Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Hydrastep & Hydratect Water/steam Monitoring Systems: Solartron Mobrey LTD B246801

Cargado por

cytech6619Descripción original:

Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Hydrastep & Hydratect Water/steam Monitoring Systems: Solartron Mobrey LTD B246801

Cargado por

cytech6619Copyright:

Formatos disponibles

WATER/STEAM MONITORING

Hydrastep & Hydratect water/steam monitoring systems

2468

Hydrastep

Electronic Gauging System

Failure to detect low water levels in steam-raising plant can have costly and potentially disastrous consequences. Reliable water level detection is vital to prevent damage to plant and personnel. The Solartron Hydrastep Electronic Gauging System is the ideal fit and forget solution to overcome the problems associated with unreliable, maintenance intensive gauge glasses. Designed for totally reliable operation, Hydrastep is both fail-safe and fault tolerant. Hydrastep electronics mounted at drum level Hydrastep is... Flexible: s Modular system to match requirements s Choice of 8 to 32 electrode resolution s Multiple remote displays s Up to 16 trips/alarms operable at selected water levels Exceptionally reliable: s Electrodes continuously monitored for open or short circuit condition s Fault indication on all displays s Multi-segment LEDs provide built-in redundancy Additional remote displays s All signal path wiring continuously monitored s Dual independent power supplies provide fail operational condition s No junction boxes required - fully tested spliced cable as standard Control room display Cost effective: s Zero maintenance - fit and forget s No nuisance trips, no lost revenue s No missed incidents s Approved by insurance companies

2462

Water detection and level measurement

Hydratect

qqqqqqqqqqqqqqqqqqqqqqq

Water column and electrodes

Modern boilers are designed to provide clean dry steam. Detection of incorrect water level in the drum is essential: too high a level can give wet steam, leading to turbine blade erosion, and if the level is too low, the boiler tubes can overheat, with the danger of explosion. All national legislatures require indication of water level in steam generating plant, and drum level indication in the control room is absolutely necessary. Conversely, however, false alarms leading to plant shutdown and loss of revenue are also highly undesirable. Hydrastep offers exceptional levels of security. All measurements are interpreted as water, steam or contamination. Both short and open circuit conditions are detected and indicated as faults. An independent report by Factory Mutual Research concluded that the probability of Hydrastep missing a trip condition is less than 1 in 3,000,000,000, and that nuisance trips will be less than 1 in 107. Hydrastep combines optimum safety indication with virtually no risk of false alarms.

Steam/Water Detection System

The Hydratect Electronic Water Detection system is designed as an electronic alternative to conventional water level switches on steam raising plant. It can be used in a wide variety of situations wherever the detection of water or steam is vital for safe and efficient operation. Designed to use the same water or steam detection system as Hydrastep, Hydratect provides much higher levels of reliability than conventional devices, and can be used in conjunction with Hydrastep level detection for ultimate protection. Hydratect provides local indication and configurable alarm / trip outputs. Hydratect Installation

sola rtro n

The 2462 Hydratect has been designed for: q fault tolerance q fail-safe operation q fully validated trips q detection of electrode contamination q detection of open circuit electrode connections q detection of faulty ground connections q operation with either a two part electrode or a three part selfmonitoring electrode The 2462: q makes routine testing unnecessary q conforms to all existing standards and legislation q continuously verifies measurement integrity q is the most economical solution for all installations.

Alarm and trip signals Hydrastep Installation The Hydrastep

system consists of a water column fitted with up to 32 electrodes, an electronic measuring unit, local and remote displays, and connecting cables. Each of these components is available with a specification to provide outstandingly reliable, cost effective protection in any application.

4-20mA signal

Alarm and trip signals

APPROVED

TYPE APPROVED

Electrodes

Hydrastep

Two interleaved vertical rows of electrodes are installed in a water column attached to the boiler and usually aligned so that half the electrodes are above the normal water level. The water column is attached to the boiler via steam and water connections, and may be isolated from the boiler by isolation valves.

by step by step...

Water column

Electronics and local display

Water column and electrodes Hydrastep electronics mounted at drum level

Electrodes from each side of the column are connected to the electronics unit by separate cables. Two separate input boards, each powered by its own power supply, measure the signal from each electrode and feed alternate segments of the display. This arrangement provides redundancy against failure in any part of the system. Up to 16 alarm relay outputs (dependent on the number of relay boards installed) can be utilized to operate trips or control audible, visual or other alarm indication. Each relay can be set to operate at any water level. For example, alarms could be set to give outputs on high-high, high, low and low-low levels, with trips on the high-high and low-low levels. The electronics unit performs a resistance measurement between the insulated tip of each electrode and the wall of the water column. The resistance measured in water is substantially less than that measured in steam. The presence or absence of water is sensed at each point and the level of water is indicated. Fault conditions are also shown on the display. Remote display units are available for control room indication of level. All functions of the main display unit are repeated on the remote display, including fault indication. Up to six remote displays can be installed.

Operation Two wires are connected to each electrode, one for the signal drive and one for the signal return. A low frequency square wave is used to drive the electrodes through drive resistors. Additional wires are used for the ground connection. When the electrode is in steam a high resistance to ground (insert wall) is presented, and therefore a large signal is returned. When the electrode is in water a low resistance to ground is presented and therefore a small signal is returned. If no signal is returned or only a very small amplitude is returned then either a short circuit to ground is present or a wire has been broken or disconnected. If a ground connection becomes broken or disconnected then a large signal will be returned (equivalent to steam) and a separate circuit detects the broken or disconnected wire.

Drive resistor Amplitude dependent on resistance Ov detection Ov Steam (high resistance) Water (low resistance) Fault (very low resistance)

Additional remote displays

Alarm and trip signals

4-20mA signal

Remote displays

Control room display

Conductivity (S/cm)

Even input board: power supply, electrode inputs, discrimination, Odd input board: validation, power supply, fault detection electrode inputs, discrimination, Power supply B validation, fault detection Even electrodes Even relay board: fail safe output

100 0.01

200

Temperature F 300 400 500 Normal steam values

600

700 10,000

Pure water 0.1 Hydrastep switching band - normal 1 Hydrastep switching band - alternate 100 1,000 Resistance KW

Odd electrodes Power supply A Odd relay board: fail safe output

10

Typical boiler water

10

To remote display Display board: display decode, opto fault output, display drivers

100 0 100 200 Temperature C

1 300 370 (Cell constant =0.1)

...by step.

Hydrastep

Density error is dependent on both water level and operating conditions, so that simply offsetting the water column cannot compensate for density error. Correct installation of the Hydrastep system (see diagram) reduces the density error to the smallest possible by minimising the difference in temperature between the water column and the drum. Partially insulating the steam leg encourages condensation which transfers latent heat from the steam to the water in the water column. Loss of heat from the water leg is prevented by correct insulation. Such a scheme is not practical with other side arm systems where condensate flow would create flooding or saturation and therefore incorrect level indication. The Hydrastep water level columns are designed and manufactured to match the reliability of the rest of the Hydrastep system. They offer plant operators the ideal answer for water level measurement on both HRSG drums and feedwater heaters. All design calculations, manufacturing and test are carried out to ASME Boiler and Pressure Vessel Code and B31.1 Power Piping Code. In addition, columns can optionally be provided with full certification to customers requirements. General ASME B31.1 design code Custom manufactured Stainless steel covers Design Pressure: 120 bar (1740 psi) Design temperature: 343C (650F) Threaded electrode fixing Helicoil protected threads Metaflex gasket seal

water level columns

Density Error All side arm level measuring systems experience an effect called density error. Errors can be as much as 150mm (6in). Correct installation of the Hydrastep system reduces this error to less than 20mm (0.8in) - well below that obtainable with most other side arm systems. Density error occurs because temperature loss causes water in the measurement system to be cooler than the water in the drum or vessel. Since cooler water has greater density a depression of the water in the side arm occurs.

Low Pressure Water Level Columns

25mm (1") Sch.80 SA106 connections

Slope down - 1 in 50 min.

High Pressure Water Level Columns Design Pressure: 210 bar (3045 psi) Design temperature: 370C (698F)

0.5m (18") min. clear of insulation

Wadelock-style electrode fixing Metal to metal pressure seal Density error 25mm (1") Sch 160 SA106 connections Supercritical Pressure Columns Solartron water columns and electrodes can be specified for supercritical pressures and temperatures. This means that level indication is provided during subcritical operation and the need for valving off when the boiler goes supercritical is eliminated. Design Pressure: 300 bar (4350 psi) Design temperature: 560C (1040F) Wadelock-style electrode 25mm (1) Sch 160 SA106 connections

Insulation

Slope down - 1 in 50 min. 2m (6.5') max.

Typical installation For optimum performance, and to minimize density error, Hydrastep water columns should be installed as shown here. For columns longer than 1m. (3'3"), it may be necessary to insulate the column itself.

Electrodes for Hydrastep and Hydratect...

Hydratect

qqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqqq

Electrode Hydratect 2462 is a two channel unit designed to operate with all existing Hydrastep and Hydratect electrodes and manifolds.

solar tron

A selection of electrode types are available for pressures up to 300 bar (4350 psi) at 560C (1040F). Electrodes are available in two basic body styles. The low pressure type (up to 120 bar) has a threaded style fitting; the high pressure type (up to 300 bar) uses a Wadelock fitting. A full list of electrodes is given on page 11.

Electrode Cables At drum level, steam generating plant has ambient conditions which are hot and humid and in coal and oil fired plants there are often sulphurous fumes present. This environment adversely affects crimped copper cables, with the formation of copper sulphate. In addition, the temperature at the screw connection to the electrode can exceed the maximum operating temperature of PVC insulation used on copper cables. To overcome these problems, pure nickel conductors with PTFE insulation can be used. However, PTFE insulated cable is expensive and is only required in the immediate vicinity of the drum. The cables supplied with the Hydrastep system have a 2m. (6'6") tail of PTFE covered nickel cable, joined to the required length of PVC covered copper. The junction between the two cables is by High Performance Environment Resistant Sealed Crimp Splice, to meet the requirements of MIL-S-81824, providing a join of the highest possible integrity. (More information, with detailed specification, is available on request.) In applications where a junction box is preferred, this can be supplied with the appropriate cables.

Typical applications Steam Normal q Turbine water induction prevention q Steam line drain control q Boiler water high level protection q Stator winding cooling circuits Water normal q Feedheater boiler low level protection q Dearator level protection

For site fabrication pre-threaded inserts are available for welding into standard pipework. The insert is designed to maintain the integrity of the basic pipe

Insert

Alarm and trip signals

Low Pressure (up to 120 bar) Choice of PTFE or ceramic insulator Threaded style fitting Metaflex gasket seal

The system consists of electrodes, an electronics unit and a manifold or water column. Alternatively, inserts can be provided so that the electrodes can be fitted directly into existing pipework. Hydratect is a fault detection system designed for maximum reliability. At installation, each electrode is specified as being either normally in steam or normally in water. Under normal operating conditions, Hydratects alarm/trip relays remain energized, and no alarm is triggered. An alarm/trip output is given if: q the electrode detects a not normal condition q a fault occurs within the Hydratect system or associated wiring q power to the Hydratect system fails Steam normal is used for high water level detection in steam drums, feedheaters and in turbine water induction prevention systems (TWIPS) on steam lines. Water normal is used for low water level detection. Hydratect and Hydrastep For ultimate protection, Hydratect and Hydrastep can be combined in a single column.

1 to 4 point Manifold Custom manifolds can be supplied for 1 to 4 points

Manifold

2462 Hydratect

Electronics and readout Turbine Water Induction Protection A Hydratect Level Switch installed on the drain pot in the super-heated steam line will detect the level of condensed water in the pot. A single electrode can be used, but for better protection a two electrode, dual power supply system ensures trouble free, fault tolerant water detection.

High Pressure (up to 300 bar) Choice of insulators Wadelock (Swagelok) style fitting Metal to metal seal

Specification

2468

Electrode channels: Water/steam threshold: Electrode cable length: Fault detection: Channel fault indication: General fault indication: Local display:

Hydrastep Electronic Gauging System

8 to 32, in pairs 0.6S/cm (normal) or 1.6S/cm (alternate) depending on water purity 3m(10'), 10m(33'), 18m(60'), 30m(98') Electrode connection open circuit Short circuit to ground (selectable): >100S >300S disabled

Remote Displays

Indication: Red/Green bargraph, 32 LED segments Power Supply: From 2468 unit (1 display only) Local power for additional displays: 20V to 54V dc, 240mA 2468 3B Case style: Panel mounted Dimensions: 144mm x 72mm x 200mm deep (5.67" x 2.38" x 7.87") Panel cutout: 137.5mm x 66mm (5.41" x 2.60") 2468 3C Case style: Dimensions: Panel cutout: 2468 3D Case style: Dimensions: Panel mounted 192mm x 96mm x 209mm deep (7.56" x 3.78" x 8.23") 186mm x 92mm (7.32" x 3.62") Rugged enclosure, IP65/NEMA 4X 302mm x 186mm x 175mm deep (11.89" x 7.32" x 6.89")

qqqq

2462

Electrode channels: Water / steam threshold: Electrode cable length: Fault detection: Indicators:

Hydratect steam / water detection system

Two 0.6S/cm (normal) or 1.6S/cm (alternate) depending on water purity 3m (10ft), 10m (33ft), 18m (60ft), 30m (98ft) Electrode connection open circuit Short circuit to ground (selectable): >100S >300S disabled One Red LED for indication of Steam One Green LED for indication of Water One Amber LED for indication of Fault

Flashing display segment Amber LED Red/Green bar graph, 32 LED segments Display blanking from the bottom with less than 32 electrodes in use

Outputs: Drive to remote displays, maximum 6 units Opto-isolated fault output Analogue output (proportional to water level): Range: 0-20mA or 4-20mA, forward or reverse Accuracy: 0.2mA Drive capability: 600 at nominal supply voltage 500 at minimum supply voltage Optional Output Boards (for alarm indication) Number of output boards: 0 to 4 (max.) Relay board 24680504C Relays: Relay contact rating: Maximum voltage: Maximum current: Maximum switching power: Four independent change-over ac dc 250V 125V 8A 8A 1500VA 240W (<30V) 65W (<60V) 25W (<125V)

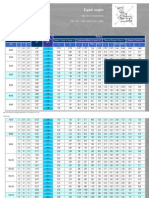

Water Level Columns

Parameter Design Pressure Test Pressure Design Temp. Design Code Protective Covers Gross Weight* LP Rectangular Section HP Series 3 HP Super 3

Status relay output (one per channel): Modes: Water normal: Energized in water Steam normal: Energized in steam Contacts: Separate normally open and normally closed Relay contact rating: ac dc Maximum voltage: 250V 125V Maximum current: 8A 8A Maximum switching power: 1500VA 240W (<30V) (resistive load) 65W (<60V) 25W (<125V) Opto-coupled: Output rating off: Output rating on:

120 bar: 1740 psi 210 bar: 3045 psi 300 bar: 4350 psi 180 bar: 2610 psi 315 bar: 4567 psi 450 bar: 6525 psi 343C: 650F ASME B31.1 18 SWG St. St. (17 AWG St. St.) 12kg (26.5lb) 459600602 or 459600802 370C: 698F ASME B31.1 18 SWG St. St. (17 AWG St. St.) 17kg (37.5lb) 2467 81Z or 2467 82A or 2467 84A 560C: 1040F ASME B31.1 18 SWG St. St. (17 AWG St. St.) 17kg (37.5lb) 2467 81A or 2467 84A

30V dc max, leakage <1mA 1A dc, voltage <1.1V @ 1A

Fault relay output (one per channel): Energized during normal operation (fail-safe) Specification as status relay above Power supply (ac): 94V to 130V or 187V to 256V 48Hz to 65Hz 2 x 10VA maximum 20V to 60V -20C to +70C (-4F to 158F) up to 100% 190mm x 190mm x 90mm deep (7.48 x 7.48 x 3.54) Stainless steel grade 304 Wall mounting (two point) Finish - natural IP65 / NEMA4X

Type N safety 5A at 12Vdc 100mA at 30Vdc 20mA at 125Vdc

Electrode Types

Power supply (dc): Operating temperature: Relative humidity: Enclosure:

Delayed relay board 24680509B Specification as 24680504C above Delay range 0 to 25s 1s

*Typical (610mm (24") steam/water range,12 port, with electrodes and covers

Opto-coupled board 24680505A Solid state relays: Four independent outputs Rating: 30V dc, 1A Maximum voltage drop: 1.1V @ 1A Maximum leakage current: 1mA @ 30Vdc Power Supplies Power supply (ac):

Manifolds

High and Low pressure specific 1 to 4 ports Design on application

Power supply (dc): General Operating temperature: Relative humidity: Enclosure:

94V to 130V or 187V to 256V 48Hz to 65Hz 60VA maximum 20V to 40V negative ground or isolated

qqqqq

Electrodes

Part No. Style Material PTFE Zircona Max Press Max Temp pH range bar (psi) C (F) 50 (725) 260 (500) 11 to 13.5 7 to 11 11 to 13.5 11 to 13.5

-20C to +70C (-4F to 158F) up to 100% Zinc sprayed mild steel with epoxy powder coating Wall mounting (four point) IP65 / NEMA4X 400mm high x 300mm wide x 163mm deep (15.75 x 11.81 x 6.42) 12kg (26.4lb) Ex N IIC T4 BS EN 61010-1: 1993 TCF950907

459600802 Threaded L.P . Col. 459600602 Threaded L.P . Col. 2467 82A 2467 84A 2467 81A 2467 81Z

120 (1740) 370 (698) 50 (725) 260 (500)

Wadelock H.P . Col. PTFE

Wadelock H.P . Col. Ceramic 300 (4350) 260 (500) PTFE coated Wadelock H.P . Col. Ceramic . Zircona

Weight Safety: Approved to: EMC:

300 (4350) 560 (1040) 7 to 11 210 (345) 370 (698) 7 to 11

IO

NS WOR

LD

SOLU

CLASS

NT

Solartron has been a market leader in supplying precision measurement solutions for the power, oil, gas, rail, aerospace and process industries for 50 years. Part of the Roxboro Group PLC, Solartron manufactures a range of electronic level gauging systems, data acquisition products, laboratory instrumentation and density and viscosity transducers which have a global reputation for excellence in performance, reliability and support. Solartrons Quality System is approved to BS EN 9001: 1994, and our Calibration Laboratories are certified by NAMAS.

CERTIFICATE No.FM1709

All our products carry the mark, showing that they are fully compatible with EC Directive 89/336/EEC. A world-wide network of Sales and Service Centers is committed to ensuring that our customers enjoy the maximum benefit from all their instrumentation. Services available include installation, commissioning, maintenance, repair and calibration of instruments and systems. Solartron is supported by a network of over 100 agents and distributors for countries where there is no direct representation.

Solartron Mobrey Inc 19408 Park Row, Suite 320 Houston, Texas 77084, USA Telephone +1 281-398-7890 Fax +1 281-398-7891

For details of agents in other countries please contact our Slough office. Email: sales@solartron.com Web: http://www.sales@solartron.com A Roxboro Group Company

Solartron Mobrey pursues a policy of continuous development and product improvement. The specifications in this document may therefore be changed without notice. SI/246801/Iss05/800 Solartron Mobrey 2000

Designed and produced by Abbott Barker Brooks

Solartron Mobrey Ltd 158 Edinburgh Avenue, Slough Berkshire SL1 4UE UK Telephone +44/0 1753 756600 Fax +44/0 1753 823589

EA

SUREM

qqqqqqqqqqqqq

Your local agent is:

B246801

También podría gustarte

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsCalificación: 3.5 de 5 estrellas3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Calificación: 2.5 de 5 estrellas2.5/5 (3)

- Introduction To Pressure VesselsDocumento52 páginasIntroduction To Pressure VesselsAkankshya Mishra100% (4)

- Altronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)Documento47 páginasAltronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)francis_mouille_iiAún no hay calificaciones

- Boiler Notes 2Documento42 páginasBoiler Notes 2Balakrishnan KannanAún no hay calificaciones

- AEGPS Protect RCS EN PDFDocumento4 páginasAEGPS Protect RCS EN PDFIrfan AshrafAún no hay calificaciones

- General Marine EngineeringDocumento67 páginasGeneral Marine EngineeringSailorprof100% (3)

- Spring Hanger & Piping Support InspectionDocumento20 páginasSpring Hanger & Piping Support InspectionAnibal Quezada100% (3)

- FL - Hvac Instrumentation and ControlsDocumento30 páginasFL - Hvac Instrumentation and Controlscytech6619Aún no hay calificaciones

- Coal Based Power PlantDocumento41 páginasCoal Based Power Plant94gaurav100% (1)

- 4472-2V-EP Operacion Ingles PDFDocumento125 páginas4472-2V-EP Operacion Ingles PDFLeonel Losada CardozoAún no hay calificaciones

- HYSYS Simulation CourseDocumento61 páginasHYSYS Simulation CourseAbbasAún no hay calificaciones

- Consensus On OperatingDocumento10 páginasConsensus On Operatingabdulrehman2010Aún no hay calificaciones

- Scottish Power AM Case StudyDocumento50 páginasScottish Power AM Case StudyAnonymous tW1zTL2ltAún no hay calificaciones

- Global Water WL 400Documento2 páginasGlobal Water WL 400へんティ ひだやAún no hay calificaciones

- In-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol IncDocumento6 páginasIn-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol IncRuben AlvaradoAún no hay calificaciones

- 12 MGDP I 1150 0 (Instr Utility Air Calculation)Documento2 páginas12 MGDP I 1150 0 (Instr Utility Air Calculation)cytech6619Aún no hay calificaciones

- Reliable water level detection solutions for steam plantsDocumento8 páginasReliable water level detection solutions for steam plantsashwaniv_6Aún no hay calificaciones

- Hydrastep & Hydratect: Water/steam Monitoring SystemsDocumento8 páginasHydrastep & Hydratect: Water/steam Monitoring Systemsगुंजन सिन्हाAún no hay calificaciones

- Hydro StepDocumento8 páginasHydro Stepamurali1986Aún no hay calificaciones

- Levelstate EDLIDocumento11 páginasLevelstate EDLIPabitraMandalAún no hay calificaciones

- Automatic Boiler ControlDocumento16 páginasAutomatic Boiler ControlbadpplAún no hay calificaciones

- Gestra Level Control Monitoring LimitationDocumento7 páginasGestra Level Control Monitoring LimitationVoicu StaneseAún no hay calificaciones

- Hydrastep & Hydratect: Water/steam Monitoring SystemsDocumento8 páginasHydrastep & Hydratect: Water/steam Monitoring SystemsSrinivasarao YenigallaAún no hay calificaciones

- Monitor liquid levels with economical water level switchDocumento2 páginasMonitor liquid levels with economical water level switchchandan GoswamiAún no hay calificaciones

- Drexelbrook H2O Cut Analyzer 420-0017-057 PDFDocumento6 páginasDrexelbrook H2O Cut Analyzer 420-0017-057 PDFmfcramerAún no hay calificaciones

- M.tech Lab ManualDocumento94 páginasM.tech Lab ManualSHINUMMAún no hay calificaciones

- 202 Manual Hydra StepDocumento56 páginas202 Manual Hydra StepKC Samantaray100% (1)

- Electrolysis Proof Water Level Indicator Using CMOS ICDocumento3 páginasElectrolysis Proof Water Level Indicator Using CMOS ICMuhammad SalmanAún no hay calificaciones

- Test Ground Resistance QuicklyDocumento3 páginasTest Ground Resistance Quicklylord_masterAún no hay calificaciones

- Signal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsDocumento11 páginasSignal Conditioning & Process Control Equipment: A Brief Introduction To Common ApplicationsFeela NazAún no hay calificaciones

- GRI 2600K Data SheetDocumento4 páginasGRI 2600K Data SheetJMAC SupplyAún no hay calificaciones

- Flow MeterDocumento9 páginasFlow MeterShin BoAún no hay calificaciones

- DB VA V 92 Viscosity Sensor Electric For Heavy Fuel OilDocumento8 páginasDB VA V 92 Viscosity Sensor Electric For Heavy Fuel Oilsike_99100% (1)

- MAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetDocumento4 páginasMAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetSebastián Alexander Flores OroscoAún no hay calificaciones

- Two-Wire Transmitters For PH, Orp, Conductivity, Oxygen, Ozone, and ChlorineDocumento16 páginasTwo-Wire Transmitters For PH, Orp, Conductivity, Oxygen, Ozone, and ChlorineKleiber OrtegaAún no hay calificaciones

- Report - Pump Room AutomationDocumento12 páginasReport - Pump Room AutomationtanujgateAún no hay calificaciones

- Level Depth Measurement MeterDocumento9 páginasLevel Depth Measurement Metersales1068Aún no hay calificaciones

- Ti094dae Promag 10 P TiDocumento20 páginasTi094dae Promag 10 P TiLê DuyAún no hay calificaciones

- Vortex: Gas Detection Control PanelDocumento4 páginasVortex: Gas Detection Control PanelDanny YapAún no hay calificaciones

- ABB 10D1477 (Magnetic Flow Meter)Documento6 páginasABB 10D1477 (Magnetic Flow Meter)1234567890Aún no hay calificaciones

- Multistack ASP X OMDocumento16 páginasMultistack ASP X OMRudy HerreraAún no hay calificaciones

- Temperature and Humidity Sensor On An ArduinoDocumento10 páginasTemperature and Humidity Sensor On An ArduinoAlfred NeriAún no hay calificaciones

- Miniproject Water Level IndicatorDocumento19 páginasMiniproject Water Level IndicatorTathagat TripathyAún no hay calificaciones

- Electrohydraulic controls troubleshooting guideDocumento4 páginasElectrohydraulic controls troubleshooting guidechandushar1604Aún no hay calificaciones

- fxDocumento6 páginasfxJorge YanezAún no hay calificaciones

- Water Level Monitoring and ControlDocumento9 páginasWater Level Monitoring and ControlNaveed AhmedAún no hay calificaciones

- Ground Fault LocationDocumento8 páginasGround Fault Locationzbyszko201234Aún no hay calificaciones

- Sensing Applications: Pressure Sensors, Load Cells, and Force SensorsDocumento8 páginasSensing Applications: Pressure Sensors, Load Cells, and Force Sensorsjarenlou100% (1)

- Omron 61F-G Floatless Level SwitchDocumento14 páginasOmron 61F-G Floatless Level SwitchParman AjeAún no hay calificaciones

- Samson - Proportional ControllerDocumento12 páginasSamson - Proportional ControllerzamburittiAún no hay calificaciones

- Denison Hydraulics 24V, 1500ma Plug Top Driver Unit.: Publ. 9-UK-22063-B Replaces 9-UK 22063-ADocumento7 páginasDenison Hydraulics 24V, 1500ma Plug Top Driver Unit.: Publ. 9-UK-22063-B Replaces 9-UK 22063-AmecambAún no hay calificaciones

- MT LevelSensing Control-7.21 PDFDocumento12 páginasMT LevelSensing Control-7.21 PDFAndrewcaesarAún no hay calificaciones

- Automatic Weather StationDocumento8 páginasAutomatic Weather StationMyat Tun OoAún no hay calificaciones

- WaterLevelSensor Nova Lynx 280 Wl400Documento1 páginaWaterLevelSensor Nova Lynx 280 Wl400Rahmi ArslanAún no hay calificaciones

- 7SG117 Argus 7: Answers For EnergyDocumento10 páginas7SG117 Argus 7: Answers For EnergygovindarulAún no hay calificaciones

- In Touch With The Medium: Level Monitoring SensorsDocumento36 páginasIn Touch With The Medium: Level Monitoring Sensorsm_najmanAún no hay calificaciones

- ABB Instrumentation: 600T Series TransmittersDocumento10 páginasABB Instrumentation: 600T Series Transmittersalbert_ben13Aún no hay calificaciones

- 132KV 2 Line Metering PanelDocumento11 páginas132KV 2 Line Metering PanelUsman RasheedAún no hay calificaciones

- In Touch With The Medium: Level Monitoring SensorsDocumento36 páginasIn Touch With The Medium: Level Monitoring Sensorsm_najmanAún no hay calificaciones

- Bhelvision-20M: Operation and Maintenance ManualDocumento37 páginasBhelvision-20M: Operation and Maintenance ManualSAROJ100% (2)

- Earth Leakage Relay P-373-ELRDocumento2 páginasEarth Leakage Relay P-373-ELRIsmet KoracAún no hay calificaciones

- Wa0002 PDFDocumento18 páginasWa0002 PDFuppulajashwanthAún no hay calificaciones

- Ultrasonic Flow MeterDocumento2 páginasUltrasonic Flow MeterKrishnudu Nalla0% (1)

- Uc Open XP: I-Vu Building Automation SystemDocumento2 páginasUc Open XP: I-Vu Building Automation SystemClaudio MerinoAún no hay calificaciones

- Ad00879m Nuflo Scanner 2200 Efm Data SheetDocumento4 páginasAd00879m Nuflo Scanner 2200 Efm Data SheetCarlos Alberto MoviAún no hay calificaciones

- Refco Brochure Condensate Pumps GBDocumento8 páginasRefco Brochure Condensate Pumps GBnairam2003Aún no hay calificaciones

- Liquid Interface Level Measurement: Special Application SeriesDocumento8 páginasLiquid Interface Level Measurement: Special Application Seriesmaqbool1Aún no hay calificaciones

- MID Flow Sensor Brochure UKDocumento6 páginasMID Flow Sensor Brochure UKifm electronicAún no hay calificaciones

- Floatless Level Controller 61F: Operating PrincipleDocumento72 páginasFloatless Level Controller 61F: Operating PrincipleMircea MiAún no hay calificaciones

- Hydrastep and Hydratect Water/Steam Monitoring SystemsDocumento12 páginasHydrastep and Hydratect Water/Steam Monitoring Systemscytech6619Aún no hay calificaciones

- Clamp ConnectorsDocumento3 páginasClamp Connectorscytech6619Aún no hay calificaciones

- Non-Insulated Terminals & Sleeves: For Safety UseDocumento1 páginaNon-Insulated Terminals & Sleeves: For Safety Usecytech6619Aún no hay calificaciones

- A08 eDocumento3 páginasA08 ecytech6619Aún no hay calificaciones

- Hydrastep WorkingDocumento166 páginasHydrastep WorkingAyan ChattarajAún no hay calificaciones

- Flat BarsDocumento3 páginasFlat Barscytech6619Aún no hay calificaciones

- Hydrastep and Hydratect Water/Steam Monitoring SystemsDocumento12 páginasHydrastep and Hydratect Water/Steam Monitoring Systemscytech6619Aún no hay calificaciones

- Equal AnglesDocumento2 páginasEqual Anglescytech6619Aún no hay calificaciones

- Sensepoint XCD: Flammable, Toxic and Oxygen Gas Detector For Industrial ApplicationsDocumento8 páginasSensepoint XCD: Flammable, Toxic and Oxygen Gas Detector For Industrial Applicationscytech6619Aún no hay calificaciones

- 2851 - MS Electrical WorksDocumento16 páginas2851 - MS Electrical WorksleoconsolacionAún no hay calificaciones

- Deformed BarsDocumento1 páginaDeformed Barscytech6619Aún no hay calificaciones

- Channels: Tis / Jis Standards (TIS 1227: 1996 / JIS G3192: 1990)Documento2 páginasChannels: Tis / Jis Standards (TIS 1227: 1996 / JIS G3192: 1990)cytech6619Aún no hay calificaciones

- Checkered PlateDocumento1 páginaCheckered Platecytech6619Aún no hay calificaciones

- Carbon Steel PipeDocumento2 páginasCarbon Steel PipemadooAún no hay calificaciones

- 475 477Documento1 página475 477cytech6619Aún no hay calificaciones

- Checkered PlatesDocumento1 páginaCheckered PlatesRamilArtatesAún no hay calificaciones

- Dell PowerEdge 4Post and 2Post Rack Rail InstallationDocumento8 páginasDell PowerEdge 4Post and 2Post Rack Rail Installationcytech6619Aún no hay calificaciones

- Sliding Rail Kit For Dell Servers: Installation Instructions P/N: 2URAIL-R7 P/N: 2UARM-R7 (Optional)Documento4 páginasSliding Rail Kit For Dell Servers: Installation Instructions P/N: 2URAIL-R7 P/N: 2UARM-R7 (Optional)cytech6619Aún no hay calificaciones

- Dell PowerEdge 4Post and 2Post Rack Rail InstallationDocumento8 páginasDell PowerEdge 4Post and 2Post Rack Rail Installationcytech6619Aún no hay calificaciones

- Insulated Adaptors ShroudsDocumento1 páginaInsulated Adaptors Shroudscytech6619Aún no hay calificaciones

- Type 475 / 477 Stopping Plug InstructionsDocumento1 páginaType 475 / 477 Stopping Plug Instructionscytech6619Aún no hay calificaciones

- DELL PowerEdge R710 Technical GuideBookDocumento63 páginasDELL PowerEdge R710 Technical GuideBooksimon_sparks_1Aún no hay calificaciones

- Rack Guide v20Documento37 páginasRack Guide v20cytech6619Aún no hay calificaciones

- Accessories: Nylon & Red Fibre Washers Serrated WasherDocumento1 páginaAccessories: Nylon & Red Fibre Washers Serrated Washercytech6619Aún no hay calificaciones

- Earthtags LocknutsDocumento1 páginaEarthtags Locknutscytech6619Aún no hay calificaciones

- 487 489Documento1 página487 489cytech6619Aún no hay calificaciones

- Thin Wall Section of Enclosure: Earth TagDocumento1 páginaThin Wall Section of Enclosure: Earth Tagcytech6619Aún no hay calificaciones

- Oventrop 3-Way ValveDocumento4 páginasOventrop 3-Way ValvePradeep T RAún no hay calificaciones

- Boiler System Survey Sheet Complete PDFDocumento2 páginasBoiler System Survey Sheet Complete PDFMuhammad Agus TianAún no hay calificaciones

- Control Marine Boiler Fuel Oil Temperature SystemDocumento10 páginasControl Marine Boiler Fuel Oil Temperature SystemArun K DasAún no hay calificaciones

- Handheld Steam Cleaner: Owner's GuideDocumento16 páginasHandheld Steam Cleaner: Owner's GuideBen SzapiroAún no hay calificaciones

- AlstomDocumento68 páginasAlstomMauricio AguilonAún no hay calificaciones

- Data Breaker @yosepDocumento36 páginasData Breaker @yosepYosep Wildan FebrianaAún no hay calificaciones

- Steam EngineDocumento3 páginasSteam EngineDyn GalsimAún no hay calificaciones

- BFBC or StrokerDocumento6 páginasBFBC or StrokerkichasAún no hay calificaciones

- Boiler 1Documento9 páginasBoiler 1wellinspectAún no hay calificaciones

- Applied Thermodynamics: Unit-IiDocumento54 páginasApplied Thermodynamics: Unit-IiRupesh Shanmughom SAún no hay calificaciones

- Complete Survey of Boiler: Inspection, Scope, ArrangementsDocumento3 páginasComplete Survey of Boiler: Inspection, Scope, ArrangementsAayush AgrawalAún no hay calificaciones

- The Rankine Cycle: Ideal Cycle Problems To SolveDocumento12 páginasThe Rankine Cycle: Ideal Cycle Problems To Solveأحمد صلاح الدينAún no hay calificaciones

- Sarjana Site Visit Schedule-CPPDocumento13 páginasSarjana Site Visit Schedule-CPPSanjay GuptaAún no hay calificaciones

- Power Generation ProductDocumento4 páginasPower Generation ProductDAVIS VELASQUEZAún no hay calificaciones

- Lecture 14 Steam Pricing Modelling and OptimisationDocumento17 páginasLecture 14 Steam Pricing Modelling and Optimisationsajni123Aún no hay calificaciones

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Documento46 páginasPower Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014manisekAún no hay calificaciones

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaDocumento67 páginasOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILAún no hay calificaciones

- Steam TrapsDocumento5 páginasSteam TrapsAdel Suker100% (1)

- Lecture On ATRS & Speed-Load ControlDocumento44 páginasLecture On ATRS & Speed-Load Control06nikhil100% (1)

- PRO 850128 04 Technical-Information-2024 enDocumento212 páginasPRO 850128 04 Technical-Information-2024 enMFERRAún no hay calificaciones

- Power Plant Steam Generators: A Historical OverviewDocumento68 páginasPower Plant Steam Generators: A Historical OverviewShiva TejaAún no hay calificaciones

- Overhauling of Boiler Burner AssemblyDocumento4 páginasOverhauling of Boiler Burner AssemblyAayush AgrawalAún no hay calificaciones