Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Ib 10

Cargado por

dchz_62Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Ib 10

Cargado por

dchz_62Copyright:

Formatos disponibles

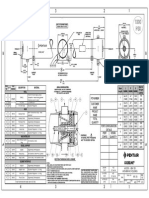

IB-10-C

Installation and Maintenance

For Y-Type Strainers

A strainer is a device which provides a means of mechanically removing solids from a flowing fluid or gas in a pipeline by utilizing a perforated or mesh straining element. Inlet To ensure against untimely shutdown of equipment, strainers should be installed ahead of pumps, loading valves, control valves, meters, steam traps, turbines, compressors, solenoid valves, nozzles, pressure regulators, burners, unit heaters and other sensitive equipment.

Strainer Screen

Outlet Retainer Gasket Screen Retainer

INSTALLATION

Clean all threaded areas of pipe thoroughly before installing strainer. Use pipe dope or teflon tape sparingly. Leave the end thread exposed to avoid introducing the sealant into the piping system. The strainer can be installed in the horizontal or vertical down position.

CAUTION: When installing socket weld strainers 1-1/4" size and larger, and all D-Series strainers, be

aware the strainer has a non-metal gasket that can be damaged by excessive heat. Try to minimize welding time, and cool the strainer after welding. If pre- and post-weld heating is needed (as for the D-Series), removing the gasket may be advisable.

OPERATION AND MAINTENANCE

After the initial operation of the system, the strainer should be blown down to remove any installation debris caught in the screen. Repeat the blowdown procedure on a regular schedule thereafter. Frequency of blowdown depends on the operating conditions to which the strainer is subjected. If no blowdown valve is to be used, the strainer can be cleaned by removing the screen retainer and screen. CAUTION:ALWAYS ISOLATE THE STRAINER FROM THE PRESSURIZED SYSTEM BEFORE OPENING TO CLEAN. USE A NEW GASKET WHEN REASSEMBLING THE STRAINER. The strainer screen should be inspected one to two times per year. Recommended spare parts are one screen and three gaskets per strainer.

ORDERING REPLACEMENT PARTS

To order replacement strainer screens, state connection size of strainer, screen material and type of perforation or mesh. See screen specification chart. When ordering replacement screens for flanged strainers, state flange rating. To order replacement strainer gaskets or retainers, state type of connection (screwed, socket weld, butt weld, or flanged), connection size and body material of strainer. Contact your Armstrong Representative if further assistance is required.

Threaded Connection For Blowdown Valve

How To Order Armstrong Strainer Replacement Screens and Gaskets

To order, specify strainer size, full details on connections and screen specifications required, or use the ordering code provided.

Available Strainer Screen Materials

Screen Specification 1/64" 1/32" .045" (3/64) Perforated 1/16" 1/8" 3/16" 1/4" 20 x 20 24 x 110 30 x 30 Mesh 40 x 40 100 x 100 200 x 200 150 x 150 Particle Retention (in) 0.016 0.031 0.045 0.062 0.125 0.188 0.25 0.034 0.0056 0.020 0.015 0.0055 0.0029 0.0041 Back-Up Screen Required 3" - 10" None None None None None None *6" - 10" 5" - 10" None 1-1/2" - 10" All Sizes All Sizes All Sizes Materials 304 SS Code 10 Code 11 Code 1 Code 12 Code 8 Code 13 Code 14 Code 15 Code 41 (1) Code 16 Code 9 Code 17 Code 40 Monel Code 18 Code 19 Code 3 Code 20 Code 21 Code 22 Code 23 Code **5 Code 24 Code 6 Code 25 Brass Code 4 Code 28 316 SS Code 31 Code 7 Code 32 Code 33 Code 34 Code 35 Code 2 Code 37 Code 38 Code 39

* Except 6" 125 lb. cast iron. ** On Code 5 2-1/2" thru 10" require back-up screens Shading indicates available screens for CA Series Strainers. (1) 30 x 30 304 SS mesh screens only available for CA series strainers

Replacement Gaskets Standard Replacement Gaskets for Strainers

Strainer Size (in) Cast Iron "A" Part No. A4469 A4469 A4470 A4471 A6256 A6267B A6263 Carbon Steel Chrome T-316 Moly Bronze Stainless Steel Steel Forged Steel "D" Part No. A6254 A6254 A6254 A6259 A6259 A6259

Strainer Size (in) 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

Strainer Repairs For CA Cast Iron Strainers Only

Blowdown Plug Part No. A6002A A6003A A6003A A6003A A6003A A6003A Size (in) 3/8" 1/2" 1/2" 1/2" 1/2" 1/2" Retainer Gasket Part No. A19251 A19251 A19252 A6256 A19253 A19254

"B" "C" "F" "E" Part No. Part No. Part No. Part No. A4469 A4470 A4471 A6257A A6262 A6264 A4469 A4470 A4471 A6252A A6253A A6255A A4469A A4470A A4471A A6257A A6262 A6264 A21274-1 A21340-1 A22106-1

3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 4" 5" 6" 8" 10"

A6258A A6256A A6258A A6267A A6265A A6263A

A21274-1 A21274-1 A21340-1 A21340-1 A22106-1 A22106-1 A21343-1 A21343-1 A22049-1 A22049-1 A21427-1 A21427-1 A21432-1

K1SC, K1SW, N1SC and N1SW Replacement Screen Assemblies

" " 1" .045 Perf. 304 Stainless Steel Screen Assy .045 Perf. 304 Stainless Steel Screen Assy .045 Perf. 304 Stainless Steel Screen Assy C1823-2 C1823-4 C1823-5

IB-10-C

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 8/03 Printed in U.S.A.

También podría gustarte

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Documento3 páginasDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiAún no hay calificaciones

- Drawing 80H30Documento3 páginasDrawing 80H30kpranjal15Aún no hay calificaciones

- Codeline, 150 PSI, Drawing - 80S15Documento3 páginasCodeline, 150 PSI, Drawing - 80S15RamanNegiAún no hay calificaciones

- Sure Flow StrainersDocumento13 páginasSure Flow StrainersNinad SherawalaAún no hay calificaciones

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocumento3 páginas(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Steam TrapDocumento2 páginasSteam TrapAmpornchai PhupolAún no hay calificaciones

- Catalog - COSCO Filter & StrainerDocumento26 páginasCatalog - COSCO Filter & Strainerkhunmyominoo100% (1)

- KVC 01Documento35 páginasKVC 01hamidreza_m85Aún no hay calificaciones

- Spence StrainersDocumento132 páginasSpence StrainersRahul LavandAún no hay calificaciones

- Spirax Sarco Commissioning Strainer 1Documento3 páginasSpirax Sarco Commissioning Strainer 1swaraj4uAún no hay calificaciones

- Roberts Oxygen Welding Industrial Catalog 2011Documento104 páginasRoberts Oxygen Welding Industrial Catalog 2011sanjibkrjanaAún no hay calificaciones

- Eaton HansenKingDocumento80 páginasEaton HansenKingKING COMERCIAL LTDAAún no hay calificaciones

- Double Block Bleed TOSVDocumento8 páginasDouble Block Bleed TOSVplanet123Aún no hay calificaciones

- NUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDocumento32 páginasNUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDanny PuchaAún no hay calificaciones

- KITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFDocumento16 páginasKITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFYulita Ika PawestriAún no hay calificaciones

- DWG REF QTY Number Description Material Shell: Order SectionDocumento2 páginasDWG REF QTY Number Description Material Shell: Order SectionRamanNegiAún no hay calificaciones

- Ti 2 516 UsDocumento2 páginasTi 2 516 Uswill_streetAún no hay calificaciones

- Duplex StrainerDocumento16 páginasDuplex StrainerKumaresan VasudevanAún no hay calificaciones

- AV13 Air Vent For Steam Systems: DescriptionDocumento2 páginasAV13 Air Vent For Steam Systems: DescriptionUtku KepcenAún no hay calificaciones

- Sb-Ag-39-Rev-A WING SPAR INSPECTION AND FATIGUE LIFE EXTENSIONDocumento14 páginasSb-Ag-39-Rev-A WING SPAR INSPECTION AND FATIGUE LIFE EXTENSIONNathaniel LuraAún no hay calificaciones

- Tee Type StrainersDocumento3 páginasTee Type StrainersSrinu AmulojuAún no hay calificaciones

- Plug Valves enDocumento24 páginasPlug Valves enAtty AttyAún no hay calificaciones

- Condensadora Westinghouse 5TR Mod DS3BA - DS5BADocumento4 páginasCondensadora Westinghouse 5TR Mod DS3BA - DS5BAOscar Sanchez Velasquez0% (1)

- SAIC-D-2009 Rev 2Documento6 páginasSAIC-D-2009 Rev 2ரமேஷ் பாலக்காடுAún no hay calificaciones

- Installation Manual TTD/TTT: Multi-Split System Condensing Unit 18,000-36,000 Btuh Models 50/60 HZDocumento16 páginasInstallation Manual TTD/TTT: Multi-Split System Condensing Unit 18,000-36,000 Btuh Models 50/60 HZchitak_80Aún no hay calificaciones

- Eaton Winner Braided Hose and Fittings: North AmericaDocumento32 páginasEaton Winner Braided Hose and Fittings: North Americawords2zhigang_612545Aún no hay calificaciones

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocumento8 páginasTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4Aún no hay calificaciones

- CI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsDocumento12 páginasCI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsAndre Gazali MalikAún no hay calificaciones

- Api Plan 11Documento6 páginasApi Plan 11johnsaballaAún no hay calificaciones

- CS310ADocumento4 páginasCS310Arabacet2923Aún no hay calificaciones

- Weld Spec 2Documento3 páginasWeld Spec 2spstainless316Aún no hay calificaciones

- Mission S and W Dims and Curve Chart PDFDocumento28 páginasMission S and W Dims and Curve Chart PDFcaballero_tigreAún no hay calificaciones

- Lead Free Series SS009 Specification SheetDocumento2 páginasLead Free Series SS009 Specification SheetWattsAún no hay calificaciones

- SAIC-D-2002 Rev 2Documento5 páginasSAIC-D-2002 Rev 2ரமேஷ் பாலக்காடுAún no hay calificaciones

- Stargrip Cat PDFDocumento12 páginasStargrip Cat PDFDGWAún no hay calificaciones

- 1200stxr FP ManualDocumento12 páginas1200stxr FP ManualJonathan RauloAún no hay calificaciones

- 3 8 2 Spence StrainersDocumento132 páginas3 8 2 Spence StrainerszayerirezaAún no hay calificaciones

- Ss 01059 eDocumento8 páginasSs 01059 eDavid LapacaAún no hay calificaciones

- Thread o Ring - Fittings (T O R)Documento2 páginasThread o Ring - Fittings (T O R)Jimmy ChanAún no hay calificaciones

- Crouse Hinds Exd JBDocumento8 páginasCrouse Hinds Exd JBomh129Aún no hay calificaciones

- Modular Dual Line SystemDocumento6 páginasModular Dual Line Systemangela_draguAún no hay calificaciones

- Erection and Commissioning Procedure PDFDocumento94 páginasErection and Commissioning Procedure PDFShankar JhaAún no hay calificaciones

- Actuator DX PDFDocumento6 páginasActuator DX PDFFelix Enrique MoratayaAún no hay calificaciones

- Eaton Hansen CatalogoDocumento80 páginasEaton Hansen Catalogorubens0001Aún no hay calificaciones

- T101 Drilling MachineDocumento4 páginasT101 Drilling MachineRemmy Torres VegaAún no hay calificaciones

- Sae J51-2004Documento11 páginasSae J51-2004khhoseAún no hay calificaciones

- Plumbing and Propane CatalogDocumento40 páginasPlumbing and Propane Catalogdannyboy738Aún no hay calificaciones

- Asco S V7394R5Documento16 páginasAsco S V7394R5Jorge Jarpa VAún no hay calificaciones

- CO2 AnsulDocumento17 páginasCO2 AnsulJorge RVAún no hay calificaciones

- Cast - Basket Strainers - 2nd EditionDocumento27 páginasCast - Basket Strainers - 2nd EditionmartinnovelAún no hay calificaciones

- Valves & Controls: Crosby Safety Valves Style HSLDocumento12 páginasValves & Controls: Crosby Safety Valves Style HSLeborresonAún no hay calificaciones

- Valves Reference PDFDocumento35 páginasValves Reference PDFJulio RodriguezAún no hay calificaciones

- Chicksan Inspection ProcedureDocumento9 páginasChicksan Inspection ProcedureBanu Stefan Adrian100% (7)

- Codeline Drawing 80S30 Non CodedDocumento2 páginasCodeline Drawing 80S30 Non CodedDarren PonichaiAún no hay calificaciones

- DB 658 688 GBDocumento6 páginasDB 658 688 GBDenial BasanovicAún no hay calificaciones

- Series 510 Specification SheetDocumento2 páginasSeries 510 Specification SheetFEBCOAún no hay calificaciones

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitAún no hay calificaciones

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAún no hay calificaciones

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsCalificación: 4.5 de 5 estrellas4.5/5 (10)

- EIL Material Selection ChartDocumento1 páginaEIL Material Selection ChartshamashergyAún no hay calificaciones

- List of Approved Shop For Manufacturer of Pressure Vessels & Safety Fittings PDFDocumento18 páginasList of Approved Shop For Manufacturer of Pressure Vessels & Safety Fittings PDFGaurav MehrotraAún no hay calificaciones

- Steel StructuralsDocumento10 páginasSteel Structuralsdchz_62Aún no hay calificaciones

- Branch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®Documento3 páginasBranch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®dchz_62Aún no hay calificaciones

- 17moorflex Brochure CompleteDocumento40 páginas17moorflex Brochure CompleteViola HippieAún no hay calificaciones

- Indian Boilers Regulations - 1950Documento21 páginasIndian Boilers Regulations - 1950dchz_62Aún no hay calificaciones

- Steel Piping Estimate Sheet Date Project System Page #Documento1 páginaSteel Piping Estimate Sheet Date Project System Page #dchz_62Aún no hay calificaciones

- Annexure BDocumento2 páginasAnnexure Bdchz_62Aún no hay calificaciones

- Auto Cad ErrorDocumento1 páginaAuto Cad Errordchz_62Aún no hay calificaciones

- TCS - 13Documento1 páginaTCS - 13dchz_62Aún no hay calificaciones

- Pipe Flow ExpertDocumento4 páginasPipe Flow Expertdchz_62Aún no hay calificaciones

- Calculation PaperDocumento1 páginaCalculation Paperdchz_62Aún no hay calificaciones

- Strainer GuideDocumento26 páginasStrainer Guidemudrijasm100% (1)

- Floor Drains Selection GuideDocumento49 páginasFloor Drains Selection GuideMohamed Ameen100% (1)

- Hayward Cast StrainersDocumento61 páginasHayward Cast StrainersPoncho RmzAún no hay calificaciones

- Y Strainer CatalogDocumento2 páginasY Strainer CatalogLandung GumilangAún no hay calificaciones

- Mueller Strainer Manual (Ms 185ss 186ss)Documento2 páginasMueller Strainer Manual (Ms 185ss 186ss)Jack YangAún no hay calificaciones

- PG 45-48 Strainers PDFDocumento4 páginasPG 45-48 Strainers PDFChamitha MadushanAún no hay calificaciones

- StrainerDocumento5 páginasStrainerMohit BauskarAún no hay calificaciones

- Strainer SizingDocumento20 páginasStrainer Sizingaliscribd46Aún no hay calificaciones

- 64721B510BF11337E10000000AD5062ADocumento1 página64721B510BF11337E10000000AD5062AKailas NimbalkarAún no hay calificaciones

- CDB Filters CatalogDocumento47 páginasCDB Filters CatalogjasonlaiymAún no hay calificaciones

- Tee Type StrainersDocumento3 páginasTee Type StrainersSrinu AmulojuAún no hay calificaciones

- Pressure Drop - Perda de Carga em Filtro YDocumento2 páginasPressure Drop - Perda de Carga em Filtro YNathalia Abadias AlvesAún no hay calificaciones

- SureFlowEquipmentInc US Price List Sept2012Documento32 páginasSureFlowEquipmentInc US Price List Sept2012mihailspiridonAún no hay calificaciones

- Operation Material 2016Documento212 páginasOperation Material 2016Anonymous GkHGMdAún no hay calificaciones

- Filter Testing PDFDocumento23 páginasFilter Testing PDFamol1321Aún no hay calificaciones

- T Pot StrainerDocumento4 páginasT Pot Strainerewanz89Aún no hay calificaciones

- Strainers Handbook Rev.2Documento4 páginasStrainers Handbook Rev.2Vu TranAún no hay calificaciones

- DRIVE SYSTEM Hydraulic and PneumaticDocumento50 páginasDRIVE SYSTEM Hydraulic and PneumaticNor AzlanAún no hay calificaciones

- Strainer Screen & Mesh Selection GuideDocumento4 páginasStrainer Screen & Mesh Selection Guidelenasko0% (1)

- Filtro Tipo H x43h EsDocumento2 páginasFiltro Tipo H x43h EseselcosacAún no hay calificaciones

- Basket StrainersDocumento1 páginaBasket StrainersBossman Instruments TechnologyAún no hay calificaciones

- Ib 10Documento2 páginasIb 10dchz_62Aún no hay calificaciones

- Basket FilterDocumento1 páginaBasket FilterShreya TrikhaAún no hay calificaciones

- PCT 304414 PDFDocumento36 páginasPCT 304414 PDFNugrawan SatriaAún no hay calificaciones