Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Stainless Steel Fabricating Process

Cargado por

elger02Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Stainless Steel Fabricating Process

Cargado por

elger02Copyright:

Formatos disponibles

Stainless steel fabricating process Keywords Steel Fabricators Surrey, Structural Steel Surrey Summary Steel fabrication is certainly

the base of several projects. Due to the variations with different grades of steel used, there are various methods of fabricating steel. Here in this post, Im bringing a brief description of that. Due to its versatility, there are various techniques of stainless steel fabrication. Its better to review some methods to understand the merits and demerits of stainless steel fabrication. Despite of its high strengths and work hardening rates, stainless steel is malleable enough to bent, folded, machined, welded, deep drawn and spun. Here we are discussing three ways of steel fabrication. Work hardening This is a process of strengthening material through deformation. Relative to other varieties of steel, stainless steel work hardens quickly though the exact rate depends on the grade of alloy. It is also helpful in matching steel grade with a work hardening treatment that is well suited to it. Machining The second one is machining stainless steel. Stainless steel grades 303, 130, 410 and 416 achieve resistance to chipping with alloyed with manganese sulphide that decrease its ductility and corrosion resistance and therefore has limited machining application. But several free machining grades have been developed to address the problem. To overcome the machining limitations, some companies incorporate exclusive steel melting techniques to improve its machinability. These can improve machining efficiency and ensure longer life. Welding And finally we come to welding. Most steel fabricators in surrey weld steel, but degree of efficiency depends on grades. Here are some tips for welding different category of stainless steel. . Austentic: Except for grade 303, most grades of this family are well suited for welding. However this group is susceptible to sensitization and inter granular corrosion on thicker products. For welding thick materials, it is better to use low carbon grades.

Martensitic. These are also good for welding but are prone to cracks. To overcome this, it is advised to pre heat and post heat the material or use supplementary austenitic filler rods. Ferritic stainless steel. Though this is less suitable to welding, some stabilized ferretic grades like 409 may be appropriate for certain projects. Duplex. This set of grades work well with low thermal expansion and is welding efficient. Contact elger engineering for high grade steel fabrication services for domestic and commercial projects.

También podría gustarte

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

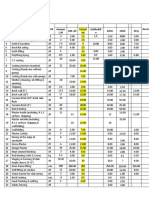

- C Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecDocumento1 páginaC Si MN Thickness (MM) Yield Point (Mpa) Tensile Strength (Mpa) Elongation (%) Bend Test (In Radius) F S Applicable Thickness (MM) SpecEri Dya FadliAún no hay calificaciones

- Newco Stainless Steel Valves Technical Data Sheets PDFDocumento52 páginasNewco Stainless Steel Valves Technical Data Sheets PDFasdfdfAún no hay calificaciones

- Supercast PVCDocumento8 páginasSupercast PVCVenkata RaoAún no hay calificaciones

- En 14700 2005Documento14 páginasEn 14700 2005Adil Malkic75% (4)

- SpecDocumento2 páginasSpecneversigAún no hay calificaciones

- Gantt ChartDocumento6 páginasGantt ChartSanieAún no hay calificaciones

- Ceramic TilesDocumento19 páginasCeramic Tilesbarupatty50% (2)

- Galvanizing ProcessDocumento27 páginasGalvanizing ProcessReymart C. EnteraAún no hay calificaciones

- GlassWool Rolls & BoardsDocumento4 páginasGlassWool Rolls & BoardsSaqib AliAún no hay calificaciones

- Plumbing Terms 4 Questionswith AnswersDocumento6 páginasPlumbing Terms 4 Questionswith AnswersJoshua Padlan EchavarriaAún no hay calificaciones

- Supplementary Cementitious Materials - LiteratureDocumento68 páginasSupplementary Cementitious Materials - LiteraturealulatekAún no hay calificaciones

- NSB - Justification LetterDocumento8 páginasNSB - Justification LetterGlenn Frey LayugAún no hay calificaciones

- Co 34Documento10 páginasCo 34Baskar Srinivas SAún no hay calificaciones

- Partition LayoutDocumento1 páginaPartition LayoutAkosh AchuAún no hay calificaciones

- Pipes - European Standards: EEMUA 144 10 Bar 20 Bar 14 Bar 16 BarDocumento4 páginasPipes - European Standards: EEMUA 144 10 Bar 20 Bar 14 Bar 16 BarjoehodohAún no hay calificaciones

- AASHTO93 Flexible 2018Documento61 páginasAASHTO93 Flexible 2018sultonAún no hay calificaciones

- Acrylonitrile-Acrylonitrile - Butadiene-Styrene Butadiene-Styrene (ABS) Pressure Pipe - (ABS) Pressure PipeDocumento14 páginasAcrylonitrile-Acrylonitrile - Butadiene-Styrene Butadiene-Styrene (ABS) Pressure Pipe - (ABS) Pressure Pipenoodlehead675Aún no hay calificaciones

- ACI 318-19 RequirementsDocumento62 páginasACI 318-19 RequirementsZhiwar oramariAún no hay calificaciones

- S.L Name of Item Unit Remarks Anower L.M Md. Ali Sazzad Vai Salahuddi N Selim Jahid SirajDocumento2 páginasS.L Name of Item Unit Remarks Anower L.M Md. Ali Sazzad Vai Salahuddi N Selim Jahid SirajhelalAún no hay calificaciones

- Bamboo Connections, JointsDocumento23 páginasBamboo Connections, JointsRosalia RestituyoAún no hay calificaciones

- Ettringite ReviewDocumento16 páginasEttringite ReviewThiagogalvaoclAún no hay calificaciones

- SDHP CataloguesDocumento12 páginasSDHP CataloguesPuppala Laxmana PrasadAún no hay calificaciones

- Non Destructive Testing Non Destructive TestingDocumento74 páginasNon Destructive Testing Non Destructive TestingPrasant Kumar BeheraAún no hay calificaciones

- AWWA C200 Steel Water Pipe Standard Improvements 2013 PDFDocumento13 páginasAWWA C200 Steel Water Pipe Standard Improvements 2013 PDFrichard.hislopAún no hay calificaciones

- Flexible Pavements PDF - UK PDFDocumento10 páginasFlexible Pavements PDF - UK PDFShua ChuahAún no hay calificaciones

- Plumber Practice Test 1Documento8 páginasPlumber Practice Test 1docino1417100% (2)

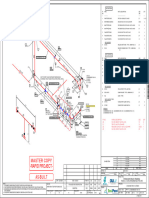

- SA-4820M00350-70541-10_00 - markup drawingDocumento1 páginaSA-4820M00350-70541-10_00 - markup drawingMohd Effiezool YaserAún no hay calificaciones

- PC2S930YPFS - Installation Instruction EnglishDocumento1 páginaPC2S930YPFS - Installation Instruction EnglishSonaina KhanAún no hay calificaciones

- Coating Systems Norsok-Brochure - 0820Documento12 páginasCoating Systems Norsok-Brochure - 0820Mameddurdy OrazalievAún no hay calificaciones

- Montana Thermal Break 120 MM Sliding SeriesDocumento74 páginasMontana Thermal Break 120 MM Sliding SeriesHisham AtraAún no hay calificaciones