loosely hanging wires or oil leakage from machines. SEIKETSU - Standardization An employee has to discuss together and decide on standards for keeping the work place / Machines / pathways neat and clean. These standards are implemented for whole organization and are tested / inspected randomly.

SHITSUKE - Self discipline Considering 5S as a way of life and bring about self-discipline among the employees of the organization. This includes wearing badges, following work procedures, punctuality, dedication to the organization etc

PILLAR 2 - JISHU HOZEN (Autonomous maintenance)

This pillar is geared towards developing operators to be able to take care of small maintenance tasks, thus freeing up the skilled maintenance people to spend time on more value added activity and technical repairs. The operators are responsible for upkeep of their equipment to prevent it from deteriorating.

POLICY 1. Uninterrupted operation of equipments. 2. Flexible operators to operate and maintain other equipments. 3. Eliminating the defects at source through active employee participation. 4. Stepwise implementation of JH activities. JISHU HOZEN Targets 1. Prevent the occurrence of 1A / 1B because of JH. 2. Reduce oil consumption by 50%

AL-AMEEN Institute of Management Studies, Bangalore

61

JK TYRE & INDUSTRIES LTD., VTP MYSORE