Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Propellers - Propulsors

Cargado por

marihomenonDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Propellers - Propulsors

Cargado por

marihomenonCopyright:

Formatos disponibles

[ MARINE / IN DETAIL ]

[ MARINE / IN DETAIL ]

Ship propulsion train efciency sensing

A U T H O R : T i b e r i u M u n t e a n , R e s e a r c h E n g i n e e r, S h i p P r o p u l s i o n Te c h n o l o g y, W r t s i l S h i p Po w e r i n t h e N e t h e r l a n d s

Precise data is critical when making decisions that affect a ships operations. This is especially true in matters relating to propulsion systems since docking may be required. For maximum efciency, therefore, accurate sensing is essential.

When comparing the energy present in the fuel burnt in the diesel engine with the output energy of the ship itself, approximately 70% is lost. Heat losses in the diesel engine are the main contributors to these energy losses, but there are also losses due to fouling and the ship environment. In practice these losses vary during the operational period. Propellers and ship hulls get fouled. The ship may be operated in adverse conditions with added resistance from waves and wind. The counteractions to minimize these non heat-related losses can be grouped into three categories: Ship route planning and navigation Ship and propeller cleaning scheduling Propulsion device setting optimization. To make meaningful gains in efciency, basically all three need optimization methods. For the rst two, the operator has to make a trade-off between the costs of corrective actions against the cost of fuel. In the operational decision process, the owner needs precise information on the gains to be achieved by alternative routing or docking a ship in order to clean the hull or polish the propeller. The propulsion device setting optimization is an integrated part of the propulsion control. An automatic search is done for the optimal rotational speed and pitch in order to minimize fuel consumption, while keeping the ships speed constant. The precise information from which to make operational decisions requires accurate sensors, as well as adequate signal processing. Contrary to the heat losses, the achievable gains are only in the magnitude of up to 5% of the energy in the fuel burnt by the diesel engine. This achievable gain sets high requirements for the accuracy of the sensors and the robustness of the signal processing. Many attempts have been made in the past to introduce performance monitoring systems. Lessons learnt from these former systems are:

Fig. 1 A Wrtsil Services propeller polishing team at work.

34

in detail

WRTSIL TECHNICAL JOURNAL 02.2008

The sensors must be sufciently accurate and reliable. There is a need to distinguish between propeller efciency and hull efciency. The human factor is very important; a performance system should not result in an extra workload, and the use of the system must be intuitive with high system integrity. For this, data reduction techniques are needed. Precise information enables the owner, for instance, to optimize the ships docking periods for hull cleaning and propeller polishing. Another possibility is to mobilize a Wrtsil propeller polishing team, as shown in Figure 1. Dening propulsion train efciencies In general terms, efciency is dened as the ratio between something that you put in and something that you get out. In shipping terms, that something that you put in is the heat input and that something that you get out is the effective propulsive power.

In mathematical terms this ratio reads: (1) where, the term R(1 + f) represents the resistive force with f as the hull factor, u represents the speed-through-water (STW), and W represents the heat input. Calculating (overall) ship efciency with high accuracy represents a challenging task. For this purpose all three components, namely, resistance, speed-throughwater, and heat input must be accurately measured. While accurate speed-throughwater and accurate heat input estimations are achievable using the hardware and the knowledge already available, accurate resistance force is more difcult to measure. Given the accuracy levels, the resistive force has to incorporate the effects of the waves and wind. However, by monitoring the ship while sailing in the same wave and wind conditions, one can express overall ship efciency independently of the resistive force.

Another way of estimating overall ship efciency is by assessing the efciencies of the components of the ships propulsion train. In Figure 2 we depict in general terms the main components of the drive train, with the corresponding efciencies. The ships overall efciency is the product of the block efciencies, as per the following: (2) The propeller efciency is calculated by using the following formula: (3) where, T is thrust, ua is advance velocity, Q is torque, and n is propeller angular velocity. The advance velocity is proportional to the speed-through-water, as follows: (4)

p

Air Fuel Diesel engine BHP Gear box & clutches SHP Shaft bearings DHP Torque Propeller RPM THP Thrust Ship hull STW EHP STW Resistive force Heat input

eng transm1 transm2

Shaftgenerator kVA

prop

hull

ship

Fig. 2 The main components of the propulsion drive train. The input and output of each of the components are indicated, as well as their corresponding efciency.

in detail 35

[ MARINE / IN DETAIL ]

[ MARINE / IN DETAIL ]

by w denoting the wake fraction number. The efciency of the ship hull is calculated by the following formula: (5) Where t represents the thrust deduction number. By combining the propeller efciency and the hull efciency, we can obtain the total propulsive efciency, as follows: (6) Where TE represents the effective thrust that is acting on the hull. The numerator is called the effective power and the denominator is called the delivered power. When assessing propeller efciency, direct measurements on the thrust, advance velocity, torque, and propeller angular velocity are needed. The rst problem related to any propeller efciency calculation is that the advance velocity, or the wake fraction number, can not be measured directly onboard ship. The second problem is that the thrust, torque and propeller angular velocity measurements have to be very accurate in order to full the requirements specied earlier. Sensors and signal processing When considering an achievable efciency gain in the order of 5%, it becomes clear that the accuracy requirements for the sensors and signal processing algorithms are demanding. In this section we give a brief explanation of the sensors and what is required of them when making propeller and overall ship efciency calculations. The means to estimate the accurate speed-through-water and the advance velocity, are also presented. Thrust, torque, and rpm measurements Thrust, torque and propeller angular velocity are the only ship variables involved in the efciency formula that can be directly measured onboard the ship. However, the direct measurements are challenging due to the accuracy demands. Propeller torque and angular velocity are the most facile variables to measure. 36

Propeller torque has been measured for decades by using strain-gauge techniques. The strain-gauges are placed directly on the propeller shaft, and measure the shaft elongation due to forces and moments. The small deformation of the sensor is translated into voltage changes. The voltage changes are then amplied in special electronic circuitries and the micro-strain (elongation) is determined. The typical deformation of a propeller shaft due to torque is about 330 micro-strains. The strain-gauges, with current technologies, are able to measure deformations of 1.5 micro-strains, with long-term stability, resulting in 0.5% accuracy for propeller torque measurement. The thrust produced by the propeller induces a deformation in the shaft of about 35 micro-strains. Measured by the strain-gauges, this means a 4% long-term accuracy. Given the achievable propeller efciency gain, the accuracy of the thrust sensor is far from that needed. Alternatives to direct measurements by straingauges are needed. Wrtsils Propulsion Technology research group has two approaches in dealing with this problem: Use of light-based thrust sensor to measure the small elongation, see Figure 3. Use of indirect measurements by strain-gauging at the thrust bearing support combined with an appropriate signal processing method.

Fuel ow sensor When overall ship efciency is being calculated, an accurate estimation of the heat input is needed. The heat input can be estimated based mainly on fuel (mass) ow measurements and fuel caloric values. Measuring the fuel mass ow for overall ship efciency purposes requires very accurate sensors. Due to re-circulation, the sensors have to be mounted on both the supply line and the return line. Furthermore, the sensors must be able to measure accurately without being affected by the existing pressure pulses. Speed-through-water sensor Speed-through-water (ship speed) is measured onboard most of the ships in service nowadays by Doppler Logs. Nevertheless, research conducted in the Wrtsil Propulsion Technology unit has indicated that the accuracy of the Doppler Logs is far from that indicated by the producers. From the analysis of direct measurements we concluded that speedthrough-water and speed-over-ground by Doppler Log have inaccuracy levels as high as 0.65% on average, when compared with the data from the Differential GPS (DGPS), while the inaccuracy level given by the producers is about 0.2%. When analyzing the speed-through-water and -over-ground in transversal direction in a ship coordinate system, we get inaccuracies of up to 50%. Wrtsils Propulsion Technology has developed a mathematical algorithm that fuses the data from the Doppler Log, DGPS, Gyrocompass, Echo-sounder, Anemometer, and Ships Roll to obtain improved speedthrough-water and speed-over-ground. The mathematical algorithm, together with the support hardware is called the speedthrough-water virtual sensor. See Figure 4 for the general scheme of the algorithm. In Figures 5 and 6 one example of an improved speed-through-water measurement in ship longitudinal and transversal direction is presented. The measurements were performed within the Ship Sense European Project onboard the SeaFrance Rodin Ro-Ro ferry. The differences between the measured STW by Doppler Log and estimated by Wrtsils virtual sensor are about 0.7% for the longitudinal component. In transversal direction the differences are usually about 40%, but higher differences are often encountered.

Fig. 3 Thrust sensor on a calibration test bench.

in detail

WRTSIL TECHNICAL JOURNAL 02.2008

Virtual sensor technology for advance velocity As mentioned earlier, the propeller advance velocity (or the wake fraction) cannot be measured directly onboard ship. The advance velocity is the velocity of water entering the propellers plane. Finding a way to estimate the advance velocity is not a new topic. There have previously been attempts to nd methods to calculate advance velocity (see M. Schmiechen 1991), but the lack of accurate sensors and proper mathematical approach has left the problem unresolved. In Wrtsils Propulsion Technology research department, a method to estimate the advance velocity based on thrust, propeller torque, propeller rpm and engine torque measurements have been developed and patented. The method is still in its development phase and measurements are currently performed for validation purposes. The method is structured around the Ship Dynamics Model (SDM) that is a 1-D model describing the dynamics of the ship. The SDM is inspired by the three-state model developed by M. Blanke et al (2000). In Wrtsils model the ship dynamics are split into four main components, namely, engine dynamics, propeller shaft rotational dynamics, propeller dynamics, and hull dynamics. Each component is assigned with one equation, as per the following: (7)

Input

Algorithm

Output Main results

Doppler Log DGPS Gyrocompass Echosounder Anemo meter Ship Roll

Improved STW Ship Kinematics Improved SOG Ocean current

Extended Kalman Filter

Side results

Bearing Drift Ships pitch Ships roll Wind Depth Improved DGPS

Linear Prediction

Fig. 4 The general procedure for estimating the improved speed-through-water.

Speed-through-water (longitudinal direction)

17.8 Improved STW Measured STW 17.6 speed [kn]

17.4

17.2 27 28 29 30 31 time [min] 32 33 34 35

Fig. 5 The improved speed-through-water in longitudinal direction.

(8) (9)

Speed-through-water (transversal direction)

1

(10)

0

Improved STW Measured STW

The SDM is then used in a parameter identication algorithm to estimate the advance velocity. In Figure 7 we give the structure of the advance velocity virtual sensor indicating the main components. The theoretical results so far indicate that we can estimate the advance velocity with 1.5% inaccuracy. To decrease the inaccuracy level well below 1%, we fuse the advance velocity data with the improved speed-through-water measurements, making use of Formula (4). p

speed [kn]

2 3 27

28

29

30

31 time [min]

32

33

34

35

Fig. 6 The improved speed-through-water in transversal direction.

in detail 37

[ MARINE / IN DETAIL ]

[ MARINE / IN DETAIL ]

The advance velocity virtual sensor is still in its development phase, and direct measurements of thrust, propeller torque, and propeller rpm are needed for verication of the SDM. Outlook eet monitoring system The technological developments presented in the previous section will result in advanced methods for a eet monitoring system. The eet monitoring system is fully integrated within Wrtsils engine and propulsion control systems. Figure 8 gives an overview of the measurement system. The overall ship efciency module represents the primordial monitoring system. This system also represents the most general index of eet performance.

The module combines accurate fuel consumption measurements with accurate speed-through-water estimations. For each ship in the eet, measurements are performed at pre-established time intervals and stored in the system. The recorded measurements are used for trending overall ship efciency in time as a function of weather conditions and operating regimes. Based on the overall ship efciency trends, ship owners will be able to decide the exact time for overall ship inspections. The propeller efciency module represents an advanced propeller monitoring system. The module includes thrust, torque, and propeller rpm sensors, and accurate speed-through-water and advance velocity sub-modules. The most important feature of this module is that

Inputs

Thrust

Algorithm

Outputs

Torque

Ship dynamics model

Main result

Advance velocity

RPM

Side result

Fuel index Parameter identication algorithm Coefcients 1, 2, 1, 2 for open water diagram

Improved STW

Fig. 7 The main components of the advance velocity virtual sensor.

GSM, Internet

Owners home base: detailed analysis for operational management and ship scheduling

Navigational & ship sensors: DGPS: position, forward speed NMEA Doppler or EM log: STW, SOG Gyrocompass : heading Draft forward and aft Rudder angle Prop. Pitch Thrust Prop. RPM Prop. Torque

IPC with software modules

Conning bridge display: Ethernet Intuitive feed-back on fuel Consumption per leg Consumption per mile Consumption per voyage STW & Drift angle

it estimates the propellers efciency onboard ship during regular operating time based on sequences of measurements of the aforementioned variables. Knowing the ships overall efciency and the propeller efciency, we can then estimate the hull efciency by using the relation (2). This implies that the efciency of the diesel engine and the efciency of the mechanical transmission are known. The eet monitoring system is conceived as a modular system in which sensors, hardware modules and software modules are added, changed or updated in time. The system will have an onboard component and an offshore component. The communication between them is done using remote access technologies, such as GSM, ISDN, or GPRS. The onboard component of the eet monitoring system will have a conning bridge display for the crew where information, such as consumption per leg, consumption per voyage, accurate speed-through-water, propeller efciency and all navigation data, are indicated. A direct intuitive feed-back is given to the crew via the conning bridge display and the alarm and monitoring system. This will motivate the crew to operate the ship in a fuel-efcient way. The offshore component is located at the owners home ofce. This component will store the measured data for trending the ships performance in time. The detailed data analysis for operational decisions, such as docking scheduling and mobilizing propeller polishing teams from Wrtsil Services, are also performed here. The eet monitoring system is not conceived as an automatic system that performs tasks normally carried out by human operators. Rather, it is conceived as a tool that provides the ships crew and owner with precise navigation and propulsion data that helps them in decision-making situations. REFERENCES

Fuel consumption

OTT

Blanke M., Lindegaard K.P., Fossen T.I., Dynamic model for thrust generation of marine propellers, Proceedings of the IFAC Conference on Manoeuvring of Marine Craft (MCMC00), Aalborg, Denmark, 2000. Schmiechen M., The method of quasisteady propulsion and its trial onboard of Meteor, Berlin Model Basin, report No 1184, 1991.

Fig. 8 Propulsion performance monitoring system as part of the eet monitoring system.

38

in detail

También podría gustarte

- Production Technology Ch39Documento20 páginasProduction Technology Ch39Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch37Documento3 páginasProduction Technology Ch37Nimmagadda BharathAún no hay calificaciones

- Engineering Metrology and InstrumentationDocumento20 páginasEngineering Metrology and InstrumentationPilar Murguia HurtadoAún no hay calificaciones

- Production Technology Ch36Documento16 páginasProduction Technology Ch36Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch34Documento13 páginasProduction Technology Ch34Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch38Documento33 páginasProduction Technology Ch38Nimmagadda BharathAún no hay calificaciones

- CH 40Documento11 páginasCH 40Lo Siento de VerdadAún no hay calificaciones

- Production Technology Ch31Documento9 páginasProduction Technology Ch31Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch30Documento22 páginasProduction Technology Ch30Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch21Documento16 páginasProduction Technology Ch21Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch33Documento13 páginasProduction Technology Ch33Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch22Documento48 páginasProduction Technology Ch22Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch32Documento10 páginasProduction Technology Ch32Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch19Documento16 páginasProduction Technology Ch19Nimmagadda BharathAún no hay calificaciones

- CH 14Documento29 páginasCH 14Lo Siento de VerdadAún no hay calificaciones

- Production Technology Ch20Documento21 páginasProduction Technology Ch20Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch17Documento33 páginasProduction Technology Ch17Nimmagadda BharathAún no hay calificaciones

- CH 16Documento47 páginasCH 16marihomenonAún no hay calificaciones

- Metal Casting ProcessesDocumento36 páginasMetal Casting Processessamurai7_77Aún no hay calificaciones

- CH 18Documento25 páginasCH 18Nimmagadda BharathAún no hay calificaciones

- CH 15Documento24 páginasCH 15marihomenonAún no hay calificaciones

- Fundamentals of Metal-CastingDocumento15 páginasFundamentals of Metal-Castingsamurai7_77Aún no hay calificaciones

- Production Technology Ch13Documento18 páginasProduction Technology Ch13Nimmagadda BharathAún no hay calificaciones

- Manufacturing Engineering and TechnologyDocumento16 páginasManufacturing Engineering and TechnologyGa Hoang ThienAún no hay calificaciones

- Production Technology Ch07Documento15 páginasProduction Technology Ch07Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch05Documento11 páginasProduction Technology Ch05Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch08Documento6 páginasProduction Technology Ch08Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch09Documento12 páginasProduction Technology Ch09Nimmagadda BharathAún no hay calificaciones

- Production Technology Ch06Documento13 páginasProduction Technology Ch06Nimmagadda Bharath100% (1)

- Production Technology Ch04Documento28 páginasProduction Technology Ch04Nimmagadda BharathAún no hay calificaciones

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2102)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- Definitions of Physical QuantitiesDocumento41 páginasDefinitions of Physical QuantitiesAnonymous QiMB2lBCJLAún no hay calificaciones

- Ascorbic Acid Iodometric TitrationDocumento2 páginasAscorbic Acid Iodometric TitrationÂngelo Jesus100% (8)

- Refrigeration Orrifice Selection Chart PDFDocumento2 páginasRefrigeration Orrifice Selection Chart PDFMacSpares100% (1)

- Annual Report 2017 English PDFDocumento90 páginasAnnual Report 2017 English PDFanand.srajuAún no hay calificaciones

- Imp25 PDFDocumento8 páginasImp25 PDFEng Marwa ElsherifAún no hay calificaciones

- Buckling Considerations in Pile Design: October 2005Documento9 páginasBuckling Considerations in Pile Design: October 2005shashank sharmaAún no hay calificaciones

- Leeson Speedmaster ManualDocumento80 páginasLeeson Speedmaster ManualOrbán Árpád100% (1)

- Breakwater Vertical BarriersDocumento10 páginasBreakwater Vertical BarriersAlbert PranataAún no hay calificaciones

- Guidebook 184Documento1 páginaGuidebook 184Anonymous 7GOnu0xeuCAún no hay calificaciones

- 132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Documento134 páginas132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Sunil S I ShippingAún no hay calificaciones

- Practical Organic BookDocumento148 páginasPractical Organic Bookliang102009Aún no hay calificaciones

- Fire Bird V ATMEGA2560 Hardware Manual 2010-03-26Documento131 páginasFire Bird V ATMEGA2560 Hardware Manual 2010-03-26Bedadipta Bain100% (1)

- CraftDocumento15 páginasCraftImamMukhri100% (1)

- ND BRG GuideDocumento32 páginasND BRG Guidemohammed barghothiAún no hay calificaciones

- Result For: Trucks & CV / 4 Wheeler - LCV / Asia Motor Works / AMW 2518 HLDocumento3 páginasResult For: Trucks & CV / 4 Wheeler - LCV / Asia Motor Works / AMW 2518 HLmanoj_doshi_1Aún no hay calificaciones

- FU2185011009 Description PICO With Bayonet Connector ENDocumento10 páginasFU2185011009 Description PICO With Bayonet Connector ENDonny Wierya pratamaAún no hay calificaciones

- Materials Engineer Test Reviewer-1Documento47 páginasMaterials Engineer Test Reviewer-1Rodrigo Castillo Cacho93% (27)

- Report Torsion TestDocumento27 páginasReport Torsion TestCherif ChokeirAún no hay calificaciones

- Build OptionsDocumento6 páginasBuild OptionsFranciscoAún no hay calificaciones

- Top 100 IT Companies (Rank-Wise List)Documento3 páginasTop 100 IT Companies (Rank-Wise List)Somesh100% (1)

- Sphere FitupDocumento103 páginasSphere FitupAnonymous wxLjBEzAún no hay calificaciones

- 367 Final Fall 2013 AnswersDocumento18 páginas367 Final Fall 2013 AnswersMona Ali100% (1)

- Guide For High Performance CoatingsDocumento34 páginasGuide For High Performance Coatingsro snAún no hay calificaciones

- 64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BDocumento18 páginas64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BChu Thi ThuanAún no hay calificaciones

- @ RhinoDocumento29 páginas@ RhinoHimanshu PatelAún no hay calificaciones

- Mini Project 1Documento16 páginasMini Project 1SadikAhmedAún no hay calificaciones

- Dowex Monosphere 650C (H)Documento2 páginasDowex Monosphere 650C (H)agnarindra01_8550147Aún no hay calificaciones

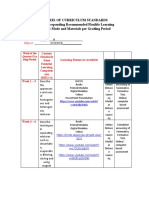

- Matrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodDocumento2 páginasMatrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodNora HerreraAún no hay calificaciones

- MYG Varistors Data SheetDocumento4 páginasMYG Varistors Data SheetPedro Giménez100% (1)

- Welding PDFDocumento6 páginasWelding PDFNavneet ChaubeyAún no hay calificaciones