Documentos de Académico

Documentos de Profesional

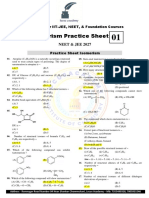

Documentos de Cultura

Lecture 1

Cargado por

Sujan BhattaraiDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Lecture 1

Cargado por

Sujan BhattaraiCopyright:

Formatos disponibles

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

1

Concrete Technology

HYDRAULI C CEMENTS

AND THEI R PROPERTI ES

Concrete Technology

2

Concr et e Basi cs

Port land cement , wat er, sand, and coarse

aggregat e are proport ioned and mixed t o

produce concret e suit ed t o t he part icular

j ob for which it is int ended.

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

2

Concrete Technology

3

Def i ni t i ons

Cement Powder

Cement + Wat er Cement Past e

Cement Past e + Fine Aggregat e (FA) Mort ar

Mort ar + Coarse Aggregat e (CA) Concret e

Concrete Technology

4

Concret e is init ially plast ic, allows

one t o mold int o desired shape.

Chemical react ion (hydrat ion) and

past e set of concret e - producing

st rengt h and st iffness.

Def i ni t i ons

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

3

Concrete Technology

5

Cement is a pulverized mat erial t hat

develops binding forces due t o a react ion

wit h wat er

Hydraulic Cement St able under wat er

Nonhydraulic Cement Product s of

hydrat ion are not resist ant t o wat er (i.e.

limest one)

Cement

Concrete Technology

6

Cement s t hat harden by react ion wit h

wat er and form a wat er-resist ant

product .

Por t l and Cement ( P.C.)

Port land cement is a hydraulic cement

capable of set t ing, hardening and

remains st able under wat er. I t is

composed of calcium silicat es and some

amount of gypsum.

Hydr aul i c Cement s

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

4

Concrete Technology

7

Cement Chemi st r y

Short Hand Not at ion

C (CaO, calcium oxide)

A (Al

2

O

3

, alumina)

S (SiO

2

, silica)

S (SO

3

, sulfat e)

H (H

2

0, wat er)

React ive Compounds

C

3

S (t ricalcium silicat e)

C

2

S (dicalcium silicat e)

C

3

A (t ricalcium aluminat e)

CSH

2

(gypsm)

C

4

AF (t et ra-calcium

alumino ferrit e)

I n cement chemist ry, t he individual oxides and clincker

compounds are expressed by t heir abbreviat ions

Concrete Technology

8

C

3

S 3CaO . SiO

2

C

2

S 2CaO . SiO

2

C

3

A 3CaO . Al

2

O

3

C

4

AF 4CaO.Al

2

O

3

.Fe

2

O

3

C

4

A

3

S 4CaO.3Al

2

O

3

.SO

3

=

=

=

=

ferrite aluminate m Tetracaciu AF C

aluminate Tricalcium A C

Silicate Dicalcium S C

Silicate Tricalcium S C

4

3

2

3

Compounds of Por t l and Cement

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

5

Concrete Technology

9

Hydr at i on React i ons

2C

3

S + 6H C-S-H + 3CH (120 cal/ g)

2C

2

S + 4H C-S-H + CH (62 cal/ g)

C

3

A + 3CSH

2

+ 26H C

6

AS

3

H

32

(300 cal/ g)

2C

3

A + C

6

AS

3

H

32

+ 4H 3C

4

ASH

12

C

4

AF + 10H + 2CH C

6

AFH

12

C

3

S

2

H

3

(C-S-H gel)

CH (calcium hydroxide)

C

6

AS

3

H

32

(et t ringit e)

C

4

ASH

12

(monosulfat e)

Cement Chemi st r y

Concrete Technology

Hydr at i on of Por t l and Cement

Cal/g 120 3CH H S C 6H S 2C

3

+ + +

Cal/g 2 6 CH H S C 4H S 2C

2

+ + +

e) (Ettringit H S A C H S C AF, C A, C

4 3

Compound Composition Morphology Amount (% Vol.)

C-S-H

Variable

C/S ~ 1.5 to 2

Poorly crystalline

High surface area: higher

bonding energy

50 60%

CH

Ca(OH)

2

Large hexagonal crystals,

low surface area, and poor

bonding energy

20 25%

C-A-S-H

C

6

AS

3

H

32

Ettringite

C

4

ASH

12-18

Monosulfate

Long, well crystallized

needles

Hexagonal small

crystals

15 20%

Hydrat ion: React i on wi t h wat er

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

6

Concrete Technology

11

Calcium silicat es are t he primary const it uent s

of port land cement .

Raw mat erial for P.C. Calcium & Silica

Calcium: Limest one, chalk, et c (CaO+ CO

2

)

Silica: Clays and shales (SiO

2

+ Al

2

O

3

+ Fe

2

O

3

+ H

2

O)

Clay 1/3

Calcium 2/3

ment heat treat

the before d homogenize

well be should mix Raw

Manuf act ur i ng Pr ocess

Concrete Technology

12

Manuf act ur i ng Pr ocess

Aer i al Phot o of a Cement Manuf act ur i ng Pl ant

(Colorado)

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

7

Concrete Technology

13

Manuf act ur i ng Pr ocess

Raw Mi l l Feed

Concrete Technology

14

Manuf act ur i ng Pr ocess

Ki l n Li ne Over vi ew

This image cannot cur r ently be display ed.

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

8

Concrete Technology

15

T = 1400C

Raw

(Limestone

+Clay)

Clinker+Gypsum

Grind

Portland Cement

Grind Mill

( )

( )

( )

( ) AF C

A C

S C

S C

O .Fe O 4CaO.Al

O 3CaO.Al

2CaO.SiO

3CaO.SiO

O H O Fe O Al SiO Clay

CO CaO Limestone

4

3

2

3

3 2 3 2

3 2

2

2

2 3 2 3 2 2

2

)

`

+ + +

+

Manuf act ur i ng Pr ocess

Rotary Kiln

Concrete Technology

16

React ivit y of cement wit h wat er is

a funct ion of it s fineness.

Generally, t he finer a cement , t he

more rapidly it will react , and t he

st rengt h development will be

enhanced (expensive).

Fi neness

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

9

Concrete Technology

17

Types of Por t l and Cement

ASTM C 150, St andard Specificat ions for

Port land Cement

Type I : General purpose. For use when t he special

propert ies specified for any ot her t ypes are not required.

Type I I : For general use, more specially when moderat e

sulfat e resist ance or moderat e heat of hydrat ion is desired.

Type I I I : For use when high early st rengt h is desired.

(limit t he C

3

A cont ent of t he cement t o maximum 15%)

Type I V: For use when low heat of hydrat ion is desired.

Type V: For use when high sulfat e resist ance is desired.

(Maximum limit of 5% on C

3

A)

Concrete Technology

18

I n classic research from over sevent y years

ago Bouge and Lerch* found t hat of t he four

port land cement phases only C

3

S and C

2

S

developed appreciable compressive st rengt h

when pure samples of each were hydrat ed.

The compressive st rengt h found by Bogue and

Lerch* * are plot t ed in t he next Fig. as a

funct ion of age. Compressive st rengt hs of C

3

A

and C

4

AF, hydrat ed alone A and have not

been plot t ed explicit ly.

Ef f ect s of Chemi cal Composi t i on of Por t l and

Cement s on St r engt h

* T.C. Powers, The Non-Evaporable Wat er Cont ent of Port land Cement Past e: I t s Significance for

Concret e Research and I t s Met hod of Det erminat ion, ASTM Bullet in, No. 158, (May 1949) pp. 68-76.

* * R H Bouge and W Lerch I ndust rial Engineering, Chem. 26 873 (1934)

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

10

Concrete Technology

The compressive st rengt h found by Bouge and Lerch* * for hydrat ed samples of t he

pure cement phases C

3

S and C

2

S are plot t ed as a funct ion of age. The compressive

st rengt hs of C

3

A and C

4

AF, hydrat ed along and wit h gypsum, fall wit hin t he cross-

hat ched region labeled A and have not been plot t ed explicit ly. The t ime scale is

linear. The t ime scale is logarit hmic, which has t he effect of expanding t he early

ages, and t his shows t he differences bet ween st rengt h gain of C

3

S and C

2

S past es.

Ef f ect s of Chemi cal Composi t i on of Por t l and

Cement s on St r engt h

Concrete Technology

20

The St r uct ur e of Concr et e

The t ype, amount , size, shape & dist ribut ion of

phases present in a solid mat erial const it ut e it s

st ruct ure.

Concret e Consist s of aggregat es, past e and voids.

The macrost ruct ure of concret e is shown below:

A polished sect ion

of concret e

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

11

Concrete Technology

21

The st ruct ure of t he aggregat es in

concret e is import ant but it can be

charact erized as a macrost ruct ure

which is visible t o t he human eye.

The limit of resolut ion of t he unaided

human eye is approximat ely 1/ 5

millimet er which is 200 microns.

The Mi cr ost r uct ur e of Por t l and Cement Concr et e

Concrete Technology

22

The use of bot h light and elect ron

microscopes allows t he st udy of t he

microst ruct ure of concret e at t he

submicron level.

The microst ruct ure of concret e can

be divided int o regions:

Cement Past e

Transit ion Zone bet ween Aggregat e

and Cement past e

The Mi cr ost r uct ur e of Por t l and Cement Concr et e

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

12

Concrete Technology

23

St r uct ur e of un-damaged Concr et e

Macr ost r uct ur e

Aggregat es (CA, FA)

Hydrat ed cement past e (hcp)

Ent rapped air voids

Mi cr ost r uct ur e

Hydrat ed cement past e

(Hydrat ion product s: C-S-H, et t riginit e;

monosulfat e; porosit y: gel, capillary pores

ent rained/ ent rapped air voids)

Transit ion zone ( TZ)

Concrete Technology

24

Mi cr ost r uct ur e of Concr et e

( Hydr at i on pr oduct s)

CH

C-S-H

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

13

Concrete Technology

25

Et t r i ngi t e

Mi cr ost r uct ur e of Concr et e

( Hydr at i on pr oduct s)

Concrete Technology

26

Charact erist ics of t he TZ

Large cryst als of Ett ringit e and

CH wit h preferred orient at ion

Porous St ruct ure

Mi cr ost r uct ur e of Concr et e

( Tr ansi t i on Zone)

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

14

Concrete Technology

27

One way t o view cement past e is t o

consider t he hydrat ion of one grain of

cement .

The part ial hydrat ion of one grain of

cement is schemat ically represent ed in t he

next slide.

There are many det ails in t his process t hat

are not yet underst ood, but t here is

sufficient informat ion available t o allow a

consist ent ment al pict ure t o be considered.

The Mi cr ost r uct ur e of Por t l and Cement Concr et e

Concrete Technology

28

The Mi cr ost r uct ur e of Por t l and Cement Concr et e

The hydrat ion product s

formed inside and out side

t he cement grain are

schemat ically represent ed.

The mult iple nat ure of t he

cement grain is neglect ed

and assumed t o be a

single phase t hat shows

t wo t ypes of product s.

P1 refers t o t he primary

port landit e which appears

early in t he originally

wat er-filled space.

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

15

Concrete Technology

29

The hydrat ion of a number of cement grains

is schemat ically represent ed in t he next slide

at different degrees of hydrat ion.

The fresh past e (i.e., t he init ial combinat ion

of wat er and cement grains) is drawn t o

approximat ely represent t he 0.4

wat er/ cement rat io, and t hus t here are not

enough hydrat ion product s t o fill t he

originally-wat er-filled space and a capillary

porosit y remains in t he final microst ruct ure.

The Mi cr ost r uct ur e of Por t l and

Cement Past e

Concrete Technology

30

A schemat ic represent at ion of t he hydrat ion of a number of cement grains. The mult iphase

nat ure t he cement grains has been neglect ed as t his is like t he hydrat ion of t ricalcium silicat e

alone. ( a) Fresh past e of wat er-t o cement rat ion of 0.4 is shown cement grains in t he

originally wat er-filled space. ( b) Aft er 33% hydrat ion, t he cement grains now have inner

hydrat ion regions and out er product s which form a columnar zone around each grain. ( c)

Aft er 67% hydrat ion, t he un-hydrat ed cores are clearly surrounded by t hick rims of inner

hydrat ion product s and t he columnar zone of out er product s is growing on t he surface of

each grain. The primary port landit e, P1, is shown wit h t he dendrit e morphology. ( d) At

100% hydrat ion, t he un-hydrat ed cement has been consumed but t he shape of t he original

cement grains can be dist inguished if t he inner product differs from t he columnar zone of

out er product s. The int ergrowt h of t he columnar zones from t wo different grains is shown

at several point s, but t his would be larger at low wat er/ cement rat ions.

Originally water-filled space = clear, unhydrated cement = , inner hydration products = ,

outer hydration products = , & primary portlandite = P1.

///

The Mi cr ost r uct ur e of Por t l and Cement Past e

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

16

Concrete Technology

31

The originally-wat er-filled space wit hin t he

cement past e becomes t he capillary pores

which act as st ress concent rat ions and

reduce t he st rengt h significant ly.

The st rengt h of most engineering mat erials is

increased wit h a decrease in porosit y, and by

cont rolling t he wat er/ cement rat io t he

engineer is assured t hat t he basic porosit y of

t he past e is also cont rolled. That is not t o

say t he ot her sources of porosit y will not

occur, but at least t he cement past e will

have a given porosit y.

Capi l l ar y Por osi t y

Concrete Technology

32

Figure below shows a graphical represent at ion of t he

relat ive volumes of hydrat ion product s during hydrat ion.

Graphical represent at ion of t he relat ive volumes of hydrat ion product s

during hydrat ion. The init ial w/ c is 0.5, and one unit of cement is shown t o

produce t wo volumes of hydrat ion product s.

Capi l l ar y Por osi t y

Concrete Technology

Hydr aul i c Cement s

Professor Kamran M. Nemati

Spring Quarter 2012

17

Concrete Technology

33

I f cement past e specimens are prepared

wit h a range of w/ c rat ios it is apparent

t hat t he densit y of high w/ c samples is

much lower t han low w/ c samples.

This is illust rat ed in t he next slide in a

present at ion originally given by T.C.

Powers* .

* T.C. Powers, The Non-Evaporable Wat er Cont ent of Port land Cement Past e: I t s Significance for

Concret e Research and I t s Met hod of Det erminat ion, ASTM Bul., No. 158, (May 1949) pp. 68-76.

Capi l l ar y Por osi t y Over a Range of W/ C Rat i os

Concrete Technology

34

Composit ion of Cement Past e at different st ages of hydrat ion. The

percent age indicat ed applied only t o past e wit h enough wat er-filled space

t o accommodat e t he product s at t he degree of hydrat ion indicat ed.

Capi l l ar y Por osi t y Over a Range of W/ C Rat i os

También podría gustarte

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Science: Quarter 2 - : Carbon Compounds General Classes and Its UsesDocumento22 páginasScience: Quarter 2 - : Carbon Compounds General Classes and Its UsesPsycho Kpop OtakuAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Objective: What Are Proteins?Documento7 páginasObjective: What Are Proteins?MusdalifahAún no hay calificaciones

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5795)

- 04 Sanchez - en 12620 Aggregates For ConcreteDocumento42 páginas04 Sanchez - en 12620 Aggregates For ConcreteMC KongAún no hay calificaciones

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- PS em Bit BankDocumento86 páginasPS em Bit BankMadhu Mahesh RajAún no hay calificaciones

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- Chemistry The Central Science 1Documento4 páginasChemistry The Central Science 1Ariane Caranto100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Msds Cleaning SolventDocumento4 páginasMsds Cleaning SolventMoineeAún no hay calificaciones

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- STEM Gen Chem 1 Q1 M2Documento20 páginasSTEM Gen Chem 1 Q1 M2Roland AgraAún no hay calificaciones

- Aspirin and SoapDocumento4 páginasAspirin and SoapyeeeyyyAún no hay calificaciones

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Bap - Bwro SystemDocumento55 páginasBap - Bwro SystemGloria HamiltonAún no hay calificaciones

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- 2019 HSC Chemistry MGDocumento21 páginas2019 HSC Chemistry MGazizi5916Aún no hay calificaciones

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Importance of BuffersDocumento7 páginasImportance of BuffersAsad AzizAún no hay calificaciones

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Class10 Science Notes Chapter1 PDFDocumento6 páginasClass10 Science Notes Chapter1 PDFdineshhissarAún no hay calificaciones

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- FINAL REPORT v1 3279Documento114 páginasFINAL REPORT v1 3279MARIANA ROCCA HERRERAAún no hay calificaciones

- Organic ConceptsDocumento83 páginasOrganic ConceptsAlisha Roy ChoudharyAún no hay calificaciones

- sp21 234 r10 Extra Problems Organometallics KeyDocumento8 páginassp21 234 r10 Extra Problems Organometallics KeySankar AdhikariAún no hay calificaciones

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Hard WaterDocumento11 páginasHard WaterJonathan OtadoraAún no hay calificaciones

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Ge Ni U S: Chemical ReactionsDocumento25 páginasGe Ni U S: Chemical ReactionsRouda AljAún no hay calificaciones

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Production of Butadiene From Ethyl AlcoholDocumento2 páginasProduction of Butadiene From Ethyl AlcoholSedef ŞıraAún no hay calificaciones

- Tests To Detect Adulteration in MilkDocumento5 páginasTests To Detect Adulteration in MilkezhilnarasuAún no hay calificaciones

- Chemistry 1 Diagnostic Test (For Printing)Documento4 páginasChemistry 1 Diagnostic Test (For Printing)Jam Uly Gasty100% (4)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- Activated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionDocumento8 páginasActivated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionS Bharadwaj Reddy100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- Assignment 2-VLSI TECHDocumento2 páginasAssignment 2-VLSI TECHSwetha KAún no hay calificaciones

- 03d - Lattice Energi (Uo)Documento21 páginas03d - Lattice Energi (Uo)Oktanio PraviakoAún no hay calificaciones

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Rules For Iupac NomenclatureDocumento8 páginasRules For Iupac NomenclaturexanshahAún no hay calificaciones

- Ranunculus K DeficiencyDocumento4 páginasRanunculus K DeficiencysilviafoteaAún no hay calificaciones

- Isomerism PracticeDocumento2 páginasIsomerism PracticeBarshan BanikAún no hay calificaciones

- Latihan NacecongratulationsDocumento13 páginasLatihan NacecongratulationsPadma Pangreksa75% (4)

- Exe 3Documento29 páginasExe 3AkashGauravAún no hay calificaciones

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- ITW Product Catalog21 PDFDocumento1 páginaITW Product Catalog21 PDFjohnAún no hay calificaciones

- PDF CMG Gem PDF - CompressDocumento2 páginasPDF CMG Gem PDF - CompressFatimah Az ZahraAún no hay calificaciones

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)