Documentos de Académico

Documentos de Profesional

Documentos de Cultura

2A Диагностика эл. систем подвески

Cargado por

tankg1000Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

2A Диагностика эл. систем подвески

Cargado por

tankg1000Copyright:

Formatos disponibles

SECTION 2A

SUSPENSION DIAGNOSIS

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . General Specifications . . . . . . . . . . . . . . . . . . Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . General Diagnosis . . . . . . . . . . . . . . . . . . . . . Input & Output Devices and Damping Force Control Logic . . . . . . . . . . . . . . . . . Input & Output Devices . . . . . . . . . . . . . . . . . . System Layout . . . . . . . . . . . . . . . . . . . . . . . . 2A-1 2A-1 2A-3 2A-3 2A-5 2A-5 2A-5

Damping Force Control Logic . . . . . . . . . . . . . 2A-6 Normal Control . . . . . . . . . . . . . . . . . . . . . . . . 2A-6 Self-Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 2A-7 Actuator Inspection . . . . . . . . . . . . . . . . . . . . . 2A-8 Schematic and Routing Diagrams . . . . . . . . 2A-9 ECS Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 2A-9 Self Diagnosis Test . . . . . . . . . . . . . . . . . . 2A-12 Diagnosis Test . . . . . . . . . . . . . . . . . . . . . . . 2A-12

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application ECS Control Type Shock Absorber Max. Length (mm) Compressed Length (mm) Stroke (mm) Front Rear

3-stage Variable Damping Force Control Type

344 - 350 245 3 102 517 - 523 331 3 188

2A-2 SUSPENSION DIAGNOSIS

GENERAL SPECIFICATIONS (Cont'd)

Application Body Vertical and Lateral Acceleration Sensor Power Voltage (V) Consuming Current (mA) Output Current (mA) Operating Characteristics

(Vertical Acceleration Sensor)

Description 4.75 - 5.25 Less than 10 Less than 2.0

(Lateral Acceleration Sensor)

Output Voltage 4.25

Output Voltage 4.25

2.5 0.75 -1.5g 1g Acceleration 3.5g

2.5 0.75 -1g 0g Acceleration 1g

Damping Force Switching Actuator

Type Voltage Rating (V) Current Rating (A) Current Time (mS)

3-stage Rotary Step Motor Type DC12 Less than 2.5 95 - 105 4.75 - 5.25 Less than 10 Less than 2.0

Output Voltage 4.25

Axle Vertical Acceleration Sensor (Wheel G Sensor)

Power Voltage (V) Consuming Current (mA) Output Current (mA) Operating Characteristics

2.5 0.75 -9g 1g Acceleration 11g

SUSPENSION DIAGNOSIS 2A-3

DIAGNOSIS

GENERAL DIAGNOSIS

Problems in the steering, the suspension, the tires, and the wheels involve several systems. Consider all systems when you diagnose a complaint. Some problems, such as abnormal or excessive tire wear and scuffed tires, may by the result of hard driving. Always road test the vehicle first. If possible, do this road test with the customer. Proceed with the following preliminary checks. Correct any substandard conditions.

Vehicle Rolling

Checks Broken Stabilizer Bar Faulty Shock Absorber Action Replace Replace

Abnormal Noises

Checks Loosened Mountings Damaged or Worn wheel Bearing Damaged Shock Absorber Damaged Tire Action Retightening Replace Replace Replace

Poor Riding

Checks Over Inflated Tire Faulty Shock Absorber Loosened wheel Nut Bent or Broken Coil Spring Damaged Tire Worn Bushing Action Pressure Adjustment Replace Tighten as Specified Replace Replace Replace

Vehicle Pulls to Right or Left

Checks Deformed Arm Assembly Worn Bushing Bent or Broken Coil Spring Difference Between L/H & R/H Heights Action Replace Replace Replace Adjust

Hard Steering

Checks Incorrect Wheel Alignment Excessive Resistance of Lower Arm Ball Joint Insufficient Tire Pressure Faulty Power Steering Action Repair Replace Adjust Repair or Replace

2A-4 SUSPENSION DIAGNOSIS

Steering Instability

Checks Incorrect Front wheel Alignment Worn or Loosened Lower Arm Bushing Action Replace Repair or Replace

Vehicle Bottoming

Checks Worn or Broken Coil Spring Action Replace

SUSPENSION DIAGNOSIS 2A-5

INPUT & OUTPUT DEVICES AND DAMPING FORCE CONTROL LOGIC

INPUT & OUTPUT DEVICES

Damping force of shock absorber will rotate shock absorber control rod in 3 modes by driving actuator on the upper shock absorber when signaled from ECS. Rotary valve in the shock absorber will control hydraulic flow according to rotation of control rod to adjust damping force of shock absorber in SOFTMEDIUMHARD. Speed Sensor Axle Vertical Acceleration Sensor (Wheel G Sensor) Stop Lamp Switch Body Vertical Acceleration Sensor (Vertical Sensor) ECS Switch Body Lateral Acceleration Sensor (Lateral Sensor) Self-Diagnosis Connector

ECS (ECU)

Indicator Lamp Actuator Damping Force Adjustment Shock Absorber

SYSTEM LAYOUT

1 ECS (ECU) 2 Body Vertical Acceleration Sensor (Vertical Sensor) 3 Body Lateral Acceleration Sensor (Lateral Sensor)

4 ECS Mode Switch 5 Stop Lamp Switch 6 Axle Vertical Acceleration Sensor (Wheel G Sensor) 7 Mode Actuator

2A-6 SUSPENSION DIAGNOSIS

DAMPING FORCE CONTROL LOGIC

Control Logic that applies on damping force variable suspension is comprised of road sensing driving comfort control logic to increase driving comfort and vehicle speed sensing control logic, anti-roll control logic and anti-dive control logic to secure control safety. Sensor Logic Road Sensing Driving Comfort Control Logic Anti-bounce Control Logic Anti-roll Control Logic Anti-dive Control Logic Vehicle Speed Sensing Control Logic Speed

Axle Vertical Lateral Acceleration Sensor (2.5g) Sensor (1g) Sensor (10g)

Brake

NORMAL CONTROL

Initial Stage When ignition switch is "ON", system initialization will be performed for approx. 3 seconds. During this time, warning lamp will stay ON and damping force will be switched to Hard status. After 3 seconds, warning lamp will turn off and normal control status will be restored. Normal Damping Force Control Establishment Damping force will have SoftMediumHard status in AUTO mode and MediumHard status in SPORT mode. When double control items are satisfied at the same time it will be HardMediumSoft in order. Normal Damping Force Control Release Control mode release will be "HardMediumSoft"or "MediumSoft". In case that returned from Hard status to Medium status during control, it will be done after elapse of setting times. Returning from Medium status to Soft status will be done immediately without delay.

SUSPENSION DIAGNOSIS 2A-7

SELF-DIAGNOSIS

ECS-ECU indicates ECS circuit defectives to the driver by flickering ECS indicator lamp in the meter cluster 0.5 second of interval if there are defectives. Code 01 Defects Body vertical acceleration sensor Judging Conditions When sensor output voltage is less than 0.5-4.5V, more than 4.5V. Set Time Remedy Stop antibounce ride control

Release Conditions

Set Time

Sensor Voltage 2.0 0.1V 3.0 0.1V

0.9 - 1.1sec.

0.9 - 1.1sec.

02

Body lateral acceleration sensor

When sensor output Stop anti-roll 0.9 1.1sec. voltage is less than control 0.550.15V, more than 4.450.1V. When sensor output voltage is less than 0.5-4.5V, more than 4.5V. Stop ride control

Sensor Voltage 2.0 0.1V 3.0 0.1V

0.9 - 1.1sec.

03

Axle vertical acceleration sensor (wheel G sensor)

0.9 - 1.1sec.

Sensor Voltage 2.0 0.1V 3.0 0.1V

0.9 - 1.1sec.

04

Front actuator

Check step motor Stop control power supply detecting 0.4 - 0.6sec. after returning circuit for open and to the previshort. ous mode check for relative connectors. When defective detectStop control ing circuit has detected 0.4 - 0.6sec. after returning defectives during to the previous output OFF. mode When ECU does not work normally. 0.4 - 0.6sec. Stop control

IGN+ SW. OFF ON

05

Rear actuator

IGN+ SW. OFF ON

06

ECU

Reset

1. Turn the ignition switch ON and if ECS system is normal, ECS indicator lamp will turn on for 3 seconds and then go off. However if defective, ECS indicator lamp will flicker in the interval of 0.5 second continuously. 2. Identify fault code with Scanner.

2A-8 SUSPENSION DIAGNOSIS

ACTUATOR INSPECTION

Output position of the actuator should be changed as below when battery voltage is applied between actuator connector terminals. Connector Battery Voltage terminal

1 (White) 2 (Black) 3 (Red) 1 (White) 2 (Black) 3 (Red) 1 (White) 2 (Black) 3 (Red) -

Position of The Actuator Output

Remark

OPEN

+ + -

SOFT Mode

MEDIUM Mode

OPEN OPEN

+ -

HARD Mode

SUSPENSION DIAGNOSIS 2A-9

SCHEMATIC AND ROUTING DIAGRAMS

ECS CIRCUIT

2A-10 SUSPENSION DIAGNOSIS

SUSPENSION DIAGNOSIS 2A-11

Connector Pin Number and Circuits

NO.

1 2 3 4 5 6 7 8 9 10 11 12 13

Circuit Ignition Actuator R-MEDIUM Actuator R-SOFT Actuator F-HEAD Select Switch Speed Sensor Wheel G Sensor Vertical G Sensor Sensor +5V Chassis Ground Indicator Lamp

NO.

14 15 16 17 18 19 20

Circuit Chassis Ground Actuator R-HEAD Actuator F-MEDIUM Actuator F-SOFT Brake Switch Lateral G Sensor

15 16 17 18 19 20 21 22 23 24 25 26 2 3 4 5 6 7 8 9 10 11 12 13

Wheel G Sensor Ground 21 Lateral G Sensor Ground

22 Vertical G Sensor Ground 23 24 25 26

Diagnosis K Line Diagnosis L Line -

2A-12 SUSPENSION DIAGNOSIS

SELF DIAGNOSIS TEST

DIAGNOSIS TEST

Special Tool Requirements : Scanner

1. Position the ignition switch to 'OFF'. 2. Connect Scanner harness connector to the engine compartment diagnosis socket. 3. Turn the ignition switch to 'ON' position. 4. Select "Electronic control vehicle diagnosis" from function selection display and press "Enter". 5. Select "Musso ('98 model year)" from vehicle model selection display and press 'Enter'. 6. Select "Electronic suspension system (ECS)" from control system selection display and press 'Enter'. 7. Select "Self-diagnosis" from diagnosis item selection display. Notice Check sensor value output display, if necessary. 8. Determine the fault code and check defective component. Notice Refer to self-diagnosis list.

SUSPENSION DIAGNOSIS 2A-13

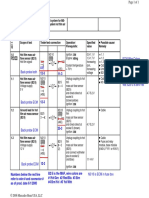

Self - Diagnosis List

Fault Code 01 Defects Vertical Acceleration Sensor Service Hint 1. Check sensor supply voltage ! Condition - IGN ON ! Standard value - voltage between pin 11 and 8 of ECU : 4.5 - 5.0V 2. Check sensor output voltage ! Condition - IGN ON ! Standard value - voltage between pin 20 and 11 of ECU : 0.5 - 4.5V 3. Check the sensor. 4. Check circuit for open. 5. Check connection of other connectors. 1. Check sensor supply voltage ! Condition - IGN ON ! Standard value - voltage between pin 11 and 8 of ECU : 4.5 - 5.0V 2. Check sensor output voltage ! Condition - IGN ON ! Standard value - voltage between pin 10 and 11 of ECU : 0.5 - 4.5V 3. Check the sensor. 4. Check circuit for open. 5. Check connection of other connectors. 1. Check sensor supply voltage ! Condition - IGN ON ! Standard value - voltage between pin 11, 8 and pin 7,11 of ECU : 4.5 - 5.0V 2. Check sensor output voltage 3. Check the sensor. 4. Check circuit for open. 5. Check connection of other connectors. 1. Check step motor supply voltage. 2. Check circuit for open. 3. Check connection of other connectors. 1. Check step motor supply voltage. 2. Check circuit for open. 3. Check connection of other connectors. 1. Check connectors of ECU. 2. Replace the ECU.

02

Lateral Acceleration Sensor

03

Wheel Acceleration Sensor

04

Front Step Motor

05

Rear Step Motor

06

ECU

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Cat 14M Centershift CylinderDocumento2 páginasCat 14M Centershift CylinderSHANEAún no hay calificaciones

- Caterpillar 3126Documento0 páginasCaterpillar 3126manuel12515100% (22)

- 981-0259 Onan HDCAA HDCAB (Spec A-D) Diesel Mobile Genset Parts Manual (10-2013)Documento68 páginas981-0259 Onan HDCAA HDCAB (Spec A-D) Diesel Mobile Genset Parts Manual (10-2013)Granville BarkerAún no hay calificaciones

- Idb 1Documento4 páginasIdb 1BUDAPESAún no hay calificaciones

- 3 Cigüeñal y Arbol de LevasDocumento32 páginas3 Cigüeñal y Arbol de LevasGuillermo Gerardo Sanchez PonceAún no hay calificaciones

- Meritor WABCO Hydraulic Anti-Lock Braking Systems (HABS) For Medium-Duty Trucks, Buses, and Motor Home ChassisDocumento8 páginasMeritor WABCO Hydraulic Anti-Lock Braking Systems (HABS) For Medium-Duty Trucks, Buses, and Motor Home ChassisDieselkAún no hay calificaciones

- PAAE229540 Manual en PDFDocumento522 páginasPAAE229540 Manual en PDFSalman Kapoor100% (1)

- Parts Catalog: Last Update Feb., 2013Documento266 páginasParts Catalog: Last Update Feb., 2013Clarence ClarAún no hay calificaciones

- 1987 RAM 50 2.6L Carburetor AdjustmentsDocumento5 páginas1987 RAM 50 2.6L Carburetor AdjustmentsMetalAnon100% (1)

- VP44 Service Manualpdf PDF FreeDocumento39 páginasVP44 Service Manualpdf PDF FreeTin Doan dinhAún no hay calificaciones

- AMICO 50 1994-1994 Spare Parts Catalogue, EnglishDocumento25 páginasAMICO 50 1994-1994 Spare Parts Catalogue, EnglishJake ElwoodAún no hay calificaciones

- 02 DICTATOR Damping SolutionsDocumento6 páginas02 DICTATOR Damping SolutionsjeanmalesAún no hay calificaciones

- Parts Manual: B30D & B25D 6X6 MKV AdtDocumento150 páginasParts Manual: B30D & B25D 6X6 MKV AdtTeknik MakinaAún no hay calificaciones

- 1600xd Owners ManualDocumento184 páginas1600xd Owners ManualForklift Systems Incorporated100% (1)

- 06 DX-LC Swing DeviceDocumento24 páginas06 DX-LC Swing DeviceSergey100% (2)

- 320-40009 Turbo 99HPDocumento177 páginas320-40009 Turbo 99HPIsa Yılmaz100% (1)

- European - JE Pistons AudiDocumento2 páginasEuropean - JE Pistons AudivepsmotorsportAún no hay calificaciones

- 0010 - Check Sheet PS PC400-7 KOMATSU 2Documento2 páginas0010 - Check Sheet PS PC400-7 KOMATSU 2sahruna japurAún no hay calificaciones

- BMW X5 Xdrive30d E70Documento54 páginasBMW X5 Xdrive30d E70vavasthiAún no hay calificaciones

- Anti Lock BrakesDocumento29 páginasAnti Lock BrakesRicardo Cornejo LafuenteAún no hay calificaciones

- Fuction1 MANAGE THE OPERATION OF PROPULSION PLANT UPDATEDocumento4 páginasFuction1 MANAGE THE OPERATION OF PROPULSION PLANT UPDATEAdii100% (1)

- Honda ECU Trouble CodesDocumento6 páginasHonda ECU Trouble Codeswarenzo100% (1)

- DHM26D0094: 12M26 Baudouin Diesel Parts CatalogueDocumento171 páginasDHM26D0094: 12M26 Baudouin Diesel Parts CataloguemunhAún no hay calificaciones

- KoothiDocumento18 páginasKoothiVIGNESH L RAún no hay calificaciones

- MAF Sensor TestDocumento1 páginaMAF Sensor TestClaudiu GalatanAún no hay calificaciones

- Instructions For Parts Books: Note About Country CodesDocumento168 páginasInstructions For Parts Books: Note About Country CodesJimmy RobertsonAún no hay calificaciones

- Marine Medium D2842 E-17-11Documento4 páginasMarine Medium D2842 E-17-11Joana Natalia PardedeAún no hay calificaciones

- Superb BrochureDocumento10 páginasSuperb BrochuregoaltechAún no hay calificaciones

- Brake System: 1986 Isuzu Trooper IIDocumento19 páginasBrake System: 1986 Isuzu Trooper IIpetarnikolicAún no hay calificaciones

- Chapter 2 (Operating Characteristics)Documento45 páginasChapter 2 (Operating Characteristics)zoro3samaAún no hay calificaciones