Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Syallbus

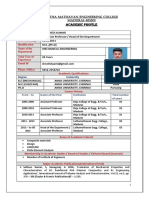

Cargado por

M.Saravana Kumar..M.ETítulo original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Syallbus

Cargado por

M.Saravana Kumar..M.ECopyright:

Formatos disponibles

ED 9121 FINITE ELEMENT METHODS IN MECHANICAL DESIGN (Common for M.

E Degree Programs in Engineering Design, CAD & PDD streams)

UNIT I GENERAL INTRODUCTION * 10 Introduction- structural element and system- assembly and analysis of a structureboundary conditions- general pattern- standard discrete system- transformation of coordinates- examples direct physical approach to problems in elasticity- direct formulation- displacement approach minimization of total potential- convergence criteria discretization error- nonconforming elements and patch test- solution processnumerical examples UNIT II GENERALIZATION OF FINITE ELEMENT CONCEPTS AND ELEMENT SHAPE FUNCTIONS* 7 Boundary value problems integral or weak statements- weighted residual methodsGalerkin method- virtual work as weak form of equations in solid and fluid mechanicsvariational principles establishment of natural variational principles for linear selfadjoint differential equations standard and hierarchical elements- shape functionsrectangular elements- completeness of polynomials- Lagrange family- Serendipity family- rectangular prisms- tetrahedral elements- global and local finite element approximation- mapped elements- coordinate transformations- geometrical conformity of elements- evaluation of element matrices- transformation in , and coordinatesorder of convergence- numerical integration example problems UNIT III APPLICATIONS TO FIELD PROBLEMS * 9 Solution to problems in linear elasticity- plane problems in elasticity- plates and shellssolution of problems in heat-transfer and fluid mechanics- numerical examplesdiscussion on error estimates UNIT IV FINITE ELEMENTS IN STRUCTURAL DYNAMICS AND VIBRATIONS ** 10 Dynamic equations- stiffness, mass and damping matrices- consistent and diagonal mass matrices- Extraction of natural frequencies and modes- Reduction of number of degrees of freedom - modal methods - component mode synthesis- harmonic analysisresponse history- explicit and implicit direct integration- stability and accuracy- analysis of response spectra- example problems UNIT V NON-LINEAR ANALYSIS *** 9 Non-linear problems in elasticity- some solution methods- plasticity: introduction, general formulation for small strains- formulation for von Mises theory- computational procedureproblems of gaps and contact- geometric non-linearity- modelling considerations

ED 9122

VIBRATION ANALYSIS AND CONTROL**

L T P C 3 0 2 4

OBJECTIVE: (i).To understands the Fundamentals of Vibration and its practical applications. (ii).To understand the working principle and operations of various vibrations Measuring instruments (iii).To understand the various Vibration control strategies UNIT I FUNDAMENTALS OF VIBRATION 10 Introduction -Sources Of Vibration-Mathematical Models- Displacement, velocity and Acceleration- Review Of Single Degree Freedom Systems -Vibration isolation Vibrometers and accelerometers -.Response To Arbitrary and non- harmonic Excitations Transient Vibration Impulse loads-Critical Speed Of Shaft-Rotor systems. UNIT II TWO DEGREE FREEDOM SYSTEM 7 Introduction-Free Vibration Of Undamped And Damped- Forced Vibration With Harmonic Excitation System Coordinate Couplings And Principal Coordinates UNIT III MULTI-DEGREE FREEDOM SYSTEM AND CONTINUOUS SYSTEM 9 Multi Degree Freedom System Influence Coefficients and stiffness coefficientsFlexibility Matrix and Stiffness Matrix Eigen Values and Eigen Vectors-Matrix Iteration Method Approximate Methods: Dunkerley, Rayleighs, and Holzer Method -Geared Systems-Eigen Values & Eigen vectors for large system of equations using sub space, Lanczos method - Continuous System: Vibration of String, Shafts and Beams UNIT IV VIBRATION CONTROL 9 Specification of Vibration Limits Vibration severity standards- Vibration as condition Monitoring tool-Vibration Isolation methods- -Dynamic Vibration Absorber, Torsional and Pendulum Type Absorber- Damped Vibration absorbers-Static and Dynamic BalancingBalancing machines-Field balancing Vibration Control by Design Modification- - Active Vibration Control UNIT V EXPERIMENTAL METHODS IN VIBRATION ANALYSIS 10 Vibration Analysis Overview - Experimental Methods in Vibration Analysis.-Vibration Measuring Instruments - Selection of Sensors- Accelerometer Mountings. -Vibration Exciters-Mechanical, Hydraulic, Electromagnetic And Electrodynamics Frequency Measuring Instruments-. System Identification from Frequency Response -Testing for resonance and mode shapes

ED 9123

MECHANISMS DESIGN AND SIMULATION**

UNIT I INTRODUCTION 9 Review of fundamentals of kinematics-classifications of mechanisms-components of mechanisms mobility analysis formation of one D.O.F. multi loop kinematic chains, Network formula Gross motion concepts-Basic kinematic structures of serial and parallel robot manipulators-Compliant mechanisms-Equivalent mechanisms. UNIT II KINEMATIC ANALYSIS 9 Position Analysis Vector loop equations for four bar, slider crank, inverted slider crank, geared five bar and six bar linkages. Analytical methods for velocity and acceleration Analysis four bar linkage jerk analysis. Plane complex mechanisms-auxiliary point method. Spatial RSSR mechanism-Denavit-Hartenberg Parameters Forward and inverse kinematics of robot manipulators. UNIT III PATH CURVATURE THEORY, COUPLER CURVE 9 Fixed and moving centrodes, inflection points and inflection circle. Euler Savary equation, graphical constructions cubic of stationary curvature. Four bar coupler curvecusp-crunode-coupler driven six-bar mechanisms-straight line mechanisms UNIT IV SYNTHESIS OF FOUR BAR MECHANISMS 9 Type synthesis Number synthesis Associated Linkage Concept. Dimensional synthesis function generation, path generation, motion generation. Graphical methodsPole technique-inversion technique-point position reduction-two, three and four position synthesis of four- bar mechanisms. Analytical methods- Freudensteins EquationBlochs Synthesis. UNIT V SYNTHESIS OF COUPLER CURVE BASED MECHANISMS & CAM MECHANISMS 9 Cognate Lingages-parallel motion Linkages. Design of six bar mechanisms-single dwelldouble dwell-double stroke. Geared five bar mechanism-multi-dwell. Cam Mechanismsdetermination of optimum size of cams. Mechanism defects.

Study and use of Mechanism using Simulation Soft-ware packages. Students should design and fabricate a mechanism model as term project.

ED 9124

MECHANICAL BEHAVIOR OF MATERIALS

UNIT I

BASIC CONCEPTS OF MATERIAL BEHAVIOR

12

Elasticity in metals and polymers Strengthening mechanisms, work hardening, solid solutioning, grain boundary strengthening, poly phase mixture, precipitation, particle, fibre and dispersion strengthening. Effect of temperature, strain and strain rate on plastic behaviour Super plasticity . Griffiths theory, Ductile, brittle transition in steel High temperature fracture, creep Larson Miller parameter Deformation and fracture mechanism maps.

UNIT II

BEHAVIOUR UNDER DYNAMIC LOADS AND DESIGN APPROACHES 10

Stress intensity factor and fracture toughness Fatigue, low and high cycle fatigue test, crack initiation and propagation mechanisms and Paris law.- Safe life, Stress-life, strain-life and fail - safe design approaches -Effect of surface and metallurgical parameters on fatigue Fracture of non metallic materials Failure analysis, sources of failure, procedure of failure analysis.

UNIT III

SELECTION OF MATERIALS

10

Motivation for selection, cost basis and service requirements Selection for mechanical properties, strength, toughness, fatigue and creep Selection for surface durability corrosion and wear resistance Relationship between materials selection and processing Case studies in materials selection with relevance to aero, auto, marine, machinery and nuclear applications Computer aided materials selection.

UNIT IV

MODERN METALLIC MATERIALS

Dual phase steels, High strength low alloy (HSLA) steel, Transformation induced plasticity (TRIP) Steel, Maraging steel, Nitrogen steel Intermetallics, Ni and Ti aluminides smart materials, shape memory alloys Metallic glass and nano crystalline materials.

UNIT V

NON METALLIC MATERIALS

Polymeric materials Formation of polymer structure Production techniques of fibers, foams, adhesives and coating structure, properties and applications of engineering polymers Advanced structural ceramics, WC, TIC, TaC, Al2O3, SiC, Si3N4 CBN and diamond properties, processing and applications.

DESIGN OF HYDRAULIC AND PNEUMATIC SYSTEMS

UNIT I

OIL HYDRAULIC SYSTEMS AND HYDRAULIC ACTUATORS

Hydraulic Power Generators Selection and specification of pumps, pump characteristics. characteristics. Linear and Rotary Actuators selection, specification and

UNIT II

CONTROL AND REGULATION ELEMENTS

12

Pressure - direction and flow control valves - relief valves, non-return and safety valves actuation systems.

UNIT III

HYDRAULIC CIRCUITS

Reciprocation, quick return, sequencing, synchronizing circuits - accumulator circuits industrial circuits - press circuits - hydraulic milling machine - grinding, planning, copying, - forklift, earth mover circuits- design and selection of components - safety and emergency mandrels. UNIT IV PNEUMATIC SYSTEMS AND CIRCUITS 16

Pneumatic fundamentals - control elements, position and pressure sensing - logic circuits - switching circuits - fringe conditions modules and these integration - sequential circuits - cascade methods - mapping methods - step counter method - compound circuit design - combination circuit design.

UNIT V

INSTALLATION, MAINTENANCE AND SPECIAL CIRCUITS

Pneumatic equipments- selection of components - design calculations application fault finding - hydro pneumatic circuits - use of microprocessors for sequencing - PLC, Low cost automation - Robotic circuits.

MAINTENANCE ENGINEERING UNIT I INTRODUCTION TO MAINTENANCE SYSTEMS 8

Introduction to repair and Maintenance -Maintenance as business - Maintenance systems such as reactive, preventive, predictive or proactive systems - Human resources management in Maintenance management -maintainability- Inherent and overall availability. - Mean time between failures, mean time to repairs and mean down time - Testability and supportability - Design for Maintenance - Poor maintainability aspects - Design for reliability. UNIT II CONDITION BASED MAINTENANCE 7

Condition based monitoring of equipment and systems -condition monitoring techniques such as a) Vibration analysis, b) Ultrasonic detection techniques, c) Thermography, d) Oil and lubricant analysis, e) Motor condition monitoring (MCM) - Shaft alignments through laser - Vibration instruments -Outline on Thermography UNIT III MAINTENANCE TECHNIQUES SUCH AS RELIABILITY CENTRED MAINTENANCE(RCM),TOTAL PRODUCTIVE AINTENANCE(TPM)& CMMS 10

Reliability centred Maintenance-Failure Mode and Effect Analysis-Root cause Analysislogic tree analysis-Criticality matrix - Total Productive Maintenance, Overall Equipment Effectiveness-Lean manufacturing- TPM and TPO- Relationship between OEE and world-class Maintenance- Ladder of Maintenance improvement- Computerized Maintenance management system in a business scenario- data acquisition for effective management of CMMS. UNIT IV ASSET PLANNING AND SCHEDULING OF ACTIVITIES IN MAINTENANCE

10

Asset and spare part management, - Conventional spare Parts management techniques such as Economic Order Quantity, two bin systems - Latest trends in monitoring through bar codes, mobile computer and wireless data transmissions -. Different aspects of planning and scheduling of Maintenance, such as shutdowns- Critical aspects of both routine and shut down Maintenance -. bar charts - PERT network during shut down -Man power Training and utilization of skilled manpower - Sequencing of activities. UNIT V SAFETY AND OTHER ASPECTS OF MAINTENANCE FUNCTIONS

Safety Engineering. - Hazard analysis -General rules and guidelines in safety and hazard prevention - Analytical tools - Hazard analysis- Fault Tree Analysis - Sneak

Circuit analysis - Integrated approach to Maintenance- Statistical distributions such as normal, gamma and Weibull in Maintenance- Maintenance effectiveness.

También podría gustarte

- M.saravana Kumar Updated Co StatementDocumento5 páginasM.saravana Kumar Updated Co StatementM.Saravana Kumar..M.EAún no hay calificaciones

- Strength of Materials - Unit 2 - Week 1Documento3 páginasStrength of Materials - Unit 2 - Week 1M.Saravana Kumar..M.EAún no hay calificaciones

- 2 & 3 - Institutional Vision, Mision, PO, PSO, PEODocumento4 páginas2 & 3 - Institutional Vision, Mision, PO, PSO, PEOM.Saravana Kumar..M.EAún no hay calificaciones

- Effective Engineering Teaching in PracticeDocumento4 páginasEffective Engineering Teaching in PracticeM.Saravana Kumar..M.EAún no hay calificaciones

- Engineering Thermodynamics - Unit 2 - Week 1 - SI Unit, Definitions & ConceptsDocumento4 páginasEngineering Thermodynamics - Unit 2 - Week 1 - SI Unit, Definitions & ConceptsM.Saravana Kumar..M.EAún no hay calificaciones

- Solution - Assignment - Laws of Thermodynamics - 3rd WeekDocumento5 páginasSolution - Assignment - Laws of Thermodynamics - 3rd WeekM.Saravana Kumar..M.EAún no hay calificaciones

- IAT2 Key PDFDocumento8 páginasIAT2 Key PDFM.Saravana Kumar..M.EAún no hay calificaciones

- Details Dr. V KhalkarDocumento1 páginaDetails Dr. V KhalkarM.Saravana Kumar..M.EAún no hay calificaciones

- NDT Syallbus Anna University ScribdDocumento2 páginasNDT Syallbus Anna University ScribdM.Saravana Kumar..M.EAún no hay calificaciones

- Engineering Thermodynamics - Unit 4 - Week 3 - Properties of Pure SubstancesDocumento4 páginasEngineering Thermodynamics - Unit 4 - Week 3 - Properties of Pure SubstancesM.Saravana Kumar..M.EAún no hay calificaciones

- Design Subject SyallbusDocumento8 páginasDesign Subject SyallbusM.Saravana Kumar..M.EAún no hay calificaciones

- Engineering Thermodynamics - Unit 6 - Week 5 - First Law of Thermodynamics For Non-Flow ProcessesDocumento4 páginasEngineering Thermodynamics - Unit 6 - Week 5 - First Law of Thermodynamics For Non-Flow ProcessesM.Saravana Kumar..M.EAún no hay calificaciones

- Latha MathavanDocumento3 páginasLatha MathavanM.Saravana Kumar..M.EAún no hay calificaciones

- Scholar List MechDocumento152 páginasScholar List MechM.Saravana Kumar..M.EAún no hay calificaciones

- Laws of Thermodynamics - Unit 3 - Week 2 PDFDocumento3 páginasLaws of Thermodynamics - Unit 3 - Week 2 PDFM.Saravana Kumar..M.EAún no hay calificaciones

- WEEK 1 SolutionsDocumento5 páginasWEEK 1 SolutionsM.Saravana Kumar..M.EAún no hay calificaciones

- Laws of Thermodynamics - Unit 3 - Week 2Documento3 páginasLaws of Thermodynamics - Unit 3 - Week 2M.Saravana Kumar..M.EAún no hay calificaciones

- Mechanics of Solids - Unit 2 - Week 01 - Introduction To Mechanics of SolidsDocumento5 páginasMechanics of Solids - Unit 2 - Week 01 - Introduction To Mechanics of SolidsM.Saravana Kumar..M.EAún no hay calificaciones

- Laws of Thermodynamics - Unit 5 - Week 4Documento3 páginasLaws of Thermodynamics - Unit 5 - Week 4M.Saravana Kumar..M.EAún no hay calificaciones

- Mechanics of Solids - Unit 5 - Week 4 - Force Displacement Relationship and Introduction To Concept of StressDocumento4 páginasMechanics of Solids - Unit 5 - Week 4 - Force Displacement Relationship and Introduction To Concept of StressM.Saravana Kumar..M.EAún no hay calificaciones

- Engineering Thermodynamics - Unit 3 - Week 2 - SI Unit, Definitions & ConceptsDocumento5 páginasEngineering Thermodynamics - Unit 3 - Week 2 - SI Unit, Definitions & ConceptsM.Saravana Kumar..M.EAún no hay calificaciones

- Strength of Materials - Unit 6 - Week 5Documento3 páginasStrength of Materials - Unit 6 - Week 5M.Saravana Kumar..M.EAún no hay calificaciones

- Strength of Materials - Unit 3 - Week 2Documento4 páginasStrength of Materials - Unit 3 - Week 2M.Saravana Kumar..M.EAún no hay calificaciones

- DTS 06Documento18 páginasDTS 06M.Saravana Kumar..M.EAún no hay calificaciones

- MT-1 Full NotesDocumento56 páginasMT-1 Full NotesM.Saravana Kumar..M.EAún no hay calificaciones

- Abrasive Jet MachiningDocumento12 páginasAbrasive Jet MachiningM.Saravana Kumar..M.EAún no hay calificaciones

- Anna University Manufacturing Technology1 Previous Year Question Papers CollectionDocumento20 páginasAnna University Manufacturing Technology1 Previous Year Question Papers CollectioneurekaAún no hay calificaciones

- Syllabi GATE2017 PDFDocumento73 páginasSyllabi GATE2017 PDFAnkit Kumar AJAún no hay calificaciones

- ME-1 Section MCQ and NAT Type Exam ResultsDocumento2 páginasME-1 Section MCQ and NAT Type Exam ResultsM.Saravana Kumar..M.EAún no hay calificaciones

- Gate PlanDocumento1 páginaGate PlanM.Saravana Kumar..M.EAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2099)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (119)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- AE420 Chpt8 Fall 2021Documento20 páginasAE420 Chpt8 Fall 2021LIU HengxuAún no hay calificaciones

- Soil Structure Interaction Method ComparisonDocumento50 páginasSoil Structure Interaction Method ComparisonManuel Alberto Sepulveda PintoAún no hay calificaciones

- Driving Innovation in Manufacturing: Morfeo v1.1 FeaturesDocumento2 páginasDriving Innovation in Manufacturing: Morfeo v1.1 FeaturesHenrique Rodrigues OliveiraAún no hay calificaciones

- Developing A Risk Assessment Model For Trenchless Technology-Box Jacking TechniqueDocumento12 páginasDeveloping A Risk Assessment Model For Trenchless Technology-Box Jacking TechniqueHồng Phương LêAún no hay calificaciones

- NTU Education (BRC Course Content) PDFDocumento15 páginasNTU Education (BRC Course Content) PDFpearlynAún no hay calificaciones

- Matlab Simulation of DrivesDocumento24 páginasMatlab Simulation of DrivessabrahimaAún no hay calificaciones

- Computer Aided Structural AnalysisDocumento149 páginasComputer Aided Structural AnalysisDeepak PandeyAún no hay calificaciones

- Dynamic Pressure For Circular Silos Under Seismic ForceDocumento10 páginasDynamic Pressure For Circular Silos Under Seismic Forcesebastian9033Aún no hay calificaciones

- FEM-2 Marks and 16 Marks Ans PDFDocumento34 páginasFEM-2 Marks and 16 Marks Ans PDFKarthik SubramaniAún no hay calificaciones

- SpecSys6 Base FEA ReportDocumento3 páginasSpecSys6 Base FEA ReportnikolaiffbAún no hay calificaciones

- Getting Started With ABAQUSDocumento177 páginasGetting Started With ABAQUSutbachAún no hay calificaciones

- Time Integration Fundamentals For ClassDocumento50 páginasTime Integration Fundamentals For ClasscucrasAún no hay calificaciones

- B.Tech Mechanical Engineering Course Material on Finite Element AnalysisDocumento160 páginasB.Tech Mechanical Engineering Course Material on Finite Element AnalysisRichie RichardAún no hay calificaciones

- Reconstruction of Electrical Impedance Tomography Using Fish School Search, Non-Blind Search and Genetic AlgorithmDocumento16 páginasReconstruction of Electrical Impedance Tomography Using Fish School Search, Non-Blind Search and Genetic AlgorithmRevanth VennuAún no hay calificaciones

- NozzlePROv12 1flyerDocumento2 páginasNozzlePROv12 1flyerdelitesoftAún no hay calificaciones

- Stability ChecksDocumento5 páginasStability Checksshobhit mohtaAún no hay calificaciones

- Verification of Numerical and Analytical Methods of Analysis of TunnelDocumento6 páginasVerification of Numerical and Analytical Methods of Analysis of TunnelAhmedAún no hay calificaciones

- (Stefanos Syllignakis, Petr Vosynek) Finite Elemen (B-Ok - Org) .Documento135 páginas(Stefanos Syllignakis, Petr Vosynek) Finite Elemen (B-Ok - Org) .Samagassi Souleymane100% (1)

- ANSYS Mechanical APDL Thermal Analysis GuideDocumento100 páginasANSYS Mechanical APDL Thermal Analysis GuideMarcelo Amaral100% (1)

- Product Development Process For Suspension Component Aided by Numerical SimulationsDocumento9 páginasProduct Development Process For Suspension Component Aided by Numerical SimulationsLuis Alberto Garrido MendozaAún no hay calificaciones

- (Conference Proceedings of the Society for Experimental Mechanics Series) Shamim Pakzad - Dynamics of Civil Structures, Volume 2_ Proceedings of the 37th IMAC, A Conference and Exposition on StructuraDocumento273 páginas(Conference Proceedings of the Society for Experimental Mechanics Series) Shamim Pakzad - Dynamics of Civil Structures, Volume 2_ Proceedings of the 37th IMAC, A Conference and Exposition on StructuraJEMAYERAún no hay calificaciones

- Dynamic Responses of Marine RisersPipesDocumento9 páginasDynamic Responses of Marine RisersPipesRajeuv GovindanAún no hay calificaciones

- M.Tech Scheme and Syllabus for Mechanical EngineeringDocumento72 páginasM.Tech Scheme and Syllabus for Mechanical EngineeringNithul DasAún no hay calificaciones

- Parker - PTFE Lip SealsDocumento170 páginasParker - PTFE Lip Sealspughreader1100% (1)

- The Road To Virtual Vehicle Prototyping - New CAE-models PDFDocumento98 páginasThe Road To Virtual Vehicle Prototyping - New CAE-models PDFSamuel HollisAún no hay calificaciones

- Standard Specifications For Concrete Structures 2012Documento4 páginasStandard Specifications For Concrete Structures 2012Tú TrầnAún no hay calificaciones

- Chung2006 PDFDocumento9 páginasChung2006 PDFNguyen Tran HieuAún no hay calificaciones

- FEM-BEM Coupling PDFDocumento18 páginasFEM-BEM Coupling PDFhasanAún no hay calificaciones

- Highly Skewed Bridge Design, Analysis, and PerformanceDocumento120 páginasHighly Skewed Bridge Design, Analysis, and PerformanceAccrete GoogleAún no hay calificaciones

- 127 3 806 PDFDocumento5 páginas127 3 806 PDFMárcioBarbozaAún no hay calificaciones