Documentos de Académico

Documentos de Profesional

Documentos de Cultura

418-250-D00-Q2-001 (Calculation For Compressed Air Package - Rev.01)

Cargado por

mehdi227Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

418-250-D00-Q2-001 (Calculation For Compressed Air Package - Rev.01)

Cargado por

mehdi227Copyright:

Formatos disponibles

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 1 of 8

BASIS DESIGN CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

01 00

REV.

13/08/2012 24/06/2012

DATE

ISSUED FOR APPROVAL ISSUED FOR APPROVAL

DESCRIPTION

H.GH H.GH.

DESIGNER

S.S.K. S.S.K.

CHECKED

M.M. M.M.

APPROVED

R.A. R.A.

P.M

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 2 of 8

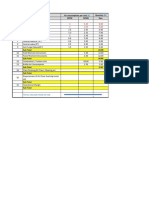

TABULATION OF REVISED PAGES

PAGE Rev.00 Rev.01 Rev.02 Rev.03 Rev.04 PAGE Rev.00 Rev.01 Rev.02 Rev.03 Rev.04

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

X X X X X X X X

X X X X

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 3 of 8

1. Introduction

Present calculation defines minimum requirements for design and selection of compressed air production station equipments to provide compressed air for process & instrument purpose to use in Sarcheshmeh Converter Off Gas Handling Project (Kerman Province) IRAN. The production shall be Oil-Inject with dry compressed air. Compressor room mainly consist of 3 rotary screw and Oil inject type compressor (Two sets in operation and one set stand-by), One air receiver, set of dryers (adsorption or desiccant), set of filters, Water Separators, piping with all accessories, set of instruments, cabling for power and instrumentation with accessories. Air compressor system must be designed according to ISO 8753-1, class 5.2.5 for Plant Air & 2.2.3 for Instrument Air

2. Site Location & Climatic Condition

Geographical location

Location Elevation Latitude Longitude Iran, Sarcheshmeh 2450 m (a.s.l.) North 29.950 East 55.850

+ 35C / -25 C +32.5 C / -17.7 C 400 mm / a 564.4 mm Hg 24% @ 33 C

Climatic Conditions

Highest / Lowest Recorded Temperature Highest / Lowest Design Temperature Annual Average Rainfall Barometric Pressure Humidity of Air

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 4 of 8

3.

Design Data

3.1. Service conditions

Gas Handled Discharge Pressure Average Flow Rate (At package outlet) Plant Air (flow) Instrument air (flow) Operation Noise Limit at 1 m Cooling System Air Tank Air Quality Natural air 7.5 bar(g) 3105 Nm/hr 3050 Nm/hr @ 6 bar(g) 55 Nm/hr @ 6 bar(g) Continuous 75 dB(A) Air cooled 12000 Lit.

ISO 8753-1, class 5.2.5 for Plant Air & 2.2.3 for Instrument Air

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 5 of 8

4. Calculations

4.1. 4.2.

Location: Sarcheshmeh Site Condition: -25 / +35 2450 44 C masl % Ave.

Min. / Max. Ambient Temperature: Altitude: Relative Humidity:

4.3.

Calculation of Rotary Screw Air Compressor Capacity: 3105 3050 55 20 Nm/hr Nm/hr Nm/hr % (ref. to heated type

1) Compressor Air Flow Rate: 2) Plant Air Flow Rate: 3) Instrument Air Flow Rate: 4) Desiccant air dryer losses:

air dryer without blower & -40C atmospheric dew point) 5) Altitude & Temperature effect correction factor: Air pressure at 2100 masl: Air pressure at sea level: 0.75 1.013 bar a bar a

55 Nm/hr x 1.20 = 66 Nm/hr (Desiccant air dryer capacity without correction factors) 3105 Nm/hr (Air compressor capacity without site condition correction factors)

Qc = Qn x ((273 + Ti) x Po) / (273 x Pi) Qc = 3105 x ((273 + 35) x 1.013) / (273 x 0.75) Qc = 3105 x 1.524 = 4732 m/hr = 78.87 m/min

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 6 of 8

78.87 m/hr x 1.15 (Over Design) = 90.7 m/min 90.7 m/hr 2 = 45.35 m/min Three compressors are needed, Two are in operation and One is stand by

4.4.

Calculation for Desiccant Air Dryers Sizing:

All air dryers (adsorption & refrigerant types) flow rate are based on 1 bar (a) and 20 C ambient conditions & 7 bar (g) and 35 C inlet temperature at 100% RH. This is standard condition. To choose a dryer on a given flow at non-standard operating condition, divide the given flow by an appropriate correction factor(s). Dryer inlet pressure: Dryer inlet temperature: 8 barg (Max.) 45 C c.f.1 = 1.12 c.f.2 = 0.7

C.F. = c.f.1 x c.f.2 = 1.12 x 0.7 = 0.784 66 Nm/hr 0.784 = 84.2 m/hr = 1.4 m/min

4.5.

Calculation for Refrigerant Air Dryer Sizing: 8 barg (Max.) 35 C 45 C +5 C c.f.1 = 1.06 c.f.2 = 1 c.f.2 = 1

Dryer inlet pressure: Max. Ambient temperature: Dryer inlet temperature: Dryer dew point:

C.F. = c.f.1 x c.f.2 = 1.06 x 1 = 1.06 3050 Nm/hr x 1.524 = 4648 m/hr (F.A.D.) 4648 m/hr 1.06 = 4385 m/hr

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 7 of 8

4.6.

Calculation for Micro Filters Sizing: 8 barg C.F. = 1.1 (7 barg C.F. = 1)

Operation pressure:

Note: Pre-Filter inlet pressure is about 8 barg and dust-filter outlet pressure will be less than 8 barg (about 7.5 barg in dry state and 7 barg in wet state), so we select a correction factor of 1 in order to better performance. a) Desiccant dryer filters: 66 m/hr 1 = 66 m/hr b) Refrigerant dryer filters: 4385 m/hr 1 = 4385 m/hr

4.7.

Calculation for Plant Air Receiver Sizing:

Capacity of Plant Air Receiver is calculated as follow and the volume intended for this purpose is 41 m based on providing 3 minutes supply of 3217.6 STD m/hr air while depressurizing from 8 barg to 4barg. V = (Q x Time x Po) / (Pu Pl) = (53.63 x 3 x 1.013) / (8 4) = 40.75 m The buffer(s) will be installed after air compressors.

4.8.

Calculation for Instrument Air Receiver Sizing:

Capacity of Instrument Air Receiver is calculated as follow and the volume intended for this purpose is 5 m based on providing 15 minutes supply of 58 STD m/hr air while depressurizing from 7 barg to 4barg. V = (Q x Time x Po) / (Pu Pl) = (0.97 x 15 x 1.013) / (7 4) = 4.9 m The buffer will be installed after air dryer.

Sarcheshmeh Converter Off Gas Handling Project

Consultant: Tadbirgaran Sanat Tehran Contract No: 3690 Document No: Rev. 01

418/250-D00-Q2-001

DOCUMENT TITLE: CALCULATION REPORT FOR COMPRESSED AIR PACKAGE

Date: 13/08/2012

Page 8 of 8

4.9.

Compressed Air Quality Class and Pressure at Outlet of Package: 1 -40 +5 1 7 8 m Class 2

a) Maximum particle size: b) Instrument air dew point: c) Plant air dew point: d) Oil content: e) Instrument air pressure: f) Plant air pressure:

C atm Class 2 C mg/m Class 2 bar g bar g at outlet of package at outlet of package

También podría gustarte

- AIR BLOWERS Calculation-of-Air-Pipe-SizeDocumento7 páginasAIR BLOWERS Calculation-of-Air-Pipe-SizeEngFaisal Alrai100% (3)

- Pump SizingDocumento2 páginasPump Sizingfzida8942100% (3)

- Engine Room Ventilation - Calculation PDFDocumento2 páginasEngine Room Ventilation - Calculation PDFSarawut Jae100% (1)

- Compressed Air SizingDocumento8 páginasCompressed Air Sizingswapnadiph100% (1)

- Instrument Air Dryer Sizing Calculation FactorsDocumento1 páginaInstrument Air Dryer Sizing Calculation FactorsAravind Kannan100% (2)

- Air Receiver SizingDocumento3 páginasAir Receiver Sizinglutfi awnAún no hay calificaciones

- Compressed Air Pipe Sizing CalculationDocumento8 páginasCompressed Air Pipe Sizing CalculationAnonymous NcB95G6Xw100% (1)

- 9 - Horizontal Flare Knock Out Drum Sizing1Documento2 páginas9 - Horizontal Flare Knock Out Drum Sizing1Anonymous APc7I7100% (1)

- Instrument Air Consumption CalculationDocumento1 páginaInstrument Air Consumption CalculationArt G. Enzi100% (1)

- Understanding the key responsibilities and requirements of the ATEX 137 DirectiveDocumento4 páginasUnderstanding the key responsibilities and requirements of the ATEX 137 DirectiveManikanda PrabhuAún no hay calificaciones

- Atlas Copco Document GA90Documento176 páginasAtlas Copco Document GA90Jhun Aquino100% (1)

- WabcoDocumento59 páginasWabcomartecmec100% (2)

- VL10 Service Installation Ver2c SN 001-012Documento62 páginasVL10 Service Installation Ver2c SN 001-012andrea772Aún no hay calificaciones

- Compressor Sizing and CalculationDocumento6 páginasCompressor Sizing and CalculationOghale B. E. Omuabor100% (5)

- Pipe Size For Cooling Water SystemDocumento5 páginasPipe Size For Cooling Water Systemnagu108Aún no hay calificaciones

- Pressure Drop Within DuctsDocumento2 páginasPressure Drop Within DuctsManoj Thakur50% (2)

- CAL-00-P-0009 Rev A Compressed Air SystemDocumento13 páginasCAL-00-P-0009 Rev A Compressed Air SystemSyed Zaki HaiderAún no hay calificaciones

- Modification & Repair of Gantry Control Room: Doc No. 2838-CAL-001 Revision No. 0 Calculation For Room PressurizationDocumento1 páginaModification & Repair of Gantry Control Room: Doc No. 2838-CAL-001 Revision No. 0 Calculation For Room Pressurizationazhar islamAún no hay calificaciones

- Compressed Air System Design for 600 MW Power PlantDocumento11 páginasCompressed Air System Design for 600 MW Power Plantkaruna346100% (2)

- Instrument Air SizingDocumento2 páginasInstrument Air Sizingmilton1987100% (1)

- Calculate Compressed Air ReceiversDocumento2 páginasCalculate Compressed Air ReceiversYYo YudiAún no hay calificaciones

- PUMP CALCULATION SHEETDocumento4 páginasPUMP CALCULATION SHEETMuhammad BilalAún no hay calificaciones

- Air Receivers Volume CalculationDocumento83 páginasAir Receivers Volume CalculationAnonymous yt4t6XjgScAún no hay calificaciones

- Sizing Air ReceiverDocumento3 páginasSizing Air ReceiverAnkon Mukherjee100% (3)

- Condensate Line SizingDocumento2 páginasCondensate Line SizingWade ColemanAún no hay calificaciones

- Compressor Capacity CalculationDocumento4 páginasCompressor Capacity CalculationHoney Tiwari100% (1)

- Compressor Sizing CalDocumento2 páginasCompressor Sizing Calcanada_198020008918Aún no hay calificaciones

- Duct Static Pressure Loss CalculationDocumento8 páginasDuct Static Pressure Loss CalculationYe Thiha Min100% (2)

- Air Consumption CalculationDocumento16 páginasAir Consumption Calculationcitramuara100% (1)

- Compressor Sizing CalDocumento2 páginasCompressor Sizing CalSimranjeet SinghAún no hay calificaciones

- 17-09 - Instrument Air PackageDocumento35 páginas17-09 - Instrument Air PackageFolayemiAún no hay calificaciones

- Air Receiver SizingDocumento3 páginasAir Receiver Sizingmazumdar_satyajit100% (2)

- Compressed Air System Design Guide Rev ADocumento13 páginasCompressed Air System Design Guide Rev AKeagan Naidoo100% (4)

- System Duct Pressure Loss CalculationDocumento6 páginasSystem Duct Pressure Loss Calculationthanh_79Aún no hay calificaciones

- PositiveDisplacementBlowerCalculations Brochuremay2017Documento4 páginasPositiveDisplacementBlowerCalculations Brochuremay2017hardik033Aún no hay calificaciones

- Hot water pump sizingDocumento2 páginasHot water pump sizingKarthy GanesanAún no hay calificaciones

- Water quality parameters and their measurementDocumento19 páginasWater quality parameters and their measurementMyungkwan Ha100% (1)

- Compressor SizingDocumento84 páginasCompressor Sizingwanto_sudar92% (13)

- Flare Knock Out Drum Sizing SheetDocumento2 páginasFlare Knock Out Drum Sizing Sheetsanjay100% (4)

- Pump Sizing CalculationDocumento24 páginasPump Sizing CalculationEbby Onyekwe100% (1)

- DBR of Ventilation System 162Documento10 páginasDBR of Ventilation System 162pukhrajsoniAún no hay calificaciones

- Pump Head CalculationDocumento12 páginasPump Head CalculationIrfan Siddiqui100% (1)

- Air Receiver SizingDocumento4 páginasAir Receiver SizingAnonymous a4Jwz14WAún no hay calificaciones

- Dust Extraction Design ReportDocumento13 páginasDust Extraction Design ReportKartik Mendiratta100% (1)

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocumento2 páginasDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraAún no hay calificaciones

- Pump SizingDocumento9 páginasPump SizingNam Vu Tran67% (3)

- Sizing Calculation of General Service PumpsDocumento193 páginasSizing Calculation of General Service Pumpsmkha87Aún no hay calificaciones

- Air Receivers Volume CalculationDocumento123 páginasAir Receivers Volume CalculationsdgthdtrtretAún no hay calificaciones

- Piping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsDocumento17 páginasPiping Pressure Drop and Pump Design Calculation Sheet: Operating Conditions Discharge ConditionsDhanny Miharja100% (1)

- Duct Pressure Drop Calculation ProcedureDocumento4 páginasDuct Pressure Drop Calculation Procedureaaditya30150% (1)

- Pump Head CalculationDocumento15 páginasPump Head CalculationYashapuja100% (1)

- Pressure Drop Calculation - Theory: View TableDocumento13 páginasPressure Drop Calculation - Theory: View Tableray_k_917775% (4)

- Line Sizing GuidelinesDocumento2 páginasLine Sizing GuidelinesHarryBouterAún no hay calificaciones

- Cooling TowerDocumento27 páginasCooling Towerjogedhayal100% (1)

- Cooling Tower Modification ProjectDocumento1 páginaCooling Tower Modification Projectrashm006ranjanAún no hay calificaciones

- Orifice Plate CalculationDocumento1 páginaOrifice Plate CalculationNethajiAún no hay calificaciones

- Line Size & Pressure Drop CalculationDocumento3 páginasLine Size & Pressure Drop Calculationsj_scribdAún no hay calificaciones

- Rooms Pressurized Calculation - RevaDocumento2 páginasRooms Pressurized Calculation - RevaDoan Tien Do100% (1)

- Operating & Instructions: ManualDocumento20 páginasOperating & Instructions: ManualjujuroyaleAún no hay calificaciones

- PressorsDocumento8 páginasPressorsManoj MisraAún no hay calificaciones

- γ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsDocumento6 páginasγ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsHhaabbde SybaritzAún no hay calificaciones

- Dust ExplosionDocumento3 páginasDust ExplosionKhoirul WaladAún no hay calificaciones

- PPUPalestine Polytechnic University Hydraulic And Pneumatic Systems Compressor Design ProjectDocumento10 páginasPPUPalestine Polytechnic University Hydraulic And Pneumatic Systems Compressor Design ProjectMohammed ShantiAún no hay calificaciones

- Variation In Refrigeration Coefficient Of PerformanceDocumento7 páginasVariation In Refrigeration Coefficient Of PerformanceFaez Feakry100% (1)

- Noise Suppression by Low-Pass Filters 3.5. The Effect of Non Ideal CapacitorsDocumento5 páginasNoise Suppression by Low-Pass Filters 3.5. The Effect of Non Ideal Capacitorsmehdi227Aún no hay calificaciones

- Murata Data Caps ESR ESLDocumento6 páginasMurata Data Caps ESR ESLecl_manAún no hay calificaciones

- TestDocumento1 páginaTestmehdi227Aún no hay calificaciones

- Thread Conversion ChartDocumento1 páginaThread Conversion Chartmehdi227Aún no hay calificaciones

- Meter ProverDocumento5 páginasMeter Proverjivajive100% (2)

- Calibration FormDocumento1 páginaCalibration Formmehdi227Aún no hay calificaciones

- ProTech203 PDFDocumento4 páginasProTech203 PDFmehdi227Aún no hay calificaciones

- Murata Data Caps ESR ESLDocumento6 páginasMurata Data Caps ESR ESLecl_manAún no hay calificaciones

- Meter ProverDocumento5 páginasMeter Proverjivajive100% (2)

- TestDocumento1 páginaTestmehdi227Aún no hay calificaciones

- 3300 System Compatibility Guide: Operation ManualDocumento23 páginas3300 System Compatibility Guide: Operation Manualmehdi227Aún no hay calificaciones

- 31000, 32000 Proximity Probe Housings: DescriptionDocumento9 páginas31000, 32000 Proximity Probe Housings: Descriptionmehdi227Aún no hay calificaciones

- Hermowells: Thermowell Design and Selection CriteriaDocumento1 páginaHermowells: Thermowell Design and Selection Criteriamehdi227Aún no hay calificaciones

- 2879 PDFDocumento2 páginas2879 PDFandimendAún no hay calificaciones

- AshThermWell8Steps PDFDocumento2 páginasAshThermWell8Steps PDFmehdi227Aún no hay calificaciones

- Thermowells: Temperature MeasurementDocumento4 páginasThermowells: Temperature Measurementmehdi227Aún no hay calificaciones

- Thermowells SelectionDocumento2 páginasThermowells Selectionmehdi227Aún no hay calificaciones

- Head and Well RefDocumento5 páginasHead and Well Refmehdi227Aún no hay calificaciones

- Hermowells: Thermowell Design and Selection CriteriaDocumento1 páginaHermowells: Thermowell Design and Selection Criteriamehdi227Aún no hay calificaciones

- Sira Technical File FORM9121Documento2 páginasSira Technical File FORM9121mehdi227Aún no hay calificaciones

- DFFJ Dfgu SSJDocumento3 páginasDFFJ Dfgu SSJmehdi227Aún no hay calificaciones

- 7070 CCG Ra 139 - Iss - 1Documento2 páginas7070 CCG Ra 139 - Iss - 1mehdi227Aún no hay calificaciones

- DFFJ Dfgu SSJDocumento3 páginasDFFJ Dfgu SSJmehdi227Aún no hay calificaciones

- IPISDocumento24 páginasIPISmehdi227Aún no hay calificaciones

- Guide To Hazardous Locations: Causes of ExplosionsDocumento1 páginaGuide To Hazardous Locations: Causes of Explosionsmehdi227Aún no hay calificaciones

- Bolting Dimensions 125 - 250 LB Flange SteelDocumento1 páginaBolting Dimensions 125 - 250 LB Flange Steelmehdi227Aún no hay calificaciones

- Guide To Hazardous Locations: Causes of ExplosionsDocumento1 páginaGuide To Hazardous Locations: Causes of Explosionsmehdi227Aún no hay calificaciones

- UTENES707BADocumento5 páginasUTENES707BAmehdi227Aún no hay calificaciones

- Air Dryyer PDFDocumento15 páginasAir Dryyer PDFrajishrrrAún no hay calificaciones

- Doosan Xhp1170fcat t3 Bid SpecDocumento7 páginasDoosan Xhp1170fcat t3 Bid Specmuhammad afiqAún no hay calificaciones

- Bendix - AD-IP Sevice Data (SD-08-2414)Documento28 páginasBendix - AD-IP Sevice Data (SD-08-2414)Eduardo SanchezAún no hay calificaciones

- Size Press 1Documento14 páginasSize Press 1Andreas Kurniawan100% (2)

- Catálogo de Secadores de AireDocumento12 páginasCatálogo de Secadores de AiredavidnpsAún no hay calificaciones

- Qsi 245i 500iDocumento8 páginasQsi 245i 500iAnkur PiparsaniaAún no hay calificaciones

- Balston Membrane Compressed Air DryersDocumento16 páginasBalston Membrane Compressed Air DryersSeva KiselevAún no hay calificaciones

- Cf-Fa12-Dpt 154 2227 12261194719Documento125 páginasCf-Fa12-Dpt 154 2227 12261194719اشرينكيل مسونكيلAún no hay calificaciones

- Internship Report On Front End Compression (Qadirpur Gas Field, OGDCL)Documento23 páginasInternship Report On Front End Compression (Qadirpur Gas Field, OGDCL)abbas_sohail11080% (5)

- Maintenance Guide: 7. Filter in Cooling SystemDocumento6 páginasMaintenance Guide: 7. Filter in Cooling SystemAnonymous Jw74aayApGAún no hay calificaciones

- Tuflo 501 Air CompressorDocumento36 páginasTuflo 501 Air CompressorSns EquipamientoAún no hay calificaciones

- Optimizing Air Instrument KPIsDocumento31 páginasOptimizing Air Instrument KPIsMindiRahayuAún no hay calificaciones

- HPU LP Accumulators and Process EquipmentDocumento4 páginasHPU LP Accumulators and Process EquipmentHuifen ChngAún no hay calificaciones

- Refrigeration Air Dryers Capacity GuideDocumento6 páginasRefrigeration Air Dryers Capacity GuideseyedAli Tabatabaee0% (1)

- Bendix BX 2150Documento36 páginasBendix BX 2150Marcos Valdez100% (1)

- B AlstonDocumento176 páginasB AlstonAnonymous uL3JlWfhAún no hay calificaciones

- Starex SD 0150Documento5 páginasStarex SD 0150claudiaAún no hay calificaciones

- Hydrovane Refrig Dryer-HV04-05-07 PDFDocumento13 páginasHydrovane Refrig Dryer-HV04-05-07 PDFMark CarterAún no hay calificaciones

- OPTIMIZED SOLUTION FOR COMPRESSED AIR TREATMENTDocumento20 páginasOPTIMIZED SOLUTION FOR COMPRESSED AIR TREATMENTigor_sandulenkoAún no hay calificaciones

- Non-Cycling Refrig Brochure For 50 HZ - A4Documento12 páginasNon-Cycling Refrig Brochure For 50 HZ - A4czar2202Aún no hay calificaciones

- ASME FiltroDocumento11 páginasASME FiltroDenise AGAún no hay calificaciones

- GPG216 Energy Saving in The Filtration and Drying of Compressed AirDocumento31 páginasGPG216 Energy Saving in The Filtration and Drying of Compressed AirIppiAún no hay calificaciones

- MAINTENANCE INSTRUCTIONS FOR HEATLESS REGENERATIVE TWIN TOWER TYPE COMPRESSED AIR DRYERDocumento43 páginasMAINTENANCE INSTRUCTIONS FOR HEATLESS REGENERATIVE TWIN TOWER TYPE COMPRESSED AIR DRYERfernanguedes2071100% (2)

- Membrane TypeDocumento46 páginasMembrane TypeDeniAún no hay calificaciones

- Air Systems Web CatalogueDocumento42 páginasAir Systems Web CatalogueCarlos MiguelAún no hay calificaciones

- P-8931 LaserStar 1530 09-17-04Documento2 páginasP-8931 LaserStar 1530 09-17-04takenoveraccountAún no hay calificaciones

- Hoi Xe MyDocumento81 páginasHoi Xe MyĐứcNhậtAún no hay calificaciones