Documentos de Académico

Documentos de Profesional

Documentos de Cultura

PT-100 RTD 4 Wire Sensor Rosemount

Cargado por

Victor de JesusDescripción original:

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

PT-100 RTD 4 Wire Sensor Rosemount

Cargado por

Victor de JesusCopyright:

Formatos disponibles

Data Sheet

10/11 8.19 EN

FieldIT Temperature Transmitter, head mounted TH02/TH02-Ex

HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

Level 0: Information

Input Resistance thermometer (2, 3, 4 wire circuit) Thermocouples Resistance remote signalling unit (0...5000 ) Voltages, mV (125...+1200 mV) Output 2 wire technique 4...20 mA, HART signal Electrical isolation (I/O) Measured error 0.1 K Customer-specific linearization 32 tie points Continuous sensor and self-monitoring Parameter saved permanently in EEPROM Monitoring of data integrety every 10 s Wire break monitoring in acc. with NAMUR NE 89 Substitution strategy in case of error (NE 43) Approvals for explosion protection Intrinsically safe II 2 (1) G EEx [ia] ib IIC T6, mount in zone 1 II 3 G EEx n A II T6, mount in zone 2 Input functionality (absolute, differential, average value) EMC acc. to EN 50082-2 and NE 21 Parameterization Device Management Tool: SV401 (SMART VISION) Hand held terminals: 691HT, STT04, HHT275 CoMeter (HART configurator/LC display) 5 years warranty

Excellent long term stability Temperature linear output signal Enhanced self diagnostics

Temperature Transmitter, head mounted TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11 8.19 EN

Technical data

Output

Output signal (temperature linear) 4...20 mA Residual ripple (peak-to-peak) < 0.3 % Current consumption < 3.6 mA Maximum output current 23.6 mA Parameterizable current error signal Underranging 3.6 mA Overranging 22 mA Default value 3.6...23.6 mA Damping t63 = 0...30 s

Sensor short-circuit < 5 (for RTD) Sensor break (temperature/resistance measurement 2, 3, 4 wire) Measuring range 0... 500 > 530 Measuring range 0...5000 > 5.3 k Sensor wire break monitoring in accordance with NAMUR NE 89 Sensor wire break detection 3 wire resistance measurement > 35 4 wire resistance measurement > 3.7 k Input filter 50/60 Hz

Thermocouples

Types B, E, J, K, L, N, R, S, T, U Voltages 125 mV...+ 125 mV 125 mV...+1200 mV Minimum measuring span 2 mV/50 mV Sensor wire break monitoring in accordance with NAMUR NE 89 Pulsed with 1 A outside of the measuring interval Monitoring disconnectible Thermocouple measurement > 5 k Voltage measurement > 5 k Input filter 50/60 Hz Internal reference junction Pt 100, via software switchable (no jumper necessary)

Input

Resistance

Resistance thermometer (IEC 751, JIS, SAMA) n Pt 100/Ni 100 to Pt 1000/Ni 1000; Cu (n = 0.1, 0.2, 0.5, 1, 1.2, 2, 3...10) Min. measuring span 15 K/50 K Resistance 0...500 /0...5000 Min. measuring span 5 /50 Maximum line resistance (Rw) per core 2, 3, 4 wire 7.5 , 10 , 50 Measuring current 300 A

Input element Standard IEC 584 1 Sensor Thermocouple type B Thermocouple type E Thermocouple type J Thermocouple type K Thermocouple type R Thermocouple type S Thermocouple type T Thermocouple type N Thermocouple type L Thermocouple type U Resistance thermometer Pt 100 Resistance thermometer Pt 1000 Resistance thermometer Ni 100 Resistance thermometer Ni 500 mV

Measuring range 250...+1820 C 250...+1000 C 210...+1200 C 250...+1372 C 50...+1768 C 50...+1768 C 200...+ 400 C 200...+1350 C (+482...+3308 F) (418...+1832 F) (346...+2192 F) (418...+2502 F) ( 58...+3215 F) ( 58...+3215 F) (328...+ 752 F) (328...+2462 F)

Min. measuring span 235 C 30 C 37 C 54 C 171 C 193 C 50 C 60 C 36 C 40 C 15 C 50 C 8 C 15 C 5 /50 2 mV 50 mV (423 F) ( 54 F) ( 67 F) ( 98 F) (308 F) (348 F) ( 90 F) (108 F) ( 65 F) ( 72 F) ( 28 F) ( 90 F) ( 15 F) ( 28 F)

DIN 43710 IEC 751; JIS; SAMA1) 2, 3 and 4 wire DIN 437602) 2, 3 and 4 wire Resistance Voltage

200...+ 900 C ( 76...+ 482 F) 200...+ 600 C (328...+1112 F) 200...+ 850 C (328...+1562 F) 200...+ 850 C (328...+1562 F) 60...+ 250 C ( 76...+ 482 F) 60...+ 250 C ( 76...+ 482 F) 0...500 /0...5000 125 mV...+ 125 mV 125 mV...+1200 mV

1) 2)

IEC 751 a = 0.00385, JIS a = 0.003916, SAMA a = 0.003902 Edison Curve No. 7

Temperature Transmitter, head mounted TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11 8.19 EN

Power supply (poling protected)

Supply voltage Non Ex application Us = 8.5...30 V DC For Ex Application, max. Ui = 8.5...29.4 V DC 2 wire methode: power supply wires = signal wires Influence of supply voltage < 0.05 %/10 V maximum residual ripple 1 % US (< 500 Hz)

Mechanical construction

Dimensions Confer dimensional drawing Weight 55 g Housing material Polycarbonat black (Non Ex type) blue (Ex type)

Power demand of indicators (only with AGLHD head)

(Power demand of transmitter and indicator have to be added)

Digital indicator Usd = 2 V DC CoMeter (HART configutor/LC display) Usd = 2.9 V DC

Electrical connection

Terminals, pluggable 2.5 mm2, screw terminals (stainless steel screws)

Characteristics at rated conditions

According to IEC 770 (related to 25 C)1)

Digital measured error Pt 100 Thermocouples Linear resistance 500 /5000 Linear voltage 120 mV/1200 mV D/A measured error 0.05 % of measuring span Additional influence of the internal reference junction Pt 100 DIN IEC 751 Kl. B

t ra io n n ra ge

Maximum load

( U smax U smin ) R ( k ) = --------------------------------------23.6

0.1 K 20 V 40 m/200 m 20 V/50 V

910

Maximum permissible load R

788

With CoMeter

Influences

Influence of ambient temperature Pt 100/resistance measurement2)

30

250

(HC)

pe

0 8,5 11,4 14,4 17,3

Z-20160

V DC Power supply Us

ME ( ) < ( 0.05 % + -------------------- 0.008 % ) 10 K MS ( ) Thermocouple/mV3)

General characteristics

Output signal refreshment rate Pt 100 0.4 s (Input signal change < 0.25 K/s) Thermocouples 0.2 s (Input signal change < 2.5 K/s) Vibration resistance Vibration in operation Resistance to shock Electrical isolation (I/O) 1.5 kV AC (60 s) Long-term stability 0.1 % p.a. 2g acc. to DIN IEC 68T.2 6 acc. to DIN IEC 68T.2 27

1) 2)

ME ( mV ) 0.14 K < ( 0.05 % + ------------------------ 0.01 % + ------------------ 100 % ) 10 K MS ( mV ) MS ( K ) Percentage related to measuring span MS = ME MA MA = lower range value, ME = upper range value

Percentage related to set measuring span Specified values corresponds to 3 (Gaussian normal distribution) Pt 100 (0...400 C): Influence of ambient temperature < (0.05 % + 0.013 %)/10 K = 0.063 %/10 K 3) Type K (0...1000 C): Influence of ambient temperature < (0.05 % + 0.01 % + 0.014 %)/10 K = 0.074 %/10 K

Environment conditions

Ambient temperature range 40...85 C Transport and storage temperature 40...100 C Relative humidity < 100 % (100 % humidity with isolated terminals only) Condensation Permitted

Temperature Transmitter, head mounted TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11 8.19 EN

Explosion protection

Intrinsically safe

Zone 1 Marking EC Type Examination certificate Temperature class T6/T5/T4 Supply circuit Max. voltage Short circuit current Max. power Internal inductance Internal capacitance Output [ib] Ui = 29.4 V Ii = 130 mA Pi = 0.8 W Li = 220 H Ci = 15 nF II 2 (1) G EEx [ia] ib IIC T6 PTB 99 ATEX 2139 X 50 C/65 C/85 C Input [ia] Uo = 5.6 V Io = 1.5 mA4) Po = 20 mW Lo = 1 mH Co = 1.55 F

Electromagnetic compatibility (EMC)

Pt 100: measuring range 0...100 C, span 100 K Type of test Burst to signal/ data lines Static discharge Contact plate (indirect) Terminals for supply5) Terminals for sensors5) Radiated field 80 MHz...1 GHz Coupling 150 kHz 80 MHz Degree 3 kV Influence < 0.1 % IEC 1000 4 4 1000 4 2 8 kV 6 kV 4 kV 10 V/m 10 V no influence no influence no influence 1000 4 3 < 1.0 % 1000 4 6 < 1.0 %

According to NAMUR NE 21 recommendation. In case of an input signal change > 0.25 K/s for Pt100 or > 2.5 K/s for thermocouples a measured value plausibility check is performed.

Zone 2 Marking Conformity statement Temperature class T6/T5/T4

II 3 G EEx n A II T6 PTB 99 ATEX 2216 X 50 C/65 C/85 C

5)

Air discharge (at 1 mm distance)

Canadian Standards Association and Factory Mutual

Intrinsically Safe FM CSA Class I, Div. 1, Groups A, B, C, D T6 Class I, Zone 0, Group IIC T6 Class I, Div. 1 and Div. 2, Groups A, B, C, D T6 Class I, Zone 0, Group IIC T6 (Class II Groups E, F, G; Class III if build in BUZH , AGL oder AGLH Kopf) Class I, Div. 2, Groups A, B, C, D, T6 Class I, Div. 2, Groups A,B,C,D T6 (Class II, Groups E, F, G; Class III wenn einge baut in BUZH , AGL oder AGLH Kopf)

Nonincendive FM CSA

4)

See 1. supplement PTB 99 ATEX 2139 X

Temperature Transmitter, head mounted TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11 8.19 EN

Displays (option in conjunction with AGLHD head)

Digital display

Digital display

Process value, sensor value or loop current value indicator Fed through current loop LC display: 3 digits ( 1999), digit height 10 mm, 7 segments Standard scaling 0...100 % Linear scaling for measuring ranges and units possible Description of the physical unit (labels)

CoMeter (HART configurator and LC display)

CoMeter (HART configurator and LC display)

4 function keys for request and programming (Code protection) Fed through current loop LC display: 5 digits ( 1999), digit height 7,6 mm, 7 segments Sign and floating point 10 segment bargraph (heading of measuring range) 7 digits alphanumeric characters 6 mm, 14 segments Dual function HART transmitter programming unit (all HART functions except for freely configurable characteristic curve and TAG Number) Process value, sensor value or loop current value indicator Request function Process variable, analog and display value, description of measuring point, serial number, error behaviour, lower/upper measuring range limit Change function Sensor type,sensor circuit, measuring range, damping, mains filter, error signalling Special function Zero point adjustment, simulation of output signal, adjustment of output signal, wet calibration

Display Response time Measuring error Overvoltage or maximum current EMC Temperature Humidity Digital display CoMeter 0.5 s 1.3 s 0.1 % 0.15 % 150 % of 215 mA input range EN 50082 2 20...+70 C 0...100 %, condensating permitted

Mind limits of application

Communication/parameterization

Hand held terminal HHT 691HT, STT04, HHT275 CoMeter Hart conigurator and LC display Device Management Tool SV401 (SMART VISION) Parameter Sensor type, error signalling, measuring range, general characteristics (i. e. TAG number), damping, signal simulation of output Software interface AMS, Cornerstone

CoMeter

Processinterface Line resistance

+

(250 min.)*

or Isolators Controller Recorders

691HT, STT04, HHT275

Z-20162d

GND

or

(optional) FSK Modem

*if necessary

Temperature Transmitter, head mounted TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11 8.19 EN

Connection diagram

Microprocessor

1

Input

+

Us = 8,5...30 V DC

Output

K1

3 +

3 3 3 3

3 3

K1

3 3 3

4...20 mA

Reference junction

4 4

K2

4

K2

4 4

4 +

2

2 2 2 2 2

V DC

V DC

a)

b)

c)

d)

e)

f)

g)

h)

i)

a) b) c) d)

Resistance thermometer, 2 wire circuit Resistance thermometer, 3 wire circuit Resistance thermometer, 4 wire circuit Double resistance thermometer, 2 wire circuit (average value or differential temperature measurement) e) Potentiometer input, 4 wire circuit

f) Thermocouple g) Double thermocouple (average value or differential temperature measurement) h) Voltage measurement i) Double voltage measurement (average value or differential temperature measurement)

Dimensional diagram (dimensions im mm)

Automation - Products Contrans TH 02

Messumformer/Transmitter/Transducteur

3

Z-18763h

44

5,5

22,5

Z-20165

Temperature Transmitter, head mounted TH02/TH02-Ex HART programmable, Pt 100 (RTD), thermocouples, electrical isolation

10/11 8.19 EN

Ordering information

Catalog No. TH02/TH 02-Ex V11518(without Ex) 1 TH02 Type of protection: intrinsically safe ATEX II 2 (1) G EEx [ia]ib IIC T6 5 TH02-Ex Zone 1: ATEX II 3 G EEx n A II T6 N TH02-Ex N Zone 2: FM 7 TH02-Ex IS Class I, Div. 1, Groups A, B, C, D T6 IS Class I, Zone 0, Group IIC T6 CSA 9 TH02-Ex IS Class I, Div.1 and Div. 2, Groups A, B, C, D T6 (Class II Groups E, F, G; Class III If build in BUZH head, AGL head or AGLH head) Nonincendive, Class I, Div. 2, Groups A, B, C, D T6 (Class II, Groups E, F, G; Class III if built in BUZH head, AGL head or AGLH head) FM M TH02-Ex N nonincendive, Class I, Div. 2, Groups A, B, C, D T6 Construction / display Module (h = 22.5 mm) Module (h = 22.5 mm) with sensor connecting line Module (h = 22.5 mm) with snap-on fixing Module (h = 27.5 mm) for mounting on measuring module Module built into connection head or cover with sensor connecting line BUZH head BUSH head BUKH-Ex head Raised B-head cover B head (completely head with raised cover) AUZH head AUSH head AGL head1) without display AGLHD head1) with digital display AGLHD head1) with cometer Attention: The sensor connecting lines correspond to the order for the type of sensor or its type of circuitry Module built into field housing: Aluminium field housing 80 x 75 x 57 mm, IP 65; 2 x M16 x 1.5 Polyester field housing 75 x 80 x 55 mm, IP 65; 2 x M16 x 1.5 Aluminium field housing 80 x 175 x 57 mm, IP 65; 1 x M16 x 1.5; 1 x M20 x 1.5 with separate terminal block Polyester field housing 75 x 190 x 55 mm, IP 65; 1 x M16 x 1.5; 1 x M20 x 1.5 with separate terminal block Notice: Other field housings with several transmitters or specially for pipe mounting on request. Programming Factory standard parameter Pt 100, 0...100 C, 4 wire circuit, damping off, direct action characteristic overranging at sensor or device error (22 mA) Customer-specific parameter setting (questionnaire) without Calibration certificates 2 point 9 point EUR 220,50 * 247,80 * 247,80 * 247,80 * 247,80 * Deliv. time 3 wks.

247,80 * 3 1 4 Z R P N L K V U X D C 7,40 * 9,70 * 5,40 * 40,10 40,60 32,60 19,20 22,90 53,60 54,80 77,80 254,10 298,00 * * * * * * * * * *

A 9 F E

70,40 * 73,00 * 86,40 * 94,50 *

0 1 0 1 2

21,50 * 75,60 * 107,10 *

Accessories

ABB FSK modem [EEx ib] IIC (parameter setting in the installation) Device Management Tool SV401 (SMART VISION) TH02 /-102 /-202 driver for AMS software 1.4 (Rosemount)2)

1)

Catalog No. see Data Sheet 10/63-6.71 EN see Data Sheet 10/63-1.20 EN 7957771

EUR

Deliv. time

107,10 *

Standard: Aluminium, metal-cable-screw-connection M20 x 1.5 EEx e; protective pipe connection M24 x 1.5 (optional M20 x 1.5; 1/2" NPT; 3/4" NPT); (do not use for EEx d applications, see data sheet 10/10-3.28 EN for EEx d details) 2) already integrated in AMS software version 5.0 or higher Notice: For a lokal programming on the desk can used as Hardware the universal FSK-Programming-Set (without Parasoft) (see Data Sheet 10/63-6.71 EN: ordering information) .

The IndustrialIT wordmark and all mentioned product names in the form XXXXXXIT are registered or pending trademarks of ABB. ABB has Sales & Customer Support expertise in over 100 countries worldwide. www.abb.com

The Companys policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. Printed in the Fed. Rep. of Germany (10.02) ABB 2002

ABB Ltd. Salterbeck Trading Estate Workington, Cumbria CA14 5DS UK Tel: +44 (0)1946 830 611 Fax: +44 (0)1946 832 661

ABB Inc. 125 E. County Line Road Warminster, PA 18974 USA Tel: +1 215 674 6000 Fax: +1 215 674 7183

ABB Automation Products GmbH Borsigstr. 2 63755 Alzenau Germany Tel: +49 6023 92 0 Fax: +49 6023 92 3430

10/11 8.19 EN Rev. A

También podría gustarte

- Advanced Materials '93: Computations, Glassy Materials, Microgravity and Non-Destructive TestingDe EverandAdvanced Materials '93: Computations, Glassy Materials, Microgravity and Non-Destructive TestingAún no hay calificaciones

- Itemp TMT111, DIN Rail: Technical InformationDocumento10 páginasItemp TMT111, DIN Rail: Technical InformationAntonio DjelicAún no hay calificaciones

- High Efficiency RF and Microwave Solid State Power AmplifiersDe EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersCalificación: 1 de 5 estrellas1/5 (1)

- RTD and Thermocouple TransmittersDocumento10 páginasRTD and Thermocouple TransmittersLenin PachecoAún no hay calificaciones

- ch-3 WKG Principle of SMPSDocumento15 páginasch-3 WKG Principle of SMPSSantosh SinhaAún no hay calificaciones

- Choppers & Ac ControllersDocumento28 páginasChoppers & Ac Controllersves vegasAún no hay calificaciones

- Smart Material Systems and MEMS: Design and Development MethodologiesDe EverandSmart Material Systems and MEMS: Design and Development MethodologiesAún no hay calificaciones

- TOPIC ON: Passive Sensors: Department of GeologyDocumento10 páginasTOPIC ON: Passive Sensors: Department of GeologyRajdeepAún no hay calificaciones

- CatalogueDocumento65 páginasCatalogueCAROL TaiwanAún no hay calificaciones

- A Brief Description of NDTDocumento31 páginasA Brief Description of NDTVictor SandovalAún no hay calificaciones

- The Transistor in A Century of ElectronicsDocumento13 páginasThe Transistor in A Century of ElectronicszayaAún no hay calificaciones

- Celestion S8 Service Manual PDFDocumento18 páginasCelestion S8 Service Manual PDFmidexAún no hay calificaciones

- Wireless World 1982 10Documento132 páginasWireless World 1982 10jacomartAún no hay calificaciones

- Chapter6 4700E Electrochemical SensorsDocumento34 páginasChapter6 4700E Electrochemical Sensorsestraj19540% (1)

- Ramsey AA7 - All Band Active Antenna PDFDocumento16 páginasRamsey AA7 - All Band Active Antenna PDFAl PetitAún no hay calificaciones

- Wireless World 1982 11Documento132 páginasWireless World 1982 11jacomartAún no hay calificaciones

- Glass Vacuum CoatingDocumento6 páginasGlass Vacuum CoatingkgvtgAún no hay calificaciones

- Focal Catalog StudioMonitor 2016Documento40 páginasFocal Catalog StudioMonitor 2016guitaristddjAún no hay calificaciones

- Plasma Speaker: NMAM Institute of Technology NitteDocumento10 páginasPlasma Speaker: NMAM Institute of Technology NittePuneeth ShettigarAún no hay calificaciones

- X Ray LithographyDocumento59 páginasX Ray LithographyMohammad RameezAún no hay calificaciones

- SDP 3000Documento26 páginasSDP 3000sorsricerche100% (1)

- Pantech - Embedded Projects List PDFDocumento8 páginasPantech - Embedded Projects List PDFSri ShandilyaAún no hay calificaciones

- 8051 2 Rs 232 InterfacingDocumento45 páginas8051 2 Rs 232 InterfacingPavankumar KalliAún no hay calificaciones

- Mullard PotCore EquivsDocumento15 páginasMullard PotCore Equivse reesAún no hay calificaciones

- A Novel, Cost-Effective Method For Loudspeakers Parameters MeasurementDocumento7 páginasA Novel, Cost-Effective Method For Loudspeakers Parameters MeasurementdzymytchAún no hay calificaciones

- Transformers: Linked Together by Mutual InductanceDocumento10 páginasTransformers: Linked Together by Mutual InductanceOyedotun TundeAún no hay calificaciones

- NAGRA 4.2: Portable Analogue Audio Tape RecorderDocumento26 páginasNAGRA 4.2: Portable Analogue Audio Tape RecordernotaminorthreatAún no hay calificaciones

- Ground Wave Propagation 2. Sky Wave PropagationDocumento18 páginasGround Wave Propagation 2. Sky Wave PropagationajiistanAún no hay calificaciones

- Sensores de PresionDocumento25 páginasSensores de PresionjorvasquAún no hay calificaciones

- Precipitation HardeningDocumento5 páginasPrecipitation Hardeningk27571Aún no hay calificaciones

- Barkhausen Noise Paper PDFDocumento19 páginasBarkhausen Noise Paper PDFdavideAún no hay calificaciones

- Magnetic MeterialsDocumento1 páginaMagnetic MeterialsmpkkbtechAún no hay calificaciones

- Experiment No.4 To Study The Variation of Photoelectric Effect With Intensity of LightDocumento8 páginasExperiment No.4 To Study The Variation of Photoelectric Effect With Intensity of LightMuhammad Zubair SharifAún no hay calificaciones

- 1992 Sony Discrete Semiconductor Data BookDocumento344 páginas1992 Sony Discrete Semiconductor Data Bookalex_81_Aún no hay calificaciones

- RadioDesigners Handbook - Ch.5 - TransformersDocumento28 páginasRadioDesigners Handbook - Ch.5 - Transformersbatum67Aún no hay calificaciones

- Types of MagnetismDocumento5 páginasTypes of MagnetismNithish KumarAún no hay calificaciones

- PHYSICS 286: Modern Physics Laboratory Experiment 6: The Photoelectric EffectDocumento6 páginasPHYSICS 286: Modern Physics Laboratory Experiment 6: The Photoelectric EffectAashirwadAún no hay calificaciones

- Electromagnetic Waves (Physics) : AnswerDocumento10 páginasElectromagnetic Waves (Physics) : Answersmsubramaniam100% (1)

- Magnetic Nano Composites - TermpaperDocumento27 páginasMagnetic Nano Composites - TermpaperIrshadAún no hay calificaciones

- Package TypesDocumento4 páginasPackage TypesDickson LamAún no hay calificaciones

- Zeiss225bosello TechnicalDescriptionDocumento42 páginasZeiss225bosello TechnicalDescriptionMuthu Selvam100% (1)

- Resistance Temperature Detector (RTD)Documento9 páginasResistance Temperature Detector (RTD)mdmahmudAún no hay calificaciones

- A Miniature HF To VHF AM-FM Receiver Using The NE605Documento2 páginasA Miniature HF To VHF AM-FM Receiver Using The NE605Miguel OyarzabalAún no hay calificaciones

- Eee4021 Sensors-And-Signal-Conditioning Eth 1.1 47 Eee4021 PDFDocumento4 páginasEee4021 Sensors-And-Signal-Conditioning Eth 1.1 47 Eee4021 PDFManan ModiAún no hay calificaciones

- RTD TutorialsDocumento11 páginasRTD TutorialsjaigodaraAún no hay calificaciones

- Advanced Power ElectronicsDocumento4 páginasAdvanced Power ElectronicsLinkan PriyadarsiniAún no hay calificaciones

- Transformer CoresDocumento17 páginasTransformer CoreskapsicumadAún no hay calificaciones

- Electronic Devices Lab MANUALDocumento24 páginasElectronic Devices Lab MANUALna_hariprsadAún no hay calificaciones

- Fuculty of Engineering Department: Instrumentoin and Control IDocumento15 páginasFuculty of Engineering Department: Instrumentoin and Control Ihappy sadAún no hay calificaciones

- The Evolution of 802.11 Wireless Security: INF 795 - Kevin BentonDocumento56 páginasThe Evolution of 802.11 Wireless Security: INF 795 - Kevin Bentondevk2011Aún no hay calificaciones

- Advanced Nanomaterials PDFDocumento270 páginasAdvanced Nanomaterials PDFMariela RguezAún no hay calificaciones

- Impedancematchinginawr 160207151307Documento12 páginasImpedancematchinginawr 160207151307Bharat Chandra SahuAún no hay calificaciones

- IC Packaging 2008Documento26 páginasIC Packaging 2008Angelo CorderoAún no hay calificaciones

- GPVDM Simulation PDFDocumento6 páginasGPVDM Simulation PDFNaas DjeddaouiAún no hay calificaciones

- HVDC Transmission SystemDocumento44 páginasHVDC Transmission SystemPravin Patel100% (1)

- S5 Solaris CCD PlusDocumento4 páginasS5 Solaris CCD PlusCarmen BáezAún no hay calificaciones

- Introduction To Time Series Analysis, LecturesDocumento49 páginasIntroduction To Time Series Analysis, LecturesnumenoreAún no hay calificaciones

- Finite Element Analysis of Automobile Transmission ShaftDocumento5 páginasFinite Element Analysis of Automobile Transmission ShaftAbhishek GuptaAún no hay calificaciones

- Single Line Diagram 3 General Notes & Specification 1 Legend & Symbol 4Documento1 páginaSingle Line Diagram 3 General Notes & Specification 1 Legend & Symbol 4Abnar KumplishaAún no hay calificaciones

- Ijece - Design and Performance Analysis of Various Parameters of Single and Multi Layer of MspasDocumento6 páginasIjece - Design and Performance Analysis of Various Parameters of Single and Multi Layer of Mspasiaset123Aún no hay calificaciones

- Quadrature Encoder Receiver Module: An Implementation On FPGADocumento12 páginasQuadrature Encoder Receiver Module: An Implementation On FPGAสหายดิว ลูกพระอาทิตย์Aún no hay calificaciones

- BAGAY JUNEE C1 Exp4Documento17 páginasBAGAY JUNEE C1 Exp4Dylan CosepAún no hay calificaciones

- IGC - RDS - ITP - 008 Install Main Power Supply 800 Amps (FLC) at Pump House 1 From Substaion Pump House 2Documento4 páginasIGC - RDS - ITP - 008 Install Main Power Supply 800 Amps (FLC) at Pump House 1 From Substaion Pump House 2noonot126Aún no hay calificaciones

- Catalog - Tesys Essential Guide - 2012 - (En)Documento54 páginasCatalog - Tesys Essential Guide - 2012 - (En)Anonymous FTBYfqkAún no hay calificaciones

- A1d1-X Csa - CeDocumento3 páginasA1d1-X Csa - Ceharshithkumar20Aún no hay calificaciones

- Review On BjtsDocumento24 páginasReview On Bjtsmichaeledem_royalAún no hay calificaciones

- Os Segredos Do PWM Do ArduinoDocumento6 páginasOs Segredos Do PWM Do ArduinoFernando EsquírioAún no hay calificaciones

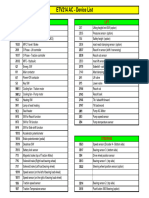

- ETV214 AC - Device List: Traction LiftDocumento41 páginasETV214 AC - Device List: Traction LiftKiều Văn TrungAún no hay calificaciones

- Record Plus Catalogue 9 RD5 RD6 RCD RelayDocumento2 páginasRecord Plus Catalogue 9 RD5 RD6 RCD RelayJosett LPAún no hay calificaciones

- Chapter 4 Solutions: 4-1) LoadDocumento28 páginasChapter 4 Solutions: 4-1) Loadpaul kioiAún no hay calificaciones

- Datasheet Cd4066Documento10 páginasDatasheet Cd4066Luis LunaAún no hay calificaciones

- CD Spectroscopy PPT FinalDocumento20 páginasCD Spectroscopy PPT FinalMukesh Yadav0% (1)

- Recruitment Test Question of Gas Transmission Company Limited (GTCL)Documento8 páginasRecruitment Test Question of Gas Transmission Company Limited (GTCL)Franch T. SougataAún no hay calificaciones

- Zxdu68 B201 DC PDFDocumento42 páginasZxdu68 B201 DC PDFronnymareAún no hay calificaciones

- Profibus Troubleshooting & MaintenanceDocumento92 páginasProfibus Troubleshooting & Maintenancemsohaibkhalid100% (3)

- Function: Electrical, Electronics and Control Engineering at Operational LevelDocumento3 páginasFunction: Electrical, Electronics and Control Engineering at Operational LevelRamesh BalasubramaniAún no hay calificaciones

- Installation of 6kWp Grid Tie Rooftop Solar SystemDocumento3 páginasInstallation of 6kWp Grid Tie Rooftop Solar SystemcunconAún no hay calificaciones

- Applied Sciences: The Power System and Microgrid Protection-A ReviewDocumento30 páginasApplied Sciences: The Power System and Microgrid Protection-A ReviewEngidAún no hay calificaciones

- 8DN8 General DescriptionDocumento9 páginas8DN8 General DescriptionsamreeniqbalAún no hay calificaciones

- 2010 Conference On Precision Electromagnetic MeasurementsDocumento2 páginas2010 Conference On Precision Electromagnetic MeasurementsluisAún no hay calificaciones

- MCQ Basic EleDocumento6 páginasMCQ Basic ElesanjuAún no hay calificaciones

- Wpa 80063 8CF 5Documento1 páginaWpa 80063 8CF 5Francisco NascimentoAún no hay calificaciones

- Worksheet of EDC - 2018Documento2 páginasWorksheet of EDC - 2018pranavmurthyAún no hay calificaciones

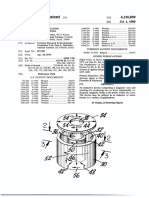

- United States Patent (19) : Meretsky Et Al. (11) 4,210,859Documento17 páginasUnited States Patent (19) : Meretsky Et Al. (11) 4,210,859Pierre ClaudeAún no hay calificaciones

- EDC Fermi LevelDocumento10 páginasEDC Fermi LevelImran BashaAún no hay calificaciones

- Experion Series 8 IO C300 Controller SpecsheetDocumento41 páginasExperion Series 8 IO C300 Controller SpecsheetTÀi VÕAún no hay calificaciones

- E12686-1601-YC21-11-04 Low Voltage Distribution Overview PDFDocumento1 páginaE12686-1601-YC21-11-04 Low Voltage Distribution Overview PDFthanhAún no hay calificaciones