Documentos de Académico

Documentos de Profesional

Documentos de Cultura

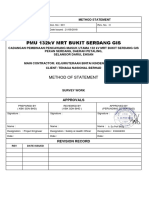

Nuclear Density Method Statement-STD Checked

Cargado por

Wr ArDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Nuclear Density Method Statement-STD Checked

Cargado por

Wr ArCopyright:

Formatos disponibles

CPG Laboratories Pte Ltd 115 Eunos Avenue 3 Singapore 409839 Tel: (65) 6848 3058 Fax: (65)

6848 3066 Website: http://www.cpglabs.com.sg/

METHOD STATEMENT FOR: NUCLEAR DENSITY TESTING

ASTM D6938 08a In-Place Density and Water Content of Soil and Soil Aggregate By Nuclear Methods (Shallow Depths)

A. INTRODUCTION These test methods cover the determination of the total or wet density of soil and soil-rock mixtures by the attenuation of gamma radiation where the source and detector(s) remain on the surface (Backscatter Method) or the source is placed at a known depth up to 300 mm (12 in.) while the detector(s) remains on the surface (Direct Transmission Method).

The density in mass per unit volume of the material under test is determined by comparing the detected rate of gamma radiation with previously established calibration data.

B. SIGNIFICANCE AND USE The test methods described are useful as rapid, non-destructive techniques for the in-place determination of density and moisture content of soil and soil-aggregate. The test methods are suitable for quality control and acceptance testing for construction and for research and development applications. The non-destructive nature of the tests allows repetitive measurement to be made at a single test location.

C. HAZARDS This equipment utilizes radioactive materials that may be hazardous to the health of the users unless proper precautions are taken. CPG Labs operators are familiar with applicable safety procedures and government regulations and are fully certified.

CPG Laboratories Method Statement Nuclear Density Testing

CPG Laboratories Pte Ltd 115 Eunos Avenue 3 Singapore 409839 Tel: (65) 6848 3058 Fax: (65) 6848 3066 Website: http://www.cpglabs.com.sg/ D. STANDARDIZATION AND REFERENCE CHECK Nuclear gages are subject to long-term aging of the radioactive source, detectors, and electronics systems, which may change the relationship between count rate and material density. To offset this aging, the gage may be calibrated as the ratio of the measured count rate to a count rate made on a reference standard. Using the reference standard take at least four repetitive readings at the normal measurement period and determine the mean. If the value obtained above is within the limits specified below, the gage is considered to be in satisfactory condition, and the value may be used to determine the count ratios for the day of use.

E. EQUIPMENTS

CPG Laboratories Method Statement Nuclear Density Testing

CPG Laboratories Pte Ltd 115 Eunos Avenue 3 Singapore 409839 Tel: (65) 6848 3058 Fax: (65) 6848 3066 Website: http://www.cpglabs.com.sg/

F. PROCEDURE FOR FIELD USE 1) 2) Standardize the gage. (Refer to Section 4) Select a test location. If the gage will be closer than 250 mm (10 in.) to any vertical mass that might influence the result, such as in a trench or alongside a pipe, follow the manufacturers correction procedure. 3) Remove all loose and disturbed material. Remove additional material as necessary to reach the material that represents a valid sample of the zone or stratum to be tested. 4) Plane or scrape a smooth horizontal surface so as to obtain maximum contact between the gage and the material being tested. The optimum condition in all cases is total contact between the bottom surface of the gauge and the surface of the material being tested. To correct for surface irregularities, use of native fines or fine sand as a filler may be necessary. The depth of the filler should not exceed approximately 3 mm and the total area filled should not exceed 10% of the bottom area of the instrument. The maximum depth of any void beneath the gage that can be tolerated without filling shall not exceed approximately 3 mm. 5) 6) Seat the gage firmly on the prepared test site. Keep all other radioactive sources away from the gauge to avoid affecting the measurement. 7) Secure and record one or more readings for the normal measurement period in the backscatter position.

CPG Laboratories Method Statement Nuclear Density Testing

También podría gustarte

- Method Statement For Road Construction Over WetlandsDocumento4 páginasMethod Statement For Road Construction Over WetlandsYibeltal ChaneAún no hay calificaciones

- PERFECT GEO TOOLS Pile Coring & Grouting Method StatementDocumento2 páginasPERFECT GEO TOOLS Pile Coring & Grouting Method Statementsaman2580Aún no hay calificaciones

- Method of Statement - Turfing WorksDocumento6 páginasMethod of Statement - Turfing Worksainamin77Aún no hay calificaciones

- L. Construction Method StatementDocumento17 páginasL. Construction Method StatementEQ13Aún no hay calificaciones

- Method Statement of Crossing Box CulvertDocumento2 páginasMethod Statement of Crossing Box CulvertNur EmalinAún no hay calificaciones

- CWYC Method Statement For Base & Sub-BaseDocumento9 páginasCWYC Method Statement For Base & Sub-Base施智捷100% (1)

- Method Statement For Trial Pit ExcavationDocumento4 páginasMethod Statement For Trial Pit ExcavationCwazy MarooyAún no hay calificaciones

- Road Pav LayerwDocumento10 páginasRoad Pav LayerwAurelius GoraAún no hay calificaciones

- Simple Drilling MethodsDocumento4 páginasSimple Drilling MethodsGreen Action Sustainable Technology GroupAún no hay calificaciones

- A-U00-C-Ms-2042-000-Crs-00c - Method Statement For Shoreline Protection - DaDocumento14 páginasA-U00-C-Ms-2042-000-Crs-00c - Method Statement For Shoreline Protection - DaKurnia AryadiAún no hay calificaciones

- EXCAVATION METHOD STATEMENT FOR HIGHLANDS HIGHWAY REHABILITATIONDocumento9 páginasEXCAVATION METHOD STATEMENT FOR HIGHLANDS HIGHWAY REHABILITATION施智捷100% (1)

- Client Details: Work Method StatementDocumento13 páginasClient Details: Work Method StatementSäbrinä ShukrìAún no hay calificaciones

- MS For Rectification Work of Concrete CrackDocumento18 páginasMS For Rectification Work of Concrete CrackFa Dyla100% (1)

- Proposal For Maintenance of Iyana Ipaja Bridge (New Lagos - Abeokuta Dual Carriageway) in Lagos StateDocumento9 páginasProposal For Maintenance of Iyana Ipaja Bridge (New Lagos - Abeokuta Dual Carriageway) in Lagos Stateadetokunbo fapuroAún no hay calificaciones

- Rock EmbankmentDocumento8 páginasRock EmbankmentSuhaidi AliasAún no hay calificaciones

- Technical Note For LimestoneDocumento15 páginasTechnical Note For LimestoneAmierul MukmienAún no hay calificaciones

- Concreting MethodologyDocumento2 páginasConcreting Methodologyervnglen08Aún no hay calificaciones

- Method Statement For Footing Concrete PouringDocumento9 páginasMethod Statement For Footing Concrete PouringKishore KumarAún no hay calificaciones

- A Lecture Notes 2012 Dda2132 CHP 3b Pile TestDocumento13 páginasA Lecture Notes 2012 Dda2132 CHP 3b Pile Testmkpasha55mpAún no hay calificaciones

- Especifications For Jet Grouting PDFDocumento7 páginasEspecifications For Jet Grouting PDFMarco Dos Santos NevesAún no hay calificaciones

- Methodology of Earth WorksDocumento8 páginasMethodology of Earth WorksMartinAún no hay calificaciones

- CORRIB FIELD DEVELOPMENT PROJECT LVI, GLENGAD COMPOUNDS AND ACCESS ROAD CONSTRUCTIONDocumento81 páginasCORRIB FIELD DEVELOPMENT PROJECT LVI, GLENGAD COMPOUNDS AND ACCESS ROAD CONSTRUCTIONTATATAHERAún no hay calificaciones

- TEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Documento8 páginasTEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Tomi Wiryandi SaputraAún no hay calificaciones

- Central Expressway ConstructionDocumento23 páginasCentral Expressway ConstructionJayaratneAún no hay calificaciones

- Guide to Subgrade Construction MethodologyDocumento4 páginasGuide to Subgrade Construction MethodologysvsrnbAún no hay calificaciones

- Overall Method Statement InfraDocumento130 páginasOverall Method Statement InfraINTAN FARHANA MOHD ROSLANAún no hay calificaciones

- Method Statement For Roadway EmbankmentDocumento6 páginasMethod Statement For Roadway EmbankmentFlavio Jose MuhaleAún no hay calificaciones

- Method Statement For Trail Pit Excavation (Manual)Documento18 páginasMethod Statement For Trail Pit Excavation (Manual)Rawoofuddin ChandAún no hay calificaciones

- SGM - Struct SpecDocumento112 páginasSGM - Struct SpecabdouAún no hay calificaciones

- RAMS For Concrete (Overt and Invert Lining) Repair WorksDocumento16 páginasRAMS For Concrete (Overt and Invert Lining) Repair WorksDeep Sherawat100% (1)

- Method Statement for Substructure ExcavationDocumento14 páginasMethod Statement for Substructure ExcavationĐărsĥąna RanasingheAún no hay calificaciones

- Plate Load TestDocumento3 páginasPlate Load TestniteshAún no hay calificaciones

- Method of Statement Bore Pile FoundationDocumento11 páginasMethod of Statement Bore Pile FoundationRendi SeptriawanAún no hay calificaciones

- Mos Survey WorkDocumento4 páginasMos Survey Workaniesbaek100% (1)

- Method Statement Installation of Sheet PileDocumento9 páginasMethod Statement Installation of Sheet PileRonnie Jungco SarmientoAún no hay calificaciones

- MS For Surface Rock Bolts and Dowels (Rev-2)Documento23 páginasMS For Surface Rock Bolts and Dowels (Rev-2)shahzadAún no hay calificaciones

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersDocumento15 páginasMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhAún no hay calificaciones

- Mackintosh Probe TestDocumento11 páginasMackintosh Probe Testmoneesha sriAún no hay calificaciones

- MS - Raft PouringDocumento14 páginasMS - Raft PouringAby ThykkodathuAún no hay calificaciones

- Method Statement For Culverts REV.BDocumento19 páginasMethod Statement For Culverts REV.BAmila Priyadarshana DissanayakeAún no hay calificaciones

- CD - Rfi .WM.22.1 Soil Engineering Method StatementDocumento17 páginasCD - Rfi .WM.22.1 Soil Engineering Method Statementcristhian9ares9oboAún no hay calificaciones

- TBPP CON 01 CM MSM 0009 D Method Statement of Quay Deck ConstructionDocumento522 páginasTBPP CON 01 CM MSM 0009 D Method Statement of Quay Deck ConstructionMr BanditAún no hay calificaciones

- Method Statement For StatnamicDocumento15 páginasMethod Statement For StatnamicMohd ZulhaidyAún no hay calificaciones

- Dewatering Method Statement ExplainedDocumento3 páginasDewatering Method Statement ExplainedSalama ShurrabAún no hay calificaciones

- Pakistan International School Jeddah Junior Section OverviewDocumento11 páginasPakistan International School Jeddah Junior Section OverviewSaquib.MahmoodAún no hay calificaciones

- GD Earth Works R2Documento22 páginasGD Earth Works R2sivaprasad_2k11Aún no hay calificaciones

- Pile Driving MethodDocumento26 páginasPile Driving MethodTrinco JettyAún no hay calificaciones

- Method Statement For Excavation & Backfilling and Compaction Works, Rev. 00Documento52 páginasMethod Statement For Excavation & Backfilling and Compaction Works, Rev. 00Amran HossainAún no hay calificaciones

- LIFTING PLAN REV Approved 2Documento12 páginasLIFTING PLAN REV Approved 2Siddique Qureshi100% (2)

- Ground Improvement TechniquesDocumento20 páginasGround Improvement TechniquesRajesh Prasad ShuklaAún no hay calificaciones

- Method Statement Patch WorkDocumento9 páginasMethod Statement Patch Worknoko100% (1)

- Method Statement of Bored Piles 21Documento40 páginasMethod Statement of Bored Piles 21Dharma Pratap LamgadeAún no hay calificaciones

- Method Statement: ApprovalDocumento21 páginasMethod Statement: ApprovalzhanghuiAún no hay calificaciones

- Plant & Guide Wall ConstructionDocumento10 páginasPlant & Guide Wall ConstructionAnonymous S7Cq7ZDgPAún no hay calificaciones

- Method Statement For Embankment FillingDocumento9 páginasMethod Statement For Embankment Fillingdamith50% (2)

- COE Group's Proposed Baraka House Foundation WorksDocumento2 páginasCOE Group's Proposed Baraka House Foundation WorksGkou Dojku100% (1)

- Wet Mix Macadam-WmmDocumento7 páginasWet Mix Macadam-WmmCheng Engi33% (3)

- Field Density Testing with Nuclear GaugeDocumento32 páginasField Density Testing with Nuclear Gaugenikita6969Aún no hay calificaciones

- D2922Documento6 páginasD2922smanoj354Aún no hay calificaciones

- ASTM D 2922-96 Standard Tests Methods For Density of Soil and Soil-Aggregate in Place by Nuclear Methods (Shallow Depth)Documento5 páginasASTM D 2922-96 Standard Tests Methods For Density of Soil and Soil-Aggregate in Place by Nuclear Methods (Shallow Depth)Pablo Antonio Valcárcel Vargas100% (1)

- Photos#2 at Zone 1 z2 z3Documento24 páginasPhotos#2 at Zone 1 z2 z3Wr ArAún no hay calificaciones

- Welcome: Ahsanullah University of Science & TechnologyDocumento69 páginasWelcome: Ahsanullah University of Science & TechnologyWr ArAún no hay calificaciones

- 1 July 2015 Sunlove Building Project PatternDocumento42 páginas1 July 2015 Sunlove Building Project PatternWr ArAún no hay calificaciones

- Drainworks ProgressDocumento2 páginasDrainworks ProgressWr ArAún no hay calificaciones

- CAFEO 33 Invitation To Delegates. - 1Documento1 páginaCAFEO 33 Invitation To Delegates. - 1Wr ArAún no hay calificaciones

- Carpet Combing June 2013Documento3 páginasCarpet Combing June 2013Wr ArAún no hay calificaciones

- Appendix 5C - Non Conformance Report1Documento2 páginasAppendix 5C - Non Conformance Report1Wr ArAún no hay calificaciones

- IR Asphalt PremixDocumento2 páginasIR Asphalt PremixWr ArAún no hay calificaciones

- ACEE List of Abstracts May 11 2016Documento11 páginasACEE List of Abstracts May 11 2016Wr ArAún no hay calificaciones

- Proposed Extension, A&A Works at Sunlove AbodeDocumento42 páginasProposed Extension, A&A Works at Sunlove AbodeWr ArAún no hay calificaciones

- DAFLOU BATIS VpCI - 2Documento6 páginasDAFLOU BATIS VpCI - 2Wr ArAún no hay calificaciones

- Rto Application Edwin FerrerDocumento4 páginasRto Application Edwin FerrerWr ArAún no hay calificaciones

- General ConditonDocumento45 páginasGeneral ConditonKiran PoudelAún no hay calificaciones

- @MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneDocumento1 página@MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneWr ArAún no hay calificaciones

- Rebar Arrangement in SlabDocumento12 páginasRebar Arrangement in Slableovorig100% (2)

- IR For RCC WorksDocumento2 páginasIR For RCC WorksWr ArAún no hay calificaciones

- Steps For RCC Design 10.01.08Documento12 páginasSteps For RCC Design 10.01.08Prisco AtabongAún no hay calificaciones

- BCM Anna University NotesDocumento112 páginasBCM Anna University NotesaruchellamAún no hay calificaciones

- Calculations of Unit Weight of Rebar PDFDocumento1 páginaCalculations of Unit Weight of Rebar PDFWr ArAún no hay calificaciones

- GeneralTechnicalInformation RebarSplicingDocumento7 páginasGeneralTechnicalInformation RebarSplicingSarakikenpachiAún no hay calificaciones

- CEEN 3304 T4 One-Way Slab PDFDocumento12 páginasCEEN 3304 T4 One-Way Slab PDFWr ArAún no hay calificaciones

- CEEN 3304 T4 One-Way Slab PDFDocumento12 páginasCEEN 3304 T4 One-Way Slab PDFWr ArAún no hay calificaciones

- Seismic Rebar DetailingDocumento11 páginasSeismic Rebar DetailingWr ArAún no hay calificaciones

- Calculations of Unit Weight of Rebar PDFDocumento1 páginaCalculations of Unit Weight of Rebar PDFWr ArAún no hay calificaciones

- Beam Rebar ArrangementDocumento10 páginasBeam Rebar Arrangementme_decent28457100% (2)

- Permit To Work On Public StreetsDocumento27 páginasPermit To Work On Public StreetsWr ArAún no hay calificaciones

- SanDiego ASCE 2005Documento10 páginasSanDiego ASCE 2005Wr ArAún no hay calificaciones

- Structural Design of Multi-Story Residential BuildingDocumento9 páginasStructural Design of Multi-Story Residential Buildingatac101Aún no hay calificaciones

- ER288 WP MembraneDocumento1 páginaER288 WP MembraneWr ArAún no hay calificaciones

- ER288 WP MembraneDocumento1 páginaER288 WP MembraneWr ArAún no hay calificaciones

- Biologicalisation - Biological Transformation in ManufacturingDocumento32 páginasBiologicalisation - Biological Transformation in ManufacturingGuillermo AvilesAún no hay calificaciones

- Motenergy Me1507 Technical DrawingDocumento1 páginaMotenergy Me1507 Technical DrawingHilioAún no hay calificaciones

- The Confidence Myth and What It Means To Your Career: by Tara MohrDocumento4 páginasThe Confidence Myth and What It Means To Your Career: by Tara MohrdargeniAún no hay calificaciones

- Scheduling BODS Jobs Sequentially and ConditionDocumento10 páginasScheduling BODS Jobs Sequentially and ConditionwicvalAún no hay calificaciones

- Jesd51 13Documento14 páginasJesd51 13truva_kissAún no hay calificaciones

- Technical Mathematics 2 SyllabusDocumento3 páginasTechnical Mathematics 2 SyllabusMHARLOU TORINGAún no hay calificaciones

- SQ3R Is A Reading Strategy Formed From Its LettersDocumento9 páginasSQ3R Is A Reading Strategy Formed From Its Letterschatura1989Aún no hay calificaciones

- Me-143 BcmeDocumento73 páginasMe-143 BcmekhushbooAún no hay calificaciones

- Colortrac Cx40 Utilities Service Manual PDFDocumento21 páginasColortrac Cx40 Utilities Service Manual PDFTintila StefanAún no hay calificaciones

- Test Bank For Environmental Science For A Changing World Canadian 1St Edition by Branfireun Karr Interlandi Houtman Full Chapter PDFDocumento36 páginasTest Bank For Environmental Science For A Changing World Canadian 1St Edition by Branfireun Karr Interlandi Houtman Full Chapter PDFelizabeth.martin408100% (16)

- ASTM C186 - 15a Standard Test Method For Heat of Hydration of Hydraulic CementDocumento3 páginasASTM C186 - 15a Standard Test Method For Heat of Hydration of Hydraulic CementKalindaMadusankaDasanayakaAún no hay calificaciones

- Welcome To Word GAN: Write Eloquently, With A Little HelpDocumento8 páginasWelcome To Word GAN: Write Eloquently, With A Little HelpAkbar MaulanaAún no hay calificaciones

- IBM's Corporate Service Corps: The Shift To A Globally Integrated EnterpriseDocumento2 páginasIBM's Corporate Service Corps: The Shift To A Globally Integrated EnterprisePYXERA GlobalAún no hay calificaciones

- Signal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaDocumento46 páginasSignal Sampling, Quantization, Binary Encoding: Oleh Albert SagalaRamos D HutabalianAún no hay calificaciones

- QTouch LibraryDocumento21 páginasQTouch LibraryLenin RuizAún no hay calificaciones

- Reservoir Characterization 3 LoggingDocumento47 páginasReservoir Characterization 3 LoggingMohamed AbdallahiAún no hay calificaciones

- E F Schumacher - Small Is BeautifulDocumento552 páginasE F Schumacher - Small Is BeautifulUlrichmargaritaAún no hay calificaciones

- 2 - Thermal Analysis of Electric Machines (1788)Documento70 páginas2 - Thermal Analysis of Electric Machines (1788)Naveed IqbalAún no hay calificaciones

- Laser Telemetric SystemDocumento2 páginasLaser Telemetric Systemdellibabu509Aún no hay calificaciones

- Devki N Bhatt01240739754Documento10 páginasDevki N Bhatt01240739754menuselectAún no hay calificaciones

- Experienced Design Engineer Seeks Challenging PositionDocumento2 páginasExperienced Design Engineer Seeks Challenging PositionjmashkAún no hay calificaciones

- Traditional Training TechniquesDocumento13 páginasTraditional Training TechniquesRachana PradeepAún no hay calificaciones

- Notes On Unit - 4 - Employees Roles in Service MarketingDocumento3 páginasNotes On Unit - 4 - Employees Roles in Service MarketingSridhar Gowda67% (3)

- "Difference Between Private and Public Nuisance": Law of TortsDocumento4 páginas"Difference Between Private and Public Nuisance": Law of Tortsaridaman raghuvanshiAún no hay calificaciones

- Accomplishment in ScinceDocumento21 páginasAccomplishment in ScinceChristine CanoyAún no hay calificaciones

- Engineering Thermodynamics Work and Heat Transfer 4th Edition by GFC Rogers Yon Mayhew 0582045665 PDFDocumento5 páginasEngineering Thermodynamics Work and Heat Transfer 4th Edition by GFC Rogers Yon Mayhew 0582045665 PDFFahad HasanAún no hay calificaciones

- Chemistry An Introduction To General Organic and Biological Chemistry Timberlake 12th Edition Test BankDocumento12 páginasChemistry An Introduction To General Organic and Biological Chemistry Timberlake 12th Edition Test Banklaceydukeqtgxfmjkod100% (46)

- Week3 Communication Skill Part 1 Student GuideDocumento10 páginasWeek3 Communication Skill Part 1 Student GuideZoe FormosoAún no hay calificaciones

- Instructional Module Training PlanDocumento5 páginasInstructional Module Training Planapi-246767803100% (1)

- Read Me Slave 2.1Documento7 páginasRead Me Slave 2.1Prasad VylaleAún no hay calificaciones

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDe EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAún no hay calificaciones

- Guidelines for Chemical Process Quantitative Risk AnalysisDe EverandGuidelines for Chemical Process Quantitative Risk AnalysisCalificación: 5 de 5 estrellas5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDe EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksCalificación: 5 de 5 estrellas5/5 (1)

- Guidelines for the Management of Change for Process SafetyDe EverandGuidelines for the Management of Change for Process SafetyAún no hay calificaciones

- Advanced Process Control: Beyond Single Loop ControlDe EverandAdvanced Process Control: Beyond Single Loop ControlAún no hay calificaciones

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDe EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationCalificación: 4 de 5 estrellas4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe EverandNuclear Energy in the 21st Century: World Nuclear University PressCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDe EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationAún no hay calificaciones

- Produced Water Treatment Field ManualDe EverandProduced Water Treatment Field ManualCalificación: 4.5 de 5 estrellas4.5/5 (5)

- Guidelines for Siting and Layout of FacilitiesDe EverandGuidelines for Siting and Layout of FacilitiesAún no hay calificaciones

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentAún no hay calificaciones

- Well Control for Completions and InterventionsDe EverandWell Control for Completions and InterventionsCalificación: 4 de 5 estrellas4/5 (10)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsDe EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsAún no hay calificaciones

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisDe EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisAún no hay calificaciones

- An Applied Guide to Water and Effluent Treatment Plant DesignDe EverandAn Applied Guide to Water and Effluent Treatment Plant DesignCalificación: 5 de 5 estrellas5/5 (4)

- Robotics: Designing the Mechanisms for Automated MachineryDe EverandRobotics: Designing the Mechanisms for Automated MachineryCalificación: 4.5 de 5 estrellas4.5/5 (8)

- Guidelines for Developing Quantitative Safety Risk CriteriaDe EverandGuidelines for Developing Quantitative Safety Risk CriteriaAún no hay calificaciones

- Chemical Process Safety: Learning from Case HistoriesDe EverandChemical Process Safety: Learning from Case HistoriesCalificación: 4 de 5 estrellas4/5 (14)

- Guidelines for Engineering Design for Process SafetyDe EverandGuidelines for Engineering Design for Process SafetyAún no hay calificaciones

- Perfume Engineering: Design, Performance and ClassificationDe EverandPerfume Engineering: Design, Performance and ClassificationCalificación: 4 de 5 estrellas4/5 (5)

- Understanding Distillation Using Column Profile MapsDe EverandUnderstanding Distillation Using Column Profile MapsAún no hay calificaciones

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsDe EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsAún no hay calificaciones

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesDe EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesAún no hay calificaciones

- Process Engineering and Industrial ManagementDe EverandProcess Engineering and Industrial ManagementAún no hay calificaciones

- Bow Ties in Risk Management: A Concept Book for Process SafetyDe EverandBow Ties in Risk Management: A Concept Book for Process SafetyAún no hay calificaciones