Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Cavitation: Cavity Cavity Cavity Cavity Cavity

Cargado por

Pavan KishoreTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Cavitation: Cavity Cavity Cavity Cavity Cavity

Cargado por

Pavan KishoreCopyright:

Formatos disponibles

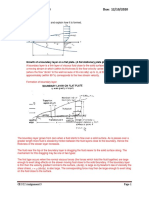

Fig. 11. The water flows evenly around the blade without bubbles.

Fig. 12. The blade is relatively thick and the water does not have time to come around the blade. Bubbles are formed, in this case on the suction side.

CAVITY

Fig. 13. Continuous bubbles (cavity) with even contact area, on super-cavitation propeller.

Fig. 14. Particles are hammered away from the propeller when the bubbles collapse. (In this case, on the suction side of the propeller).

Cavitation

A propeller blade screws itself through the water with a rather high speed. Measured at 70 % of the propeller radius, the speed is about 6080 knots. The speed in this case is the blade speed, not the boat speed. If the blade is too thick (in relation to the blade width) the water which is pushed away from the blade edge has such a high speed from the blade that it does not flow back over the blade before it has passed. One gets a space (cavity), which is filled with steam and air, which is always present in the water. See figs. 11 and 12. Cavitation at a propeller blade will gradually form and starts with bubbles and possible small eddies around the areas with low pressure. As the speed increases the bubbles get larger and at higher speeds float out in a continuous gas bubble with an even contact surface (super-cavitation) as per fig. 13. Speeds equal to the transformation zone little cavitation should be avoided. The reason is that the blades profile resistance increases at transformation and therefore reduces the propellers efficiency at the same time as there are risks for erosion damage at those places where the bubbles collapse. At the collapse, large pressure pulses are created which can quickly hammer away particles from the metal surface (erosion). See fig. 14. Erosion starts on the suction side if the propeller works with a too high load (high output, high revolutions and low speed), alternatively, if the blades leading edge is damaged or if the blade passes through a dead zone (for example behind a thick but not tapered keel). The erosion on the pressure side (which can be intensive) can be the result of too low propeller loading, that is low output, low revolutions and high speed, too high blade arching or the forward edge of the suction side has been badly ground. Fig. 15. The propeller should be designed so that cavitation on the pressure side never occurs. Cavitation on the suction side can be accepted to a certain level, if it is of the so called layer type. Many propellers have a small diameter in relation to the output, so that cavitation will more or less always occur. This, in combination with the water flow from a not so well designed stern (which gives eddies and release zones), initiates cavitation bubbles whose volume at the blade pulsates when the propeller rotates. One can get powerful propeller noise, partly through the pressure pulses in the water against the hull (this power is equivalent to about 5 % of the propellers thrust), and partly through bending vibrations in the propeller shaft.

Fig. 15. Erosion damage on the propellers pressure side. Particles are hammered away.

Fig. 16. The risk of erosion damage on propellers is greater if the stern is of a bad design. Eddies and release zones cause cavitation.

También podría gustarte

- Headsail Trim GuideDocumento8 páginasHeadsail Trim GuideLuiz Vieira100% (1)

- Collage Lab PDFDocumento145 páginasCollage Lab PDFmaa siddhi92% (12)

- How Do Sails WorkDocumento13 páginasHow Do Sails WorkStephen J Chandler100% (1)

- Inlet Geometry Flow Distribution SeparatorDocumento5 páginasInlet Geometry Flow Distribution Separatorchemsac2Aún no hay calificaciones

- Discharge Recirculation and CavitationDocumento2 páginasDischarge Recirculation and Cavitationdk4monjure100% (1)

- Illustrated Sail & Rig Tuning: Genoa & mainsail trim, spinnaker & gennaker, rig tuningDe EverandIllustrated Sail & Rig Tuning: Genoa & mainsail trim, spinnaker & gennaker, rig tuningCalificación: 3.5 de 5 estrellas3.5/5 (2)

- Turning Circles and Stopping DistancesDocumento7 páginasTurning Circles and Stopping DistancesBisrat100% (1)

- Hydrofoil CraftDocumento9 páginasHydrofoil CraftAnonymous e3ceN15100% (1)

- Describe The Effect of CavitationDocumento8 páginasDescribe The Effect of CavitationAnakin SkywalkerAún no hay calificaciones

- Analytical Methods in Conduction Heat TransferDocumento242 páginasAnalytical Methods in Conduction Heat TransferMayank Sharma50% (2)

- Chief Mate Orals Revision NotesDocumento178 páginasChief Mate Orals Revision NotesShankar Singh100% (1)

- Jet Powered BoatDocumento22 páginasJet Powered BoatMagesh OfficialAún no hay calificaciones

- Effect of Cavitation On PropellersDocumento3 páginasEffect of Cavitation On PropellersMohd Zaid100% (1)

- Class4 Question & Answers Ship ConstDocumento48 páginasClass4 Question & Answers Ship ConstNarine100% (2)

- Scuba Diving - Technical Terms MK IDocumento107 páginasScuba Diving - Technical Terms MK IJoachim MikkelsenAún no hay calificaciones

- Turning Circle NotesDocumento6 páginasTurning Circle Notesss_tayadeAún no hay calificaciones

- (Mechanical Engineering Series) Yuntao Song, Weiyue Wu, Shijun Du (Auth.) - Tokamak Engineering Mechanics-Springer-Verlag Berlin Heidelberg (2014)Documento249 páginas(Mechanical Engineering Series) Yuntao Song, Weiyue Wu, Shijun Du (Auth.) - Tokamak Engineering Mechanics-Springer-Verlag Berlin Heidelberg (2014)Pavan Kishore100% (1)

- Transverse Thrust: Ahead Movement of The PropellerDocumento5 páginasTransverse Thrust: Ahead Movement of The PropellerFaizaan BadarAún no hay calificaciones

- Span Squared?: Article by Paul BogatajDocumento6 páginasSpan Squared?: Article by Paul BogatajRoger AdamsAún no hay calificaciones

- SquatDocumento22 páginasSquatbgarneiro100% (1)

- Squat CalculationDocumento2 páginasSquat CalculationAjay SinghAún no hay calificaciones

- Turning Circles and Stopping Distances: Ship ManoeuvringDocumento3 páginasTurning Circles and Stopping Distances: Ship ManoeuvringrigelAún no hay calificaciones

- Narrow ChannelDocumento6 páginasNarrow ChannelAurelio DutariAún no hay calificaciones

- Agitation Equipment: Impellers Are Divided Into Two ClassesDocumento13 páginasAgitation Equipment: Impellers Are Divided Into Two ClassesMêhrän AlîAún no hay calificaciones

- Aizimuth Tug BoatDocumento3 páginasAizimuth Tug BoatTuan Dao QuangAún no hay calificaciones

- Introduction To Cavitation in Pumps and Their TypesDocumento12 páginasIntroduction To Cavitation in Pumps and Their TypesMujadid Khawaja100% (1)

- The Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisDe EverandThe Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisAún no hay calificaciones

- Transverse Thrust On The PropellerDocumento12 páginasTransverse Thrust On The PropellerNuman Kooliyat IsmethAún no hay calificaciones

- Propeller ElectricityDocumento23 páginasPropeller ElectricitysoneraktasAún no hay calificaciones

- Blowout (Well Drilling) : Differential Sticking Is A Problem That Occurs When Drilling ADocumento6 páginasBlowout (Well Drilling) : Differential Sticking Is A Problem That Occurs When Drilling AMEUBROAún no hay calificaciones

- Taper Lock BushesDocumento4 páginasTaper Lock BushesGopi NathAún no hay calificaciones

- CavitationDocumento1 páginaCavitationThommas HofmannAún no hay calificaciones

- Cavitation: A) The Basics of CavitationDocumento4 páginasCavitation: A) The Basics of CavitationYekta Fırat İnciAún no hay calificaciones

- Propeller and Hull-Induced VibrationDocumento3 páginasPropeller and Hull-Induced Vibrationnavalzero910Aún no hay calificaciones

- Vaporous Cavitation Is The Most Common Form of Cavitation Found in Process Plants. Generally It OccursDocumento4 páginasVaporous Cavitation Is The Most Common Form of Cavitation Found in Process Plants. Generally It OccursArun AzhakesanAún no hay calificaciones

- Propeller TheoryDocumento8 páginasPropeller TheorybolsjhevikAún no hay calificaciones

- Well Control Manual: E.amirov@hw - Ac.ukDocumento108 páginasWell Control Manual: E.amirov@hw - Ac.ukUMA SHANKAR TRIPATHIAún no hay calificaciones

- Dam From: Safety Valve For A DamDocumento28 páginasDam From: Safety Valve For A DamRashmi SahooAún no hay calificaciones

- A Bulbous Bow Is A Protruding Bulb at The BowDocumento7 páginasA Bulbous Bow Is A Protruding Bulb at The BowAshim AliAún no hay calificaciones

- Transverse ThrustDocumento5 páginasTransverse ThrustHarikrishnaAún no hay calificaciones

- Pumps and Propellers: Suction CavitationDocumento1 páginaPumps and Propellers: Suction CavitationRichard HoseAún no hay calificaciones

- The Temperature of Water Is Kept Constant During SwimmingDocumento2 páginasThe Temperature of Water Is Kept Constant During SwimmingBizay MarikhuAún no hay calificaciones

- Article CFB Studies On The Operation of Loop Seal in Circulating Fluidized Bed Boilers-3Documento1 páginaArticle CFB Studies On The Operation of Loop Seal in Circulating Fluidized Bed Boilers-3nguyenhuutan91Aún no hay calificaciones

- B3-1.FAST2011.Davis Et Al PDFDocumento8 páginasB3-1.FAST2011.Davis Et Al PDFtoshugoAún no hay calificaciones

- SurfaceDocumento10 páginasSurfaceManoj Kumar BisoyiAún no hay calificaciones

- HovercraftDocumento8 páginasHovercraftAnonymous e3ceN15Aún no hay calificaciones

- Figure 1. Stages of Cavitation. Source: (Marchegiani, 2006)Documento6 páginasFigure 1. Stages of Cavitation. Source: (Marchegiani, 2006)Steven PalaciosAún no hay calificaciones

- Cavitation ForDocumento26 páginasCavitation FormitkiedegaregeAún no hay calificaciones

- Assignment 3-Solutions PDFDocumento6 páginasAssignment 3-Solutions PDFNickson KomsAún no hay calificaciones

- CE 361 - Lecture 8Documento13 páginasCE 361 - Lecture 8Sai KrishnaAún no hay calificaciones

- Hydrodynamic Lift On BoatsDocumento26 páginasHydrodynamic Lift On BoatsHemanth KumarAún no hay calificaciones

- Chief Mate Orals Revision NotesDocumento163 páginasChief Mate Orals Revision NotesravelobeAún no hay calificaciones

- 1.stresses On Propeller Shaft: 2.excessive Stern Tube Bearing Wear Down ReasonsDocumento10 páginas1.stresses On Propeller Shaft: 2.excessive Stern Tube Bearing Wear Down ReasonsSubham SamantarayAún no hay calificaciones

- Extruder ScrewsDocumento7 páginasExtruder ScrewsShiven KapilAún no hay calificaciones

- Or Four?: Propeller-Excited Vibration Five BladesDocumento16 páginasOr Four?: Propeller-Excited Vibration Five Bladesacar1Aún no hay calificaciones

- Ship Design For Efficiency and Economy-7-226-53-60Documento8 páginasShip Design For Efficiency and Economy-7-226-53-60galin8575Aún no hay calificaciones

- Day 4Documento7 páginasDay 4MALIK TALHA ALI SAJIDAún no hay calificaciones

- Velikanov's Equation PDFDocumento19 páginasVelikanov's Equation PDFnirajlamichhane100% (1)

- Vertedores en SifónDocumento21 páginasVertedores en SifónEfrenAún no hay calificaciones

- Turning CircleDocumento8 páginasTurning CircleAkash KandwalAún no hay calificaciones

- Common Problems With Groundwater in EngineeringDocumento5 páginasCommon Problems With Groundwater in EngineeringBiswarup AkhuliAún no hay calificaciones

- SpillwaysDocumento18 páginasSpillwaysTitus EapenAún no hay calificaciones

- Model aeroplanes: The building of model monoplanes, biplanes, etc., together with a chapter on building a model airshipDe EverandModel aeroplanes: The building of model monoplanes, biplanes, etc., together with a chapter on building a model airshipAún no hay calificaciones

- PanelDocumento3 páginasPanelPavan KishoreAún no hay calificaciones

- Engine 2018 BrochureDocumento2 páginasEngine 2018 BrochurePavan KishoreAún no hay calificaciones

- MosDocumento2 páginasMosPavan KishoreAún no hay calificaciones

- ANSYS Tutorial: Jake Blanchard January 2008Documento24 páginasANSYS Tutorial: Jake Blanchard January 2008Joan HeviaAún no hay calificaciones

- Materials Methodology Stress FactorsDocumento21 páginasMaterials Methodology Stress Factors538540Aún no hay calificaciones

- Call For PapersDocumento7 páginasCall For PapersPavan KishoreAún no hay calificaciones

- Lesson Plan Subject: Engineering Mechanics (BME-101), Date Topics To Be CoveredDocumento1 páginaLesson Plan Subject: Engineering Mechanics (BME-101), Date Topics To Be CoveredPavan KishoreAún no hay calificaciones

- Selection Procedure For Teaching PositionsDocumento15 páginasSelection Procedure For Teaching PositionsPavan KishoreAún no hay calificaciones

- Jsir 69 (9) 680-683 PDFDocumento4 páginasJsir 69 (9) 680-683 PDFPavan KishoreAún no hay calificaciones

- Auxiliary File FormatDocumento133 páginasAuxiliary File FormatPavan KishoreAún no hay calificaciones

- 15746Documento21 páginas15746Pavan KishoreAún no hay calificaciones

- 32 Forms of Lord Ganesh: Dr.S.KannanDocumento1 página32 Forms of Lord Ganesh: Dr.S.KannanPavan KishoreAún no hay calificaciones

- MosDocumento101 páginasMosPavan KishoreAún no hay calificaciones

- Lab Consumables Requirement - 2018-19 A. Y.Documento4 páginasLab Consumables Requirement - 2018-19 A. Y.Pavan KishoreAún no hay calificaciones

- Stress Concentration Analysis Between Two Neighboring Circular Holes Under Internal Pressure of A Non-Explosive Expansion MaterialDocumento12 páginasStress Concentration Analysis Between Two Neighboring Circular Holes Under Internal Pressure of A Non-Explosive Expansion MaterialPavan KishoreAún no hay calificaciones

- Nonlinear Free Vibration Analysis of Single and Doubly Curved Composite Shallow Shell PanelsDocumento29 páginasNonlinear Free Vibration Analysis of Single and Doubly Curved Composite Shallow Shell PanelsPavan KishoreAún no hay calificaciones

- Notification ClarificationDocumento1 páginaNotification ClarificationPavan KishoreAún no hay calificaciones

- Material Property DataDocumento13 páginasMaterial Property DataKshitij SharmaAún no hay calificaciones

- Indian Institute of Petroleum & Energy (Iipe) : Size: 8x5 40 SQ - CM The Hindu, EenaduDocumento1 páginaIndian Institute of Petroleum & Energy (Iipe) : Size: 8x5 40 SQ - CM The Hindu, EenaduPavan KishoreAún no hay calificaciones

- Heat ConductionDocumento1 páginaHeat ConductionPavan KishoreAún no hay calificaciones

- 2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsDocumento1 página2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsPavan KishoreAún no hay calificaciones

- Unsteady Heat ConductionDocumento8 páginasUnsteady Heat ConductionRamesh KonakallaAún no hay calificaciones

- A Method For Propeller Blade Optimization and Cavitation Inception MitigationDocumento1 páginaA Method For Propeller Blade Optimization and Cavitation Inception MitigationPavan KishoreAún no hay calificaciones

- De DT K K K: 38 J.D. Anderson, JRDocumento1 páginaDe DT K K K: 38 J.D. Anderson, JRPavan KishoreAún no hay calificaciones

- EnergyDocumento8 páginasEnergyPavan KishoreAún no hay calificaciones

- 2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsDocumento1 página2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsPavan KishoreAún no hay calificaciones

- 2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsDocumento1 página2.8 Summary of The Governing Equations For Fluid Dynamics: With CommentsPavan KishoreAún no hay calificaciones

- ACD2505-03 - Eqns of Fluid FlowDocumento67 páginasACD2505-03 - Eqns of Fluid FlowPavan KishoreAún no hay calificaciones

- Primakuro Catalogue Preview16-MinDocumento10 páginasPrimakuro Catalogue Preview16-MinElizabeth LukitoAún no hay calificaciones

- Vol07 1 PDFDocumento275 páginasVol07 1 PDFRurintana Nalendra WarnaAún no hay calificaciones

- High Performance Dialysis GuideDocumento28 páginasHigh Performance Dialysis GuideRoxana ElenaAún no hay calificaciones

- Novel Image Enhancement Technique Using CLAHE and Wavelet TransformsDocumento5 páginasNovel Image Enhancement Technique Using CLAHE and Wavelet TransformsInnovative Research PublicationsAún no hay calificaciones

- AVR Brosure Basler Decs 100Documento2 páginasAVR Brosure Basler Decs 100NikolayAún no hay calificaciones

- Asynchronous ChipsDocumento27 páginasAsynchronous ChipsSai TejaAún no hay calificaciones

- Bluforest, Inc. (OTC: BLUF) InvestigationDocumento5 páginasBluforest, Inc. (OTC: BLUF) Investigationfraudinstitute100% (1)

- Lab Centre of Pressure Ecw341Documento4 páginasLab Centre of Pressure Ecw341danialAún no hay calificaciones

- Theology of Work and Practical ImplicationsDocumento28 páginasTheology of Work and Practical ImplicationsVinicius CardosoAún no hay calificaciones

- Soal Bahasa Inggris X - XiDocumento6 páginasSoal Bahasa Inggris X - XiBydowie IqbalAún no hay calificaciones

- 1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016Documento3 páginas1 Quarter: 5 Grade Benchmark Scope and Sequence Pacing Guide 2015-2016api-292307509Aún no hay calificaciones

- Vibrations - NptelDocumento3 páginasVibrations - NptelMSK65Aún no hay calificaciones

- ScheduleDocumento1 páginaScheduleparag7676Aún no hay calificaciones

- Zetor Crystal 150 170 Tractor Operator Manual PDFDocumento234 páginasZetor Crystal 150 170 Tractor Operator Manual PDFAntonAún no hay calificaciones

- Epilepsy Lecture NoteDocumento15 páginasEpilepsy Lecture Notetamuno7100% (2)

- 173 EvidenceDocumento6 páginas173 EvidenceSantiago RubianoAún no hay calificaciones

- Fluid Solids Operations: High HighDocumento20 páginasFluid Solids Operations: High HighPriscilaPrzAún no hay calificaciones

- TC AdvisoryDocumento1 páginaTC AdvisoryJerome DelfinoAún no hay calificaciones

- Mercedes (DTC) 976990001963 20220615144147Documento3 páginasMercedes (DTC) 976990001963 20220615144147YB MOTOR Nissan - Datsun SpecialistAún no hay calificaciones

- Master of Business Administration in Aviation Management MbaamDocumento10 páginasMaster of Business Administration in Aviation Management MbaamAdebayo KehindeAún no hay calificaciones

- Modular Air Handling Unit (FMA)Documento3 páginasModular Air Handling Unit (FMA)Salamet TeguhAún no hay calificaciones

- Nano ScienceDocumento2 páginasNano ScienceNipun SabharwalAún no hay calificaciones

- Wilson FR & Power Cable CatalogDocumento56 páginasWilson FR & Power Cable CatalogRohim SuhadiAún no hay calificaciones

- With EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMDocumento4 páginasWith EU Stage V Engine Installed: 200 HP (149 KW) / 2,200 RPMSara Sarmiento EcheverryAún no hay calificaciones

- EQ Cheat SheetDocumento7 páginasEQ Cheat SheetGabrielAún no hay calificaciones

- Med Chem Exam 2Documento24 páginasMed Chem Exam 2cAún no hay calificaciones

- Technical Methods and Requirements For Gas Meter CalibrationDocumento8 páginasTechnical Methods and Requirements For Gas Meter CalibrationIrfan RazaAún no hay calificaciones