Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Astm G 65

Cargado por

Rodrigo PereaDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Astm G 65

Cargado por

Rodrigo PereaCopyright:

Formatos disponibles

Eidgenssische Materialprfungs- und Forschungsanstalt Laboratoire fdral d'essai des matriaux et de recherche Laboratorio federale di prova dei materiali

e di ricerca C Institut federal da controlla da material e da retschertgas Swiss Federal Laboratories for Materials Testing and Research

EMPA Feuerwerkerstrasse 39 CH-3602 Thun Tel. +41-33-228 46 26 Fax +41-33-228 44 90

ASTM G 65

Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Richtlinien fr die Durchfhrung von Abriebversuchen mit Trockensand und rotierendem Gummirad (DE) This test method covers laboratory procedures for determining the resistance of metallic materials to scratching abrasion by means of the dry sand/rubber wheel test. It is the intent of this test method to produce data that will reproducibly rank materials in their resistance to scratching abrasion under a specified set of conditions. Abrasion test results are reported as volume loss in cubic millimetres for the particular test procedure specified. Materials of higher abrasion resistance will have a lower volume loss. This test method covers four recommended procedures which are appropriate for specific degrees of wear resistance or thicknesses of the test material. 1 Procedure A -This is a relatively severe test which will rank metallic materials on a wide volume loss scale from low to extreme abrasion resistance. It is particularly useful in ranking materials of medium to extreme abrasion resistance. 2 Procedure B -A short-term variation of Procedure A. It may be used for highly abrasive resistant materials but is particularly useful in the ranking of medium- and low-abrasive- resistant materials. Procedure B should be used when the volume-loss values developed by Procedure A exceeds 100 mm3. 3 Procedure C -A short-term variation of Procedure A for use on thin coatings. 4 Procedure D -This is a lighter load variation of Procedure A which is particularly useful in ranking materials of low-abrasion resistance. It is also used in ranking materials of a specific generic type or materials which would be very close in the volume loss rates as developed by Procedure A. 5 Procedure E -A short-term variation of Procedure B that is useful in the ranking of materials with medium- or low-abrasion resistance. (Ref. ASTM)

Sample geometry: Abrasives: Feed rate: Contact force: Rotation speed: equivalent distance: Wheels: 1 x 3 x 0.12 - 0.5 300 ... 600 gr/min. 20 ... 130 ... 250 N -1 1000 ... 6000 U min 718 ... 4309 m, drying and other materials than rubber on request e.g. (St37, CK45, GG25, X155)

Eidgenssische Materialprfungs- und Forschungsanstalt Laboratoire fdral d'essai des matriaux et de recherche Laboratorio federale di prova dei materiali e di ricerca C Institut federal da controlla da material e da retschertgas Swiss Federal Laboratories for Materials Testing and Research

EMPA Feuerwerkerstrasse 39 CH-3602 Thun Tel. +41-33-228 46 26 Fax +41-33-228 44 90

También podría gustarte

- A Practical Handbook for Drilling Fluids ProcessingDe EverandA Practical Handbook for Drilling Fluids ProcessingAún no hay calificaciones

- G65 16 PDFDocumento14 páginasG65 16 PDFHa Dao SongAún no hay calificaciones

- Astm G65-04Documento13 páginasAstm G65-04Kyle H100% (4)

- 2015 - Standard Method of Test For Sieve Analysis of Fine and Coarse AggregatesDocumento9 páginas2015 - Standard Method of Test For Sieve Analysis of Fine and Coarse AggregatesSameh AhmedAún no hay calificaciones

- ASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesDocumento6 páginasASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesPablo Antonio Valcárcel Vargas100% (1)

- Asphalt Materials Science and TechnologyDe EverandAsphalt Materials Science and TechnologyCalificación: 4 de 5 estrellas4/5 (9)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDe EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Day / Month / Year: Certificate of No Criminal Conviction Applicant Data Collection Form (LOCAL)Documento4 páginasDay / Month / Year: Certificate of No Criminal Conviction Applicant Data Collection Form (LOCAL)Lhea RecenteAún no hay calificaciones

- Slurry Abrasion Test ("Miller Test" ASTM G75) : Coating TechnologyDocumento3 páginasSlurry Abrasion Test ("Miller Test" ASTM G75) : Coating Technologysm_carvalhoAún no hay calificaciones

- Abrasion Testing of Cementitious Floors - Technical Note 2Documento4 páginasAbrasion Testing of Cementitious Floors - Technical Note 2BamsiamAún no hay calificaciones

- Standard Test Method For Measuring Abrasion Using The Dry Sand - Rubber Wheel ApparatusDocumento14 páginasStandard Test Method For Measuring Abrasion Using The Dry Sand - Rubber Wheel ApparatusBastian Calderon DonosoAún no hay calificaciones

- Norma ASTM G65Documento14 páginasNorma ASTM G65MATTHEWS HENRIQUE COTA ARAUJOAún no hay calificaciones

- G 137 PDFDocumento7 páginasG 137 PDFGrato Jr SingcoAún no hay calificaciones

- C 136 Â " 96 QZEZNI05NKE - PDFDocumento5 páginasC 136 Â " 96 QZEZNI05NKE - PDFCristian Ivan ParraAún no hay calificaciones

- Measuring Abrasion Using The Dry Sand/Rubber Wheel ApparatusDocumento14 páginasMeasuring Abrasion Using The Dry Sand/Rubber Wheel Apparatustiago.melo.066Aún no hay calificaciones

- G 65 - 04 (2010)Documento12 páginasG 65 - 04 (2010)ruben carcamoAún no hay calificaciones

- D 693 - 03 Rdy5mwDocumento3 páginasD 693 - 03 Rdy5mwRufo CascoAún no hay calificaciones

- Astm D5963-04Documento9 páginasAstm D5963-04Sampath WeragodaAún no hay calificaciones

- C136 PDFDocumento5 páginasC136 PDFIndira GintingAún no hay calificaciones

- ASTM D 3105 - 99 Testing Elastomeric and Plastomeric Roofing and Waterproofing MaterialsDocumento3 páginasASTM D 3105 - 99 Testing Elastomeric and Plastomeric Roofing and Waterproofing Materialsalin2005Aún no hay calificaciones

- D 559 - 96 Rdu1os1sruq - PDFDocumento9 páginasD 559 - 96 Rdu1os1sruq - PDFLupita CarelyAún no hay calificaciones

- Project Wearing Surface TechnoloigyDocumento20 páginasProject Wearing Surface TechnoloigySajeer SayedaliAún no hay calificaciones

- BS 598-104-1989Documento18 páginasBS 598-104-1989hibonardo100% (1)

- Astm D1709-16ae1 Standard Test Methods For Impact Resistance of Plastic Film by The Free-Falling Dart MethodDocumento9 páginasAstm D1709-16ae1 Standard Test Methods For Impact Resistance of Plastic Film by The Free-Falling Dart MethodHASSAN WASEEMAún no hay calificaciones

- Sieve Analysis of Mineral Filler For Bituminous Paving MixturesDocumento2 páginasSieve Analysis of Mineral Filler For Bituminous Paving MixturesArnold RojasAún no hay calificaciones

- 066 JadDocumento6 páginas066 Jadthekill5717Aún no hay calificaciones

- 12 Astm D 6928Documento7 páginas12 Astm D 6928Joel BecerraAún no hay calificaciones

- C 864 - 99 Qzg2naDocumento3 páginasC 864 - 99 Qzg2naRufo CascoAún no hay calificaciones

- CBR Test Method for Soil StrengthDocumento11 páginasCBR Test Method for Soil StrengthMuhammad Iqbal100% (4)

- LS-628 R23 PDFDocumento7 páginasLS-628 R23 PDFqwerysqlAún no hay calificaciones

- Rubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method ForDocumento9 páginasRubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method Forسعید اینانلوAún no hay calificaciones

- UNBOUND PAVES MATERIALSDocumento26 páginasUNBOUND PAVES MATERIALSzakariaAún no hay calificaciones

- Sieve Analysis of Aggregate C 136Documento5 páginasSieve Analysis of Aggregate C 136Bisma Masood100% (2)

- G 75 - 95 Rzc1lvjfra - PDFDocumento22 páginasG 75 - 95 Rzc1lvjfra - PDFWaldomiroCanoAún no hay calificaciones

- Abrasion (Mechanical)Documento29 páginasAbrasion (Mechanical)stallone21Aún no hay calificaciones

- Measuring Abrasion Using The Dry Sand/Rubber Wheel ApparatusDocumento12 páginasMeasuring Abrasion Using The Dry Sand/Rubber Wheel ApparatusTeymur RegenmaisterAún no hay calificaciones

- Self-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectionDocumento5 páginasSelf-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectiondaovandongpktAún no hay calificaciones

- Laboratory Equipment ReportDocumento16 páginasLaboratory Equipment ReportNavneeth G MenonAún no hay calificaciones

- Lev's Presentation, US-Russia Symposium English Only PDFDocumento50 páginasLev's Presentation, US-Russia Symposium English Only PDFJulio César ChávezAún no hay calificaciones

- BHPBIO - Wear Liner Testing - MaloneDocumento6 páginasBHPBIO - Wear Liner Testing - MalonemiladrahimianAún no hay calificaciones

- Rubber AgingDocumento3 páginasRubber AgingSree SAún no hay calificaciones

- Aashto T 283-14Documento9 páginasAashto T 283-14Chandrasekhar Chintada100% (1)

- Rubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method ForDocumento9 páginasRubber Property-Abrasion Resistance (Rotary Drum Abrader) : Standard Test Method Formohammed karasnehAún no hay calificaciones

- ASTM C580 Mortar FlexuralDocumento6 páginasASTM C580 Mortar FlexuralHiren Joshi100% (1)

- Abrasion (Mechanical) : in Stone ShapingDocumento4 páginasAbrasion (Mechanical) : in Stone ShapingMarvin Berrenstein100% (1)

- ArticleDocumento86 páginasArticled_winarto680100% (1)

- D 558 - 96 - Rdu1oc1sruq - PDFDocumento8 páginasD 558 - 96 - Rdu1oc1sruq - PDFMelgarejo AlexanderAún no hay calificaciones

- Air Jet ManualDocumento35 páginasAir Jet ManualKumar SahebAún no hay calificaciones

- D 1139 - 00 R04 RdexmzkDocumento4 páginasD 1139 - 00 R04 RdexmzkRufo CascoAún no hay calificaciones

- Unboound Pavement MaterialsDocumento25 páginasUnboound Pavement MaterialsHABTE DEBISAAún no hay calificaciones

- AASHTO Fatigue-Flexural TestDocumento12 páginasAASHTO Fatigue-Flexural TestTamanna KabirAún no hay calificaciones

- ASTM D 559-96 Standard Test Method For Wetting and Drying Compacted Soil-Cement MixturesDocumento6 páginasASTM D 559-96 Standard Test Method For Wetting and Drying Compacted Soil-Cement MixturesPablo Antonio Valcárcel Vargas50% (2)

- LAB LESSON 2 Types of AggregatesDocumento5 páginasLAB LESSON 2 Types of AggregatesajaytrixAún no hay calificaciones

- Astm D1709-16ae1 Standard Test Methods For Impact Resistance of Plastic Film by The Free-Falling Dart MethodDocumento7 páginasAstm D1709-16ae1 Standard Test Methods For Impact Resistance of Plastic Film by The Free-Falling Dart MethodHASSAN WASEEMAún no hay calificaciones

- Aggregate Durability Index: Standard Test Method ForDocumento9 páginasAggregate Durability Index: Standard Test Method ForMatías Ignacio Loyola GaldamesAún no hay calificaciones

- ASTM D429 Rubber To Metal Adhesion Test EquipmentDocumento4 páginasASTM D429 Rubber To Metal Adhesion Test EquipmentLimAún no hay calificaciones

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingDe EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingAún no hay calificaciones

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIDe EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemAún no hay calificaciones

- Cambridge IGCSE: GEOGRAPHY 0460/13Documento32 páginasCambridge IGCSE: GEOGRAPHY 0460/13Desire KandawasvikaAún no hay calificaciones

- Integrated Project Management in SAP With Noveco EPMDocumento34 páginasIntegrated Project Management in SAP With Noveco EPMrajesh_das3913Aún no hay calificaciones

- StarletDocumento16 páginasStarletMohsen SirajAún no hay calificaciones

- Critical Aspects in Simulating Cold Working Processes For Screws and BoltsDocumento4 páginasCritical Aspects in Simulating Cold Working Processes For Screws and BoltsstefanomazzalaiAún no hay calificaciones

- Cryptography Seminar - Types, Algorithms & AttacksDocumento18 páginasCryptography Seminar - Types, Algorithms & AttacksHari HaranAún no hay calificaciones

- Group Assignment: Consumer Buying Behaviour Towards ChipsDocumento3 páginasGroup Assignment: Consumer Buying Behaviour Towards ChipsvikasAún no hay calificaciones

- Flex VPNDocumento3 páginasFlex VPNAnonymous nFOywQZAún no hay calificaciones

- BSC in EEE Full Syllabus (Credit+sylabus)Documento50 páginasBSC in EEE Full Syllabus (Credit+sylabus)Sydur RahmanAún no hay calificaciones

- Hydropneumatic Accumulators Pulsation Dampeners: Certified Company ISO 9001 - 14001Documento70 páginasHydropneumatic Accumulators Pulsation Dampeners: Certified Company ISO 9001 - 14001Matteo RivaAún no hay calificaciones

- Gustilo Vs Gustilo IIIDocumento1 páginaGustilo Vs Gustilo IIIMoon BeamsAún no hay calificaciones

- Design of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI UnitDocumento41 páginasDesign of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI Unityoga arkanAún no hay calificaciones

- Environmental Pollution and Need To Preserve EnvironmentDocumento3 páginasEnvironmental Pollution and Need To Preserve EnvironmentLakshmi Devar100% (1)

- Rubrics For Lab Report For PC1 Lab, PC2 Lab, CIC LabDocumento4 páginasRubrics For Lab Report For PC1 Lab, PC2 Lab, CIC LabHunie PopAún no hay calificaciones

- Modicon Quantum - 140DDI85300Documento5 páginasModicon Quantum - 140DDI85300Samdan NamhaisurenAún no hay calificaciones

- Fayol's Principles in McDonald's ManagementDocumento21 páginasFayol's Principles in McDonald's Managementpoo lolAún no hay calificaciones

- Steps To Private Placement Programs (PPP) DeskDocumento7 páginasSteps To Private Placement Programs (PPP) DeskPattasan U100% (1)

- Fin 464 Chapter-03Documento18 páginasFin 464 Chapter-03Shantonu Rahman Shanto 1731521Aún no hay calificaciones

- PrefaceDocumento16 páginasPrefaceNavaneeth RameshAún no hay calificaciones

- Assignment # 4 26 CH 22Documento6 páginasAssignment # 4 26 CH 22Ibrahim AbdallahAún no hay calificaciones

- A Study of Factors Influencing The Consumer Behavior Towards Direct Selling Companies With Special Reference To RCM Products1Documento79 páginasA Study of Factors Influencing The Consumer Behavior Towards Direct Selling Companies With Special Reference To RCM Products1Chandan SrivastavaAún no hay calificaciones

- Group 1 RRLDocumento19 páginasGroup 1 RRLAngelo BolgarAún no hay calificaciones

- OrcaSecurity Solution OverviewDocumento2 páginasOrcaSecurity Solution Overviewandini eldanantyAún no hay calificaciones

- Personal Selling ProcessDocumento21 páginasPersonal Selling ProcessRuchika Singh MalyanAún no hay calificaciones

- Lab Equipment Catalog Research Concept LabDocumento40 páginasLab Equipment Catalog Research Concept LabSeetanshu AwasthiAún no hay calificaciones

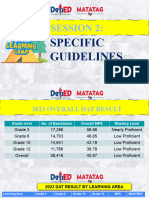

- FINAL Session 3 Specific GuidelinesDocumento54 páginasFINAL Session 3 Specific GuidelinesBovelyn Autida-masingAún no hay calificaciones

- MatrikonOPC Server For Simulation Quick Start Guide PDFDocumento2 páginasMatrikonOPC Server For Simulation Quick Start Guide PDFJorge Perez CastañedaAún no hay calificaciones

- T. Herndon, M. Asch, R. Pollin - Does High Public Debt Consistently Stifle Economic Growth. A Critique of Reinhart and RogoffDocumento26 páginasT. Herndon, M. Asch, R. Pollin - Does High Public Debt Consistently Stifle Economic Growth. A Critique of Reinhart and RogoffDemocracia real YAAún no hay calificaciones

- Loans and AdvanceDocumento8 páginasLoans and AdvanceDjay SlyAún no hay calificaciones

- CASE FLOW AT REGIONAL ARBITRATIONDocumento2 páginasCASE FLOW AT REGIONAL ARBITRATIONMichael Francis AyapanaAún no hay calificaciones