Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Tech Note 0091

Cargado por

trynext0 calificaciones0% encontró este documento útil (0 votos)

26 vistas48 páginasHYPERSONIC HEAT TRANSFER MEASUREMENTS ON REENTRY VEHICLE SURFACES AT HIGH REYNOLDS NUMBER B.E. RICHARDS JUNE 1973. Report was supported under project 7381, "Materials Applications Useful in USAF Weapon Systems" report covers work conducted during the period June 1971 through July 1972.

Descripción original:

Título original

Tech_Note_0091

Derechos de autor

© Attribution Non-Commercial (BY-NC)

Formatos disponibles

PDF, TXT o lea en línea desde Scribd

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoHYPERSONIC HEAT TRANSFER MEASUREMENTS ON REENTRY VEHICLE SURFACES AT HIGH REYNOLDS NUMBER B.E. RICHARDS JUNE 1973. Report was supported under project 7381, "Materials Applications Useful in USAF Weapon Systems" report covers work conducted during the period June 1971 through July 1972.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

26 vistas48 páginasTech Note 0091

Cargado por

trynextHYPERSONIC HEAT TRANSFER MEASUREMENTS ON REENTRY VEHICLE SURFACES AT HIGH REYNOLDS NUMBER B.E. RICHARDS JUNE 1973. Report was supported under project 7381, "Materials Applications Useful in USAF Weapon Systems" report covers work conducted during the period June 1971 through July 1972.

Copyright:

Attribution Non-Commercial (BY-NC)

Formatos disponibles

Descargue como PDF, TXT o lea en línea desde Scribd

Está en la página 1de 48

-1 t El t.

van KARMAN INSTITUTE

FOR FLUID DYNAMICS

TECHNICAL NOTE 91

HYPERSONIC HEAT TRANSFER MEASUREMENTS

ON REENTRY VEHICLE SURFACES

AT HIGH REYNOLDS NUMBER

B.E. RICHARDS

JUNE 1973

K!:.!}'VC-''/:;) 1 - O:::"FT

~ ! ~

- ~ O ~ - RHODE SAINT GENESE BELGIUM

~ V W

von KARMAN INSTITUTE FOR FLUID DYNAMICS

TECHNICAL NOTE 91

HYPERSON IC HEAT TRANSFER MEASUREMENTS

ON REEN TRY VEHICLE SURFACES

AT HIGH REYNOLDS NUMBER

B.E. RICHARDS

JUNE 1973

Bibliotheek TU Delft

Fac. Lucht- en Ruimtevaart

111111 11111 1111 I 11111 I I 111111 11111

c 3087787

FOREWORD

The activities and results documented in this report

were supported under Project 7381, "Materials Applications

Useful in USAF Weapon Systems", Task 738102 "Space, Missile and

Propulsion System Materials and Component Evaluation" with

Mr. Gary L. Denman, Technical Manager for Thermal Protective

Systems, Systems Support Division, Air Force Materials Labora-

tory, acting as project engineer. The report covers work

conducted during the period June 1971 through July 1972.

The technical advice and guidance of Mr. Victor

DiCristina, Manager, Thermodynamics and Material Test Department,

AVCO Systems Division, AVCO Corporation, Wilmington, Massachusetts

in the areas of model design and instrumentation was particularly

valuable. The author would like to acknowledge the help of

Mr. Jos Slechten and Mr. Cyriel Appels for their contribution

to the data reduction of the data, Mr. Jean Huge and Mr. Fernand

Van de Broek who operate the Longshot facility, and other members

of the technical staff of the Institute. Miss D. Sandford

type d the manuscript.

- 1 -

ABSTRACT

Heat transfer rates, using calorimeter sensors, and

pressures, using variabIe reluctance diaphragm transducers,

have been measured on five model shapes in the VKI Longshot

facility at Mach numbers of 15 and 20 and over a unit Reynolds

number range of 2 x 10

6

to 7 x 10

6

per foot. Two basic shapes,

a hemisphere and a 50 - 8 half angle biconic configuration

with and without nose bluntness, were tested with different

surface roughnesses. Pressures were weIl predicted by the

theory of Belotse:rkovskii .fur spherical surfaces, and tangent

cone theory, using the tables of Jones for conical surfaces.

Laminar heat transfer rates, slightly underpredicted _by

Eckert Reference Enthalpy method on cones and reasonably weIl

predicted by Lees similarity theory on hemispheres, were gene-

rally achieved for the tests at M = 20 which used low Reynolds

numbers. Turbulent heat transfer rates, overpredicted by

Sommer and Short Reference Enthalpy method on a smooth wall

by 10 % and underpredicted by the same method for walls with

0.004 in roughness by 15 %, were measured on the 50 half

angle forebodies of the biconic models tested at M = 15 high

Reynolds number. Transition was completed by the first gauge

on the rough model and by the fourth gauge on the smooth model.

- ii -

ABSTRACT

LIST OF

LIST OF

TABLE OF CONTENTS

..............................................

..............................................

ILLUSTRATIONS ................................ .

TABLES ....................................

I. INTRODUCTION ...................................

11. MODEL INSTRUMENTATION AND CALIBRATION .......... .

111. TEST FACILITY ..................................

IV. MEASUREMENT RESULTS ............................ .

1. Hemisphere models (D and E)

..................

2. Smooth sharp-nosed biconic model A .........

3. Rough biconic models (F and G)

...............

V. CONCLUSIONS ....................................

REFERENCES

APPENDIX

TABLES

............................................

iii

i

ii

iv

v

1

3

4

5

5

6

9

1 1

13

1 5

17

LIST OF ILLUSTRATIONS

,. Details of models .................................... 24

2. Pressure distributions on smooth hemisphere, M=20 .... 25

3. Pressure distribution on rough hemisphere, M=20 ......

4. Pressure distribution on rough hemisphere, M=15 ......

5 Heat transfer distribution on smooth hemisphere, M=20

6. Heat transfer distribution on rough hemisphere, M=20 .

7. Heat transfer distribution on rough hemisphere, M=15 .

8. Pressure distribution on sharp smooth biconic model

25

26

27

27

28

M= 1 5 an d 20 .......... . 28

9. Heat transfer rate on smooth biconic model (Raw data)

10. Heat transfer rate on rough biconic models (Raw data)

1,. Heat transfer rate on smooth sharp biconic model

( Smoothed

data)

................................

12. Comparison of heat transfer data on smooth and rough

sharp biconic models (Smoothed data) .........

13. Heat transfer on rougt sharp biconic model at a=10

(Srnoothed da.ta) .. : ............................ .

14. Heat transfer rate on rough blunt biconic model

(Smoothed data) ............................... .

15. Pressure distribution on sharp rough biconic model,

M= 1 5 .......................................... .

16. Pressure distribution on blunt rough biconic model,

M= 1 5 .......................................... .

- J.V -

29

30

31

32

33

34

35

35

LIST OF TABLES

1. Heat transfer sensor calibration constants 17

2. Estimated test conditions at nose of model at time,

t=O msecs from peak ........................

18

3. Typical test section conditions ............... 19

4. Pressure measurements on hemisphere models D and E .

20

5. Pressure measurements on biconic models A, F and G

21

6. Heat transfer measurements on hemisphere models D

.

an dE ..................................

22

7. Heat transfer measurements on biconic models A,

23

F and G, time t=o msecs ...................

- v -

I. INTRODUCTION

In the design of thermal protection components for

re-entry vehicles, it is critical to have dependable heat transfer

coefficient correlations available over the range of conditions

encountered. Before tackling the problem of understanding the

processes in for instance a highly blown boundary layer with

ablative thermal protection, it is necessary to correlate basic

pressure and heat transfer results under non-blown hypersonic

flow conditions. However, there is a lack of dependable pressure

distribution and heat transfer measurements on entry vehicle

frontal sections under hypersonic freestream conditions with

which to test analyses. Data is required particularly within the

most citical regions of sub-orbital or orbital re-entry which

are defined by maximum surface heating. These regions occur

at aerodynamic conditions of high Reynolds number betwen Mach

numbers of 15 and 20.

Following a first test series, reported in Ref. 1,

more tests, in which were taken pressure and heat transfer rate

distributions and schlieren flow visualisation photographs on

several axisymmetric bodies, were conducted in the nitrogen test

flow of Longshot. The models included

1. Two metallic hemisphere bodies with nose radius R

N

= 3.5. in.,

one model having a smooth surface (designated model D), the other

(model E) having a uniform surface roughness (0.001 in. to

0.004 in.) created by a chem-etching process.

2. Two sharp nosed metallic 50 - 8 half angle biconic ~ o d e l s ~

one model (model A) having a smooth surface, and the other having

a uniform rurface roughness (0.004 in. to 0.005 in.) on the 50

co ne forebody created by flame-spraying with copper (model F).

The sharp tip of the rough biconic model could be replaced by a

rough spherical nose of 0.75 in. nose radius (model G) providing

five configurations whicp were tested in this test series.

The experimental data recorded in this study is

compared with current engineering theories, suggested in a review

of ablation phenomenology by (Ref. 2), to assess

point from laminar to turbulent flow. Laminar heat transfer rates

are compared with the reference enthalpy method of Eckert (Ref. 3)

and the local similarity solution of Lees (Ref. 4) using the

stagnation point correlation of Fay and Riddell(Ref. 5). The

heat transfer measurements are also compared against tw turbulent

theories, the Sommer and Short reference enthalpy method (Ref. 6)

and the semi-empirical method of Spalding and ehi (Ref. 7). All

these theories have proven useful in many compressible flow

applications and the interest here is to examine their validity

under more severe conditions. For instance the boundary layer

on a 50

0

half-angle cone tested in the M = 20 flow of Longshot

develops in a M = 1.5 flow-field with a stream temperature of the

order of 2,300

0

K and a wall temperature of 300

0

K. These

conditions are outside the range in which these empirical

theories were originally correlated or verified. The comparison

will also be used to assess the position of transition.

2

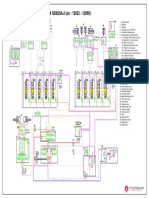

11. MODEL INSTRUMENTATION AND CALIBRATION

The five models supplied by AVCO Corporation were

fitted with heat flow gauges and pressure taps. Ten heat

transfer gauges were mounted axi&lly along and flush with the

model surface beginning at or ne ar the geometrie stagnation

point. Seven pressure taps were similarly spaeed along the

surface but at 180

0

around the model from the row of heat

transfer gauges. The models are illustrated schematically in

Fig. 1. Details of the heat and pressure sensors used, their

calibration and associated recording equipment is given in Ref. 1.

The heat sensors mounted in the rough models differed from those

mounted in the smooth models as described in Ref. 1 by the

calorimeter disc being 0.008 in. thick and roughened to

approximately the same extent as the model surface. The exposed

surface of the insulating holder was also roughened. Most of the

heat gauges were calibrated in the AEDC radiant heat flow

calibration facility before mounting. The gauges were calibrated

over a heat flux range from 20 to 80 B.T.U/ft

2

sec. The

calibration constants are presented in Table 1.

3

111. TEST FACILITY

The VKI Longshot test facility was used for this program.

Longshot differs from a conventional gun tunnel in that a heavy

piston is used to compress the nitrogen test gas to very high

pressures and temperatures (Ref. 8). The test gas is then trapped

in a reservoir at peak conditions by the closing of a system of

check valves. The flow conditions decay monotonically during 10

to 20 milliseconds running times as the nitrogen trapped in the

reservoir flows through the 6 half-angle conical nozzle into

the pre-evacuated open jet test chamber. The maximum supply

conditions used in these tests are approximately 4000 atmospheres

at 2000

0

K to 2,400

0

K. These provide unit Reynolds numbers of

7 x 10

6

and 3 x 10

6

per ft. at nominal Mach numbers of 15 and 20.

Tests at M = 20 with a lower Reynolds number of 2 x 10

6

per ft.

were also employed in this series. The two Mach numbers were

obtained at the 14 1n. diameter nozzle exit plane by using throat

inserts with different diameters.

4

IV. MEASUREMENT RESULTS

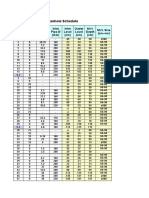

The testscarried out on the five models are summarised

in Table 2 listed in order of testing. Measured reservoir con-

ditions and Pitot pressures at peak conditions are given.

Also tabulated are the calculated conditions of Mach number,

Reynolds number, dynamic pressure and stagnation point heat

transfer on a 7 in. diameter basic test section

conditions vere used throughout. These were a high and a low

Reynolds number case at M = 20, and a low Reynolds number case

at M = 15. The peak condit i ons are revi ewd i -n 3

Pressure and heat transfer distribution

each of the five models are presented in 4-7 and in

figures following Fig. 2. The results are compared to appropriate

theories more fully explained in the section. Such

comparisons have been made to assess the quality of the measure-

ments and to illustrate the effects of conicity on them. Each

model configuration is examined in turn.

1. Hemisphere models (D and E)

Figs. 2-4 show the pressure distribution for all the

three test runs on the smooth and rough hemispheres. The results

were compared with the theory of Belotserkovskii (Ref. 9) includ-

ing a correct ion for flow conicity. Generally the experiment al

spread of the nondimensionalised data lay within a region of

3 % of the stagnation point pressure and in excellent agreement

with the conicity-corrected theory. This is in agreement with

the earlier results of Ref. 1. Some scatter in the data from

the rough model can be explained by the viscous-inviscid inter-

action of the roughness elements with the flow.

5

The heat transfer rate on the smooth hemisphere are

shown in Fig. 5 and on the rough hemisphere are shown in

Figs. 6 and 7 compared with the laminar similarity theory of

Lees (Ref. 4) corrected both for conicity and for a

Belotserkovskii (Ref. 9) instead of a Newtonian pressure dis-

tribution. Also shown in Fig. 5 are results of a test under

similar conditions carried out in a previous test (Run 288 of

Ref. 1) but with different gauges. Within approximately the first

30 fr om the stagnation point in all tests, the same trend was

evident as fuund in Ref. 1 in that the measured values were higher

than the theoretical values. This effect, as yet unexplained, is

contrary to tests on the blunt biconic model and in other reported

tests (Ref. 10). The Mach 20 flow case (Run 350) shows this effect

extended, inexplicably, further than its earlier counterpart

(Run 288) up to 50. For the Mach 15 high Reynolds number test on

the rough body considerable higher values than laminar theory

suggests (particularly in the region within 40 from the nose)

were measured which indicates that turbulent flow on the model

was achieved (Fig. 7).

2. Smooth sharp-nosed biconic model (A)

The wall pressure, nondimensionalised with respect

to the tangent cone theory, for the three tests (Runs 354 to

356) are presented in Fig. 8. Close agreement of the experiments

with tangent cone theory is obtained for the cross-flow case

(Run 355) as weIl as the zero angle of attack cases, confirming

and extending the findings of Ref. 1.

The heat transfer results of the three tests on model

A are shown in Fig. 9 plotted against distance from the tip. Also

shown are the laminar predictions using Eckert reference enthalpy

theory (Ref. 3) for all three tests and the Sommer and Short

(Ref. 6) and Spalding and Chi (Ref. 7) theories for turbulent

6

flow for the M = 15 test. The method of application of these

theories is described in Ref. 1 Appendix C. The M = 20 tests

(Runs 354 and 355) agree closely with the trends given by the

laminar theories, indicating (as in the previous tests at

similar conditions reported in Ref. 1) that the flow is indeed

laminar.

On examination of the experimental points obtained in

these two runs, one sees that the data scatter is similar from

run to run. If one assumes that the heat transfer rate variation

on a smooth body in a near uniform flow is without seatter then

comparison of the data with theory shows that a particular gauge

gives values which are consistently high, similar or low values

compared to theory in consecutive runs. The same result is found

on the rough biconic model, only the pattern of scatter along the

model is different (see Fig. 10). Although most of the gauges

were calibrated, this calibration was carried out before mounting

them in the model, and one might conceive that the calibrations

have changed slightly during mounting, or the gauges are very

sensitive to mounting. This latter remark may be reasonable

because of the extremely small dimensions of the boundary layer

on the modelsurfaces. To examine this finding, correction

factors obtained by fitting the data from a selected test (Run 355)

to a best fit curve with the same slope as the theory, were applied

to the data of the other tests and the results plotted in Figs. 11

and 12 (Figs. 12 and 13 for the rough sharp-nosed biconic model)

against local Reynolds number are seen to be somewhat smoother.

The correct ion factors applied to the data extended from

0.89 to 1.11 for the smooth model and 0.87 to 1.21 for the

rough model.

For both Runs 354 and 355 (M = 20 tests, plotted in

Fig. 1) the experiment al results are, on average, 10 per cent

above Eckert reference enthalpy theory. Run 354 is a repeat

7

test of Runs 209 and 210. The latter experiment al data reported

in Ref. 1 are found, however, to agree weIl with theory. One

reason for the difference in is that the earlier

runs used uncalibrated gauges and the calibration constant,

obtained fr om calibrations of spare gauges, used was 0.715

(BTU/ft

2

sec)/(mv/sec) whilst the average calibration constant

for the latter tests was 0.77 (BTU/ft

2

sec)/{mv/sec), a differen-

ce of 8 per cent. The specification of the gauges used in each

series was similar. It was considered that the latter calibration

constant was correct for both series of tests. Thus it is

considered that repeatability was obtained and that the laminar

Eckert theory underpredicts experiment by 8 to 10 per cent.

The assumption made to simplify the calculation of the

inviscid flow over the cross-flow surface (i.e. 90

0

from the

windward or "leeward" surfaces) of the 50

0

cone at 10

0

angle

of attack as in Run 355 was that it was the same as that on a

50

0

cone at zero angle of attack. The smoothed results of Fig. 11,

again show that the Eckert theory discrepancy as found in the

ealier test (Run 354), and thus one can conclude that the above

assumption can lead to a good assessment of the cross-flow heat

transfer ratel

At M = 15 and high Reynolds numbers, the test conditions

of Run 356, the heat transfer variation near the tip plotted in

Fig. 12 can be seen to be close to the laminar theory, but near

the end of the cone forebody close to turbulent theory of Sommer

and Short (Ref. 6) and several times higher than the laminar

prediction. This test shows that transition occurred in a region

between one and in. from the tip.

It is also observed that the measured turbulent heating

rate near the end of the cone is overpredicted by Sommer-Short

by 10 %. The measurements are also underpredicted by Spalding-

8

ehi by 30 %. It 1S pointed out here that the range of conditions

of Mach number, wall to recovery ratio, and Reynolds number

are out of the range of the correlations used in these empirical

theories.

3. Rough biconic models (F and G)

The wall pressure, nondimensionalised with respect to

the tangent cone theory, for the two tests (Runs 351 and 352) on

the pointed model F are presented in Fig. 15. General agreement

of experiment al data with tangent cone thoery is obtained,

although considerable data scatter is found which is again due

to the layer of roughness sprayed onto the model in some cases

distorting the geometry around the pressure ~ a p s . The non-

dimensionalised wall pressures on the blunt model G for the Run

353 are presented in Fig. 16 and again general agreement with

Belotserkovskii (Ref. 9) theory on the hemisphere part and

tangent cone theory on the conical part of the model is

obtained with similar scatter as on the sharp-nosed model.

The heat transfer results of the two tests on model F

and the tests on model Gare shown in Fig. 11 plotted against

distance fr om the tip. Also shown are the laminar and turbulent

predictions as used for the smooth sharp-nosed model, zero

angle of attack case. On comparison of theory and experiment, it

is strikingly obvious that the data is turbulent over the

whole 50

0

half-angle cone forebody. As noted in the last sub-

section a regular pattern of data scatter is seen. A similar

correction procedure is thus made (but this time the data of Runs

351-353 is smoothed to vary as the Sommer and Short theory

using Run 351) and illustrated in Figs. 12 and 13. It is seen

from Fig. 12 that the measured heat transfer rate of Run 351

on the rough model is 15 per cent higher than the Sommer-Short

prediction, and hence at least 25 per cent higher than the

9

smooth body result of Run 356 also shown on Fig. 12. Fig. 13,

illustrating the results of heat transfer rate on the "leeward"

side of the rough sharp-nosed biconic model at . 10 angle of

attack similarly show that the experiment is 30 per cent over

Sommer and Short theory. It is shown in the Appendix that the

simple strip theory used for this angle of attack case may be

in error.

The "smoothed" measurements from Fig. 10 of the heat

transfer rate on the rough blunt-nosed biconic model Gare

replotted in Fig. 14 against distance from the nose, non-

dimensionalised with nose radius R

N

. The results are compared

with the sharp-nosed cone Sommer and Short turbulent theory,

and Eckert and Lees laminar theory. It is seen that the laminar

theory undergoes transition, from its laminar state on the

spherical nose, very gradually between gauges 2 and 5 achieving

the heating ~ a t e as obtained on the sharp-nosed model at the

end of the forebody.

10

V. CONCLUSIONS

Tests have been cariied out on 3 biconic and 2

hemisphere models in a M = 15 and 20 flow in the VKI Longshot

tunnel at unit Reynolds numbers from 2 x 10

6

to 7 x 10

6

. The

data has been compared with simple engineering theories. The

following conclusions can be made from the comparisons.

1. Pressure data on the biconic forebodies and the

hemispheres agree very weIl with tangent-cone and Belotser-

kovskii theories where appropriate. More scatter was found on rough

models than on the smooth due to interactions of the roughness

elements with the pressure holes.

2. The stagnation point heating on the blunt cone

model agreed fairly weIl with the theory of Fay and Riddell,

but some inexplicable high heating rates are found in the 7 in.

hemisphere results. similar sized unexplained deviations fr om

Lees' laminar similarity heat transfer theory within 30 fr om

the stagnation point are found. At Mach 20 these data agree

weIl with this latter theory further from the stagnation point.

At a Mach 15, high Reynolds number ease higher heat transfer

rates than laminar theory over the whole surfaee, partieularly

within 40 fr om the stagnation point ~ u g g e s t the presence of a

turbulent boundary layer.

3. For M = ,20, and hence low Reynolds number, tests

laminar flow was maintained over the whole of the bieonic

forebodies. The heat transfer rates measured for the cases of

symmetrie flow and cross-flow on the forebody at 10 incidence

were underpredieted by laminar Eekert reference enthalpy theory

by about 10%.

1 1

4. At M = 15 and high Reynolds number, transition to

turbulent flow occurred between one to two in. from the tip for

the smooth-surfaced sharp-nosed biconic forebody model and

before half an inch from the tip on the equivalent rough surfaced

model. Sommer and Short reference enthalpy method overpredicted

the turbulent heating on the former case by 10 % and under-

predicted the latter by 15%. Hence 25% more turbulent heating was

caused by the presence of roughness which has a height from

0.004 ~ n . to 0.0005 in. The transition point on the blunt-

nosed rough-surfaced model was delayed over that found on the

sharp-nosed equivalent model, but its turbulent heating rate

was similar. The turbulent heating on the "l ees ide" of the sharp-

nosed rough-surfaced model at 10 incidence was underpredicted

by Sommer and Short theory by 30%. Some of this discrepancy

may be due to the deficiency of the application of the theory

in the lack of explanation of the boundary layer thinning due

to cross-flow.

1.2

REFERENCES

1. Richards, B. E., Culotta, S., Slechten, J.: "Heat transfer and

pressure distributions on re-entry nose shapes in the

VKI Longshot tunnel",

A.F.M.L. Report No 71200, June 1971

2. Minges , M. L.: "Ablation phenomenology", (A review) High

temperatures - High Pressures,

1969, vol. 1, pp. 607-649

3. Eckert, E.R.G.: "Survey on heat transfer at high speeds",

University of Minnesota, ARL 189, December 1961

4. Lees, L.: "Laminar heat transfer over blunt-nosed bodies at

hypersonic flight speeds", Jet Propulsion,

April 1956, pp. 259-269

5. Fay, J.A., Riddell, F.R.: "Theory of stap;nation point heat

transfer in dissociated air", Journalof Aerospace

Sciences,

vol. 25, 1958, pp. 73-85

6. Sommer, S.C., Short, B.J.: "Free flight rneasurements of

turbulent boundary layer skin friction in the presence

of severe aerodynamic heating at Mach numbers from

2.8 to 7.0",

NACA TN 3391, 1955

7. Spalding, D.B., Chi, S.\.J.: "The drag of a compressible

turbulent boundary layer on a smooth flat plate with

and without heat transfer", Journalof Fluid Machanics,

vol. 18, part 1, pp. 117-143, 1964

8. Richards, B.E., Enkenhus, K.R.: "Hypersonic testing in VKI

Longshot piston tunnel", AIAA Journal,

vol. 8, No 6, June 1970, pp. 1020-1025

1.3

9. Belotserkovskii, O.M. "The calculation of flow over

axisymmetric bodies with a decaying shock wave",

Translation from Academy of Sciences USSR, Compu-

tation Center Monograph, 1961,

AVCO-RAD-TM-62-64, 1962

10. Richards, B.E., Enkenhus, K.R. "Stagnation point heat

transfer and pressure distribution on a hemisphere

at M = 15",

VKI TR 39, 1970

11. Jones, D.J. "Tables of inviscid supersonic flow about

circular cones at incidence, y = 1.4",

AGARDograph 137, part II, November 1969

12. Jones, D.J. "Tables of inviscid supersonic flow about

circular cones at incidence, y = 1.4",

AGARDograph, part lIl, 1971

1 4

APPENDIX

Further notes on the prediction of heat transfer

rate on a sharp 50 half-angle cone

J. Slechten and B.E. Richards

Appendix C of Ref.1 describes a computer program to

estimate the laminar and turbulent flow over a 50 half-angle

cone 1n a hypersonic flow. The program calculates the inviscid

flow over the cone by curve fitting tabulated data from Jones

(Ref.11). At the time of Ref.1, the tables of Jones extended

only to cone half-angles up to 40 and th us it was necessary to

use extrapolations to the data. Since this work was reported,

Jones has published another report (Ref.12) which extends the

tables up to cone angles of 57 1/2 enabling interpolation to be

used. Extrapolation was still necessary for the case of the 50

half-angle cone at 10 angle of attack, since subsonic flow

would be produced on the "windward" side which case is beyond

the scope of the method used to generate the tables. Comparison ,

of the "extrapolated" calculations of the cone flow parameters

with "interpolated" calculations of the cone flow parameters with

"interpolated" calculations showed very little changes. In both

calculations, however, some anomalies, occur, indicating that

the simple approach used to predict heat transfer rates on cones

at angle of attack is in error. These anomalies are illustrated

in the following table concerning the Longshot flow of M = 20

with reservoir pressure of 60,000 psi and a temperature of

2,400

0

K.

15

a -10

0

0 +10

p (ps i) 3.1,6

5.24 6.61

e

T

e

(OK)

2,203

2.749

u (ft/sec)

e

4,138 4,495 2,838

M

1.279 1 .432 0.809

e

qlaminar ' (BTU/ft

2

sec)

94.7 1 1 7 0 104.8

qturbulent(BTU/ft

2

sec)

93. 1 129.2 101 .4

Re

( ft -1 )

2.23Xl0

s

3.69

x

10

5

2.09xl0

s

Some of the results shown in this table look intuitively

wrong. For example: T (too high), M (too low) at a = - 10

0

;

e . e

heat transfer rates too low at a =+ 10. The former anomalies

are probably associated with the cross-flow effects.

The 10'"

heat transfer rates at a = + 10 is probably associated with

the application of a transformation used in the program

not being adequate to cope with the th inning of the boundary

layer due to the cross-flow. The conclusion of this appended note

is that the simple approach used here for predicting heat

transfer rates on a 50 half-angle cone at 10 angle of attack

is not adequate. The solution of this problem will be

particularly complex because of the combination of three-

dimensional boundary layer in a mixed elliptic-hyperbolic flow.

GAUGE

TABLE 1

MODEL

No 0

2

3

4

5

6

7

8

9

10

12

HEAT TRANSFER SENSOR CALIBRATION CONSTANTS

(BTU/FT

2

SEC)/(MV/SEC)

-_ .. __ ._._- - _ .. _-.. '-_._------------_. _._---.

A D E F G

1 .86*

0.77*' 0.77*

1 .6* 1 .86*

1 .91

0.78 0.64 1 .6 1 .86* 1 .86*

0.735 0.83 1. 519 1 .857 1 .857

0.60 0.77 1 .796

1 .86*' 1 .86

0.80 0.88 2.044 1 .826 1 .826

x

0.77 (0.89) 0.74

1 .6*

1 .747 1 .747

0.73

x

(0.90) 0.77* 1 .871 1 .950 1 .950

0.81 0.77

1 .757 1 .836 1 .836

0.77* 1 .609 1 .778 1 .778

0.77- 0.77" 1 .924 2. 196 2.196

o . 9 1

~ - - , ..... _---,..-.. .. -.. _-.----------.--_ .. __.-. .. -._-----, .....

uncalibrated gauges, average value used, 0.77 for model A,

1.86 for models F and G, 1.6 for model E

x gauge broke in test 354, replaced with another gauge for

Runs 355 and 356 with calibration constant given in brackets

TABLE g : ESTIMATED TEST CONDITIONS AT NOSE OF MODELS AT TIME T = 0 FROM PEAK

RUN MODEL AVCO nrCIDENCE P T

o

Pitot M Re

X

10-

6

qD

q

RUN

0

No.

350 D 2

]

355

A 4 58,900 2400 8.2 19.7 3.03 630 69.0

357

E ( 1 )

3

-9 flow)

354 A 0 37,600 2250 5.0 19.5 2. 16 383 47.0

351 F 6 0

}

352 F 8 -10

353

G

7

0 55,000 2100 24.5 1 5.8 6.8 1893 82.3

356

A

0

358

E ( 1 )

5

0

Units Pand pitot (1b/in

2

); dynamic pressure, qD (1b/ft

2

); T (OK);

o 0

Re stagnation point heat transfer, Q, B.T. U/ft

2

sec.

TABLE 3

TYPICAL TEST SECTION CONDITIONS

T(MS)

PO (PS I )

TO (K)

PI TOT (PS, )

MACH NO

POP (PS I )

TO P (K)

RE/FT

p (PS I )

T(K)

ruw

V( FT /S EC)

Q!H Lt3/FT **2) Q(BTU)

TT2fl(K)

COW1ENSATION

CASE 1

O. O.CO

O.5.39000E OS

O. 2.40 00 0 E 0 4

O.7G:J9g9E

Ol

_ 19.965

O.6.99723E OS

3.09583E 04

O.2:l3812E 07

O.14302aE-OI

C.383497E 02 O.173874E-04

0.8.2716 SE 04

U. 4 815 E u3

0-6.71600 E 02

0.2.7035 SE 04

O.3GG777E 02

CASE 2 o 0.00

0.3.76000 E 05

0.2.2S000E 04

Ol

O.3:J7990E 05

0.2.7 74 53 E 04

O.203557E 07

o 9.3086 1 E - 0 2 O.3.53(j90E

02 O.118SS2E-04

C. 7 329171: 04

O.3.63j40E 03 C ,I.G 1570 E 02

O.2.44:J4:JE 04

0.349571E 02

CASE 3

0.000

0.5.50000 E CS

O. 2.1C 00 OE 04 0.245000E 02

15,360

0,7.% 3038E 05 O. 2.G J g 3 G E 04

0.6.39077 E 0 7

o,74710JE-01

0.5.26163E 02

C. 6. 39 G 0 6 E - 0 4

O.7G96ti!jE 04

('4

.lC2047E 03 O. 2,3 2 OE C4

0.4237tilE 02

Case 1 . Runs 350, 355, 357.

Pitot a.t 1t$ cm from nozzle exit

Case 2. Runs 354. Pitot at

19.5 cm from nozzle exit

Case 3. Runs 351 , 35;2, 353, 356, 358. Pitot at 18.3 cm

from nozzle exit

19

RUN No

INCIDENCE

TEST CASE

MODEL

PITOT

2

3

4

5

6

7

8

9

TABLE 4 PRESSURE MEASUREMENTS ON MODELS D & E (1b/in

2

)

HEMISPHERE MODELS

M = 20

High Re

D

7.97

7.86

7 1 1

3.71

3.60

2.41

1. 50

0.89

0.73

20

357

9

M = 20

High Re

E

7.88

8. 18

7.08

6.86

6.33

4.61

3.24

2.35

1 .80

M = 15

High Re

E

26.0

26.8

23.3

20. 1

14.5

1 1 .3

7.3

4.3

2.9

...

TABLE 5 PRESSURE MEASUREMENTS ON MODELS F. G AND A (1b/in

2

)

BICONIC MODELS

RUN No

351

352 353 354 355 356

INCIDENCE 0 10 0 0 10 0

TES'l' CASE M = 1 5 M = 1 5

M = 1 5 H = 20 M = 20 M = 15

High Re Hi gh Re High Re

Low Re High Re High Re

Cross flow

MODEL F F G A A A

PITOT 24.9 24.0 24.2 4 .71 7.66 24.5

11 .3* 10.4

15.6 3.48 5 .16 17.9

2 22.6 13.6 3 . 0 1 4.94 16 1

3 16.4 20.9 1 5.7 3.19 4.67 16.3

4 18.6 22.6 17.3 3 . 1 8 4.56

15.9

5

18.8 22.6 3.30 4.84 15.8

6 17.4 21.9 17.7 3 14 4.66 15.6

7

14.0 18.7 13.5 3.32 4.96 1 6. 1

8. 0.82 2.0 0.79 o. 195 0.30 0.97

crimped tube (low values)

TABLE 6 HEAT TRANSFER MEASUREMENTS ON HEMISPHERE

MODELS D & E TIME T = OMSEC (BTU/ft

2

sec)

RUN No 350 358

MODEL D E E

GAUGE 1 . 88.7* 88. 1 *"

209 ll-

2 87.6

6 6 . 4 ~ 164*'

3 99.0 59.5 186

4 63.8

50.0 168

5

68.7 47.5 172.5

6 50.7 22.5

Jt

93.6"

7

29.9*

13.9 60. 1

8

2 4 . 9 ~

1 1 . 7 5 1 . 1

9 1 1 . 5 * 8.05 35 . 1

10.

6. 1 .- 4.8 .

17.9

* uncalibrated gauge

22

"

IU

lAl

TABLE 7

RUN No

MODEL

GAUGE 0

2

3

4

5

6

7

8

9

10

12

HEAT TRANSFER MEASUREMENTS ON MODELS A. F AND G TIME T = OMSEC

(BTU/ft

2

sec)

351 352 353 354 355 356

F F G A A A

239-

423 324' 111. 5 71 .5* 120* 141.5"

248* 224' 189-- 65.3 97.7 150

286 232 222 52.7 76.5 182

216

183* 189* 50. 1 73.7

218 172 220 39.8 58.7 182

226

179

226 49.6 171

218 172 243 43. 1 52.0 169

13.8 7.7 13. 9 4.5 8.55 15.6

7.43 4.7

12.6 3.8 10. 3 3.15* 5.24* 7 . 5 ~

3.37 5:78 10.65

~ uncalibrated gauge

"\)

=-

Heat flux

gauges

Pressure

gauges

MOOELS A, F, G

7.00

EO. SP

go APART

EQ ~ S P

go APART

Fig. 1 OETAI LS OF MOOELS

Pressure

gauges

~ 7.00

MOOELS D, E

lOL

.

0.

6

4

2

.

RUN 350

CORRECTED

o / BELOTSERKOVSKII

THEORY

o 10 20 30 40 50 60 70 80 e

o

90

Fig.2 PRESSURE DISTRIBUTION ON SMOOTH HEMISPHERE

M =20

8

N

Z

...... 6

m

-l

2

RUN 357

o 10 20 30 40 50 60 70 Ba 90

eO

Fig.3 PRESSURE DISTRIBUTION ON ROUGH HEMISPHERE

M= 20

?5

N

z

-

-

al

-l

w

a::::

:::>

U')

U")

w

ct:

Cl.

22

20

18

16

1l.

12

tO

8

6

4

2

RUN 358

-

o CORREC1ED

\, / BEL01SERKOVSKII

~ lHECRY

\

o

\

0 ~

o tO 20 30 40 50 60 70 80 90

e

FIG. 4 PRESSURE DISTRIBUTION ON ROUGH

HEMISPHERE M = 15

0

0

RUN

350

1.4

<> RUN 288

1.2

iJ

q

1.0

(qst )th

O ~

0.8

corrected lees

0

0.6

similarity theory

0.4

Experiment

o calibrated gauges

0.2

Cf un-calibrated gauges

o ~ ~ - - ~ - - ~ ~ ~ ~ - - ~ - - ~ ~ ~ ~

10 20 30 40 80 Er 90

Fig.5 HEAT TRANSFER DISTRIBUTION ON SMOOTH

HEMISPHERE, M= 20

1.4

1.2

q 1.0

(qst )th

0.8

cf

RUN 357

Experiment

o calibrated gauges

o. aun-calibrated gauges

o

o - - ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ - - ~ ~ ~ ~

80 e

o

90

Fig.6 HEAT TRANSFER

HEMISPHERE,

DISTRIBUTION . ON ROUGH

M= 20

21

RUN 358

o

1.2

d

06 corrected Lees

. similarity theory

o

o

0.4 Experiment

o calibrated gauges

d un-calibrated gauges

o

o

o

Fig. 7 HEAT TRANSFER DISTRIBUTION ON

ROUGH HEMISPHERE, M=15

Pmeasa

Ptheor.

0.6

0.4

0.2

o RUN 354. M=20

o RUN 355, M = 20, cross-flow

o RU N 356, M = 15

O ~ - - - - ~ - - - - ~ - - ~ ~ - - - -

10 20 . 30 .40.

dlstance from tip, 5 In.

Fig.8 PRESSURE DISTRIBUTION ON SHARP

SMOOTH BICONIC MODEL, M :15 and 20

?R

u

C

U)

N_

...

-

;::)

~

cri

1000

300

200

100

80

60

1.0

30

20

MODEL A

o RUN 351.

[] RUN 355

o RUN 356

....

..

..

--.........

M=20 Re Ift=2xl0

oL = O

M = 20

Re Ift=3x lOG d =10(cross-flow)

M = 15 Re/H=7xl0

6

C( =0

o

--:::-- -

... ---

....... ---

356

o 0 0

...... 0

...

"'s..

..

...

,

.....

...

...

......

,

...

..

.....

............ 0 ------- _____ 356

...... -----

...

...

......

...

...

...... ,..... 8

...

... .

...

...

..

...

.. ..... El

....

...

...

...

........ <2>

'... ....... f";1

.... ... ~

" ...... ~ ~ '" ~

... :::' "V' ... .... L:J &.:J

......... ' ~ f S S

......... <2>

....

......

Sommer- Short

_ __ Spalding-Chi

____ Eckert

1 0 - - - - ~ ~ ~ ~ - - ~ - - - - - - - - - - ~ - - - - ~ - - ~ ~

1-0 2-0 3-0 1.-0 5-0

Sin

Fig.9 HEAT TRANSFER

BICONIC MODEL

RATE ON SMOOTH SHARP

(RAW DATA)

1000

800

600

400

200

u

al

11) 100

""

t-

(Ij 60

40

M :15 Re/ft: 7xl01)

o

Sommer - 5 hor t

o

.......... , ......

- - . ~

...... -::------

.... -.

.......... ---

.... ------

...... , -----

.......... ...... Spalding- a;r- --

.... ,

...........

Eckert ' ......

......

...........

.....

......

....

.....

.........

.....

.....

.....

.....

o RUN 351 Model F C(: 0

El RUN 352 Model F Q( :-10

30 0 RUN 353 Model G ~ : 0

2 0 - - ~ ~ - - ~ ~ ~ - - - - - - - - - - - - ~ - - - - - - - - ~

04 06 0.8 10 20 30 40 50

5 in.

Fig.l0 HEAT TRANSFER RATE ON ROUGH BICONIC

MODELS (RAW DATA)

u

~

11)

N

....

.......

-

::::>

400

300

200

100

80

60

40

30

20

MODEL A

El RUN 3S4 M= 20 Re/ft=2xl0

6

=00

Re I ft= 3 )( 10

6

c( = 10

Cross-flow test

o RUN 3SS M =20

" 0

....

....

"

....

....

...

....

-<IJ

............... 0

....

.............. 0

......

....

' ............ 0

' ..... ,...... <:)

......

........ 0

.. ........

...........

......

..

-- - - - Eckert I aminar theory

1 0 ~ ~ ~ - - - - - - ~ - - - - ~ - - ~ ~ ~ ~ ~ ~ ~

104 2 3 4 S 6 8 105

local Reynolds number

Fig. l1 HEAT TRANSFER RATES ON SMOOTH SHARP

BICONIC MODEL (SMOOTHED DATA)

4 0 ~ __ ~ ~ ~ ~ ~ ~ - - - - - - - - ~ - - ~ - - ~ ~

4xlO' 6 8 lOS 2 3 4 S

local Reynolds number

Fig.12 COMPARISON OF HEAT TRANSFER DATA ON

SMOOTH AND ROUGH SHARP BICONIC MODELS

(SMOOTHED DATA)

1000

800

o RUN 352 M = 15 Re Ift :: 7x 10

6

0( :-10-

600

Model F

400

300

f[J

u 0

~

IJ)

0

N

200

-'-

-

-=>

o 0

0

00

.c

~

m

0-

100

80

- Sommer- Short turbulent theory

60

~ O ~ __ ~ ~ __ ~ ~ ~ __ ________ __

2 3 4 6 8 10 2 3

local Reynolds number

Fig.13 HEAT TRANSFER ON ROUGH SHARP BICONIC

MODEL AT 0.=10

0

(SMOOTHED DATA)

33

MODEL G

12 0 RUN 352 M =15 Re/ft: 7 x 10'

06

o

04

02

0::

W

o

...J

::::>

~

(J')

,

,

,

,

,

,

'"

'"

'" ..

.....

...

...

....... Lees

- -- - Eckert

.........

.... -- ....... --

0.. -_ .... _ ..

- Sommer- Short

O ____ I - - - - - - - - - - - - ~ - - - - ~ - - - - - -

1.0 2 0 30 40 50

5/RN

Fig.1l. HEAT TRANSFER RATE ON ROUGH BLUNT

BICONIC MODEL (SMOOTED DATA)

'2

. 0 0

' .0 - ----O--"A--

o

--

Q

-

iL

--

C

Ptheor. 0.8

o RUN 351 M =15

Fig.15

o RUN 352 M= 15

04

02

'0 20 30 [.0

distance from tip I 5 in

PRESSURE DISTRIBUTION ON SHARP

BICONIC MODEL

J

M=15

' 5

1-0

w

05 0

-J

:::>

o

J:

IJ)

o

-ru

theory

o

o

/

tangent co ne theory

' 0 20 3.0

51

RN 40

ROUGH

o

Fig.16 PRESSURE DISTRIBUTION ON BLUNT

BICONIC MODEL

J

M=15

35

UnclassifieJi

-!;toc-urity CI lhcotlon

DOCUMENT CONTROL D T R &. D

c1 lflc.,I<oft ol t"'., boet, ol .b."."t .rtd Irtd "., _ot.,lon w>u., t># .",erH- wh .. " Ilu. 0"""" ,.,..", I. cI tlledJ

' OR'G'N"T'NG "CTIVITY (Corpor.' ulI".),

Fluid Dynamics

ze, REPORT 5ECURITV CLA5SIFICATION

von Karman Institute of

Unclassified

1640

Rhode-Saint-Gense

,Zb. GROVP

:Belgium

REPORT TlTLE

HYPERSONIC HEAT TRANSFER MEASUREMENTS ON RE-ENTRY VEHICLE SURFACES AT

HIGH REYNOLDS NUMBER

OESCRIPTIVE NOTES (Type ol report _d I"c:I_' ... , )

Scientific. Final.

AU THOR"I (Flr./ ... ",., ",Iddl. ,,,,,,.,. , , __ )

Bryan E. Richards

REPORT DATE 7 TOT4L NO. OF PAGE5

17b. NO. OF REFS

P ugust

1973

40

12

CONTRACT OR GRANT .. O ... ORIGINATOJII'S REPORT NUM.ERtS,

USAF contract F-61052-70-C-

b. PROJEC T HO .

0031

N.A.

7381-02

62102F

leb. NO(S, (A",. oth., " ... ;..,. ",.,_,. ba 'F.d

687381

thl.

AFML-TR-73-187

VKI-TN-91

10 STATEMENT

This document l.S approved for pUblic release and sale; its distribution

1.S unlimited

,

SVPPLE"ENTARV NOTES IZ ..... ONSO.UNG MILITARV ACTlYITV

Tech. Other Air Force Materials Laboratory(LAS)

Wright-Patterson AFB

Ohio 45433

ABSTRACT

Heat transfer rates, using calorimeter sensors, and pressures,

USl.ng variabIe reluctance diaphragm transducers, have been measured on

five model shapes in the VKI Longshot facility at Mach numbers of 1 5

and

20 and over a unit Reynolds number range of 2

x 10

6

to 7x 10

6

per foot.

Two basic shapes, a hemisphere and a 50

0

-8

half-angle biconic configu-

ration with and without nose bluntness, were tested with different sur-

face roughness. Pressures were weIl predicted by the theory of

Belotserkovskii for spherical surfaces, and tangent cone theory, USl.ng

the tables of Jones for conical surfaces. Laminar heat transfer rates,

slightly underpredicted by Eckert Reference Enthalpy method on cones and

reasonably well predicted by Lees similarity theory on hemispheres, were

generally achieved for the tests at M

=

20 whieh used low Reynolds

numbers. Turbulent heat transfer rates, overpredicted by Sommer and

Short Referenee Enthalpy method on a smooth wall by 10

%

and underpre-

di ct ed by the same emthod for walls with 0.004 l.n. roughness by 1 5 % ,

were measured on the 50

0

half-angle forebodies of the bieonic roodels

tested at M

= 1 5 high Reynolds number. Transition was eoropleted by the

first gauge on the rough model and by the fourth on the smooth model.

tD ,f

N

O

o

R: .. 1473

Security lassirication

Unclassified

Secunty Clasllllcatlon

I.

LINK A LINK e - LINK C

K EY WOROI

.. RpLE WT ROI..E WT ROL..E WT

I

I

HYPERSONIC

RE-ENTRY

ABLATION

NOSE SHAPES

HEAT TRANSFER

PRESSURE

LAMINAR BOUNDARY LAYER

TURBULENT BOUNDARY LAYER

BOUNDARY LAYER TRANSIT ION CRITERIA

I

i

I

I

I

I

I

I

I

i

I

I

I

i I

,

!

I

I

I

1

,

,

1 I

I

Security Clasaification

También podría gustarte

- Chap3 Forward KinematicsDocumento32 páginasChap3 Forward Kinematicstrynext100% (1)

- Modeling of The Plasma Jet of A Stationary Plasma ThrusterDocumento8 páginasModeling of The Plasma Jet of A Stationary Plasma ThrustertrynextAún no hay calificaciones

- Development of Barrier Discharges Operation Modes and Structure FormationDocumento9 páginasDevelopment of Barrier Discharges Operation Modes and Structure FormationtrynextAún no hay calificaciones

- Denavit-Hartenberg convention robot kinematicsDocumento17 páginasDenavit-Hartenberg convention robot kinematicsHarris ChackoAún no hay calificaciones

- 38 Bird Molecular Gas Dynamics BookDocumento479 páginas38 Bird Molecular Gas Dynamics BookBrendyn SarnackiAún no hay calificaciones

- Emission Spectroscopy of Atmospheric Pressure Plasmas For Biomedical and Environmental ApplicationDocumento8 páginasEmission Spectroscopy of Atmospheric Pressure Plasmas For Biomedical and Environmental ApplicationtrynextAún no hay calificaciones

- Emission Spectroscopy of Atmospheric Pressure Plasmas For Biomedical and Environmental ApplicationDocumento8 páginasEmission Spectroscopy of Atmospheric Pressure Plasmas For Biomedical and Environmental ApplicationtrynextAún no hay calificaciones

- Denavit-Hartenberg convention robot kinematicsDocumento17 páginasDenavit-Hartenberg convention robot kinematicsHarris ChackoAún no hay calificaciones

- Emission Spectroscopy of Atmospheric Pressure Plasmas For Biomedical and Environmental ApplicationDocumento8 páginasEmission Spectroscopy of Atmospheric Pressure Plasmas For Biomedical and Environmental ApplicationtrynextAún no hay calificaciones

- 38 Bird Molecular Gas Dynamics BookDocumento479 páginas38 Bird Molecular Gas Dynamics BookBrendyn SarnackiAún no hay calificaciones

- The Scientific Letters and Papers of James Clerk Maxwell-Volume OneDocumento4 páginasThe Scientific Letters and Papers of James Clerk Maxwell-Volume OnetrynextAún no hay calificaciones

- General Program For The Computation of Two-Dimentional or Axially Symmetric Flows by The Direct Simulation Monte Carlo TechniqueDocumento56 páginasGeneral Program For The Computation of Two-Dimentional or Axially Symmetric Flows by The Direct Simulation Monte Carlo TechniquetrynextAún no hay calificaciones

- 38 Bird Molecular Gas Dynamics BookDocumento479 páginas38 Bird Molecular Gas Dynamics BookBrendyn SarnackiAún no hay calificaciones

- The Inadequate Reference Electrode, A Widespread Source of Error in Plasma ProbeDocumento11 páginasThe Inadequate Reference Electrode, A Widespread Source of Error in Plasma ProbetrynextAún no hay calificaciones

- Millimeterwave Interferometer For Measuring Plasma Electron DensityDocumento4 páginasMillimeterwave Interferometer For Measuring Plasma Electron DensitytrynextAún no hay calificaciones

- Nonlinear Transformation of Electromagnetic Wave in Time-Varying Plasma Medium LongitudinalDocumento7 páginasNonlinear Transformation of Electromagnetic Wave in Time-Varying Plasma Medium LongitudinaltrynextAún no hay calificaciones

- Plasma Diagnostics Techniques for Measuring Electron PropertiesDocumento25 páginasPlasma Diagnostics Techniques for Measuring Electron PropertiestrynextAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- FLUID MACHINERY TURBINE CHARACTERISTIC CURVESDocumento2 páginasFLUID MACHINERY TURBINE CHARACTERISTIC CURVESsarathkumararasu007Aún no hay calificaciones

- Hydraulic system diagram labelsDocumento1 páginaHydraulic system diagram labelsAhmad khairudin100% (1)

- Newton's Laws of Motion Link Segment ModelDocumento10 páginasNewton's Laws of Motion Link Segment ModelHossein NajjarzadeAún no hay calificaciones

- Fhc-Hydraulic CalculationDocumento5 páginasFhc-Hydraulic CalculationmostafaabdelrazikAún no hay calificaciones

- Proportional Flow ChartDocumento1 páginaProportional Flow ChartAkyAún no hay calificaciones

- Pressure in Flowing FluidsDocumento10 páginasPressure in Flowing FluidsIan SorzAún no hay calificaciones

- Design of Water Distribution System - Sample ProblemsDocumento7 páginasDesign of Water Distribution System - Sample ProblemsSharaine CastilloAún no hay calificaciones

- Flow Simulation Report PRIMER TTRABAJODocumento29 páginasFlow Simulation Report PRIMER TTRABAJOGian MorenoAún no hay calificaciones

- Gravitation (XII) Eng WADocumento16 páginasGravitation (XII) Eng WAPrashantcool1999Aún no hay calificaciones

- Tutorial 3 Fluid Statics Part 2 - SolutionDocumento10 páginasTutorial 3 Fluid Statics Part 2 - SolutionJeshurun96Aún no hay calificaciones

- Physics I ProblemsDocumento1 páginaPhysics I ProblemsbosschellenAún no hay calificaciones

- Aerodynamically Augmented Air-Hockey PucksDocumento46 páginasAerodynamically Augmented Air-Hockey PucksjekAún no hay calificaciones

- Our Official Android App - REJINPAUL NETWORK FromDocumento2 páginasOur Official Android App - REJINPAUL NETWORK FromcmuruganAún no hay calificaciones

- Fluid Structure InteractionDocumento16 páginasFluid Structure InteractionhahaerAún no hay calificaciones

- Kinematics Test W SolutionsDocumento5 páginasKinematics Test W SolutionsNicholas ChevalierAún no hay calificaciones

- Practice Questions in Projectile MotionDocumento3 páginasPractice Questions in Projectile MotionMikai Trillanes ColloAún no hay calificaciones

- Lab 1 Flow Through A Venturi MeterDocumento5 páginasLab 1 Flow Through A Venturi MeterAfwan IrfanAún no hay calificaciones

- Helmhotz TheoremDocumento18 páginasHelmhotz TheoremHariharanAún no hay calificaciones

- Prandtl's Lifting-Line Theory for Incompressible Flow Over Finite WingsDocumento30 páginasPrandtl's Lifting-Line Theory for Incompressible Flow Over Finite WingsrevandifitroAún no hay calificaciones

- Problem Set 2: Ce123 - HydraulicsDocumento2 páginasProblem Set 2: Ce123 - HydraulicsZENRIRAún no hay calificaciones

- Chap 12 Jeopardy With Force DiagramsDocumento62 páginasChap 12 Jeopardy With Force Diagramsapi-261372832Aún no hay calificaciones

- 09 External FlowsDocumento29 páginas09 External FlowsFindo TriandhanaAún no hay calificaciones

- Drag and Lift - Lecture Notes PDFDocumento66 páginasDrag and Lift - Lecture Notes PDFsanjana jainAún no hay calificaciones

- Chapter 5 AnswersDocumento2 páginasChapter 5 AnswersJose Popoff100% (1)

- FrontmatterDocumento16 páginasFrontmattermewisaw923Aún no hay calificaciones

- PHY130 Exam#2 StudyGuideDocumento2 páginasPHY130 Exam#2 StudyGuideSagar GogiaAún no hay calificaciones

- Modeling Simulation and Validation of 14 DOF Full Vehicle ModelDocumento6 páginasModeling Simulation and Validation of 14 DOF Full Vehicle ModelShine Khant Mg MgAún no hay calificaciones

- CH 2 Velocity DistributionDocumento16 páginasCH 2 Velocity DistributionLv Liska100% (1)

- Sky Rider - Measure Speed and Acceleration on a Ferris WheelDocumento4 páginasSky Rider - Measure Speed and Acceleration on a Ferris WheelWills BicuaAún no hay calificaciones

- IGCSE Physics - Newton's Laws of MotionDocumento9 páginasIGCSE Physics - Newton's Laws of MotionKasunDilshanAún no hay calificaciones