Documentos de Académico

Documentos de Profesional

Documentos de Cultura

High-performance hydraulic servoactuators

Cargado por

Cesar PomposoDescripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

High-performance hydraulic servoactuators

Cargado por

Cesar PomposoCopyright:

Formatos disponibles

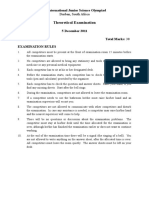

SPECIFICATIONS

Operating Pressure: Standard: 500 to 3000 psi * Optional (special order): 4000 psi Fluid: Compatible with common hydraulic fluids Recommended viscosity range: 60-450 SUS @ 100F (10-97 cSt @ 38C) Cleanliness Level: ISO DIS 4406 code 16/13 max. 14/11 recommended Operating T emperature: Minimum: -20F (-28C) (maximum fluid viscosity 6000 SUS) Maximum: +200F (+93C) Seals: Fluorocarbon O-Rings with anti-extrusion device External Leakage: Rod Seals: slight rod wetting Radial Load: Maximum: 50 lbs. Transducer Null Adjustment: 0.25 inch Orientation: Any Cycle Life: > 107 cycles between seal changes Exterior Materials: - Aluminum Alloy (chromic acid anodized) - Alloy Steel (zinc or chrome plated; black oxide treated) - Stainless Steel

A085 Series Servoactuators

The Moog A085 Series Servoactuators combine high performance cylinders, linear feedback devices and servovalves in one assembly.These servoactuators have been specifically developed to offer the advantages of custom engineered units designed for industrial applications without the costs or delays that can accompany a custom designed unit. The choice of servovalves, feedback transducers, working areas and strokes available will accommodate most control requirements. Maximum compatibility with other Moog components such as electronics and special function manifolds. The benefits of the A085 Series include totally assembled and self contained units that are 100% tested before shipment. Minimized plumbing and fixturing as well as case drain for zero rod leakage.

STANDARD OPTIONS

Piston Areas: 1.1 in2, 3.4 in2, 6.8 in2 Strokes: 1 in, 2 in, 4 in, 6 in

PRESSURE TRANSDUCER LVDT

Servovalve Selection: 62 Series, 760 Series Selection of Cylinder Mounting: Base Mount, Front or Rear Flange Mount, Front or Rear Trunnion Mount Optional Crossports Relief Valves (CRV) Optional Cylinder Bypass Orifice (AMO) Optional Pressure Transducers Optional Filter for supply fluid Wide Range of Flow Capacity and Dynamic Response Selection Selection of LVDT or DCDT for position feedback

SERVOVALVE

TYPICAL HYDRAULIC CIRCUIT

SERVOVALVE

ELECTRICAL SCHEMATIC

A B C D A B C D POLARITY: Input: A (+), B (-) Output: C positive with respect to D with pressure applied

AMO [ADJUSTABLE METERING ORIFICE] AND PRESSURE TRANSDUCERS CRV [CROSSPORT PRESSURE RELIEF VALVES]

POLARITY: Parallel coils: A & C (+), B & D (-) actuator extends Series coils: B & C inteconnected, A (+), D (-) actuator extends

DCDT

A B C D E F PHASING: Input:* C (+), F (-) Output: with actuator extended E is positive with respect to D * Input polarity must be observed

A B C D E F PHASING: Input: A & B Output: interconnect D & E; with actuator extended, B & C common, A & F are in phase

+

RETURN SUPPLY CYLINDER AND PISTON

A085 SERIES INSTALLATIONS AND MANIFOLDS

MOOG CONTROLS SERVOVALVE PORT PER SAE J1926 1.0625-12UNF-2B DASH 12 STR THD O-RING BOSS (.75 TUBE OD REF) PRESSURE THIS SIDE RETURN FAR SIDE 2.48 [63.0] 1.32 [33.5] 1.375 [34.92] + - 0.25 ADJ. [+ - 6.4] 1.375 [34.92] 1.00 [25.4] FULLY RETRACTED .75 0.12 [3.04] RAD. .656 [16.66] CASE DRAIN, PORT PER SAE J1926-3 (3/16" O.D. TUBE) 2 PLACES 1.000-14UNF-3B THD x 1.64 [41.6] MIN DP P 4X OPTIONAL FLANGE PLATE .344 [8.74] THRU .014 M 3.50 [88.9]

ACCESSORIES

Rod End Adapter: P/N A31558 converts rod end to female 1/220 UNF-3 x 1.00 DP thd; adapter adds 0.50 inch to rod end length

A

1.66 [42.2]

OPTIONAL TRUNNIONS 2.50 [63.5] 1.750 [44.45]

1.50 2.75 1.313 [33.35]

Servovalve Mating Electrical Connector: P/N 49054F14S2S (MS3106F14S-2S) Position Transducer Mating Electrical Connector: P/N 49054F14S6S (MS3106F14S-6S) Pressure Transducer Mating Electrical Connector: P/N 49532-18 (MS3116E8-4S)

B/ 2 B C

.70 [17.8]

1.313 [33.35]

4.250 [107.95] 5.00 [127.00] 5.70 [144.8]

4X .375-24 UNF THD .014 M

1.50 [38.1]

1.1 in2 Size

OPTIONAL TRUNNION PLATE THICKNESS 0.70 [17.8] 3.70 [94.0]

MOOG CONTROLS SERVOVALVE PORT PER SAE J1926 1.062-12 UNF-2B DASH 12 STR THD O-RING BOSS (.75 IN. O.D. TUBE REF) PRESSURE THIS SIDE RETURN FAR SIDE

CASE DRAIN, PORT PER SAE J1926-3 (3/16" O.D. TUBE) 2 PLACES 1.00 - 14 UNF-3B THD X 1.60 [40.6] DEEP P

M

1.1 in2 Size

3.50 [88.9]

OPTIONAL FLANGE PLATE 4X .468 [11.89] THRU .014 M

3.00 [76.2]

2.18 [55.4]

3.50 [88.9]

1.75 [44.5]

2.250 [57.15]

Actuator plus 760 Servovalve Servovalve only Servovalve plus Relief Valves (CRV) Servovalve plus Metering Orifice (AMO) Servovalve plus Relief Valves (CRV) & Metering Orifice (AMO)

A 5.48 [139.2] 6.73 [170.9] 6.46 [164.1] 7.71 [195.8]

Piston Stroke 1.00 [25.4] 2.00 [50.8 ] 4.00 [101.6] 6.00 [152.4]

B 4.84 [122.9] 5.84 [148.3] 7.84 [199.1] 9.84 [249.9]

C 9.17 [232.9] 11.17 [283.7] 15.17 [385.3] 19.17 [486.9]

D

+ - 0.25 ADJ. [+ - 6.4]

D/ 2

0.89 [22.6]

1.375 OPTIONAL TRUNNIONS [34.93] 1.00 [25.4] FULLY RETRACTED 0.12 [3.04] RAD.

B/ 2 B C

4X .375-24 UNF THD .014 M .75

4.250 [107.95] 5.00 [127.0] 5.70 [144.8]

1.375 [34.93]

3.4 in2 Size

Actuator plus 760 Servovalve Servovalve only Servovalve plus Relief Valves (CRV) Servovalve plus Metering Orifice (AMO) Servovalve plus Relief Valves (CRV) & Metering Orifice (AMO) A 6.00 [152.4] 7.25 [184.2] 6.98 [177.3] 8.23 [209.0] Piston Stroke 1.00 [25.4] 2.00 [50.8] 4.00 [101.6] 6.00 [152.4] B 4.98 [126.5] 5.98 [151.9] 7.98 [202.7] 9.98 [253.5] C 9.31 [236.5] 11.31 [287.3] 15.31 [388.9] 19.31 [490.5] D 1.00 [25.4] 1.50 [38.1] 3.00 [76.2] 5.00 [127.0]

.875 [22.23]

3.4 in2 Size

OPTIONAL TRUNNION PLATE THICKNESS .890 [22.61]

3.70 [94.0]

MOOG CONTROLS SERVOVALVE PORT PER SAE J1926 1.062-12 UNF-2B DASH 12 STR THD O-RING BOSS (.75 IN. O.D. TUBE REF) PRESSURE THIS SIDE RETURN FAR SIDE

CASE DRAIN, PORT PER SAE J1926-3 (3/16" O.D. TUBE) 2 PLACES 1.00-14 UNF-3B THD X 1.60 [40.6] DEEP P 4X OPTIONAL FLANGE PLATE .531 [13.49] THRU .014 M OPTIONAL TRUNNIONS 4.00 [101.6] 3.12 [79.2]

4.00 [101.6]

6.8 in2 Size

A

Actuator plus 760 Servovalve Servovalve only Servovalve plus Relief Valves (CRV) Servovalve plus Metering Orifice (AMO) Servovalve plus Relief Valves (CRV) & Metering Orifice (AMO) A 6.40 [162.5] 7.65 [194.3] 7.38 [187.4] 8.63 [219.2] Piston Stroke 1.00 [25.4] 2.00 [50.8] 4.00 [101.6] 6.00 [152.4] B 5.43 [137.9] 6.43 [163.3] 8.43 [214.1] 10.43 [264.9] C 8.88 [225.6] 10.88 [276.4] 14.88 [377.9] 18.88 [479.6] D None 1.38 [35.1] 3.00 [76.2] 5.00 [127.0]

3.40 [86.4]

2.58 [65.5]

2.00 [50.8]

D/ 2

+ - 0.25 ADJ. [+ - 6.4]

D B/ 2 B C

1.625 [41.28] 1.01 [25.7] 1.00 [25.4] FULLY RETRACTED

5.00 [127.0] 6.00 [152.4] 6.20 [157.5]

1.625 [41.28]

4X .500-20 UNF THD .75 .014 M

0.12 [3.04] RAD. 1.00 [25.40]

6.8 in2 Size

OPTIONAL TRUNNION PLATE THICKNESS 1.01 [25.7]

Industrial Controls Division

4.20 [106.7]

The products described herein are subject to change at any time without notice, including, but not limited to, product features, specifications, and designs.

Moog Inc., East Aurora, NY 14052-0018 Telephone: 716/652-2000 Fax: 716/687-7910 Toll Free: 1-800-272-MOOG

CDL6340 Rev C 500-308 0405

También podría gustarte

- 631 500seriesvalves PDFDocumento2 páginas631 500seriesvalves PDFsaiful_tavipAún no hay calificaciones

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAún no hay calificaciones

- 62 Series Servovalves Technical OverviewDocumento8 páginas62 Series Servovalves Technical OverviewDevendra BangarAún no hay calificaciones

- Engineers Precision Data Pocket ReferenceDe EverandEngineers Precision Data Pocket ReferenceCalificación: 3 de 5 estrellas3/5 (1)

- Bomba Hidrailica A10VSODocumento44 páginasBomba Hidrailica A10VSOkiarabenitezparejaAún no hay calificaciones

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsCalificación: 4.5 de 5 estrellas4.5/5 (10)

- Proportional Control Valves ISO 4401 Size 05Documento8 páginasProportional Control Valves ISO 4401 Size 05Devendra BangarAún no hay calificaciones

- D631 Series Servo Control Valves ISO 4401 Size 05Documento12 páginasD631 Series Servo Control Valves ISO 4401 Size 05José OlaveAún no hay calificaciones

- It6427-0409 SMDocumento24 páginasIt6427-0409 SMavalente112100% (1)

- 110 Waveform Generator Projects for the Home ConstructorDe Everand110 Waveform Generator Projects for the Home ConstructorCalificación: 4 de 5 estrellas4/5 (1)

- PT420A Series: FeaturesDocumento3 páginasPT420A Series: FeaturesA.K.A. HajiAún no hay calificaciones

- Moog ServovalvesDocumento8 páginasMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Re 15228 Radial Piston Hydraulic Motor With A Fixed DisplacementDocumento36 páginasRe 15228 Radial Piston Hydraulic Motor With A Fixed Displacementraj8378100% (1)

- NuFlo Gas TurbineDocumento4 páginasNuFlo Gas TurbineANIKRADAún no hay calificaciones

- Control Valve Specification and Sizing DetailsDocumento34 páginasControl Valve Specification and Sizing DetailsRahulTewari67% (3)

- ACW Booster Pump CalculationDocumento7 páginasACW Booster Pump CalculationgreenenergykolkataAún no hay calificaciones

- 4r75e Ford TransmissionDocumento5 páginas4r75e Ford TransmissionDavid Prince71% (7)

- NOVA Servo CatalogueDocumento7 páginasNOVA Servo CatalogueDip Narayan BiswasAún no hay calificaciones

- 2 and 3 Genesis Series PD Meter SpecificationsDocumento6 páginas2 and 3 Genesis Series PD Meter Specificationsjimbo2032Aún no hay calificaciones

- NIMCO CV300newDocumento24 páginasNIMCO CV300newBruno SamaeianAún no hay calificaciones

- TelmaDocumento7 páginasTelmafugega100% (1)

- Cong Tac Dong ChayDocumento2 páginasCong Tac Dong ChaynatechAún no hay calificaciones

- DirectionalControlValves NACHIDocumento47 páginasDirectionalControlValves NACHICarlos Mauricio Guerrero Aguilar100% (1)

- Aircon MSH Ga50 80 Ob367Documento24 páginasAircon MSH Ga50 80 Ob367John KeyAún no hay calificaciones

- Rexroth电磁阀手册Documento12 páginasRexroth电磁阀手册davidwang85120% (1)

- DLM142EDocumento28 páginasDLM142Eseaqu3stAún no hay calificaciones

- Paquete Miller 7.5 y 10 TonsDocumento12 páginasPaquete Miller 7.5 y 10 TonscarlamarianaeliasAún no hay calificaciones

- Desalination pump design bookletDocumento14 páginasDesalination pump design bookletBenicio Joaquín Ferrero BrebesAún no hay calificaciones

- 2 and 3 Genesis Series PD Meter SpecificationsDocumento6 páginas2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanAún no hay calificaciones

- RE50214 Nivometer PDFDocumento16 páginasRE50214 Nivometer PDFCaspar Heerkens100% (1)

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDocumento4 páginasData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990Aún no hay calificaciones

- Omega Injection Moulding MachineDocumento9 páginasOmega Injection Moulding Machinerajpujara50% (2)

- Datasheet Amt102 EncoderDocumento8 páginasDatasheet Amt102 EncoderPablo Davila100% (1)

- Directional Control Valves GuideDocumento193 páginasDirectional Control Valves GuidephaindikaAún no hay calificaciones

- Axial Piston Compact Unit A10CODocumento8 páginasAxial Piston Compact Unit A10COJohn SimmondsAún no hay calificaciones

- B3 - ARB120 - SR Belimo Three Way ValvesDocumento3 páginasB3 - ARB120 - SR Belimo Three Way ValvesJose SurielAún no hay calificaciones

- Rexroth FDDocumento116 páginasRexroth FDIvan GudeljAún no hay calificaciones

- CDX centrifugal pumps technical manualDocumento13 páginasCDX centrifugal pumps technical manualLiz BargolaAún no hay calificaciones

- DX B Ironless Linear Motor - PBASystemsDocumento28 páginasDX B Ironless Linear Motor - PBASystemsjuliangoalAún no hay calificaciones

- Afv TDB 9610.6 Capacity TablesDocumento24 páginasAfv TDB 9610.6 Capacity TablesJorge BaronAún no hay calificaciones

- 2/2-way valves DN 20 to 50 for air solenoid actuated diaphragm valvesDocumento4 páginas2/2-way valves DN 20 to 50 for air solenoid actuated diaphragm valvesOscar CurimanyaAún no hay calificaciones

- 041159X85Z Re18318-07 PDFDocumento2 páginas041159X85Z Re18318-07 PDFHamid CRAún no hay calificaciones

- Reliable flow measuring system for steam, air and waterDocumento4 páginasReliable flow measuring system for steam, air and waterEdgarParedesAún no hay calificaciones

- Mustan 05-09 AutomaticDocumento6 páginasMustan 05-09 AutomaticJohn MooreAún no hay calificaciones

- Re17017 2008-08Documento72 páginasRe17017 2008-08toothtoothtoothAún no hay calificaciones

- DKRCC - pd.Vd1.d5.02 Ets6 SWDocumento16 páginasDKRCC - pd.Vd1.d5.02 Ets6 SWJaroslav BiresAún no hay calificaciones

- Bomba Hidraulica para Trituradora TESABDocumento8 páginasBomba Hidraulica para Trituradora TESABFerneli Moises Barbosa OjedaAún no hay calificaciones

- Re 10039Documento10 páginasRe 10039Ahmed Abd ElhakeemAún no hay calificaciones

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Documento6 páginasHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianAún no hay calificaciones

- Butterfly ValveDocumento20 páginasButterfly Valvenazar750Aún no hay calificaciones

- Principal 5svbk8Documento56 páginasPrincipal 5svbk8badillojdAún no hay calificaciones

- Problem Encounterd and Their SolutionDocumento6 páginasProblem Encounterd and Their SolutionTophe DimaapiAún no hay calificaciones

- Bomba Rexroth PDFDocumento36 páginasBomba Rexroth PDFplasticos_jfm6580100% (11)

- Axial Piston Pump CatalougeDocumento36 páginasAxial Piston Pump Catalougemrkadu_61Aún no hay calificaciones

- Actuador NeumaticoDocumento12 páginasActuador NeumaticoJose Alfredo Rojas UribeAún no hay calificaciones

- p9nb50 PDFDocumento9 páginasp9nb50 PDFceftv1Aún no hay calificaciones

- MFAC Brochure GBDocumento8 páginasMFAC Brochure GB15472Aún no hay calificaciones

- MobiluxeDocumento3 páginasMobiluxesharin79Aún no hay calificaciones

- MACO ObsolescenceDocumento1 páginaMACO ObsolescenceCesar PomposoAún no hay calificaciones

- 8 Channel Scanner: Channel 8N - Channel 8ANDocumento1 página8 Channel Scanner: Channel 8N - Channel 8ANCesar PomposoAún no hay calificaciones

- Tisoft 2 ManualDocumento418 páginasTisoft 2 ManualDaniel100% (1)

- Maco - Control2009HA136715 - Iss7 (1) Temper PDFDocumento44 páginasMaco - Control2009HA136715 - Iss7 (1) Temper PDFCesar PomposoAún no hay calificaciones

- Adjustable Speed Drives A&bDocumento15 páginasAdjustable Speed Drives A&bCesar PomposoAún no hay calificaciones

- Digital Servo Drive Product ManualDocumento94 páginasDigital Servo Drive Product ManualCesar PomposoAún no hay calificaciones

- Semaphore Twinsoft ManualDocumento101 páginasSemaphore Twinsoft ManualCesar PomposoAún no hay calificaciones

- Plastech Manual LTU6000 enDocumento34 páginasPlastech Manual LTU6000 enCesar PomposoAún no hay calificaciones

- Manifolds Complete PDFDocumento156 páginasManifolds Complete PDFCesar Pomposo100% (1)

- Blow MoldDocumento52 páginasBlow Moldnmjbose100% (2)

- Maco - Control2009HA136715 - Iss7 (1) Temper PDFDocumento44 páginasMaco - Control2009HA136715 - Iss7 (1) Temper PDFCesar PomposoAún no hay calificaciones

- SIMOREG DCM-6RA70-Base Drive Manual Rev 7 PDFDocumento233 páginasSIMOREG DCM-6RA70-Base Drive Manual Rev 7 PDFCesar Pomposo100% (2)

- 14 - HPL2010-EN. AutomatizaciónDocumento126 páginas14 - HPL2010-EN. AutomatizaciónCesar PomposoAún no hay calificaciones

- SIMOREG DCM-6RA70-Base Drive Manual Rev 7 PDFDocumento233 páginasSIMOREG DCM-6RA70-Base Drive Manual Rev 7 PDFCesar Pomposo100% (2)

- 1 2 3 4 5 6 Operator Panel OP47-12 Simatic Hmi: Equipment ManualDocumento80 páginas1 2 3 4 5 6 Operator Panel OP47-12 Simatic Hmi: Equipment ManualCesar PomposoAún no hay calificaciones

- Test For Cations, Anions and Gases (QA) NotesDocumento10 páginasTest For Cations, Anions and Gases (QA) Noteschong56100% (2)

- TDS - Mastertop 1330Documento2 páginasTDS - Mastertop 1330Venkata RaoAún no hay calificaciones

- Solvent Extraction Principles and Practice 2nd Ed - Jan Rydberg Et Al. (Marcel Dekker, 2004)Documento724 páginasSolvent Extraction Principles and Practice 2nd Ed - Jan Rydberg Et Al. (Marcel Dekker, 2004)Milena Katarina Stojiljkovic100% (6)

- Liquefied Gas HandbookDocumento38 páginasLiquefied Gas HandbookAndri Suharto100% (1)

- MEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner GuideDocumento8 páginasMEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner Guidequestionbank.com.au50% (2)

- BenchTop Orbital Shakers GuideDocumento8 páginasBenchTop Orbital Shakers Guidedéborah_rosales100% (1)

- MCQ IjsoDocumento20 páginasMCQ IjsommhabgAún no hay calificaciones

- Unit 1 - Construction Materials - WWW - Rgpvnotes.inDocumento21 páginasUnit 1 - Construction Materials - WWW - Rgpvnotes.inmadhavi likharAún no hay calificaciones

- Homogenization and Lysis (2021!06!12)Documento22 páginasHomogenization and Lysis (2021!06!12)Wreck of HeartsAún no hay calificaciones

- Acid RainDocumento35 páginasAcid RainAshish Deotale100% (4)

- Preslia 68 - MSDSDocumento12 páginasPreslia 68 - MSDSFraAún no hay calificaciones

- Mineral NutritionDocumento23 páginasMineral NutritionRahul KumarAún no hay calificaciones

- Cassida Chain Oil 150-SdsDocumento5 páginasCassida Chain Oil 150-SdsInggil Budi PekertiAún no hay calificaciones

- Merck Price List 2018 To 2019 Vijay ChemicalsDocumento404 páginasMerck Price List 2018 To 2019 Vijay Chemicalsnikhilesh2011Aún no hay calificaciones

- Improved Conductivity and Mechanism of Carrier Transport in Zinc Oxide With Embedded Silver LayerDocumento8 páginasImproved Conductivity and Mechanism of Carrier Transport in Zinc Oxide With Embedded Silver LayerAbdul BasitAún no hay calificaciones

- IB Chemistry Molarity, Concentration, Standard Solution and Serial Dilution PreparationDocumento13 páginasIB Chemistry Molarity, Concentration, Standard Solution and Serial Dilution PreparationoscarbecAún no hay calificaciones

- Thermodynamics Chapter OverviewDocumento40 páginasThermodynamics Chapter OverviewdeusleanAún no hay calificaciones

- 02 Heubach No 00181 ZPA RZ Epoxy Dispersion WDocumento2 páginas02 Heubach No 00181 ZPA RZ Epoxy Dispersion WnanoAún no hay calificaciones

- World Fertilizer Trends and Outlook To 2020Documento38 páginasWorld Fertilizer Trends and Outlook To 2020SudhirAún no hay calificaciones

- Advanced Manufacturing Technology 2-Marks Question and Answer Unit-IDocumento44 páginasAdvanced Manufacturing Technology 2-Marks Question and Answer Unit-IM.ThirunavukkarasuAún no hay calificaciones

- Gruvlok Stainless SteelDocumento16 páginasGruvlok Stainless Steellink2u_007Aún no hay calificaciones

- Report GCWDocumento34 páginasReport GCWArchit HaldiaAún no hay calificaciones

- Unit 1 - Part A-Water Supply IDocumento24 páginasUnit 1 - Part A-Water Supply IIsha SinghAún no hay calificaciones

- ME6008 WELDING TECHNOLOGY Part B IQDocumento1 páginaME6008 WELDING TECHNOLOGY Part B IQVikram mAún no hay calificaciones

- Chloroplast, PPTDocumento21 páginasChloroplast, PPTSuchitra Sk88% (8)

- Presentation1. AEC GeoTech LANDFILLDocumento22 páginasPresentation1. AEC GeoTech LANDFILLAyan BorgohainAún no hay calificaciones

- 6 Microbial ControlDocumento36 páginas6 Microbial ControlGladish RindraAún no hay calificaciones

- Studies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional ProfileDocumento4 páginasStudies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional Profileamco2kAún no hay calificaciones

- Dust Collection Design and Maintenance GuideDocumento36 páginasDust Collection Design and Maintenance GuideMadan YadavAún no hay calificaciones

- The Grid: The Fraying Wires Between Americans and Our Energy FutureDe EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureCalificación: 3.5 de 5 estrellas3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualDe EverandIndustrial Piping and Equipment Estimating ManualCalificación: 5 de 5 estrellas5/5 (7)

- Introduction to Power System ProtectionDe EverandIntroduction to Power System ProtectionCalificación: 5 de 5 estrellas5/5 (1)

- Produced Water Treatment Field ManualDe EverandProduced Water Treatment Field ManualCalificación: 4.5 de 5 estrellas4.5/5 (5)

- Renewable Energy: A Very Short IntroductionDe EverandRenewable Energy: A Very Short IntroductionCalificación: 4.5 de 5 estrellas4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesCalificación: 4.5 de 5 estrellas4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAún no hay calificaciones

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyDe EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyAún no hay calificaciones

- Asset Integrity Management for Offshore and Onshore StructuresDe EverandAsset Integrity Management for Offshore and Onshore StructuresAún no hay calificaciones

- Handbook on Battery Energy Storage SystemDe EverandHandbook on Battery Energy Storage SystemCalificación: 4.5 de 5 estrellas4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentCalificación: 4.5 de 5 estrellas4.5/5 (21)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDe EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe EverandShorting the Grid: The Hidden Fragility of Our Electric GridCalificación: 4.5 de 5 estrellas4.5/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAún no hay calificaciones

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDe EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsAún no hay calificaciones

- Build Your Own Electric Vehicle, Third EditionDe EverandBuild Your Own Electric Vehicle, Third EditionCalificación: 4.5 de 5 estrellas4.5/5 (3)

- The Rare Metals War: the dark side of clean energy and digital technologiesDe EverandThe Rare Metals War: the dark side of clean energy and digital technologiesCalificación: 5 de 5 estrellas5/5 (2)

- Transmission Pipeline Calculations and Simulations ManualDe EverandTransmission Pipeline Calculations and Simulations ManualCalificación: 4.5 de 5 estrellas4.5/5 (10)

- Introduction to Power System ProtectionDe EverandIntroduction to Power System ProtectionAún no hay calificaciones

- Implementing an Integrated Management System (IMS): The strategic approachDe EverandImplementing an Integrated Management System (IMS): The strategic approachCalificación: 5 de 5 estrellas5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe EverandNuclear Energy in the 21st Century: World Nuclear University PressCalificación: 4.5 de 5 estrellas4.5/5 (3)

- ISO 50001: A strategic guide to establishing an energy management systemDe EverandISO 50001: A strategic guide to establishing an energy management systemAún no hay calificaciones

- Pocket Guide to Flanges, Fittings, and Piping DataDe EverandPocket Guide to Flanges, Fittings, and Piping DataCalificación: 3.5 de 5 estrellas3.5/5 (22)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDe EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideCalificación: 2 de 5 estrellas2/5 (1)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksDe EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksAún no hay calificaciones

- The Way Home: Tales from a life without technologyDe EverandThe Way Home: Tales from a life without technologyCalificación: 4 de 5 estrellas4/5 (45)

- Well Control for Completions and InterventionsDe EverandWell Control for Completions and InterventionsCalificación: 4 de 5 estrellas4/5 (10)