Documentos de Académico

Documentos de Profesional

Documentos de Cultura

AB-040 Boil PV Repair-Alter Report

Cargado por

johnjuantamadDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

AB-040 Boil PV Repair-Alter Report

Cargado por

johnjuantamadCopyright:

Formatos disponibles

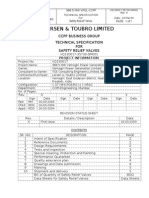

AB-40 (Side A) 2012-09

BOILERS AND PRESSURE VESSELS REPAIR OR ALTERATION REPORT

(A) #:

Final

OWNER EQUIP. NO: REPAIR ORG. JOB NO:

REPAIR

1.

and/or

ALTERATION

Partial

Name of Organization doing Repair/Alteration Address AQP No. & Expiry Date

2.

Name of Owner

Address Location of Installation

3.

Boiler/Pressure Vessel Description

CRN

Manufacturers Name Serial No. 4. Original Design Conditions: a) b) 5. Vessel/Shellside/Boiler: Jacket/Tubeside: Max Allowable Working Press. Max Allowable Working Press. Min/Max Design Temp Min/Max Design Temp / /

New Design Conditions: a) b) Vessel/Shellside/Boiler: Jacket/Tubeside: Max Allowable Working Press. Max Allowable Working Press. Min/Max Design Temp Min/Max Design Temp / /

6.

Description of defects (location and types of deterioration that resulted in the repair/alteration).

7. 8. 9.

Original Code Edition and Addenda ASME Sect.

Year

Addenda Year Addenda

Code Edition and Addenda used for performing the work ASME Sect .

Description of Work performed. (Step by step description of repair/alteration method used. Attach additional pages as required, and reference any additional documents used to provide the required information; such as repair or alteration procedures, drawings, and specifications

10. Heat Treatment:

Preheat Temp

Post Weld HT (Temp./Time)

Other

11. Non Destructive Examination (Specify type and extent).

12. Pressure Test a) b) Hydrostatic Other Test Vessel/Shellside/Boiler Tubeside/Jacket

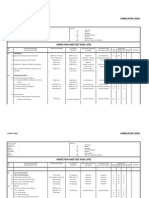

AB-40 (Side B)

(A) #:

OWNER EQUIP. NO.

13. Material - List any material used in repair/alteration and any base material welded on: Item Material Specifications Thickness / Schedule Diameter Item Heads/ Ends Tubes Flanges/Fittings Material Specifications Thickness / Schedule Class Diameter

Shell/Drums Tubesheet Nozzles

14. Welding Procedures Alberta Registration Number WP-

WPS Numbers used:

15. Welded Replacement Parts: Attached are Manufacturers Partial Data Reports or Repair/Alteration Reports properly identified and signed by Authorized Inspector for the following items of this report: (Welded parts supplied by others). 16. Responsibility Owner/Client. Identify below items that the owner/client has assumed responsibility for. Note (2) a) Alteration Design Submission d) Welding Control e) NDE b) Repair/Alteration Procedure: f) Heat Treatment c) Material Control g) Pressure Test

Note 2: Owner/client must have a valid Alberta Quality Program (AQP), for the scope of work, to assume responsibility for function c, d, e, f, or g. 17. REMARKS: 18.

CERTIFICATE OF COMPLIANCE

We certify that the statements made in this Report are correct and that all design, material, construction and workmanship on this repair/alteration conform to the requirements of the Alberta Safety Codes Act and Regulations and the AB-513. b) For items identified in 16 only: (Owner/Client Organization Name) (AQP Number & Expiry Date) (Signature & Date) (Print Name)

a) For all items except for items identified in 16: (Repair/Alteration Organization Name) (AQP Number & Expiry Date) (Signature & Date) (Print Name) 19. DATE WORK WAS COMPLETED: 20.

CERTIFICATE OF INSPECTION

I have inspected the repairs and/or alterations described in this report. To the best of my knowledge, this work has been done in accordance with the Safety Codes Act and Regulations and the requirements established in AB-513. b) ABSA Safety Codes Officer Certification a) In-service Inspector (ISI ) Certification (when work is inspected by ABSA). ( When the repair is inspected by an ISI per the requirements established in AB-513 ) Owner-User/Inspection Company Name In-Service Inspector Signature & Date In-Service Inspector Name (Please Print) In-Service Inspector Alberta Cert # Report Received by ABSA SCO AQP#

ABSA SCO Signature & Date Print Name

También podría gustarte

- ASME Form A-1 Data Report for Vertical TankDocumento2 páginasASME Form A-1 Data Report for Vertical TankYuvraj ThoratAún no hay calificaciones

- Sample UDS DocumentDocumento14 páginasSample UDS Documentnilesh_raykarAún no hay calificaciones

- Ab-083fa Guide For Completing Form Ab-83fDocumento5 páginasAb-083fa Guide For Completing Form Ab-83fDrewAún no hay calificaciones

- Indicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalDocumento3 páginasIndicate If (1) Seamless (2) Fusion Welded. Indicate If (1) Flat (2) Dished (3) Ellipsoidal (4) HemisphericalmsuidAún no hay calificaciones

- PE-ADZ-7E05010104-PIT-712-R00 Powerhouse - Quality Assurance Plan - Excitation CubiclesDocumento8 páginasPE-ADZ-7E05010104-PIT-712-R00 Powerhouse - Quality Assurance Plan - Excitation CubiclesCoquin AntAún no hay calificaciones

- FORM U-1 MANUFACTURER'S DATADocumento2 páginasFORM U-1 MANUFACTURER'S DATAjeff501Aún no hay calificaciones

- AB-083 Const Data Report Piping SystemsDocumento2 páginasAB-083 Const Data Report Piping Systemsjamaljamal20Aún no hay calificaciones

- FormU 1Documento2 páginasFormU 1Mohamed Ahmed MaherAún no hay calificaciones

- Nav Fluorine Air Compressor SpecDocumento15 páginasNav Fluorine Air Compressor Specdhanu_lagwankarAún no hay calificaciones

- 43 00 00 - LPG InstallationDocumento13 páginas43 00 00 - LPG InstallationNiong David100% (1)

- Asme Boiler StandardsDocumento2 páginasAsme Boiler StandardsHasan RiazAún no hay calificaciones

- Instrumetation Report ClarificationDocumento10 páginasInstrumetation Report ClarificationTayebASherifAún no hay calificaciones

- FL Aquatherm Clean VersionDocumento22 páginasFL Aquatherm Clean VersionCherukunnon JubuAún no hay calificaciones

- FormP 2Documento2 páginasFormP 2Mohamed Ahmed MaherAún no hay calificaciones

- BPVC Viii-1 U-1Documento3 páginasBPVC Viii-1 U-1wisnu_bayusaktiAún no hay calificaciones

- Form U-1Documento2 páginasForm U-14508366279Aún no hay calificaciones

- Essar Steel PlantDocumento62 páginasEssar Steel PlantKrishnadev C.SAún no hay calificaciones

- Acdb FQPDocumento9 páginasAcdb FQPAnonymous vcadX45TD7Aún no hay calificaciones

- SM 001 SRV SpecDocumento5 páginasSM 001 SRV Specvardan_vardanAún no hay calificaciones

- Form P-4A Manufacturer'S Data Report For Fabricated Piping As Required by The Provisions of The ASME Code Rules, Section IDocumento2 páginasForm P-4A Manufacturer'S Data Report For Fabricated Piping As Required by The Provisions of The ASME Code Rules, Section Iganesh82Aún no hay calificaciones

- 23 21 14 Hydronic SpecialtiesDocumento7 páginas23 21 14 Hydronic SpecialtiesSoumojit SamantaAún no hay calificaciones

- Form U-1a Manufacturer's Data Report For Pressure VesselsDocumento33 páginasForm U-1a Manufacturer's Data Report For Pressure VesselsPercyAlexanderAún no hay calificaciones

- 15785-Pca Air Handling UnitsDocumento10 páginas15785-Pca Air Handling Unitsadel rihanaAún no hay calificaciones

- 049-Itp For Lighting and Small Power (Building) PDFDocumento15 páginas049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- ScopeDocumento7 páginasScopeSiva ShankarAún no hay calificaciones

- FORM U-2 MANUFACTURER DATADocumento1 páginaFORM U-2 MANUFACTURER DATAalbejo_r9Aún no hay calificaciones

- Technical Notes and Specifications Part CDocumento29 páginasTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- 411 SRR Mat e 0011 Generator Kohler Usa Rev 00Documento4 páginas411 SRR Mat e 0011 Generator Kohler Usa Rev 00Pervez Ahmad KhanAún no hay calificaciones

- Manufacturer Data ReportDocumento3 páginasManufacturer Data Reporthaikal86100% (1)

- 300 kW EB Melting Furnace Design and TestingDocumento14 páginas300 kW EB Melting Furnace Design and Testingjkhgvdj mnhsnjkhgAún no hay calificaciones

- Specification For LP Gas Reciprocating Compressor PackageDocumento25 páginasSpecification For LP Gas Reciprocating Compressor PackageashokAún no hay calificaciones

- ISO FORMATS PaperDocumento42 páginasISO FORMATS Papermilkbikis1114100% (1)

- SECTION 23 23 00 Refrigerant PipingDocumento11 páginasSECTION 23 23 00 Refrigerant PipingCamio HormazabalAún no hay calificaciones

- Temperature .: Psig 200 Deg FDocumento28 páginasTemperature .: Psig 200 Deg Fabdelazeem ElhajAún no hay calificaciones

- 23 21 13 Hydronic PipingDocumento15 páginas23 21 13 Hydronic PipingSoumojit SamantaAún no hay calificaciones

- M-00-d04 Urs Air Compressor (50 CFM) - r0Documento15 páginasM-00-d04 Urs Air Compressor (50 CFM) - r0dhanu_lagwankarAún no hay calificaciones

- Air Reciever 538017Documento20 páginasAir Reciever 538017ismailinesAún no hay calificaciones

- Compressed Air CommentsDocumento4 páginasCompressed Air CommentsEslam ElsayedAún no hay calificaciones

- Form U-1ADocumento2 páginasForm U-1ADanDeMarcoAún no hay calificaciones

- CPV-1 form composite pressure vessel reportDocumento2 páginasCPV-1 form composite pressure vessel reportEmma DAún no hay calificaciones

- 15 K067-C2-SD-55-011-RevBDocumento4 páginas15 K067-C2-SD-55-011-RevBAngel Castro MarceloAún no hay calificaciones

- Attachment 1 - Section 15620 Centrifugal ChillersDocumento21 páginasAttachment 1 - Section 15620 Centrifugal ChillersMohammad Ali DiabAún no hay calificaciones

- FormP 4Documento2 páginasFormP 4Mohamed Ahmed MaherAún no hay calificaciones

- Technical Specifications for Jet Fan InstallationDocumento16 páginasTechnical Specifications for Jet Fan InstallationDewanggaAún no hay calificaciones

- TQ - Air Fin Cooler (CS) - ModificationDocumento6 páginasTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaAún no hay calificaciones

- Form P-4 Manufacturer'S Partial Data Report As Required by The Provisions of The ASME Code Rules, Section IDocumento2 páginasForm P-4 Manufacturer'S Partial Data Report As Required by The Provisions of The ASME Code Rules, Section Iganesh82Aún no hay calificaciones

- PROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01Documento8 páginasPROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01totongopAún no hay calificaciones

- BPVC - VIII-1 - U-2A FormDocumento2 páginasBPVC - VIII-1 - U-2A FormPranesh BhatAún no hay calificaciones

- 2009 02 M HD 319 0Documento5 páginas2009 02 M HD 319 0ZoebairAún no hay calificaciones

- ITP-40Documento10 páginasITP-40Wijayanto BekasiAún no hay calificaciones

- Approved: Pöyry EnergyDocumento5 páginasApproved: Pöyry Energytvpham123Aún no hay calificaciones

- Section 14510 - Shaftless Screw Conveyors City of San Diego, CWP Guidelines Part 1 - GeneralDocumento11 páginasSection 14510 - Shaftless Screw Conveyors City of San Diego, CWP Guidelines Part 1 - GeneralcesakzAún no hay calificaciones

- Project Standard Specification: Fuel Gas Piping 15194 - Page 1/17Documento17 páginasProject Standard Specification: Fuel Gas Piping 15194 - Page 1/17adel rihanaAún no hay calificaciones

- Part 1 - General: SpecificationsDocumento6 páginasPart 1 - General: SpecificationsDiego Plata VasquezAún no hay calificaciones

- SPEC TECH SPEC BRINE CHILLER 0°CDocumento17 páginasSPEC TECH SPEC BRINE CHILLER 0°Cdhanu_lagwankar100% (1)

- Saipem - Serept - Piping ClassDocumento67 páginasSaipem - Serept - Piping ClassAHMED AMIRAAún no hay calificaciones

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Documento6 páginasZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarAún no hay calificaciones

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Calificación: 3.5 de 5 estrellas3.5/5 (3)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisDe EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisCalificación: 5 de 5 estrellas5/5 (1)

- The Art of WarDocumento89 páginasThe Art of Warjade15495100% (12)

- SMAWFacilitator GuideDocumento62 páginasSMAWFacilitator Guidesdkeskar40Aún no hay calificaciones

- Geothermal Pipe Line DesignDocumento15 páginasGeothermal Pipe Line DesignjohnjuantamadAún no hay calificaciones

- AB-040 Boil PV Repair-Alter ReportDocumento2 páginasAB-040 Boil PV Repair-Alter ReportjohnjuantamadAún no hay calificaciones

- Plipdeco Haulier Inspection Checklist Sample FormDocumento2 páginasPlipdeco Haulier Inspection Checklist Sample FormjohnjuantamadAún no hay calificaciones

- API 510 VesselsDocumento11 páginasAPI 510 Vesselsmoonstar_dmeAún no hay calificaciones

- 360 Q Inspection ChecklistDocumento3 páginas360 Q Inspection CheckliststanleyAún no hay calificaciones

- Effect of Flow Velocity and Particle Size On Erosion in A Pipe With Sudden ContractionDocumento17 páginasEffect of Flow Velocity and Particle Size On Erosion in A Pipe With Sudden ContractionHao XuAún no hay calificaciones

- Geothermal Pipe Line DesignDocumento15 páginasGeothermal Pipe Line DesignjohnjuantamadAún no hay calificaciones

- Effect of Flow Velocity and Particle Size On Erosion in A Pipe With Sudden ContractionDocumento17 páginasEffect of Flow Velocity and Particle Size On Erosion in A Pipe With Sudden ContractionHao XuAún no hay calificaciones

- Book 1Documento1 páginaBook 1johnjuantamadAún no hay calificaciones