Documentos de Académico

Documentos de Profesional

Documentos de Cultura

CFD Simulation of SDHW Storage Tank With and Without Heater

Cargado por

Mainak BhaumikDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

CFD Simulation of SDHW Storage Tank With and Without Heater

Cargado por

Mainak BhaumikCopyright:

Formatos disponibles

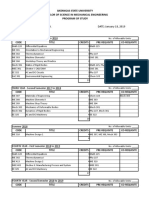

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

CFD SIMULATION OF SDHW STORAGE TANK WITH AND WITHOUT HEATER

(1) Mr. Mainak Bhaumik M.E. (Thermal Engg.) Mechanical Engineering Department SPCE, Mumbai - 400058 Maharashtra, India +91 9819568377 mainak_bhaumik@yahoo.com

ABSTRACT 2D-Single Phase heat and fluid flow analysis of solar domestic hot water (SDHW) storage tank has been carried out by using CFD tools, ICEM for modelling & meshing and FLUENT for analysis. The tank fluid is in static mode. Heat diffusion and convective heat loss from the tank without heater and with the involvement of additional heater is studied. After heating water gets lighter and moves upward in the tank and cold denser water remains at the bottom of the tank. The movement of the water particles are also analysed to find the effect on heat transfer and heat loss. Time transient analysis is focused on for a constant fixed temperature of water inside the tank and the heat drop is captured. Investigation gives guidelines how long the water temperature can be maintain warmer within the tank while the tank is uninsulated. If it is required to maintain temperature constant then the involvement of heater can be useful in what extend.

INTRODUCTION

Solar hot water storage systems are dependable on climatic condition. This system can provide up to 90 per cent of our hot water for free using the suns energy. Solar systems cost more to buy and install but the extra upfront cost will be recovered over the life of the system through reduced energy bills. It takes longer time to recover costs in smaller households, in cooler parts of the country, or where access to sunlight is restricted. To provide hot water on cloudy days or when demand of hot water exceeds especially during winter season then it needs to involve additional heater to boost up the heating process and to maintain consistency of hot water supply at any time throughout the day. Hot water storage tank is a vertical vessel made of steel which is used to store thermal energy in terms of water to fulfil the domestic and industrial hot water demands. The operation of SDHW Storage tank is mainly of two types forced convection SDHW Storage system and natural convection SDHW type. Natural convection SDHW storage tank works based on the temperature and density difference of water. Initially the tank and collector piping is filled with cold water. As the water gets heated up it becomes lighter and it rises up automatically and enters into the top of the tank from solar collector. While cold denser water from the bottom of the tank fills the empty space within the collector and collector piping. The schematic diagram of the SDHW system is as shown in Fig. 1.

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

Fig.1: Schematic diagram of SDHW system.

PROBLEM DEFINITION

The Problem contains a study model vertical hot water storage tank. The storage tank is filled with constant hot water temperature of 60 . Transient analysis of hot water tank is carried out using commercial CFD Software. The tank is at static mode, there is no inlet and outlet of energy only heat diffusion and heat movement takes place internally. Walls of the tank considered are uninsulated. A schematic of the model vertical cylindrical storage tank is as shown in Fig. 2.The storage tank is having height of 1200mm and diameter 300mm. Inside the storage tank the water experience heating and cooling process due to temperature gradient present there.

Fig.2: Schematic diagram of the Hot Water Storage Tank under study.

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

Case1 The tank is filled with constant hot water at a temperature of 60 . It is uninsulated tank without any electric heater inside. Heat diffusion occurs inside the fluid molecules and heat loss takes place through the walls of the tank. Main intention of this case is to find out the diffusion rate and time taken for heat loss from a constant hot temperature, if any tank is uninsulated. Fig. 3 illustrates the schematic diagram.

Fig. 3: Hot water in the tank at constant temperature.

Case2 Case 2 consists of same tank in size. The walls of the tank considered as uninsulated walls. The tank contains one electric heater at the centre of the tank to keep warm water at constant a temperature of 60 with less heat flow. This case investigates to maintain a constant hot water temperature and also to raise the temperature when the tank water gets colder. Fig. 4 shows the schematic diagram.

Fig. 4: Hot water tank at constant temperature with electric heater.

NUMERICAL MODELING, SIMULATION AND ANALYSIS

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

The most important aspects of CFD code are its ability to incorporate governing equations and conservation laws. CFD code must apply conservation of energy, momentum and continuity equations for steady state and transient behaviour. In this study geometric modelling techniques in fixed-grid schemes are outlined including grid size and boundary layer construction in two dimensions. Modeling Proper and effective modelling of geometry is essential for the accuracy of numerical simulations. The geometry created must satisfy the accuracy of simulation analysis, should be simple to permit simulation easily and contains sufficient computational volumes to achieve accurate results. A two-dimensional SDHW storage tank of length 1.2m and 0.30m width is created using ICEM software. Also meshing is done using ICEM meshing tools. The tank contains hot water inside. The complete mesh geometric model is as shown in Fig.5.

Fig.5: Complete 2-D view of geometry having mesh size 18,360.

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

Fig.6: Complete 2-D view of geometry with central heater with mesh size 18,360.

Simulation The computational procedures used in FLUENT are complex and much research has gone into developing the many algorithms used in FLUENT to sole the differential equations in fluid flow and heat transfer problems. As a result, numerous algorithms and discretization schemes are used from FLUENT. Transient CFD calculations are performed with a density of water as function of temperature, shown in equation (1). The PRESTO and second order upwind method are used for the discretization of the pressure and momentum/energy equations respectively. The SIMPLE algorithm is used to treat the pressure-velocity coupling. The transient simulations start from a tank with hot water uniform temperature of 60 . The calculation is considered as convergent for the continuity equation, the momentum equations and the energy equation. The simulation runs with a time step of 1 s. Investigations are carried out to detect the optimal time step and grid density. Density, (kg/m3) = 863 + 1.21*T 0.00257*T2 Where, T is fluid temperature, [K]. Boundary conditions After the computational domain is configured, it requires to set initial and boundary conditions. The energy balance of equation is enabled and water properties are set via the Boussinesq natural convection. The entire domain is initialized to a temperature of 60 . Also the convective heat transfer boundary condition is set using the Boundary Conditions panel. The tank wall is specified as a nonadiabatic wall. The convective heat transfer from the tank wall with the ambient surrounding temperature at and surrounding tank wall air average heat transfer co-efficient is 10w/m2 k is set. For natural convection gravity is enabled. The gravitational acceleration is set to 9.81m/s2 in the negative y-direction. In case 2 the boundary condition is applied in the central heater walls. To keep the tank water at a constant temperature of 60 the heater starts. Convection heat transfer from the heater wall specified is 1000 w/m2k. Analysis The governing equations are solved and analyzed to determine temperature, flow path and momentum. The energy equation is activated to solve buoyancy driven heat transfer equation using Bousssinesq equation. Even though the tank is in static mode and no external mass and heat takes place, then to as internally heat diffusion occurs, due to that flow of the atoms takes place also movement of the particles takes place so both flow and momentum equation is also activated. Natural-convection flow is modelled with Boussinesq approximation during CFD simulation. The buoyancy for an incompressible fluid with constant fluid properties is modelled by using the Boussinesq approximation in ANSYS FLUENT 6.3. The model uses a constant density fluid model but applies a local gravitational body force throughout the physical domain which is a linear function of the fluid thermal expansion coefficient () and the local temperature difference relative to a datum called the buoyancy referen ce temperature. The Boussinesq approximation models the change in density using eq.4. ( ref) = ref. .. (T Tref) Where, T is the local temperature in K, Tref is the buoyancy reference temperature in K, is the thermal expansion coefficient in K-1,

Copyright 2012 SciResPub.

(1)

(2)

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

ref is the density of water in kg/m3 and is the local density in kg/m3 A zero velocity field is assumed at the start of all simulations. The calculation is considered convergent for the continuity equation, the momentum equations and energy equations.

RESULTS AND DISCUSSION

Using ICEM software tools solid modelling and mesh is prepared. Fluent 13 has been used as solver. The investigation starts with grid sensitivity test. As the time passes heat loss from the uninsulated walls of the tank takes place. Through the walls of the tank cool water settles down and forms stratified water tank. Slowly the level of cold water rises from the bottom part of the tank. Case 1 CFD Result It is seen that the tank cools as the time progresses. The darker regions indicate cooler temperature when the heater is in off mode as shown in Fig. 6. Due to buoyancy driven natural convection currents and also heat loss from the tank walls, the higher denser cold water settles down at the bottom of the tank. Fig. 7 explains how the temperature drops gradient occurs due to heat loss from 60 to 47 . It takes 10 hours to drop down temperature. These 10 hours is unavailable hot water temperature time.

Fig. a: Temperature contour after 04 hours.

Fig. a: Temperature contour after 08 hours.

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

Fig. a: Temperature contour after 24 hours.

Fig. 7: Temperature drop from constant temperature of 60 .

Fig.8: Time v/s temperature plot in the tank when heater is OFF and temperature drop from the tank.

Case 2 CFD Results To keep constant hot water temperature the heater can be switch on. The electric heater of capacity 1,000 watts can maintain a constant temperature of 60 with minor fluctuation of temperature. Fig. 9 shows the temperature profile at different time interval. Because of this there is a heat input from the heater and losses (output) of heat from the walls. So if we can keep heat input from the heater to an optimized value (that is equal to the heat output from the walls) we can maintain the average temperature of water inside the storage tank at constant value (initial temperature). Fig. 10 shows the pictorial view of the surface plot of temperature of the water inside of storage tank with heater on and off at different time interval. Because of the heater being ON and the heat losses being compensated temperature of the water inside the storage tank increases only 1C (virtually constant). It is shown in Fig. 11.

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

Fig. a: Temperature contour after of 04 hours.

Fig. b: Temperature contour after of 06 hours. Fig. 9: Temperature contour when the tank heater is switch on.

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

Fig. 10: Plot of comparison when heater is ON and OFF in the storage tank

Fig. 11: Plot of temperature rise by 1C while heater is on inside the storage tank at the centre of the tank.

Grid independent test

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

10

Five different sizes of grids viz., 12,680, 18,360, 22,236, 36,780 and 73,440 are taken. These five grid mesh domain are simulated for one hour. The values of Temperature v/s grid size are plotted as shown in Fig.12. From the plotted graph it is found that the grid size 18,360 and 36,780 are grid independent. The grid number 18,360 is used for all the cases.

Fig.12: Grid independent test

CONCLUSION

From the simulated results it can be concluded that SDHW storage tank installed should be insulated. Because of uninsulation the constant hot water temperature inside the tank drops after of certain period due to heat diffusion and natural convection from the tank walls and constant temperature becomes unavailable at all the time. To keep temperature constant it needs to start heater. Heater can provide constant temperature but the electric bill may rise. So to avoid cost and world emission it is better to maintain optimum insulation thickness with good insulating material. Further cases can be simulated in future with insulated tank. Also the position of the heater can be optimized.

REFERENCES

1. Sukhumi S. P., Solar Energy, McGraw-Hill, New Delhi, 1996. 2. Fan J. and Furbo S., Thermal stratification in a hot water tank established by heat loss from the tank, Proceedings of the ISES Solar World Congress, Renewable Energy Shaping Our Future. PP. 341-350, 2009. 3. Anderson J. D., 1995. Computational Fluid Dynamics, International Edition, McGraw-Hill.

Copyright 2012 SciResPub.

International Journal of Advancements in Research & Technology, Volume 1, Issue2, July-2012 ISSN 2278-7763

11

4. Versteeg H. K. and Malalasekara W. An Introduction to computational fluid dynamics John Wiley and sons Inc., 605 Third Avenue, New York. 19. Patanker S. V., Numerical Heat transfer and Fluid Flow, T aylor& Francis. 1980. 5. Michael et al., Thermocline Movement Dynamics and Thermocline Growth in Stratified Tanks for Heat Storage, Chemical Engineering Transactions.,Vol. 21, pp. 991-996, 2010. 6. Joko Waluyo et al., Temperature Profile and Thermocline Thickness Evaluation of a Stratified Thermal Energy Storage Tank, International Journal of Mechanical & Mechatronics Engineering IJMME -IJENS., Vol. 10, pp. 7-12, 2010. 7. Jabbar Abdul et al., Experimental Study of Temperature Stratification in a Ther mal Storage Tank in the Static Mode for Different Aspect Ratios, ARPN Journal of Engineering and Applied Sciences., Vol. 6, No. 2, pp. 53-60, Feb. 2011. 8. ANSYS FLUENT 6.3.26 Users Manual, ANSYS, Inc. 9. ICEM-CFD 12.0 Users Guide, ANSYS, Inc.

Copyright 2012 SciResPub.

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Quantum Magick Reconfiguring The Field, A Powerful Companion To Mind Magic Methods (The Mind Magic System Book 2) (Merlin Starlight) (Z-Library)Documento225 páginasQuantum Magick Reconfiguring The Field, A Powerful Companion To Mind Magic Methods (The Mind Magic System Book 2) (Merlin Starlight) (Z-Library)Raynald Sumampouw100% (1)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2101)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- Design of Foundation 6/8 MVA Power TransformerDocumento2 páginasDesign of Foundation 6/8 MVA Power TransformerSujit Rasaily0% (2)

- Two DimensionsDocumento7 páginasTwo Dimensionsalex murker100% (1)

- Still Water BM and SFDocumento5 páginasStill Water BM and SFpothirajkalyanAún no hay calificaciones

- Economic Operation of Power SystemDocumento45 páginasEconomic Operation of Power SystemDogbey BrightAún no hay calificaciones

- ESD Asociation Standard For Protection of Electrostatic Disharge ANSI-ESD S6.1-1999Documento14 páginasESD Asociation Standard For Protection of Electrostatic Disharge ANSI-ESD S6.1-1999EmilianoAún no hay calificaciones

- Introduction To Antenna Types and Their Applications: Abstract This Paper Introduces Antenna Theory and DiscussesDocumento7 páginasIntroduction To Antenna Types and Their Applications: Abstract This Paper Introduces Antenna Theory and DiscussesNag ChallaAún no hay calificaciones

- 7 E Lesson Plan Impulse and MomentumDocumento3 páginas7 E Lesson Plan Impulse and MomentumCristina Nicomedes Aguinaldo86% (21)

- Physical Science Study Committee-2018Documento682 páginasPhysical Science Study Committee-2018kerooAún no hay calificaciones

- Strength of Material 2Documento12 páginasStrength of Material 2mjdalenezi100% (1)

- Crystal Lattice Vibrations: Phonons: Introduction To Solid State PhysicsDocumento25 páginasCrystal Lattice Vibrations: Phonons: Introduction To Solid State PhysicsJack CaoAún no hay calificaciones

- Questions & Answers - RT Level 2Documento5 páginasQuestions & Answers - RT Level 2Mohan Raj100% (1)

- Installation Operation & Maintenance of 33kV & 11kV SwitchgearDocumento23 páginasInstallation Operation & Maintenance of 33kV & 11kV SwitchgearSaff MdAún no hay calificaciones

- Energy Use Pullen2000Documento9 páginasEnergy Use Pullen2000LuqmanAún no hay calificaciones

- Gate-Me-2024, V-IiDocumento401 páginasGate-Me-2024, V-Iiyash guptaAún no hay calificaciones

- Grade 7 Daily Lesson Plan: I. ObjectivesDocumento3 páginasGrade 7 Daily Lesson Plan: I. ObjectivesJanecil A. BonzaAún no hay calificaciones

- Dielectric Resonator Antenna Theory Anf FabricationDocumento39 páginasDielectric Resonator Antenna Theory Anf FabricationjacnjillAún no hay calificaciones

- Rohini 42795977333Documento3 páginasRohini 42795977333madesh1047Aún no hay calificaciones

- شيت مختبر الاسس PDFDocumento23 páginasشيت مختبر الاسس PDFMohamad AlhadithyAún no hay calificaciones

- 8-Blade Element Theory in Forward FlightDocumento22 páginas8-Blade Element Theory in Forward Flightnikhil raoAún no hay calificaciones

- Me 6711 - Simulation & Analysis LaboratoryDocumento71 páginasMe 6711 - Simulation & Analysis Laboratorymallikarjuna.handiAún no hay calificaciones

- Atwoods MachineDocumento4 páginasAtwoods MachineMelissa Smith0% (1)

- LHC Project Report 374Documento9 páginasLHC Project Report 374Binay Prasanna JenaAún no hay calificaciones

- OATBooster Formula Sheet (July 2022) PDocumento11 páginasOATBooster Formula Sheet (July 2022) PzainabAún no hay calificaciones

- PosDocumento3 páginasPosAndre De VillaAún no hay calificaciones

- Electron StructureDocumento13 páginasElectron Structuredejla67Aún no hay calificaciones

- Geankoplis 2.6-4 2.7-4Documento7 páginasGeankoplis 2.6-4 2.7-4BenePicarAún no hay calificaciones

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 27Documento5 páginasMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 27amir moniriAún no hay calificaciones

- Gorom Angelica Lirio R. Phys101l b8 E102 2q1819Documento3 páginasGorom Angelica Lirio R. Phys101l b8 E102 2q1819Janno RafaelAún no hay calificaciones

- CHEM Part2Documento90 páginasCHEM Part2Reiniel Cirujano AntonioAún no hay calificaciones