Documentos de Académico

Documentos de Profesional

Documentos de Cultura

A Guide To Working Near The Electric Power Network

Cargado por

Milos VajagicDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

A Guide To Working Near The Electric Power Network

Cargado por

Milos VajagicCopyright:

Formatos disponibles

2837 23.09.

2010 Page 1 of 33

A GUIDE TO WORKING NEAR THE ENERGEX NETWORK

INCLUDING:

Working near ENERGEX Overhead Power Lines Trenching adjacent ENERGEX Power Poles Working Near ENERGEX Underground Cables

2837 23.09.2010 Page 2 of 33

Table of Contents

Introduction About this Guide Section 1 - Working near exposed live electrical parts of the ENERGEX network Performing work near exposed live parts What is the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts? Who does the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts apply to? What must be done if planning to work potentially within 3.0m of exposed live parts of the ENERGEX network? What Clearances must be maintained during construction Disconnection of a customers installation by a licensed electrical contractor to eliminate an exclusion zone Definition of Terms Operating Plant Other control measures Work close scaffold barrier guidelines Horizontal clearances Vertical clearances What clearances must be maintained once the work is completed Section 2 - Trenching adjacent ENERGEX power poles Purpose What are the conditions applicable to these guidelines Managing excavating near poles Certified Engineering Assessment requirements What additional requirements are to be considered? Guidelines for supporting poles using a Lifter / Borer vehicle Section 3 - Working in the vicinity of ENERGEX underground cables Introduction Sample DBYD maps DBYD Terms and Conditions Section 4 Process & Forms Process flowchart Summary of standard forms Form 1227 Application for Safety Advice Form 1228 Important Notice Form 0347 Safety Advice on Working Near ENERGEX Exposed Live Electrical Parts Appendices Appendix A Exclusion zones 33 28 28 29 30 31 22 23 24 16 16 16 17 18 19 12 13 14 6 6 6 7 7 8 8 9 10 3 4

Version and Revision Details

Date 23/09/2010 Name Peter Davies Steve Biegel Action Original Draft

2837 23.09.2010 Page 3 of 33

Introduction

The purpose of this document is to provide guidance to anyone who may be contemplating working or operating plant near any ENERGEX electricity poles, structures or mains or working in the vicinity of ENERGEX overhead or underground electricity cables or excavating adjacent to ENERGEX poles and structures. The Electrical Safety Act places obligations on certain persons to ensure electrical safety. Obligation holders include an employer or self-employed person but excludes householders who are not operating as an employer or self-employed person. For example, a householder engaging the services of a plumber, the plumber will have an obligation under the Electrical Safety Act, not the householder, unless the householder is operating as an employer or self-employed person (eg. Owner / builder). Electrical safety is ensured when a person or property is free from electrical risk. This means that the electrical risk to the person or property is as low as reasonably achievable, having regard to likelihood of harm and likely severity of harm. Ensuring electrical safety involves identifying and managing exposure to risks at the workplace. Similarly, the Workplace Health and Safety Act 1995 places obligations on certain persons to ensure workplace health and safety. Workplace health and safety is ensured when persons are free from death, injury or illness and the risk of death, injury or illness created by workplaces, relevant workplace areas, work activities or plant or substances for use at a workplace. Ensuring workplace health and safety involves identifying and managing exposure to risks at the workplace. When deciding on control measures to remove the hazard or minimise the risk of injury or property damage that may result the preferred hierarchy of control is to: PREFERRED OPTIONS 1. 2. Eliminate the hazard relocate or place underground the overhead conductors Isolate the hazard through network switching, isolate supply to the section/s concerned

OTHER OPTIONS 3. Implement administrative controls visual markers, barriers etc

If the overhead network is to be removed or placed underground, as part of the development, ENERGEX would encourage the developer, in the interests of electrical safety, to underground or remove the conductors early in the project to remove the risk of contacting overhead conductors during construction. In cases where replacing the overhead mains with underground cables is not a condition of development approval ENERGEX recommends the developer consider initiating such works to improve streetscape and property visual appeal in addition to improving electrical safety by eliminating hazards during construction. The information provided in this document is for guidance only and must be read in conjunction with the requirements of the Workplace Health and Safety Act 1995, the Electrical Safety Act 2002 (ESA), the Electrical Safety Regulations 2002, relevant Codes of Practice and other applicable legislation. Before commencing any work in the vicinity of ENERGEX overhead or underground electricity cables or excavating adjacent to ENERGEX poles and structures you should ensure you are familiar with your obligations under the legislation and Codes. You should take particular care you are familiar with your obligation under the ESA, particularly the general obligation of an employer or self-employed person to ensure that its business or undertaking is conducted in a way that is electrically safe. Electrically safe means that the electrical risk to the person is as low as reasonably achievable having regard to the likelihood of harm and the severity of risk. Compliance with the guidelines set out in this document does not negate your responsibility and obligation to comply with all legislative requirements relevant to work to be performed whether in the vicinity of ENERGEXs infrastructure or otherwise.

2837 23.09.2010 Page 4 of 33

About this guide

This guide to working near the ENERGEX network is designed to assist you to meet your obligations under the Workplace Health and Safety Act 1995, the Electrical Safety Act 2002, Electrical Safety Regulation 2002 and relevant Codes of Practice and help you to identify the steps needed to ensure risks are minimised for all who work or are likely to be affected by the work in these situations. The Guide is not to be a substitute for obtaining qualified legal or technical advice. Structure of the document This document outlines: Section 1 Working in the vicinity of exposed live electrical parts of the ENERGEX network The clearances required during construction or working near exposed lines Suggested methods of managing the risks (to be applied in conjunction with the Electrical Safety Act and Regulations and the applicable Code of Practice) The minimum clearances required on completion of any building or maintenance work What information you are required to provide and the necessary timing.

Section 2 Trenching adjacent ENERGEX Power Poles Limitations to these Guidelines Excavations and Excavation Zones Certified Engineering Assessment

Section 3 Working in the vicinity of ENERGEX underground cables Dial Before You Dig maps and underground cable details Dial Before You Dig Terms and Conditions

Section 4 Process & Forms Process flowchart Standard forms

Disclaimer This document refers to various standards, guidelines, calculations, legal requirements, technical details and other information. This document is current as at 23/09/2010. Over time, changes in industry standards and legislative requirements, as well as technological advances and other factors relevant to the information contained in this document, may affect the accuracy of the information contained in this document. Accordingly, caution should be exercised in relation to the use of the information in this document. ENERGEX accepts no responsibility for the accuracy of any information contained in this document or the consequences of any person relying on such information. Copies of the relevant Acts, Regulation and Codes of Practice and any other relevant legislation can be found on the Queensland Government web site - www.justice.qld.gov.au

2837 23.09.2010 Page 5 of 33

SECTION 1

WORKING NEAR EXPOSED LIVE ELECTRICAL PARTS OF THE ENERGEX NETWORK

2837 23.09.2010 Page 6 of 33

Are you intending to perform work where you will potentially be within 3.0m of an ENERGEX overhead power line or 4.5m of an overhead steel tower transmission line?

The Queensland Government has a legislative framework for electrical safety for all to prevent people from being killed, hurt or property from being destroyed or damaged by electricity. The Electrical Safety Act 2002 is supported by the Electrical Safety Regulation 2002 and the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts which include overhead and underground power lines and overhead service lines.

What is the Electrical Safety Code of Practice 2010 Working Near Exposed Live Parts?

To assist you to comply with this requirement, guidance should be obtained from the 'Working Near Exposed Live Parts' Code of Practice. This Code of Practice describes the main electrical safety problems linked to working around electricity and gives practical advice on how to address them. The Code of Practice - Working Near Exposed Live Parts will apply to people such as plant operators, painters, and people erecting or working on scaffolds, sign makers and people working with irrigation pipes near exposed live parts. It is important to remember that the Code of Practice does not specify everything that should or should not be done to meet an electrical safety obligation. However, you will fail to meet your obligations if you: go against or act inconsistently with the Code of Practice; do not adopt a method as safe as, or safer than, the code.

Who does the Electrical Safety Code of Practice 2010 Working Near Exposed Live Parts apply to?

The Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts applies to anyone who will be working within 3.0m from the ENERGEX electrical network. This may include, but is not limited to: crane and plant operators painters, carpenters and builders working near exposed live parts people erecting or working on scaffolds signmakers agricultural workers carriers of high loads anyone who clears vegetation near overhead lines

2837 23.09.2010 Page 7 of 33

What must I do if I will be working or planning to work potentially within 3.0m of any exposed electrical part of the ENERGEX network?

You must consult with ENERGEX before commencing any work. Phone 131253 o ENERGEX will require you to complete some documents in relation to the proposed work. o ENERGEX will identify the relevant voltages. o ENERGEX will require an on-site consultation at which you must bring your copy of the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts. o ENERGEX will provide Safety Advice if your description of work indicates there is a likelihood the work could encroach on a legislative exclusion zone. This Advice will draw your attention to the requirements for working near exclusion zones. o ENERGEX will provide a quote for any Network related control measures, such as replacement, relocation or de-energising of the electrical network, if requested. o Your payment will be required prior to any control measures being implemented. A copy of the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts is available from the following link: www.justice.qld.gov.au or copy and paste this into your web browser.

An exclusion from the Electrical Safety Regulation 2002 Section 64A Requirement to Consult exists for an eligible person undertaking low voltage work. Refer below for the definition of eligible person.

What are the clearances that must be maintained during construction?

The Electrical Safety Regulation 2002 and the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts detail the Exclusion Zones that must be maintained. Before carrying out any work where you might encroach the exclusion zone you should ensure that the potential hazards are identified and the necessary steps taken to minimise risks to ensure the safety of all workers and by-standers. The purpose of consultation is to inform ENERGEX that you are carrying out work near the line and for ENERGEX to determine the voltage of the line and provide safety advice advising how to comply with the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts and how you can best ensure the electrical safety of persons and property in the performance of the work.

2837 23.09.2010 Page 8 of 33

Disconnection of a customers installation by an eligible person to eliminate an exclusion zone.

The Electrical Safety Regulation 2002 s155 (Part 8, Division 1 Connection to source of electricity) states an eligible person may isolate a consumers electrical installation to eliminate an exclusion zone that would otherwise exist. Note: Isolation of the consumers electrical installation by an eligible person is only permitted at an underground service pillar or service pole by removing a fuse wedge(s) from a service line, in accordance with Electricity Industry practices ie. using appropriate insulated tools, PPE and mats. Any controls used by the eligible person to identify and confirm isolation and ensure supply to the consumers installation is not inadvertently re-energised would need to be in line with s11 and s20 of The Electrical Safety Regulation 2002.

Definition of Terms

These are terms used through the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts and the Electrical Safety Regulation 2002 (ESR). Authorised Person For an electrical part, means a person who: Has enough technical knowledge and experience to do work that involves contact with, or being near to, the electrical part; and Has been approved by the person in control of the electrical part to do work that involves contact with, or being near to, the electrical part, or is authorised to act for the person in control of the electrical part. Instructed Person For an electrical part, means a person who is acting under the supervision of an Authorised Person for the electrical part. Untrained Person For an electrical part, means a person who is not an Authorised Person or an Instructed Person for the electrical part. Eligible Person A licensed electrical contractor; or A person who holds an electrical mechanic licence and is performing work for a licensed electrical contractor as an employee of the contractor; or A person who holds an electrical mechanic licence and is performing work for the person or a relative of the person at premises owned or occupied by the person or relative. Applicant The term Applicant means a person contacting ENERGEX for safety advice or submitting an application (Form 1227) to ENERGEX requesting safety advice. Electrical Safety Legislation Electrical Safety Legislation means the Electrical Safety Act 2002, Electrical Safety Regulation 2002 and any Ministerial Notices and Codes of practice issued pursuant to that legislation.

2837 23.09.2010 Page 9 of 33

Operating Plant

In accordance with the Electrical Safety Legislation workers, other than an authorised or instructed person, and their plant must not approach overhead powerlines any closer than the following as per schedule 2 of the Electrical Safety Regulation 2002:

Exclusion Zones for exposed parts for Untrained Persons for operating plant. Powerlines with Voltages Up to 33kV Above 33kV and up to 132kV Above 132kV and up to 220kV* Examples e.g. Low Voltage (LV) Residential Supply, High Voltage (HV) 11kV and 33kV. e.g. exposed 132kV Steel pylons, concrete poles. e.g. Steel pylons, concrete poles, long spans between towers. Exclusion Zone 3m 3m 4.5m*

* Refer to the Electrical Safety Regulation 2002 and the Electrical Safety Code of Practice 2010 - Working

Near Exposed Live Parts for exclusion zone distances for voltages greater than 220kV.

Although these are the minimum exclusion zone clearances required, in many cases you can reduce the likelihood of damage or injury by operating machinery well clear of powerlines. For an authorised or instructed person and their plant to approach overhead powerlines closer than the above exclusion zone a safety observer or another safe system must be used. Refer to the Electrical Safety Regulation 2002 and the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts for exclusion zone distances for authorised and instructed persons operating plant with a safety observer or another safe system. Where a safety observer is used the safety observer should: Not be required to carry out any other duties at the time, and Not be required to observe more than one item of plant at a time, and Should be in attendance at all times when the item of plant is operating. Other control measures may include, but are not restricted to:

Constructing physical barriers or height warning indicators that are lower than the legislated

distance from the line, either side of the line;

Applying appropriate signage at least 8 to 10 metres either side of powerlines; Installing visual indicators such as Tiger Tails fitted to the powerlines (contact ENERGEX for

advice);

Ground barriers, where appropriate; Informing workers of required work practices; Ensuring operators are aware of the height of their machinery in both stowed and working

positions;

Lowering all machinery to the transport position when relocating; Providing workers with maps or diagrams showing the location of underground and overhead

powerlines; zone; and

Appointing a safety observer to ensure that the operating plant does not enter an exclusion Where possible, directing work away from powerlines not towards them.

2837 23.09.2010 Page 10 of 33

Other control measures

If there is no way of performing the required work safely without the possibility of entering the exclusion zone, you will need to ensure other control measures are implemented. Appropriate control measures will depend on the particular circumstances. Control measures include, but are not limited to, the following examples in order of hierarchy:

1. Eliminate the hazard 1.1. Placement of the overhead lines underground

Development approval may require overhead lines to be placed underground. If not required for development approval ENERGEX recommends the applicant consider initiating such works in the interests of electrical safety and to improve streetscape and property visual appeal.

1.2. Relocation of the overhead lines to outside the Exclusion Zone

If overhead lines are not to be placed underground then they may be able to be relocated to outside the exclusion zone. Relocation to outside the exclusion zone can only be achieved if the relocated line does not introduce new exclusion zone conflicts in its relocated position and it receives relevant approvals. Existing low voltage lines may be replaced with insulated cables (applicable to LV only). o o o Removal or relocation of the overhead lines early in the project will remove the hazard and risk of contacting overhead conductors during construction. This activity would require negotiation between the applicants architect / consultant / builder and ENERGEX and sufficient lead time should be allowed. Where poles, lines and other ENERGEX infrastructure are to be placed underground or relocated, this work will be carried out by ENERGEX with input and contribution by the applicant. There will be costs applicable to this activity which must be paid by the party for whom the work is being performed.

2. Isolate the hazard 2.1. Isolation (de-energising) the overhead lines

If the overhead line is not to be placed underground or relocated outside the exclusion zone and cannot be replaced with insulated cables then it may be possible to isolate the line by deenergising part of the network. The network configuration, customer and network loads may restrict the time and duration that the network can be de-energised. Sufficient lead time should be allowed for ENERGEX to investigate the feasibility of these arrangements. This work can only be performed by ENERGEX. There will be costs applicable to this activity which must be paid by the party for whom the work is being performed.

2.2. Placement of physical barriers to prevent encroachment

This type of work can only be done in conjunction with an established and maintained safe system of work which may include, but is not limited to: o Temporary isolation. o Reduced exclusion zone with an Authorised Person on site. This requires the Applicant to install a suitable barrier that will prevent workers or plant from coming into accidental contact with any exposed live part of the ENERGEX network. This work is to be carried out by the Applicant at the Applicants cost. Once the barrier is erected, the clearances from the barrier to the exposed lines must be maintained in accordance the exclusion zones detailed in the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts.

2837 23.09.2010 Page 11 of 33

Other control measures (cont.)

3. Administrative controls 3.1. Installation of visual indicators (Tiger Tails)

This installation is only to be used as an indication only. These Tiger tails are not to be treated as insulated. The placement of these covers on overhead conductors should not completely cover the conductor as they are not to be used for, or be considered as providing, insulation. There will be costs applicable to this activity which must be paid by the party for whom the work is being performed.

3.2. Use of a Safety Observer

The Safety Observers role is to ensure that no one comes within the exclusion zone when working near exposed live parts of the ENERGEX network. A Safety Observer is mandatory when operating plant when any part of the plant or its load COULD enter the exclusion zone. The Applicant will be responsible for engaging a Safety Observer at their cost in accordance with the Electrical Safety legislation.

ENERGEX preferred hierarchy of control for Control Measures following Safety Advice

Category of work

Safety Advice Service isolation

Hierarchy of control

Base information 1. Isolation carried out by customers electrical contractor

Description

Provide safety advice Isolation of OH Service by removal of the primary fuse. (Preferred option to isolate supply and eliminate the exclusion zone)

Costing arrangement

Nil cost to customer No involvement by ENERGEX

2. Isolation carried out by ENERGEX

Customer requested isolation of OH Service by removal of the primary fuse or Customer requested physical disconnection & reconnection of OH service Verification of insulation integrity to classify as insulated service Insulation integrity can only be verified at the time of inspection visual inspection is required before confirmation in all cases. Replacement of service with new XLPE service cable, primary fuses fitted at pole to allow isolation of service. Insulation integrity can be verified for new XLPE services at the time of installation visual inspection is required before confirmation Service installations where: a. the consumers mains cannot be insulated and an exclusion zone must be maintained, and b. the service cannot be isolated at the primary fuse Service to be isolated by breaking the service cable connection to the LV mains at the pole.

Insulation integrity verification

3. Verification of insulation integrity to remove exclusion zone to no touch only 4. Open wire service, primary fuses at house/building

Cost to customer - use standard fees and charges where applicable otherwise POA quote.

Service replacement

Nil cost to customer for service replacement. Customer to upgrade consumers installation and MCB if required. Nil cost to customer for first disconnection and reconnection. Cost to customer for subsequent requests - use standard fees and charges where applicable otherwise POA quote.

5. All other service replacements

Customer requested replacement of existing service with new XLPE service cable to classify as insulated service, in lieu of isolation, to allow work close.

Cost to customer for service replacement - use standard fees and charges. Customer to upgrade consumers installation and MCB if required. Cost to customer - POA quote for labour only (plus monthly rental cost of tiger tails). Cost to customer - POA quote for labour only.

Tiger Tails

Installation of Tiger Tails

Customer requested coverage of LV mains Customer requested switching to allow customer/contractor to work close

Switching

Customer requested switching

2837 23.09.2010 Page 12 of 33

Work Close Scaffold Barrier Guidelines

MINIMUM DIMENSIONS BETWEEN ERECTED SCAFFOLDING & ENERGISED MAINS USING PHYSICAL BARRIERS TO ACHIEVE

HORIZONTAL SAFETY CLEARANCE

NOTE: The following information is only applicable after receiving written Safety Advice from ENERGEX

Barrier fixed securely to the face of the scaffold. Barrier material must be fit for the intended purpose.

Reference: * Electrical Safety Code of Practice 2010 Working Near Exposed Live Parts, Electrical Safety Act 2002

Minimum Horizontal Dimensions for A Source reference: Worker classification: Services LV Insulated mains LV Bare mains with consultation LV Bare mains without consultation >LV <= 33kV Bare mains with consultation >LV <= 33kV Bare mains without consultation Code of Practice Exclusion Zone* (exposed live part during construction) Untrained Person 1.0m 1.0m 1.0m Up to but no contact allowable 3.0m 2.0m 700mm 3.0m Instructed Persons (IP) & Authorised Persons (AP) Up to but no contact allowable (with consultation & insulation verified by AP) Up to but no contact allowable (with consultation & insulation verified by AP)

NOTE: 1. No gaps should exist between fitted components of a barrier that could allow contact with the energised mains. 2. No exposed cut or drilled holes are permitted in the barrier. 3. The installer is responsible for attaching the barrier to the scaffold, and ensuring that the arrangement can sustain an appropriate wind load. 4. The information provided is for guidance only and should be read in conjunction with the Workplace Health and Safety Act 1995, the Electrical Safety Act 2002, relevant Codes of Practice and associated legislation.

2837 23.09.2010 Page 13 of 33

Work Close Scaffold Barrier Guidelines (cont)

MINIMUM DIMENSIONS BETWEEN ERECTED SCAFFOLDING & ENERGISED MAINS USING PHYSICAL BARRIERS TO ACHIEVE

VERTICAL SAFETY CLEARANCE

NOTE: The following information is only applicable after receiving written Safety Advice from ENERGEX

Barrier fixed securely to the face of the scaffold. Barrier material must be fit for the intended purpose.

Barriers and Live Conductors warning signs to be placed along scaffolding

Min 100mm between pole and scaffolding subject to relevant Local Authority local laws.

Reference: * Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts, Electrical Safety Act 2002

Minimum Vertical Dimensions for B Source reference: Worker classification: Services LV Insulated mains LV Bare mains with consultation LV Bare mains without consultation >LV <= 33kV Bare mains with consultation >LV <= 33kV Bare mains without consultation Code of Practice Exclusion Zone* (exposed live part during construction) Untrained Person 1.0m 1.0m 1.0m Up to but no contact allowable 3.0m 2.0m 700mm 3.0m Instructed Persons (IP) & Authorised Persons (AP) Up to but no contact allowable (with consultation & insulation verified by AP) Up to but no contact allowable (with consultation & insulation verified by AP)

NOTE: 1. No gaps should exist between fitted components of a barrier that could allow contact with the energised mains. 2. No exposed cut or drilled holes are permitted in the barrier. 3. The installer is responsible for attaching the barrier to the scaffold, and ensuring that the arrangement can sustain appropriate wind loads. 4. Dimension B is to the conductor. 5. The information provided is for guidance only and should be read in conjunction with the Workplace Health and Safety Act 1995, the Electrical Safety Act 2002, relevant Codes of Practice and associated legislation.

2837 23.09.2010 Page 14 of 33

What clearances must be maintained once the construction work is completed?

On completion of the building, construction or maintenance work, statutory clearances must be achieved. These statutory clearances can be found in the Electrical Safety Regulation 2002, Schedule 4.

2837 23.09.2010 Page 15 of 33

SECTION 2

TRENCHING ADJACENT ENERGEX POWER POLES

2837 23.09.2010 Page 16 of 33

Why are these guidelines required?

To provide general advice to Applicants in regards to acceptable excavation zones adjacent to ENERGEX distribution poles.

What conditions are applicable when excavating adjacent to poles?

The guidelines for excavations contained within this document are applicable under the following conditions: Excavation must be commenced and completed with the hole backfilled within the same day where the pole is being supported by an authorised Lifter/Borer machine (Applicant to source plant)*; Excavation should not be carried out if a severe weather warning has been issued by the Bureau of Meteorology; Exclusion Zones as detailed in the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts apply; These conditions for holding poles apply only to inline poles (less than 5 degrees deviation) and with the following additional limitations: Poles that have a lean away from the direction of a resultant pole load (ie. the pole has been raked at the time of installation) can be supported; Poles that have a lean in the direction of a resultant pole load (ie. the pole foundation and ground has failed) (Lean twice the diameter of the head of the pole) can NOT be supported. Additional Engineering advice should be sought in these instances at your cost. Poles close to excavations are in normal soil conditions (still clays) * Note: It is the responsibility of the person engaging the service provider to confirm that authorisation is current at the time the work is undertaken.

How to manage excavating near poles with underground cables and other ground mounted attachments.

The ENERGEX overhead network has been constructed using concrete, steel and timber poles. These poles may support wires, streetlights, transformers or other plant, earth downlead wires, underground cables or stays. For poles with earth downleads or underground cables attached the full section of the cable or earthlead in the area to be excavated must be hand dug (pot-holing) to visually locate and expose the cables and leads.

2837 23.09.2010 Page 17 of 33

When is an engineering assessment required?

Engineering assessment is not required for excavation depths up to 250mm. All excavations are to be kept to minimum. The pole may require support where excavation or other interference with the land within 250mm of any pole or stay wire of an overhead electric line is at a greater depth than 250mm or within the Do not disturb zone shown below.

Minimum soil area required for pole support Do Not Disturb zone

Inline Pole 250mm

Ground Line 250mm

No assessment required for excavation depths up to 250mm

Trench

45 Do not disturb

Excavating near poles

Maximum Trench Depth 0.25m (250mm) 1.0m 1.5m 2.0m 2.5m 3.0m Minimum Distance from pole without pole support Can trench or hand dig (where cables and leads exist) right up to pole 1.0m 1.5m 2.0m 2.5m 3.0m

What is required in a Certified Engineering Assessment

A certified engineering assessment shall be carried out to ensure that the short and long term structural stability of ENERGEX assets are maintained. A Certified Engineering Assessment shall be obtained in the following circumstances a) Where the scope of excavation works and excavation conditions are outside of the limitations listed above. b) Where doubt exists as to the suitability of the soil within the Do Not Disturb zone to adequately support the pole. c) Where excavation is required to be carried out within the Do Not Disturb zone. The assessment shall be forwarded to ENERGEX for review and comments prior to works being carried out. Approval by ENERGEX shall not relieve the Applicant of its obligation to perform the work in a safe and proper manner and in accordance with all applicable legislation. The assessment shall consider and address as a minimum the following

2837 23.09.2010 Page 18 of 33

Pole loading (vertical and lateral) Condition of pole (with and without pole nailing) Foundation depth of pole Proximity of excavation in relation to pole Soil conditions Proposed shoring methods Duration of works Shoring installation and removal process Requirements to independently support pole/structure during the works. Proximity of existing adjacent services and excavations Proposed backfilling method Staging of work Monitoring and engineering/ geotechnical supervision during the works.

The engineering assessment shall be certified by a Registered Professional Engineer Queensland (RPEQ) ADDITIONAL REQUIREMENTS To ensure the safety and security of the ENERGEX electricity network, workers and the general public the following issues must also be considered: Network switching Network switching may be required for HV poles lead time and costs should be allowed for these arrangements to be made; Pole Inspection Poles may need to be inspected before being supported lead time and cost should be allowed for the inspection to be carried out; Nailed poles shall be inspected in conjunction with the assessment if it is more than 6 months since the pole was last inspected; Pole Maintenance Systems Excavations should be designed to maximise the undisturbed ground around the pole base with particular attention to nailed poles; Where a chemically treated pole bandage is fitted to the pole at the ground line the soil around the pole bandage should not be disturbed.

Visible section of a Pole Bandage

Pole Nail

2837 23.09.2010 Page 19 of 33

Supporting Poles using a Lifter / Borer Vehicle When excavating near ENERGEX poles a Lifter / Borer vehicle may be used to support the pole. The pole weight, overhead line configuration and resultant pole load must be assessed to determine if the pole can be safely supported by the lifter / borer vehicle. Other equipment attached to the pole, such as underground cables and items of plant, must be taken into consideration in the assessment. Lifter / Borer Operators Only ENERGEX authorised Lifter / Borer vehicles and operators are permitted to support ENERGEX poles. Lifter / Borer operators must hold current competencies as listed in ENERGEX Standard Work Procedure SWP84 The operation of Lifter Borer / General Purpose Vehicles. Note: It is the responsibility of the person engaging the service provider to confirm that authorisation is current at the time the work is undertaken.

General Arrangements Supporting poles must only be carried out in accordance with an established and documented safe system of work. The weight of the pole is to be supported by the hook with a chain fitted around the pole; The pole grabs should only be used to control sideways movement of the pole and are not to be used to support the weight of the pole; The pole should be secured / restrained at ground level to prevent the pole butt from kicking out into the excavation; Sufficient clearance is required to allow the boom head, hook and chain to be fitted to the pole, above the pole balance point, without encroaching the exclusion zones; The lifter / borer should be setup and positioned to maximise support effectiveness and minimise impact on traffic, pedestrian and the excavation and machinery. LV Poles LV poles can generally be supported by a lifter / borer vehicle. 11kV Poles In-line poles with sufficient clearance can generally be supported; If insufficient clearance exists the mains may need to be de-energised. 33kV Poles These poles will require a detailed engineering assessment to determine suitable support methods. Poles with attached plant Poles with attached plant eg. Transformer, regulator, recloser, cannot be supported by a typical lifter / borer vehicle and will require a detailed engineering assessment to determine suitable support methods; Poles with underground cables attached cannot be supported by a typical lifter / borer vehicle and will require a detailed engineering assessment to determine suitable support methods. Note: It is the Applicants responsibility to arrange site assessments, detailed engineering assessments and to pay all associated costs.

2837 23.09.2010 Page 20 of 33

This page left blank

2837 23.09.2010 Page 21 of 33

SECTION 3

WORKING IN THE VICINITY OF ENERGEX UNDERGROUND CABLES

2837 23.09.2010 Page 22 of 33

Introduction

Underground cables can exist in a vast number of locations. Underground cables may or may not be marked to show their location. ENERGEX has currently 2 alignments approved by the local authorities, these are: 0 900mm from the property alignment this alignment is used for the majority of our Distribution cables ENERGEX, from time to time also has to place our cables off this alignment due to other services being in the vicinity or due to a lack of space on the designated path. At the Kerb line this alignment is used for ENERGEXs Transmission cables, nominally with a voltage of ~ 33kV As with the Distribution cables, the Transmission cables may also be in locations other than above. It is a legislative requirement that, prior to carrying out any digging activity where there may or may not be underground cables, you contact Dial Before You Dig service by telephoning 1100 or accessing their web site http://www.dialbeforeyoudig.com.au/ The following is a sample of the documents and details that will be provided by ENERGEX:

2837 23.09.2010 Page 23 of 33

Example of ENERGEXs DBYD Map

Example of underground cable details

2837 23.09.2010 Page 24 of 33

2837 23.09.2010 Page 25 of 33

2837 23.09.2010 Page 26 of 33

This page left blank

2837 23.09.2010 Page 27 of 33

SECTION 4

PROCESS & FORMS

2837 23.09.2010 Page 28 of 33

Process flowchart

Safety Advice on Working Near ENERGEX Exposed Live Parts

Project initiated by customer / principle contractor / contractor representative

Is work near ENERGEX assets?

No

No action required

Conduct work

Have site conditions changed?

No

Advise ENERGEX work is complete

No

Applicant

Yes Are safety control measures to be implemented by applicant? Yes

Implement safety control measures

Yes No Advise ENERGEX of changed site conditions

Contact ENERGEX ph 13 12 53 To request Safety Advice

Applicant completes Form 1227 Application fo Safety Advice and forwards to ENERGEX

Applicant signs Form 347 Safety Advice on Yes Working near ENERGEX Exposed Live Parts and retains original copy

Are changes required to safety control measures?

Form 1228 Important Notice and Form 1227 Application fo Safety Advice sent to applicant

ENERGEX

ENERGEX completes Form 347 Safety Advice on Working near ENERGEX Exposed Live Parts in consultation with applicant Duplicate copy of signed Form 347 Safety Advice on Working near Live Parts filed as per BMS requirements

Review changed conditions update safety control measures and Safety Advice Form 1227

Finalise safety advice record

Completed Form 1227 Application fo Safety Advice received by ENERGEX

ENERGEX meets with applicant to identify risks and safety control measures

Standard Forms

Form 1227 Application for Safety Advice Working near ENERGEX exposed live parts Form to be faxed to the applicant requesting safety advice together with a copy of Form 1228 Important Notice - Working near ENERGEX Power Lines Including Overhead Services. Form to be completed by the applicant and faxed to the relevant ENERGEX Hub Work Close officer Form 1228 Important Notice Working near ENERGEX Power Lines Including Overhead Services Form to be faxed to the applicant with a copy of Form 1227. Form 0347 Safety Advice on working near ENERGEX exposed live parts Form to be completed in consultation with the applicant and signed by ENERGEX officer and the person who will be responsible for the work site. When ENERGEX is requested to implement additional safety control measures identified on the Safety Advice form, the form shall be signed-off and returned to ENERGEX prior to those control measures being removed from the work site.

2837 23.09.2010 Page 29 of 33

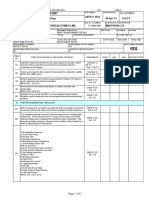

Form 1227 Application for Safety Advice Working near ENERGEX exposed live parts

2837 23.09.2010 Page 30 of 33

Form 1228 Important Notice Working near ENERGEX Power Lines Including Overhead Services

2837 23.09.2010 Page 31 of 33

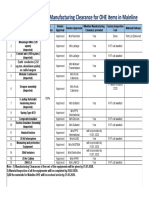

Form 0347 Safety Advice on working near ENERGEX exposed live parts

2837 23.09.2010 Page 32 of 33

Form 0347 (cont.) Safety Advice on working near ENERGEX exposed live parts

2837 23.09.2010 Page 33 of 33

Appendix A

Exclusion Zone (in millimetres) The distances shown in the table below are for information only. To ensure up to date Exclusion Zone distances are used reference should be made the Electrical Safety Code of Practice 2010 - Working Near Exposed Live Parts, Electrical Safety Act 2002.

Exclusion zones for exposed parts Untrained Persons Authorised & Instructed Persons Operating plant operated by authorised person or Vehicle instructed operated by Authorised person for the authorised person or exposed part, person or with safety instructed instructed person for observer or person for the the exposed another safe exposed part system (mm) (mm) part (mm) (No exclusion 1000 600 zone prescribed) (No exclusion 1000 600 zone prescribed) 700 1200 700

Nominal phase to phase voltage of exposed part Low voltage (with consultation with person in control of exposed part) Low voltage (without consultation with person in control of exposed part) Above low voltage, up to 33kV (with consultation with person in control of exposed part) Above low voltage, up to 33kV (without consultation with person in control of exposed part) Above 33 kV up to 50 kV Above 50 kV up to 66 kV Above 66 kV up to 110 kV Above 110 kV up to 132 kV Above 132 kV up to 220 kV Above 220 kV up to 275 kV

Untrained person for the exposed part (mm) 1000

Operating plant operated by untrained person for the exposed part (mm) 3000

Vehicle operated by untrained person for the exposed part (mm) 600

3000

3000

600

2000

3000

900

3000 3000 3000 3000 3000 4500 5000

3000 3000 3000 3000 3000 6000 6000

900 2100 2100 2100 2100 2900 2900

700 750 1000 1000 1200 1800 2300

1200 1300 1400 1800 1800 2400 3000

700 750 1000 1000 1200 1800 2300

Exclusion zones for low voltage overhead insulated electric line Untrained Persons Authorised & Instructed Persons Operating plant operated by authorised person or Vehicle instructed operated by person for the authorised Authorised person or electric line, person or instructed with safety instructed observer or person for the person for the electric another safe electric line line (mm) system (mm) (mm) (No (No exclusion (No exclusion exclusion zone zone zone prescribed) prescribed) prescribed) (No (No exclusion exclusion zone 600 zone prescribed) prescribed)

Low voltage overhead insulated electric line With consultation with, and insulation verified by, an authorised person for the electric line Without consultation with, and without insulation verified by, an authorised person for the electric line

Untrained person (mm) (No exclusion zone prescribed) 3000

Operating plant operated by untrained person for the electric line (mm) 1000

Vehicle operated by untrained person for the electric line (mm) 300

3000

600

Note: All exclusion zones must be maintained and there must be no contact with verified insulated conductors

También podría gustarte

- Best Practice Guide 2Documento20 páginasBest Practice Guide 2Jelena PerićAún no hay calificaciones

- Underground Electric Transmission LinesDocumento20 páginasUnderground Electric Transmission LinesJosé100% (1)

- Electrical Safety in Metallic Pipeline ConstructionDocumento9 páginasElectrical Safety in Metallic Pipeline ConstructionAnonymous FBoGmPpAún no hay calificaciones

- EP-MS-P4-S3-052 - Non Metalic Fiber Optic CablesDocumento19 páginasEP-MS-P4-S3-052 - Non Metalic Fiber Optic CablesKarthikAún no hay calificaciones

- Guide To Live LV Electrical Work (March 2005)Documento17 páginasGuide To Live LV Electrical Work (March 2005)Monish KrishnaAún no hay calificaciones

- The IEE Wiring Regulations Explained and IllustratedDe EverandThe IEE Wiring Regulations Explained and IllustratedCalificación: 4 de 5 estrellas4/5 (14)

- As 3007.5 - Electrical InstallationsDocumento13 páginasAs 3007.5 - Electrical Installationsduckman2009Aún no hay calificaciones

- Electrical Hazards and Arc Flash Awareness: Instructor: Brian TerryDocumento129 páginasElectrical Hazards and Arc Flash Awareness: Instructor: Brian TerryLuis Rafanan Abiog100% (1)

- How To Calculate A Pipe BendDocumento2 páginasHow To Calculate A Pipe BendYaneYangAún no hay calificaciones

- 22-Earthing and Bonding-On ClickDocumento96 páginas22-Earthing and Bonding-On ClickKishan KumarAún no hay calificaciones

- High Voltage Test EquipmentDocumento6 páginasHigh Voltage Test EquipmentPaulo CardosoAún no hay calificaciones

- TR - Line Construction (Electric Power Distribution) NC IIDocumento61 páginasTR - Line Construction (Electric Power Distribution) NC IISim Belsondra100% (1)

- Basic Electrical Engineering: Define The Terms With Their UnitsDocumento58 páginasBasic Electrical Engineering: Define The Terms With Their Unitsbujjibabu1977Aún no hay calificaciones

- QA/QC Responsibilities: InspectionsDocumento1 páginaQA/QC Responsibilities: InspectionsVenkata Suresh MandavaAún no hay calificaciones

- Measurement of Insulation Resistance Withstand of Cables: Experiment 6Documento15 páginasMeasurement of Insulation Resistance Withstand of Cables: Experiment 6shalini nimsAún no hay calificaciones

- A Protocol For Railway Systems Integration-The Hudson-Bergen Experience PDFDocumento45 páginasA Protocol For Railway Systems Integration-The Hudson-Bergen Experience PDFpoketupiAún no hay calificaciones

- Ex Cable GlandsDocumento18 páginasEx Cable GlandsAntonis BafatakisAún no hay calificaciones

- Understanding Electrical Inspection and TestingDocumento3 páginasUnderstanding Electrical Inspection and TestingI Wayan Aries DarmawanAún no hay calificaciones

- Electrical StandardDocumento29 páginasElectrical Standardmohan babuAún no hay calificaciones

- Earthing System: Low-Voltage SystemsDocumento8 páginasEarthing System: Low-Voltage SystemsTony KontisAún no hay calificaciones

- Dalekovod Zagreb - Izolatorski-Lanci PDFDocumento64 páginasDalekovod Zagreb - Izolatorski-Lanci PDFboan87Aún no hay calificaciones

- Electricity at Work Regulations 1989.Documento52 páginasElectricity at Work Regulations 1989.kagkaggAún no hay calificaciones

- 2006 19 Summer Wiring Matters Periodic Inspection of Critical SystemsDocumento5 páginas2006 19 Summer Wiring Matters Periodic Inspection of Critical Systemsaxia_films256Aún no hay calificaciones

- Theory of Electrical1Documento15 páginasTheory of Electrical1Pradeep Kumar KamarajAún no hay calificaciones

- InstruDocumento37 páginasInstrucxrxixsxAún no hay calificaciones

- Electrical Safety Guidelines - Working On Fixed Electrical InstallationsDocumento7 páginasElectrical Safety Guidelines - Working On Fixed Electrical Installationsdbarron00Aún no hay calificaciones

- KYN28 Withdrawable Metal-Clad Switchgear PDFDocumento24 páginasKYN28 Withdrawable Metal-Clad Switchgear PDFGustavo SotoAún no hay calificaciones

- Application Guide: Working With HART NetworksDocumento14 páginasApplication Guide: Working With HART NetworkscuongnammuAún no hay calificaciones

- Arc Flash Analysis: Electrical SafetyDocumento16 páginasArc Flash Analysis: Electrical SafetyOsha InstructorsAún no hay calificaciones

- Type of Transformer Testing: Tests Done at FactoryDocumento6 páginasType of Transformer Testing: Tests Done at FactoryVenkata Suresh MandavaAún no hay calificaciones

- Tech Note 26Documento6 páginasTech Note 26Srinivas PentapatiAún no hay calificaciones

- Descargas ParcialesDocumento46 páginasDescargas ParcialesManuelAún no hay calificaciones

- 561 Live Work - A Management PerspectiveDocumento97 páginas561 Live Work - A Management Perspectiveasi midobarAún no hay calificaciones

- Exhibit C - Testing and Acceptance - 201210191417400204Documento3 páginasExhibit C - Testing and Acceptance - 201210191417400204Yousif_AbdalhalimAún no hay calificaciones

- Guideline On Earthing Bonding Railway StationsDocumento31 páginasGuideline On Earthing Bonding Railway StationsnecmettinsengunAún no hay calificaciones

- Actm 1Documento169 páginasActm 1TPC 7850% (2)

- 7 BCD 1 B 28Documento12 páginas7 BCD 1 B 28pedro perezAún no hay calificaciones

- 7 Step Industrial Ethernet ChecklistDocumento10 páginas7 Step Industrial Ethernet ChecklistDUARDOFRMAún no hay calificaciones

- Commissioning Test Procedure Subtransmission CablesDocumento8 páginasCommissioning Test Procedure Subtransmission Cablesjkhgvdj mnhsnjkhgAún no hay calificaciones

- Tecnical Specification - AC CABLE DATASHEETDocumento7 páginasTecnical Specification - AC CABLE DATASHEETEisac SagimanAún no hay calificaciones

- NETA Handbook Series II - Safety Vol 2 PDFDocumento76 páginasNETA Handbook Series II - Safety Vol 2 PDFadmer_lauristaAún no hay calificaciones

- Safe Working On Low Voltage Electrical SystemsDocumento39 páginasSafe Working On Low Voltage Electrical Systemsamrutjagtap0% (1)

- Grounding and Bonding in Data CenterDocumento3 páginasGrounding and Bonding in Data CenterLuis Ivan Moreno ParraAún no hay calificaciones

- Living and Working Around High Voltage Power Lines 11-07Documento15 páginasLiving and Working Around High Voltage Power Lines 11-07api-49714586Aún no hay calificaciones

- Testing and Commissioning of MV CablesDocumento8 páginasTesting and Commissioning of MV CablesYJoe18Aún no hay calificaciones

- SECTION 16450 Grounding Part 1 - GeneralDocumento8 páginasSECTION 16450 Grounding Part 1 - Generalno nameAún no hay calificaciones

- Zero-Phase Filtering For Lightning Impulse EvaluatDocumento11 páginasZero-Phase Filtering For Lightning Impulse EvaluatMB AshrafAún no hay calificaciones

- Cabletrays Institute Technical Bulletin15 PDFDocumento3 páginasCabletrays Institute Technical Bulletin15 PDFjayabalkcetAún no hay calificaciones

- DESIRO UK Electrical Multiple Unit FamilyDocumento4 páginasDESIRO UK Electrical Multiple Unit FamilyVíctor FaucheretAún no hay calificaciones

- Railway Applications - Fixed Installations - Electric Traction Overhead Contact LinesDocumento12 páginasRailway Applications - Fixed Installations - Electric Traction Overhead Contact LinesandreadelsoleAún no hay calificaciones

- SensorsDocumento64 páginasSensorsJoão SantosAún no hay calificaciones

- Introduction of CablesDocumento14 páginasIntroduction of CablesRanganath SriAún no hay calificaciones

- Tella HND Project - Determination of Engineering Properties of Sandcrete Block Using Different Grade of CementDocumento77 páginasTella HND Project - Determination of Engineering Properties of Sandcrete Block Using Different Grade of CementDavid TellaAún no hay calificaciones

- 1.1 Live Line Dry Cleaning in Electrical Installations FPDocumento3 páginas1.1 Live Line Dry Cleaning in Electrical Installations FPWalter PossoAún no hay calificaciones

- 2.0. Methodology For Clearing Grubbing DismantlingDocumento2 páginas2.0. Methodology For Clearing Grubbing DismantlingharshaAún no hay calificaciones

- Earth Resistance ValueDocumento5 páginasEarth Resistance ValueZulfequar R. Ali KhanAún no hay calificaciones

- Arc Flash StudyDocumento2 páginasArc Flash Studychampion2007100% (1)

- 22-4-2019 - Instrumentation CourseDocumento54 páginas22-4-2019 - Instrumentation CourseGasmi KrAún no hay calificaciones

- Draka 2Documento260 páginasDraka 2Sakinah Cik KinoAún no hay calificaciones

- Satr-P-3912 Transformer InsulationDocumento8 páginasSatr-P-3912 Transformer InsulationSurendren R100% (1)

- XLPE UGC Withstand TestDocumento6 páginasXLPE UGC Withstand TestFuad BurhaniAún no hay calificaciones

- Inspection and Testing of Electrical InstallationDocumento8 páginasInspection and Testing of Electrical InstallationKamugasha KagonyeraAún no hay calificaciones

- R8005C MvawDocumento20 páginasR8005C MvawRinda_RaynaAún no hay calificaciones

- Cara Nak Pasang Wayar Cats Eye Utk NetworkDocumento15 páginasCara Nak Pasang Wayar Cats Eye Utk NetworkKrull Hzm100% (1)

- Testing & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981Documento14 páginasTesting & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981PKAún no hay calificaciones

- MEP SpecificationDocumento2 páginasMEP SpecificationcarlomaderazoAún no hay calificaciones

- Group 6 Nec Nfpa 70Documento5 páginasGroup 6 Nec Nfpa 70jeraldanchetajean05Aún no hay calificaciones

- Article 90. Introduction: 90.1. Purpose (A) - Practical SafeguardingDocumento14 páginasArticle 90. Introduction: 90.1. Purpose (A) - Practical SafeguardingLaurence MalanumAún no hay calificaciones

- NECvsNESC FinalDocumento6 páginasNECvsNESC FinalDBachai84Aún no hay calificaciones

- Maintenance Manual AC DC EMU (Siemens) - Draft For Comments From RailwaysDocumento293 páginasMaintenance Manual AC DC EMU (Siemens) - Draft For Comments From RailwaysTA CWMAún no hay calificaciones

- Demand No. 16 Assets-Acquisitions, Construction and ReplacementDocumento3 páginasDemand No. 16 Assets-Acquisitions, Construction and ReplacementukarthikbhelAún no hay calificaciones

- SOP MAINTENANCE FINAL - Part2Documento55 páginasSOP MAINTENANCE FINAL - Part2mansoorAún no hay calificaciones

- Vanguard FTS 370d, 370w, 370r: LED Medium Intensity Obstruction Lighting System Reference Manual Part Number F7913702Documento122 páginasVanguard FTS 370d, 370w, 370r: LED Medium Intensity Obstruction Lighting System Reference Manual Part Number F7913702Prasenjit DuttaAún no hay calificaciones

- Technical Comparison of Commercially Available TramsDocumento16 páginasTechnical Comparison of Commercially Available TramsmilandivacAún no hay calificaciones

- Spacers and Spacer Dampers For Twin - Is 10162 - 1982Documento18 páginasSpacers and Spacer Dampers For Twin - Is 10162 - 1982Gnanavel GAún no hay calificaciones

- Applications of Power Electronics in Railway Systems PDFDocumento10 páginasApplications of Power Electronics in Railway Systems PDFnpfhAún no hay calificaciones

- OHE Parameters To RememberDocumento3 páginasOHE Parameters To RememberjogienderAún no hay calificaciones

- Electrical Railway Power Supply Systems: Current Situation and Future TrendsDocumento15 páginasElectrical Railway Power Supply Systems: Current Situation and Future TrendsPranjali AgnihotriAún no hay calificaciones

- Elect SafDocumento14 páginasElect Safrussel1435Aún no hay calificaciones

- Cmaa 70Documento90 páginasCmaa 70keanu kunaAún no hay calificaciones

- Ae-02r1 Ohe2-4 PDFDocumento1 páginaAe-02r1 Ohe2-4 PDFAbhishek GuptaAún no hay calificaciones

- ACC Ametha PFRDocumento24 páginasACC Ametha PFRSSE TRD JabalpurAún no hay calificaciones

- USI FullCatalog 2018Documento96 páginasUSI FullCatalog 2018Nguyễn Thị HườngAún no hay calificaciones

- Handing Over Note-1Documento5 páginasHanding Over Note-1Ram PrakashAún no hay calificaciones

- Guidelines For Use OF Under Ground Cable System AND Overhead Conductor System Along With Cost Benefit AnalysisDocumento13 páginasGuidelines For Use OF Under Ground Cable System AND Overhead Conductor System Along With Cost Benefit AnalysisabdulAún no hay calificaciones

- ESB Construction SafetyDocumento12 páginasESB Construction Safetytexas_peteAún no hay calificaciones

- Siemens Electrification Solutions - IEEE 20160913Documento21 páginasSiemens Electrification Solutions - IEEE 20160913Victor Manuel BonettoAún no hay calificaciones

- DR09051 DR09051Documento292 páginasDR09051 DR09051Hemantha BalasuriyaAún no hay calificaciones

- Rajeev - L&T New Technologies in Electrification R3Documento17 páginasRajeev - L&T New Technologies in Electrification R3Krishna DaravathuAún no hay calificaciones

- Tram Electric Power PDFDocumento101 páginasTram Electric Power PDFkanbouchAún no hay calificaciones