Documentos de Académico

Documentos de Profesional

Documentos de Cultura

RA-LE008 For Sheetpiling by Excavator-Mounted Vibro Machine - Upper Changi Road

Cargado por

Wr ArTítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

RA-LE008 For Sheetpiling by Excavator-Mounted Vibro Machine - Upper Changi Road

Cargado por

Wr ArCopyright:

Formatos disponibles

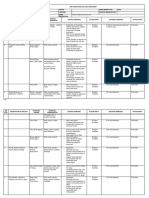

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

Page 1 to 8

Company Process

LE CONTRACTS PTE. LTD.

Sheet piling Works By Excavator-Mounted Vibro Piler Upper Changi Road

Conducted by (Names, Designations, Date, Signature) Last Review Date Revision 2

MR. NYEW MENG KEE (PROJECT CO-ORDINATOR) MR. MOHD NAEEM (WSH CO-ORDINATOR) 07 APR 2016 08 APR 2013

Next Review Date

Approved by (Name, Designation, Date, Signature)

ALAN TAY (PROJECT DIRECTOR)

RA-LE008

Acknowledged by (Name, Designation) No.

1 2 3 4 5 6 7 8 9 10 11 12

Signature Hazard Elements

Approved Date

Last Review Date

Next Review Date

Inventory Of Activities Or Task

Mobilization Of Project Team Mobilization/Demobilization Of Equipment Loading & Unloading Of Materials Shifting Of Sheet Piles Condition Of Vibro Machine Operation Of Vibro Machine Installation & Extraction Of Sheet Pile Stocking Of Materials Hot Works Machine Maintenance & Repair Works Topping Of Diesel For Excavator & Welding Machine Site Clearing

Personal Risk, Unaware Of Site Safety Rules & Regulations Traffic Hazard, Site Condition, Toppling Of Machine Faulty Equipment, Lifting Operation, Materials Striking Person, Manual Handling, Overturn Lorrycrane Sheet Pile Striking Persons & Other Machines Tripping Hazard, Electrical Hazard Lifting Operation, Sheet Pile Striking Persons, Hand Injuries Falling Objects, Damage To Utilities & Services Soil Erosion, Toppling Of Materials Fire Hazard, Explosion Falling From Height, Chemical Hazard, Electrocution Fire Hazard, Explosion Toppling Of Machine

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

1. Hazard Identification 2. Risk Evaluation 1d Possible Accident / Ill Health & Persons-at-Risk / Env. Impact 2a Existing Risk Control (If Any) Ensure all site personnel to undergo In-House Safety Induction Course. 2b S 2c L 2d RL 3a Additional Risk Control Site personnel to possess valid certification & proper PPE. Daily RA, TBM, SWP briefing before work commencement. Safety briefing & standing supervision. Daily RA, TBM, SWP briefing before work commencement. Regular maintenance of site access (by Main Contractor) & traffic signs subjected to wear and tear Daily RA, TBM, SWP briefing before work commencement. Advance scheduling or urgent recall of qualified operator for unloading. Daily RA, TBM, SWP briefing before work commencement. Regular maintenance of site access (by Main Contractor) & traffic signs subjected to wear and tear. Safety briefing to be done. Daily RA, TBM, SWP briefing before work commencement. Provide proper access with steel plates below (minimum 02 numbers) by Main Contractor. Safety briefing & standing 3. Risk Control 3b Action Officer, Designation

Page 2 to 8

4. Residual Evaluation 4a S 4b L 4c RL

1a No.

1b Work Activity

1c Hazard / Environmental Aspect Personal risk, unaware of site safety rules & regulations

1.

Mobilization Of Project Team

Entering into prohibited zone, injury to person(s)

Mo

WSH Coordinator

Mo

Toppling of machineries

Injury due to crushing of limbs and body/death to person(s)

Ensure that items are properly tightened by experienced person with sling or wire ropes. Properly prepared access (by Main Contractor) and traffic controller for public awareness & safety. Cordon off loading / unloading area.

Ma

Mr Mayandi Ganesan

Ma

Collision with site facility or properties Mobilization & Demobilization Of ExcavatorMounted Vibro Machine By Low Bed Trailer

Injury/death to person(s) and or damage to public property / site facility

Ma

Lifting Supervisor Operator

Ma

2.

Improper unloading from trailer

Injury to person(s) such as amputation, fracture, laceration cut and/or damage to public property / site facility

Qualified operator with valid certificate.

Mo

Operator

Mo

Person(s) hit by transporting machineries

Injury / death to person(s), amputation, fracture or laceration/cut

Ensure that there are no loose components attached to the machine. Properly prepared access (by Main Contractor) and traffic controller & warning signs. Apply PTW for all lifting operation. Ensure valid LM certificate and ensure proper parking & ground condition. When using mobile crane or lorry crane, the outriggers must be extended fully. Ensure that items are properly

Ma

Lifting Supervisor Operator

Ma

3.

Loading & Unloading Of Sheetpiles By Lorry Crane / Mobile Crane / Vibro Machine

Toppling Of mobile crane / lorry crane / vibro machine

Injury due to crushing of limbs and body/death to person(s) and or damaged to public property / site facility

Ma

WSH Coordinator Lifting Supervisor

Ma

Toppling of sheetpiles

Ma

Site Supervisor

Ma

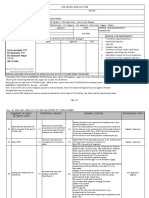

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

1. Hazard Identification 2. Risk Evaluation 1d Possible Accident / Ill Health & Persons-at-Risk / Env. Impact Injury due to crushing of limbs and body/death to person(s) and or damaged to public property / site facility 2a Existing Risk Control (If Any) tightened by experienced person with sling or wire ropes. Cordon off loading / unloading area. Ensure that items are properly tightened by experienced person with sling or wire ropes. Cordon off loading / unloading area. To provide banksman and to comply with site speed limit at all times. 2b S 2c L 2d RL 3a Additional Risk Control supervision. Daily RA, TBM, SWP briefing before work commencement. Regular maintenance of site access (by Main Contractor) & traffic signs that may be subjected to wear and tear. Daily RA, TBM, SWP briefing before work commencement. Advance scheduling or urgent recall of qualified rigger for unloading. Daily RA, TBM, SWP briefing before work commencement. Advance scheduling or urgent recall of qualified rigger for unloading. Daily RA, TBM, SWP briefing before work commencement. Regular maintenance of site access (by Main Contractor) & traffic signs subjected to wear and tear. Safety briefing to be conducted. Daily RA, TBM, SWP briefing before work commencement. Ensure that the sheet-piles are stacked properly & neatly before dragging to nearby designated location. Provide banks-man to ensure sufficient safety clearance from other machines working nearby. Daily RA, TBM, SWP 3. Risk Control 3b Action Officer, Designation Operator Rigger / Signalman 1c Hazard / Environmental Aspect 4a S

Page 3 to 8

4. Residual Evaluation 4b L 4c RL

1a No.

1b Work Activity

Collision with site facility or property

Damage to public property / site facility

Ma

WSH Coordinator Lifting Supervisor

Ma

Improper rigging

Injury to person(s) such as amputation, fracture, laceration, cut and or damage to site facility

Qualified rigger with valid certificate.

Mo

Lifting Supervisor

Mo

Failure of lifting gear

Fatality or injury to person(s) amputation, fracture, laceration cut and or damage to site facility

LG with valid certificate Rigger / signalman to conduct daily visual checks. No standby under suspended load.

Mo

Lifting Supervisor

Mo

Person(s) hit by sheetpiles

Permanent disability, injury / death to person(s) with amputation or fracture

Ensure that items are properly tightened by experienced person with sling or wire ropes. Properly prepared access (by Main Contractor) and traffic controller & warning signs.

Ma

WSH Coordinator Lifting Supervisor

Ma

4.

Shifting Of Sheetpiles

Slippage of sheetpiles

Permanent disability & injury to person(s) and collision with other machines

Ensure that items are properly tightened by experienced person with sling or wire ropes. Cordon off the working area.

Ma

WSH Coordinator Operator Rigger / Banks-man

Ma

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

1. Hazard Identification 2. Risk Evaluation 1d Possible Accident / Ill Health & Persons-at-Risk / Env. Impact 2a Existing Risk Control (If Any) 2b S 2c L 2d RL 3a Additional Risk Control briefing before work commencement. 3. Risk Control 3b Action Officer, Designation 1c Hazard / Environmental Aspect 4a S

Page 4 to 8

4. Residual Evaluation 4b L 4c RL

1a No.

1b Work Activity

5.

Vibro Machine Condition

Using equipment in poor condition leading to structural failure

Injury due to crushing of limbs and body/death to person(s) and or damage to public property / site facility

Provide inspection and certification of machine by Authorised Examiner.

Ma

Regular maintenance of site access (by Main Contractor) & traffic signs subjected to wear and tear. Safety briefing to be conducted. Daily RA, TBM, SWP briefing before work commencement. Ensure machine is turned off & cabin locked upon resting or work completion for the day. Daily RA, TBM, SWP briefing before work commencement.

WSH Coordinator Lifting Supervisor Operator Rigger

Ma

Operating of vibro machine by uncertified personnel 6. Vibro Machine Operation Collapse of excavator or structure damage by vibro machine due to mechanical failure

Injury due to crushing of limbs and body/death to person(s) and or damaged to public property / site facility

Ensure that vibro is operated by experienced person and must be a Singapore Power Grid certified operator by appointment. Properly prepared access (by Main Contractor) and traffic controller & warning signs. Wear proper PPE. Ensure all items are fixed securely to sheet piles / loads by sling wire shackle and proper lifting gears. Keep clear of raised loads & avoid moving under or near rotating / swinging of crane and suspended loads. Ensure that only qualified riggers are allowed to handle the load. Cordon off the working area. Ensure sheet pile is clamped between the jaws tightly prior to hoisting up vertically for installation.

Ma

WSH Coordinator Lifting Supervisor Operator Rigger

Ma

7.

Installation & Extraction Of Sheet Piles (Refer to Method of Statement)

Falling items from suspended sheet piles / materials

Injury to person(s) such as amputation, fracture, laceration cut and/or damage to public property/site facility Injury to person(s) such as amputation, fracture, laceration cut and crushing of limbs/body Injury due to crushing of limbs and body/death and damage to public property / site facility

Ma

Daily RA, TBM, SWP briefing before work commencement.

WSH Coordinator Lifting Supervisor Operator Rigger / Signal Man WSH Coordinator Lifting Supervisor Operator Rigger / Signal Man WSH Coordinator Lifting Supervisor Operator Rigger / Signal Man

Ma

Limbs caught in machinery and under loads Persons hit by falling / dislodged sheet piles

Ma

Daily RA, TBM, SWP briefing before work commencement. Safety briefing to be done. Daily RA, TBM, SWP briefing before work commencement.

Ma

Ma

Ma

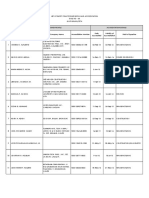

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

1. Hazard Identification 2. Risk Evaluation 1d Possible Accident / Ill Health & Persons-at-Risk / Env. Impact 2a Existing Risk Control (If Any) Ensure the protected trees under conservation are made known to site team (where applicable). Ensure the protected trees are clearly demarcated & protected. Ensure the protected trees are pruned or pollard where necessary in order that the branches are not in the hoisting alignment of the sheet-piles. Ensure there are 02 numbers of steel plates below the vibro excavator (by Main Contractor). Do not park the vibro excavator near the slope of the excavated trench. Place materials at least 600mm away from edge of excavation or slope. Place materials on firm & levelled ground. Refrain from stacking material too high above ground. Place sheet piles on firm & levelled ground and slightly tilted to prevent ponding after raining. Ensure daily clearing of any ponding water. 2b S 2c L 2d RL 3a Additional Risk Control Ensure sufficient clearance to conservation trees & existing hoarding as much as site conditions permit (where applicable). Daily RA, TBM, SWP briefing before work commencement. Ensure ground below the steel plates is firm & properly levelled. Daily RA, TBM, SWP briefing before work commencement. 3. Risk Control 3b Action Officer, Designation 1c Hazard / Environmental Aspect 4a S

Page 5 to 8

4. Residual Evaluation 4b L 4c RL

1a No.

1b Work Activity

Vibro excavator hitting conservation trees or hoarding (where applicable)

Head Injury to person(s) and or damage to trees or hoarding

Mo

WSH Coordinator Lifting Supervisor

Mo

Toppling of vibro excavator

Injury due to crushing of limbs and body/death or damage to public property / site facility

Ma

WSH Coordinator Lifting Supervisor

Ma

Soil erosion

Buried alive, permanent disability, injury due to crushing of soil and asphyxiation Death/crushing injury to person(s) and or damage to public property/site facility

Ma

Safety briefing to be done. Daily RA, TBM, SWP briefing before work commencement.

Lifting Supervisor

Ma

8.

Stockpiling Of Materials

Toppling of material

Water stagnation

Possibility of mosquito breeding

Mo

Daily RA, TBM, SWP briefing before work commencement. Additional briefing on the awareness of water ponding possibility.

Lifting Supervisor WSH Coordinator

Mo

Acetylene cylinders kept 6 meters apart or separated with a non-combustible barrier at least 1.5m having a fire resistance rating of at least 0.5 hour

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

1. Hazard Identification 2. Risk Evaluation 1d Possible Accident / Ill Health & Persons-at-Risk / Env. Impact 2a Existing Risk Control (If Any) PTW must be applied & approved before commencement of hot works. Cordon off the hot works area. Provide fire watchman & standby fire extinguisher & fire blanket. Install flashback arrestor & nonreturn valve. Provide soap water for leakage test and tighten the hose connection with double hose clips. Gas cylinders shall be stored upright in a proper steel cage. Trained Welder Welding machine Cable in sound condition and avoid submerging in water 2b S 2c L 2d RL 3a Additional Risk Control 3. Risk Control 3b Action Officer, Designation 1c Hazard / Environmental Aspect 4a S

Page 6 to 8

4. Residual Evaluation 4b L 4c RL

1a No.

1b Work Activity

9.

Hot Works By Welding & Flame Cutting (Where Necessary)

Fire, explosion & electrocution

Death, effect of electricity, physical shock, chemical burns to person(s) and or damage to public property / site facility

Ma

Welder must have valid welding certificate. Remove any surrounding combustible or flammable materials. Ensure adequate warning signboards placed conspicuously at strategic locations. Daily RA, TBM, SWP briefing before work commencement.

WSH Coordinator Welder

Ma

Hand or limb injuries Maintenance & Repair To Vibro Machine & Welding Machine

Crushing or pinching injuries to person(s)

10.

Qualified & trained mechanic to carry out maintenance & repair works. All hand tools to be properly consolidated at all times. Ensure proper housekeeping before work, during work & end of day work. Ensure appropriate PPE. Ensure appointment of trained mechanic.

Mo

Falling from height Oil or hydraulic fluids leakage onto existing ground

Death, permanent disability, fracture injury to person(s) Slip and fall injury, contamination to ground and fracture injury

Carry out maintenance works on the machine at 2.0m & below. Ensure monthly maintenance of machine. Qualified & trained mechanic to carry out maintenance & repair

Mo

Maintenance checklist to be submitted. Machine must be properly shut down & isolated to prevent accidental movement or operation. Mechanic must be escorted by the Safety Supervisor from the Main Entrance to the actual site location. Safety Supervisor to inform the Main Contractor Safety Department. Daily RA, TBM, SWP briefing before work commencement. Provide safety harness for maintenance mechanic where necessary. Standby saw dust to soak up any leakage & properly disposed offsite.

WSH Coordinator Mechanic

Mo

WSH Coordinator WSH Coordinator Mechanic

Mo

Mo

Mo

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

1. Hazard Identification 2. Risk Evaluation 1d Possible Accident / Ill Health & Persons-at-Risk / Env. Impact 2a Existing Risk Control (If Any) works. Provide proper drip trays or containers. Electrocution Death, permanent disability Ensure trained and appointed personnel Ensure appropriate PPE & handling methods. Provide & brief on MSDS for awareness. Mo O M Provide earth rod & LEW checks for the welding machine. Safety briefing by WSH Coordinator. Diesel supplier must be escorted & guided from the Main Entrance to the actual topping up location. Lifting Supervisor to inform the Main Contractor Safety Department accordingly. Safety briefing by WSH Coordinator. Temporary stop all activities nearby that may cause any ignition or sparks. Fire Extinguisher Ensure final inspection of machine prior to demobilization. Daily RA, TBM, SWP briefing before work commencement. Lighting protection installation on site, check and close supervision to ensure compliance. Supervisor to ensure workers drink plenty of water during hot weather. Check and ensure new workers and those returning from colder climates acclimatized to work in the hot environment. WSH Coordinator Mo 2b S 2c L 2d RL 3a Additional Risk Control 3. Risk Control 3b Action Officer, Designation 1c Hazard / Environmental Aspect 4a S

Page 7 to 8

4. Residual Evaluation 4b L 4c RL

1a No.

1b Work Activity

Skin contact

Skin irritation to person(s)

Mo

WSH Coordinator

Mo

11.

Topping Of Diesel For Excavator

Diesel leakage onto existing ground

Slip and fall injury, contamination to ground and fracture injury

Ensure proper handling method by diesel supplier.

Mo

WSH Coordinator Diesel Supplier

Mo

Fire or explosion

Burnt injury to person(s) and or damage to public property / site facility

Ensure engine or machine is turned off before topping up of diesel. Ensure no oil spilt onto hot engine Cordon off the working area. Conduct TBM to instruct workers not to enter the working radius. Ensure daily visual check of lifting gears before commencement of work and adhere to the monthly colour code of lifting gears (where applicable) & lifting plan. In the event of heavy downpour or lightning, all works must be stopped immediately and take shelter. All workers must be accounted for. Provision of water drinking point. Regularly remind workers to drink plenty of water during hot weather especially from noon to 4 pm in the morning mass safety talk. Poster put up at the canteen to educate workers. Worker not feeling well must inform

Ma

WSH Coordinator Diesel Supplier

Ma

12.

Site Clearing

Toppling of machineries failure of lifting machine / gear, equipment

Death, permanent disability and crushing injury to person(s) and or damage to public property/site facility

Ma

Lifting Supervisor

Ma

13

Sheet Piling Work by Vibro Machine

Adverse weather, Struck by lightning

Electrocution, burnt & fatality

Ma

Site Supervisor

Ma

14

Sheet Piling Works by Vibro Machone

Heat stroke or heat injuries

Fatigue, permanent disability, disorientation or fatality

Ma

Site Supervisor

Ma

S/N: RA-LE008

Risk Assessment Form For Sheetpiling Work By Excavator-Mounted Vibro Machine

1. Hazard Identification 2. Risk Evaluation 1d Possible Accident / Ill Health & Persons-at-Risk / Env. Impact 2a Existing Risk Control (If Any) their supervisors immediately. Rotation of worker Ensure to maintain a maximum of 22 meter safe distance between machinery during operation. Cordon off loading/unloading or installation area. Ensure monthly maintenance service to all machinery. Ensure engine is not overheating. Machine equipped with fire extinguisher Ensure workers put on ear plug or ear muff. Close up noise control closures when machines are in use. To stop work at 7pm 2b S 2c L 2d RL 3a Additional Risk Control Introduce job rotation to alternate between exterior and interior works. Ensure adequate warning signboards placed conspicuously at strategic locations. Daily RA, TBM, SWP briefing before work commencement. Daily RA, TBM, SWP briefing before work commencement. Ensure adequate warning signboards Daily RA, TBM, SWP briefing before work commencement. Annual audiometric medical examination for all workers involved noisy environment 3. Risk Control 3b Action Officer, Designation 1c Hazard / Environmental Aspect 4a S

Page 8 to 8

4. Residual Evaluation 4b L 4c RL

1a No.

1b Work Activity

15

Safe Distance Between Vibro Machinery

Collision between each vibro machinery during operation

Crushing injury/death to person(s) and or damaged to public property / site facility

Ma

WSH Supervisor

Ma

16

Vibro Machinery Overheating

Engine caught fire, Excessive emission

Environmental pollution, inhalation causing breathing difficulties

Mo

WSH Supervisor

Mo

17

Vibro Machinery Installation & Extraction

Noise exposure level exceeding 85dB(A)-100 dB(A)

Excessive noise induced deafness, permanent hearing lose or temporary hearing loss Public nuisance

Mo

WSH Supervisor

Mo

También podría gustarte

- DemolitionDocumento2 páginasDemolitionGanga Daran100% (1)

- HSF-PR-0063 Work at HeightDocumento32 páginasHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- Concrete Pouring JSaDocumento12 páginasConcrete Pouring JSaTheo Vidallon BautistaAún no hay calificaciones

- JSA Electrical WiringDocumento10 páginasJSA Electrical WiringWeru Morris100% (1)

- 05 LiftingDocumento6 páginas05 LiftingabdulhalimbinamrinAún no hay calificaciones

- Mobilization of CabinDocumento1 páginaMobilization of CabinRashidi RahmanAún no hay calificaciones

- JSA NO 2-Piling WorkDocumento3 páginasJSA NO 2-Piling WorkKarthik GanesanAún no hay calificaciones

- Rapid P20ai Jsa Box CulvertDocumento8 páginasRapid P20ai Jsa Box Culvertfadli.lpgAún no hay calificaciones

- 1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002Documento3 páginas1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002nurul sarahAún no hay calificaciones

- JsaDocumento7 páginasJsaAnees TAún no hay calificaciones

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Documento18 páginasSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- 002 JHA On ConcretingDocumento10 páginas002 JHA On ConcretingBhupinder khindaAún no hay calificaciones

- Jha For Cfa PilingDocumento10 páginasJha For Cfa PilingFaremi Oluwaseun BabatundeAún no hay calificaciones

- TRA 13 Loading or Unloading Chems With ForkliftDocumento2 páginasTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Documento9 páginasSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- RS Concrete Pumping Risk AssessmentDocumento8 páginasRS Concrete Pumping Risk AssessmentLito PanchoAún no hay calificaciones

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocumento4 páginasDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustAún no hay calificaciones

- Doku - Pub Risk-AssessmentDocumento10 páginasDoku - Pub Risk-AssessmentUlviyye ElesgerovaAún no hay calificaciones

- Hse JsaDocumento22 páginasHse JsaAnonymous y1pIqcAún no hay calificaciones

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocumento5 páginasJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyAún no hay calificaciones

- 31.HIRA - Boom Placer OperationDocumento3 páginas31.HIRA - Boom Placer OperationMMRDACA07 SAFETYAún no hay calificaciones

- JHA For Pipe Work-01.09Documento3 páginasJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocumento2 páginasLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanAún no hay calificaciones

- Job Safety Analysis - Cone ErectionDocumento7 páginasJob Safety Analysis - Cone ErectionMohammed MinhajAún no hay calificaciones

- Hirarc ExcavationDocumento6 páginasHirarc ExcavationKalai Arasan100% (1)

- Safety Method StatementDocumento14 páginasSafety Method StatementnayakyaAún no hay calificaciones

- JSA Format Erection of Column 903-C-02,03Documento5 páginasJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Documento3 páginasRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichAún no hay calificaciones

- Job Safety Assessment (Jsa)Documento19 páginasJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- Risk Assessment Determining Control: Prosedur Hazard Identification, (Hiradc)Documento4 páginasRisk Assessment Determining Control: Prosedur Hazard Identification, (Hiradc)Muhammad Naim Abd Wahab100% (1)

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Documento4 páginasJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSAún no hay calificaciones

- JSA-Hydraulic Press Testing For PilesDocumento6 páginasJSA-Hydraulic Press Testing For PilesUMUTAún no hay calificaciones

- Job Safety Analysis - Clinker StorageDocumento4 páginasJob Safety Analysis - Clinker StorageMohammed MinhajAún no hay calificaciones

- Risk Assessment Removal of Walers & StrutsDocumento6 páginasRisk Assessment Removal of Walers & StrutsBhargav BbvsAún no hay calificaciones

- Maeda-Onaka, Joint Venture: Generic Lifting PlanDocumento4 páginasMaeda-Onaka, Joint Venture: Generic Lifting PlanJaycee Pagador100% (2)

- Proposed Damansara Shah Alam Elevated Expressway (Dash)Documento8 páginasProposed Damansara Shah Alam Elevated Expressway (Dash)Nurulhidayah Abdul JalilAún no hay calificaciones

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Documento2 páginasComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsAún no hay calificaciones

- Lifting OperationDocumento8 páginasLifting OperationFILE 1131Aún no hay calificaciones

- JSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesDocumento10 páginasJSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesNazreen AzriAún no hay calificaciones

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Documento2 páginasRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- OSHA Training and Reference Materials Library - PPE AssessmentDocumento10 páginasOSHA Training and Reference Materials Library - PPE AssessmentOluwafemi Samuel AdesanmiAún no hay calificaciones

- Risk Assessment PDFDocumento4 páginasRisk Assessment PDFAnonymous iI88LtAún no hay calificaciones

- List of Safety Practitioners - 2014Documento26 páginasList of Safety Practitioners - 2014JackophiliAún no hay calificaciones

- ENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous AreaDocumento4 páginasENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous Areamyn maliQue0% (1)

- HIRA No. 02-Use of Access Scaffolding SBDDocumento2 páginasHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- 37 HSE Lesson Learnt 29 - Eye InjuryDocumento1 página37 HSE Lesson Learnt 29 - Eye InjuryKyaw MinAún no hay calificaciones

- 2640.011SWP - Excavations and TrenchesDocumento7 páginas2640.011SWP - Excavations and TrenchesHasanuddin HAMIDAún no hay calificaciones

- Hirarc Piling Work PDF FreeDocumento4 páginasHirarc Piling Work PDF Freewan lahAún no hay calificaciones

- Mobilization and Installation of CHW PipesDocumento8 páginasMobilization and Installation of CHW PipesYounis KhanAún no hay calificaciones

- Piling Rig Plant Pre-Acceptance ChecklisDocumento3 páginasPiling Rig Plant Pre-Acceptance Checklisosama F. MohamedAún no hay calificaciones

- Excavation (Company Name) : Phase Hazard AnalysisDocumento11 páginasExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieAún no hay calificaciones

- Power Distribution Works: Job Safety AnalysisDocumento30 páginasPower Distribution Works: Job Safety AnalysisRekha LinusAún no hay calificaciones

- RISK ASSESSMENT - Tower Crane DraftDocumento12 páginasRISK ASSESSMENT - Tower Crane Draftloveson70933% (3)

- HIRA-Metalic Pipe ErectionDocumento13 páginasHIRA-Metalic Pipe ErectionShams Tabrez100% (2)

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Documento4 páginas09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- Tower Crane Dismantling JSA HSE ProfessionalsDocumento2 páginasTower Crane Dismantling JSA HSE ProfessionalsnabeelAún no hay calificaciones

- GroutingDocumento1 páginaGroutingraphael damanikAún no hay calificaciones

- TPB 100 Method of StatementDocumento6 páginasTPB 100 Method of Statement5483370Aún no hay calificaciones

- Safe Work Method StatementDocumento15 páginasSafe Work Method StatementSampath AhAún no hay calificaciones

- Risk Assessment - Construction of DWFI, Sewerage System and Deepening of Kai Tak River BedDocumento8 páginasRisk Assessment - Construction of DWFI, Sewerage System and Deepening of Kai Tak River Bed逍逾Aún no hay calificaciones

- Welcome: Ahsanullah University of Science & TechnologyDocumento69 páginasWelcome: Ahsanullah University of Science & TechnologyWr ArAún no hay calificaciones

- ACEE List of Abstracts May 11 2016Documento11 páginasACEE List of Abstracts May 11 2016Wr ArAún no hay calificaciones

- 6 July 2015 Sunlove Building ProjectDocumento42 páginas6 July 2015 Sunlove Building ProjectWr ArAún no hay calificaciones

- CAFEO 33 Invitation To Delegates. - 1Documento1 páginaCAFEO 33 Invitation To Delegates. - 1Wr ArAún no hay calificaciones

- Appendix 5C - Non Conformance Report1Documento2 páginasAppendix 5C - Non Conformance Report1Wr ArAún no hay calificaciones

- IR Asphalt PremixDocumento2 páginasIR Asphalt PremixWr ArAún no hay calificaciones

- Photos#2 at Zone 1 z2 z3Documento24 páginasPhotos#2 at Zone 1 z2 z3Wr ArAún no hay calificaciones

- 1 July 2015 Sunlove Building Project PatternDocumento42 páginas1 July 2015 Sunlove Building Project PatternWr ArAún no hay calificaciones

- Drainworks ProgressDocumento2 páginasDrainworks ProgressWr ArAún no hay calificaciones

- Carpet Combing June 2013Documento3 páginasCarpet Combing June 2013Wr ArAún no hay calificaciones

- Rto Application Edwin FerrerDocumento4 páginasRto Application Edwin FerrerWr ArAún no hay calificaciones

- @MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneDocumento1 página@MCO2 50 Linear Meters of Sheet Piles & Waler - Strutting Had Been Installed FOR 1500MM Wide Drain-6.21% DoneWr ArAún no hay calificaciones

- DAFLOU BATIS VpCI - 2Documento6 páginasDAFLOU BATIS VpCI - 2Wr ArAún no hay calificaciones

- BCM Anna University NotesDocumento112 páginasBCM Anna University NotesaruchellamAún no hay calificaciones

- CEEN 3304 T4 One-Way Slab PDFDocumento12 páginasCEEN 3304 T4 One-Way Slab PDFWr ArAún no hay calificaciones

- General ConditonDocumento45 páginasGeneral ConditonKiran PoudelAún no hay calificaciones

- Rebar Arrangement in SlabDocumento12 páginasRebar Arrangement in Slableovorig100% (2)

- Steps For RCC Design 10.01.08Documento12 páginasSteps For RCC Design 10.01.08Prisco AtabongAún no hay calificaciones

- CEEN 3304 T4 One-Way Slab PDFDocumento12 páginasCEEN 3304 T4 One-Way Slab PDFWr ArAún no hay calificaciones

- IR For RCC WorksDocumento2 páginasIR For RCC WorksWr ArAún no hay calificaciones

- Calculations of Unit Weight of Rebar PDFDocumento1 páginaCalculations of Unit Weight of Rebar PDFWr ArAún no hay calificaciones

- Calculations of Unit Weight of Rebar PDFDocumento1 páginaCalculations of Unit Weight of Rebar PDFWr ArAún no hay calificaciones

- GeneralTechnicalInformation RebarSplicingDocumento7 páginasGeneralTechnicalInformation RebarSplicingSarakikenpachiAún no hay calificaciones

- SanDiego ASCE 2005Documento10 páginasSanDiego ASCE 2005Wr ArAún no hay calificaciones

- Seismic Rebar DetailingDocumento11 páginasSeismic Rebar DetailingWr ArAún no hay calificaciones

- ER288 WP MembraneDocumento1 páginaER288 WP MembraneWr ArAún no hay calificaciones

- Structural Design of Multi-Story Residential BuildingDocumento9 páginasStructural Design of Multi-Story Residential Buildingatac101Aún no hay calificaciones

- Beam Rebar ArrangementDocumento10 páginasBeam Rebar Arrangementme_decent28457100% (2)

- ER288 WP MembraneDocumento1 páginaER288 WP MembraneWr ArAún no hay calificaciones

- Permit To Work On Public StreetsDocumento27 páginasPermit To Work On Public StreetsWr ArAún no hay calificaciones

- LT89Documento116 páginasLT89Alejandro BustosAún no hay calificaciones

- Cics and XML: Geoff SharmanDocumento28 páginasCics and XML: Geoff SharmangatrivedAún no hay calificaciones

- Wiring and Grounding For Pulse Width Modulated (PWM) AC Drives - Allen-Bradley - PowerFlexDocumento170 páginasWiring and Grounding For Pulse Width Modulated (PWM) AC Drives - Allen-Bradley - PowerFlexNixiusAún no hay calificaciones

- Srs For Hotel Management SystemDocumento11 páginasSrs For Hotel Management SystemANSUL KOTADIAAún no hay calificaciones

- Cache Replacement Policies Revisited: The Case of P2P TrafficDocumento8 páginasCache Replacement Policies Revisited: The Case of P2P TrafficAniket KumarAún no hay calificaciones

- DCT-Switch LAB Exam SheetDocumento10 páginasDCT-Switch LAB Exam SheetSagarAún no hay calificaciones

- Subnet SupernetingDocumento9 páginasSubnet SupernetingSam PashaAún no hay calificaciones

- Assignment On PROBABILITYDocumento2 páginasAssignment On PROBABILITYSushobhit ChoudharyAún no hay calificaciones

- 14.H Out of Specification ResultsDocumento10 páginas14.H Out of Specification Resultsعبدالعزيز بدرAún no hay calificaciones

- Jis G 3106 PDFDocumento38 páginasJis G 3106 PDFTùng Lê Đinh50% (2)

- Plastics Piping Systems For Non-Pressure Underground Drainage and Sewerage Polyethylene (PE)Documento38 páginasPlastics Piping Systems For Non-Pressure Underground Drainage and Sewerage Polyethylene (PE)MohamedHanyAún no hay calificaciones

- CSharp For Sharp Kids - Part 1 Getting StartedDocumento10 páginasCSharp For Sharp Kids - Part 1 Getting StartedBrothyam Huaman CasafrancaAún no hay calificaciones

- 2001 Hermetic Check Operating InstructionsDocumento6 páginas2001 Hermetic Check Operating InstructionsAndres CarmonaAún no hay calificaciones

- Pueblo Revival Transitional Housing: Tucson ArizonaDocumento51 páginasPueblo Revival Transitional Housing: Tucson ArizonaJermaine FoxxAún no hay calificaciones

- (Company Name) : Interpersonal/Organizational Skills AssessmentDocumento2 páginas(Company Name) : Interpersonal/Organizational Skills AssessmentZaffir Zainal AbidinAún no hay calificaciones

- Power Tech India: D-6 Kavi Nagar Industrial Area Ghaziabad, MDocumento13 páginasPower Tech India: D-6 Kavi Nagar Industrial Area Ghaziabad, MHari HaranAún no hay calificaciones

- Hydran M2Documento2 páginasHydran M2Al De LeonAún no hay calificaciones

- Baupunkt 32-133iDocumento2 páginasBaupunkt 32-133itravel for photoAún no hay calificaciones

- ISTQB CTFL 2018v3.1 Sample Exam B Answers v1.4Documento32 páginasISTQB CTFL 2018v3.1 Sample Exam B Answers v1.4Kseniia HavrylenkoAún no hay calificaciones

- Brakes PDFDocumento61 páginasBrakes PDFZein ElserfyAún no hay calificaciones

- 835ht2 SpecDocumento5 páginas835ht2 SpecSuku Cadang AlatberatAún no hay calificaciones

- Iec 60404 7 2019Documento12 páginasIec 60404 7 2019amh.fpdAún no hay calificaciones

- Data Teknis Dan Penomoran IP Address Jaringan HotspotDocumento6 páginasData Teknis Dan Penomoran IP Address Jaringan HotspotEgit WidiyantoAún no hay calificaciones

- BS en Iso 4287-98 A1-09Documento36 páginasBS en Iso 4287-98 A1-09fernando salvatierra100% (2)

- RexrothDocumento132 páginasRexrothmotasem alqaisiAún no hay calificaciones

- National Step Tablet Vs Step Wedge Comparision FilmDocumento4 páginasNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarAún no hay calificaciones

- Jetstream Europe Brochure EnglishDocumento6 páginasJetstream Europe Brochure EnglishFernando ZamoraAún no hay calificaciones

- Trane Manual XL900Documento52 páginasTrane Manual XL900V100% (2)

- Islplesson 1Documento2 páginasIslplesson 1api-279509605Aún no hay calificaciones

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDe EverandArizona, Utah & New Mexico: A Guide to the State & National ParksCalificación: 4 de 5 estrellas4/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDe EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptCalificación: 5 de 5 estrellas5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDe EverandNew York & New Jersey: A Guide to the State & National ParksAún no hay calificaciones

- The Bahamas a Taste of the Islands ExcerptDe EverandThe Bahamas a Taste of the Islands ExcerptCalificación: 4 de 5 estrellas4/5 (1)

- Best Dives of the Western HemisphereDe EverandBest Dives of the Western HemisphereCalificación: 4 de 5 estrellas4/5 (2)

- Best Dives West Hemisphere ExcerptDe EverandBest Dives West Hemisphere ExcerptCalificación: 4.5 de 5 estrellas4.5/5 (3)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDe EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensAún no hay calificaciones

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDe EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoCalificación: 5 de 5 estrellas5/5 (1)