Documentos de Académico

Documentos de Profesional

Documentos de Cultura

RainGun SR3003 Teknik Katalog

Cargado por

HakanTuzmenDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

RainGun SR3003 Teknik Katalog

Cargado por

HakanTuzmenCopyright:

Formatos disponibles

45

bar m m

3

/h

4,0 44,0 32,1

4,5 45,7 34,0

21 mm 5,0 47,5 35,9

5,5 48,2 37,6

6,0 49,0 39,3

6,5 50,2 40,9

4,0 45,0 38,6

4,5 46,7 40,8

23 mm 5,0 48,5 43,1

5,5 49,5 45,2

6,0 50,5 47,3

6,5 51,0 49,2

4,0 46,5 50,5

4,5 48,7 53,0

26 mm 5,0 51,0 56,0

5,5 51,5 58,5

6,0 52,0 61,1

6,5 52,2 63,6

4,0 50,0 58,1

4,5 52,5 61,7

28 mm 5,0 55,0 65,3

5,5 56,7 68,3

6,0 58,5 71,3

6,5 59,2 74,1

4,0 51,5 67,7

4,5 54,2 71,7

30 mm 5,0 57,0 75,8

5,5 59,2 79,4

6,0 61,5 83,0

6,5 63,2 86,4

4,0 54,0 82,4

4,5 56,0 87,3

33 mm 5,0 58,0 92,2

5,5 58,7 96,5

6,0 59,5 100,9

6,5 60,5 104,5

bar m m

3

/h

3,0 32,0 13,0

3,5 33,5 13,9

4,0 34,7 14,8

14 mm 4,5 36,0 15,7

5,0 37,5 16,5

5,5 39,0 17,4

6,0 40,2 18,2

3,0 32,5 16,8

3,5 34,0 18,0

4,0 36,0 19,2

16 mm 4,5 38,0 20,4

5,0 38,5 21,4

5,5 39,0 22,5

6,0 40,5 23,6

3,0 36,0 21,6

3,5 38,0 23,0

4,0 40,0 24,5

18 mm 4,5 42,0 26,0

5,0 43,2 27,4

5,5 44,5 28,8

6,0 45,5 30,2

3,0 40,5 26,5

3,5 42,0 28,4

4,0 42,7 30,3

20 mm 4,5 43,5 32,2

5,0 45,0 33,8

5,5 46,5 35,5

6,0 48,0 37,3

3,0 40,0 31,5

3,5 41,5 33,8

4,0 42,5 36,1

22 mm 4,5 43,5 38,5

5,0 46,2 40,5

5,5 49,0 42,6

6,0 50,5 44,5

3,0 40,0 38,0

3,5 42,0 40,4

4,0 43,0 43,1

24 mm 4,5 44,0 45,9

5,0 47,2 48,3

5,5 50,5 50,7

6,0 53,0 53,2

SR2005

SR3003

APPLICATIONS

These Rain Gun

sprinklers are designed for

large irrigation installations:

sports feld complex, athletic felds (football),

etc. deal for artifcial grass applications.

FEATURES

Slow reverse

Trajectory angle: 23

Standard irrigation fange mount

Part circle models with adjustable arc: 40-

360

Easy arc adjustment, Friction collar settings

require no tools

Single nozzle confguration

SR2005 is shipped with set of 6 taper bore

nozzles (GNS-2005T), Sizes: 21, 23, 26,

28, 30 and 33 mm

SR3003 is shipped with set of 6 plastic

taper bore nozzles (GNS-3003T), Sizes:

14, 16, 18, 20, 22 and 24 mm

SR3003 features a spoon design with

adjustable bracket to increase or decrease

rotation speed

Counterweights available

Sealed, lubed-for-life ball bearings

Optional 2 (50/60) female BSP adapter

available for SR3003 permits 2 (50/60)

riser mount

MODELS

SR2005: 3 (80/90) Part circle Rain Gun

-

Slow reverse

SR3003: 2 (50/60) Part circle Rain Gun

-

Slow reverse

RAIN BIRD SR2005/SR3003 SERIES

SIow Reverse Rain Gun

SprinkIers

PERFORMANCE

RAN GUNS

Nozzles

Nozzles

Design example

along with the pressure at the

Rain Gun, dictate flow rate and

radius of throw and should be

selected accordingly.

b. If you are using a part circle

Rain Gun, manually set the

desired rotation arc by pushing

the two friction collars to the

desired position (See Figure 3

of Installation Tips).

c. Flush pipeline delivery system

prior to installing Rain Gun.

d. If you are using the BSP or NPT

adapter, make sure that it is

securely bolted to the Rain Gun

using the 6 bolts and gasket

supplied. Make sure that the

adapter is securely tightened to

the 2" riser.

USER MANUAL

Rain Guns are high quality, high

performance sprinklers designed for a

variety of uses and applications where

relatively high flows and extended

radius of throw are desired. For best

results, please read the following

instructions before construction to

ensure optimal performance.

Start Up Note

Always verify pressure. Pressure at the

pump or point of connection does not

equal pressure at the sprinkler. The

most common problem associated

with sprinkler installations is

insufficient or too much pressure at

the sprinkler head. Your Rain Gun is

equipped with a pressure port to

accommodate a 1/ 4" NPT thread

pressure gauge, also included,

specifically for this critical system

pre-check.

Quick Start Guide

1. Configuring Your Rain Gun

a. A set of 6 nozzles and a spoon

adjustment bracket are

included to customize your

Rain Gun to your application.

The spoon bracket allows you

to set the rotation speed based

on the nozzle size and the

pressure at the gun. To ensure

a fast, problem free start up,

please refer to the spoon

bracket adjustment guide (Ref.

Table 2) to configure your Rain

Gun accordingly. The nozzles,

Rain Gun

SR3003 / F3002 User Manual

2. Installing Your Rain Gun

Now that you have configured your

Rain Gun, make sure that it is

mounted securely. If there is wobble

while your Rain Gun is in operation,

it is a signal that you are losing

energy needed to ensure optimal

rotation speed. Refer to Installation

Tips for more information if needed.

3. Starting Your Rain Gun

a. Make sure that the Rain Gun is

pointed in a safe direction and all

people in the area are ready.

b. Activate valve if automatic. If

controlled by a manual valve,

open valve slowly until the desired

pressure and flow are reached.

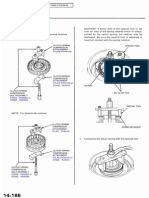

Spoon Adjustment Bracket

Refer to table 2

Nozzle

Refer to Table 2 to integrate

with spoon adjustment bracket

Front Arm Counterweight

Rear Arm Counterweight

Pulls spoon into the water stream

Rear Counterweight

Used in sloping

installations where

riser is not set

vertical to horizon

(sold separately)

Pressure Port

Check pressure here

at installation or when

troubleshooting

NPT or BSP Thread Adapter

Used to mount Rain Gun

to threaded riser

Arm Stop

Table 1 Performance Data

NOZZLE SIZE

(.55") (.63") (.71") (.79") (.87") (.94")

PSI @

14 mm 16 mm 18 mm 20 mm 22 mm 24 mm

Nozzle

Rad. Flow Rad. Flow Rad. Flow Rad. Flow Rad. Flow Rad. Flow

40 103 55 105 72 113 92 131 114 126 134 126 162

50 109 61 111 79 124 101 137 124 136 148 137 177

60 115 66 120 86 133 110 141 136 140 162 142 193

70 121 72 126 93 140 118 146 147 149 175 151 209

80 128 77 128 99 146 127 153 157 161 188 166 224

90 134 82 135 106 151 136 159 168 168 201 175 240

100 140 88 141 113 154 144 164 178 176 214 184 255

(ft.) (gpm) (ft.) (gpm) (ft.) (gpm) (ft.) (gpm) (ft.) (gpm) (ft.) (gpm)

Example (see shaded area):

You have 60 PSI and a 14 mm nozzle; the chart

recommends configuration A or B. This means that your

Rain Gun

will operate properly in either configuration,

but the rotation speed will be faster in A than in B.

SR3003 / F3002 Configuration Details

Rotati on Angl e

Nozzle Selection

Select one of the six nozzles

provided based on your

performance requirements,

available water pressure

(at the Rain Gun), and flow

capacity. Refer to Table 1

and Figure 1.

Spoon Adjustment

Bracket

Install the Spoon

Adjustment Bracket, if

needed, in accordance with

Table 2. Refer to Figures A,

B, and C.

Rotation Angle Adjustment

For part circle (SR3003) model only, adjust desired rotation angle manually as shown.

Figure 1

Table 2 Spoon Adjustment Bracket

NOZZLE SIZE

(.55") (.63") (.71") (.79") (.87") (.94")

PRESSURE

14 mm 16 mm 18 mm 20 mm 22 mm 24 mm

PSI

40 A A A A / B A / B A / B

45 A A / B A / B A / B A / B A / B

50 A / B B B B B B

60 A / B B B B B B

65 B B B B B / C B / C

75 B B B B / C B / C B / C

80 B B B / C C C C

90 B B B / C C C C

95 B B / C B / C C C C

100 B B / C B / C C C C

Figure A: Bracket not installed

Provides maximum drive and

rotation speed at low pressures.

Figure 2 Figure 3

Figure B: Plus position (+)

Provides an intermediate

position to regulate rotation

speed at intermediate pressures.

Figure C: Minus position ()

Provides greatest slowing of

rotation speed at high pressures.

Riser Installation

a. To ensure proper operation and performance for the life of

your Rain Gun, the riser must be stable and solidly installed to

resist vibration. An unsupported riser is insufficient for proper

operation. Additionally, a PVC riser will not support the

reaction load of a Rain Gun. Some options that may be used

are: (Note: confirm friction loss and flow in your application)

Option 1: Galvanized riser strapped to a 6" x 6" pressure

treated wood post (See Figure 4).

Option 2: Galvanized riser set in a pillar of concrete

(See Figure 5).

Option 3: A portable gun stand designed to support a Rain

Gun. (Contact your dealer for a recommended supplier.)

b. Install Rain Gun to riser as shown in Figure 6

or 7.

c. Inclined operation:

The preferred installation on an inclined plane

is on a vertical riser regardless of angle of

incline.

If the riser must be set at an angle, use the rear

counterweight (part number L00270) for

proper rotation of your Rain Gun. The weight is

designed to help the Rain Gun rotate up hill.

If you are using a portable gun stand, please

consult the manufacturer to be sure it is

designed to support inclined terrain.

d. For more help with your installation, please call

your Rain Bird Dealer or District Manager. The

toll free Rain Bird number is listed on the back

page of this guide.

Traveler Installation

a. Make sure that the pressure at the gun is over

45 psi. Most users underestimate the pressure loss

in the pipe, which is very high. Adjust your spoon

bracket in relation to the nozzle size and the

pressure at the gun.

b. On sloped terrain, weight compensation may be

required for proper rotation. For such conditions,

a rear counterweight is available (Part number

L00270, sold separately).

c. As an alternative to using a counterweight, some

travelers can be vertically adjusted.

Center Pivot Installation

a. For proper operation, make sure that the pressure

at the gun is over 45psi. Many users underestimate

the pressure loss in the pivot, which is very high,

especially at the end-gun location. Adjust your

spoon bracket in relation to the nozzle size and

the pressure at the gun (Refer to spoon bracket

adjustment guide, Table 2).

b. Make sure that the pivot end-gun mounting

position is stable.

Installation Tips

Figure 5

Figure 6 Figure 7

Dimensions of concrete

required will vary depend-

ing on riser height, soil

bearing capacity, and

Rain Gun flowrate.

Example shown is for

compact clay soil with

18 mm nozzle and

maximum pressure 80 psi.

2" Elbow swing assembly

Provide drain valve

as necessary

Lateral

10

12

2 Galv.sch. 40

Figure 4

2" Elbow swing

assembly

Provide drain valve

as necessary

Lateral

Use pressure

treated wood

Use hi-torque

stainless steel bands

Keep riser vertical

Min. of 36 depth

is recommended.

Compact dirt

around post.

12 to bolt

flange

Using thread adapter Using bolt flange

Max. of 72 height is

recomended. Post should be

continuous to base of Rain Gun.

Ref. Part Description Part Numbers

1 Arm Shaft Assembly Included in Kit B

2 Arm Assembly/ Counterweight 71- P50472

3 Spoon Assembly 71- P50824

4 Spacer 71- P50420

5 Snap Ring 71- P00358

6 Pivot Cap Assembly 71- P50825

7 Pivot Assembly 71- P50826

8 Arm Spring 71- P50812

9 Spring Spacer 71- P50706

10 Arm Locknut Included in Kit B

11 Arm Washer Included in Kit B

12 Counterweight Kit 71- P50827

13 Elbow/ Range Tube Assembly 71- P50471

14 O- Ring 71- P50155

15 Brake Assembly 71- P51176

16 Bearing Assembly 71- P50976

17 Friction Collar (2 Required) 71- P50116

18 Snap Ring 71- P50463

19 Ball Bearing 71- P50544

20 Lock Nut 71- P50793

21 O- Ring 71- P50121

22 Bearing Sleeve 71- P50794

23 Trip Lever Assembly 71- P50538

24 Trip Link Bushing 71- P50539

25 Elbow Shaft Washer (3 Required) Included in Kit A

26 Cotter Pin (3 Required) Included in Kit A

27 Trip Rod 71- P50478

28 Nozzle Retainer 71- 105943

29 GNS- 3003T Nozzle Set L003003

35 Spring, Red (8 Required) 71- P51165

36 Pressure Port Plug (1/ 4" ) 71- P20006

37 Spoon Bracket 71- P51099

38 Dry Pressure Gauge (not shown) DV160

Accessories

30 2" Female BSP Adapter 71- P50545

31 2" Female NPT Adapter 71- P50596

32 Bearing Wrench 71- P50697

33 Riser Installation Kit 71- P50368

34 Rear Counterweight L00270

Spare Parts Kit

A Misc. Kit 71- P50590

B Arm Shaft Kit 71- P50591

Parts Diagram and Description

Should you experience operating

difficulties, here are some tips that

may apply to your application. For

further assistance, please record the

date code, the serial number on the

elbow, and the pressure at the gun,

and call your Rain Bird Dealer or the

toll free Rain Bird number listed at the

back of this guide.

Rain Gun does not rotate

or rotation speed is too slow

Install a 1/ 4" pressure gauge into

the Rain Gun pressure port and

verify adequate operating pressure.

Refer to Spoon Bracket Adjustment

guide (table 2) for proper

configuration of spoon bracket

based on nozzle size. Also check

the spoon and the arm for damage.

If pressure is below specification

and the Rain Gun is properly

configured, decrease the nozzle

size to increase pressure at the gun.

If pressure is lower than it was at

installation, check for obstructions

in the water line. You may be able

to flush obstructions from the

sprinkler and water line by

removing the nozzle and turning

on the water.

If pressure is still low after

removing obstructions, and your

Rain Gun still does not rotate, you

may need to add a booster pump or

increase pressure in another way.

Rotation speed too fast

Install a pressure gauge at the Rain

Gun pressure port and refer to Spoon

Bracket Adjustment guide (table 2) for

proper configuration of spoon bracket

to nozzle size. Also check the spoon

for damage. For proper operation, the

operating pressure at the gun should

not exceed 100 psi.

Rotation speed varies from

one direction to another

Check that the spoon is properly

installed on the arm.

Check that the arm is not bent.

Check that the nozzle is properly

installed in the nozzle housing.

It should be seated squarely.

Check the condition of the spoon.

If broken, it will need to be

replaced.

Gun does not reverse

Install a pressure gauge at the Rain

Gun pressure port and refer to

Spoon Bracket Adjustment guide

(Table 2) for proper configuration

of spoon bracket to nozzle size.

Pressure at gun should not exceed

100 psi.

Check trip mechanism by manually

operating it. Operation should be

free and smooth.

Check trip mechanism spring. It

must have tension and be properly

installed.

Check bushings at the trip

mechanism. They must be clean

and not damaged.

Arm stroke frequency is

too high

Make sure pressure is not above

100 psi.

Make sure the front arm

counterweight is installed

(below spoon).

Make sure the rear arm

counterweight is installed.

Gun rotation slows down

over time

Refer to first troubleshooting tip

above for non-rotating or slow

rotation.

Trip stop mechanism is not

holding the gun at the

desired arc

Make sure that the trip stops are

not loose by pushing against them

with your finger. (See Figure 3)

Turn your gun manually to the trip

stops. They should hold when the

trip lever pushes against them.

If your Rain Gun has recently been

re-assembled, make sure that the

trip lever was not reinstalled in

between the trip stops. This will

open the trip mechanism and not

stop the Rain Gun.

Arm does not move

Check the pressure at the gun

Check that the nozzle is properly

installed on the nozzle housing

Make sure that the nozzle retainer

is tightened

Check that the spoon is not broken

Check that the mechanical stop

(arm stop) on the arm is not

damaged

Check that the arm is not bent

Troubleshooting Tips

Rain Gun

Warranty

Agricultural Applications

Our latest generation of Rain Guns is built on a legacy of

knowledge, trust, and feedback from end users like you.

Our warranty is simple and in line with Rain Birds reputation

as the most reliable agricultural sprinkler in the world.

To back up our claim, we offer the best warranty in the

agriculture industry. For all agricultural applications, we

offer a three year, no questions asked warranty including

free service or parts replacement.

Non-agricultural Applications

We understand that Rain Guns are often utilized in

applications that may be more demanding than general

agricultural applications. In these circumstances, Rain Bird

offers an eighteen month warranty including free service or

parts replacement, but excludes coverage in the following

general applications or environments:

Electrolytic conditions, such as high salt environments

or salt water spray applications

Applications where environmental conditions are not

compatible with the materials used in Rain Guns

Caustic or corrosive chemical conditions or spray

applications

Abrasive fluid spray applications

Rain Bird International, Inc.

145 N. Grand Ave.

Glendora, CA 91741-2469

Phone: (626) 963-9311

Fax: (626) 963-4287

Rain Bird Agri-Products Co.

633 W. Foothill Blvd.

Glendora, CA 91741-2469

Phone: (800) 435-5624

Fax: (626) 852-7310

www.rainbird.com

Registered trademark of Rain Bird Sprinkler Mfg. Corp.

2002 Rain Bird Sprinkler Mfg. Corp. 7/02 PN L357

También podría gustarte

- JCB HOSE AND COUPLING CATALOGUE ISSUE 2Documento42 páginasJCB HOSE AND COUPLING CATALOGUE ISSUE 2Cryy7350% (2)

- FS4-3 - Installation Instructions (MM-601J)Documento8 páginasFS4-3 - Installation Instructions (MM-601J)mendozaAún no hay calificaciones

- 13481981Documento17 páginas13481981Anonymous xFV7bg7Q100% (1)

- Rain Gun II PDFDocumento4 páginasRain Gun II PDFkhalidcosmosAún no hay calificaciones

- Attach-A-Puller battery transport attachment dimensions & specsDocumento4 páginasAttach-A-Puller battery transport attachment dimensions & specsCarlos MurilloAún no hay calificaciones

- Manual Sc32.PDF Prenza Hidraulica GatesDocumento16 páginasManual Sc32.PDF Prenza Hidraulica GatesEsteban Sándiga GrandaAún no hay calificaciones

- Valve Lash G3408Documento9 páginasValve Lash G3408Djebali MouradAún no hay calificaciones

- Actuator 657Documento24 páginasActuator 657DineshAún no hay calificaciones

- Toro 760 & 780 Series SprinklersDocumento12 páginasToro 760 & 780 Series SprinklersLuca Riccardi100% (1)

- Series 900 Meter: Owner's Operation & Safety ManualDocumento16 páginasSeries 900 Meter: Owner's Operation & Safety ManualWalter A Gómez de la CruzAún no hay calificaciones

- Series 774DCDA Specification SheetDocumento2 páginasSeries 774DCDA Specification SheetWattsAún no hay calificaciones

- Manual - Tong XQ6B RDCDocumento26 páginasManual - Tong XQ6B RDCJavier Danilo Aranda PinzonAún no hay calificaciones

- Mechanical Instruction ManualDocumento16 páginasMechanical Instruction ManualMorarescu AndreiAún no hay calificaciones

- TangShan Dachuan Machinery Co., Ltd. SB Series Sand Pump Operation ManualDocumento31 páginasTangShan Dachuan Machinery Co., Ltd. SB Series Sand Pump Operation ManualRinatAún no hay calificaciones

- Hydraulic Cylinder Parker 3lDocumento48 páginasHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- PETRO FILL-RITE 900 Series Meter Owner ManualDocumento4 páginasPETRO FILL-RITE 900 Series Meter Owner Manualpaulm3565Aún no hay calificaciones

- API Spec 10D Casing CentralizersDocumento20 páginasAPI Spec 10D Casing CentralizersfaridAún no hay calificaciones

- V-belt drive design factorsDocumento12 páginasV-belt drive design factorsPeter IyereAún no hay calificaciones

- Fluid Tech-Info enDocumento17 páginasFluid Tech-Info enadhityaAún no hay calificaciones

- Cat Pumps 3DNX25GSI ServiceDocumento4 páginasCat Pumps 3DNX25GSI ServiceK89523729Aún no hay calificaciones

- Mechanical Setting Procudere of CR & Bridge PlugDocumento7 páginasMechanical Setting Procudere of CR & Bridge PlugChandra FadhillahAún no hay calificaciones

- CS Series Operation Manual PDFDocumento70 páginasCS Series Operation Manual PDFDArio Mainini60% (10)

- SM 64250Documento20 páginasSM 64250HENKO7659Aún no hay calificaciones

- NuFlo EZ-In User Manual - PEDDocumento32 páginasNuFlo EZ-In User Manual - PEDsarkaft100% (1)

- Repair Manual: PS-6400, PS-6400 H PS-7300, PS-7300 H PS-7900, PS-7900 HDocumento44 páginasRepair Manual: PS-6400, PS-6400 H PS-7300, PS-7300 H PS-7900, PS-7900 HRepairmanJimAún no hay calificaciones

- Cilindros Hidráulicos Parker - 2H - 1110-UkDocumento42 páginasCilindros Hidráulicos Parker - 2H - 1110-UkPeterson MagroAún no hay calificaciones

- 2 Cilindri Per Elsa2 BC and Spring Brakes For Elsa2Documento5 páginas2 Cilindri Per Elsa2 BC and Spring Brakes For Elsa2Andreea BoacaraAún no hay calificaciones

- Ключ Гідравлічний Xq114-6bDocumento26 páginasКлюч Гідравлічний Xq114-6bЮрчик ПерчукAún no hay calificaciones

- lt3 00032 2 A p24 p30sDocumento67 páginaslt3 00032 2 A p24 p30sBruno SamaeianAún no hay calificaciones

- Span Tables For Simply Supported Composite BeamsDocumento8 páginasSpan Tables For Simply Supported Composite BeamsDenise2512Aún no hay calificaciones

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDocumento7 páginasResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationPedro JonesAún no hay calificaciones

- Catalog HRC Jaw CouplingsDocumento8 páginasCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Mil Series 37,38 ActuatorDocumento12 páginasMil Series 37,38 ActuatorSam100% (3)

- Flame ArresterDocumento16 páginasFlame Arresteriran1362Aún no hay calificaciones

- Greenlee Dobladora de TubosDocumento16 páginasGreenlee Dobladora de TuboswilfredoAún no hay calificaciones

- VDO Gauge InstallationDocumento4 páginasVDO Gauge Installationurule2kAún no hay calificaciones

- 3DX SchematicDocumento4 páginas3DX Schematicab59510% (1)

- Online HDM690Documento20 páginasOnline HDM690Kyle SchwulstAún no hay calificaciones

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3Documento200 páginas1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part3CandieApple100% (1)

- Armado Y Desarmado Rollers ExcavadorasDocumento1 páginaArmado Y Desarmado Rollers ExcavadorasgabicckAún no hay calificaciones

- Pump Suction Diffuser ManualDocumento2 páginasPump Suction Diffuser ManualAnonymous 7xHNgoKE6eAún no hay calificaciones

- Operating Manual of XYQ6B TongDocumento26 páginasOperating Manual of XYQ6B TongV.D. J.Aún no hay calificaciones

- SB 1197BDocumento9 páginasSB 1197B80proofAún no hay calificaciones

- Snap-Tite Check ValvesDocumento8 páginasSnap-Tite Check ValvesMauricio De'LeónAún no hay calificaciones

- Series U009 Specification SheetDocumento4 páginasSeries U009 Specification SheetWattsAún no hay calificaciones

- Hydratight PDFDocumento40 páginasHydratight PDFTamer Farahat100% (1)

- Series 757DCDA, 757NDCDA Specification SheetDocumento4 páginasSeries 757DCDA, 757NDCDA Specification SheetWattsAún no hay calificaciones

- Torque SpecificationsDocumento50 páginasTorque SpecificationsNilton sergio gomes lins100% (1)

- CH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsDocumento46 páginasCH 11 - Rocker Arm Assembly, Camshaft Assembly, Tappets & Push RodsEnrrique LaraAún no hay calificaciones

- SM47013 PDFDocumento8 páginasSM47013 PDFHENKO7659Aún no hay calificaciones

- Telescoping RHS & PIPE PDocumento2 páginasTelescoping RHS & PIPE PRichard WebbAún no hay calificaciones

- QSG12 C CheckDocumento5 páginasQSG12 C CheckNikkikumar MaisuriyaAún no hay calificaciones

- Es Lfu009Documento4 páginasEs Lfu009WattsAún no hay calificaciones

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3De EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Aún no hay calificaciones

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDe EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsCalificación: 5 de 5 estrellas5/5 (1)

- Prompting Science and Engineering Students in Practical TrigonometryDe EverandPrompting Science and Engineering Students in Practical TrigonometryAún no hay calificaciones

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDe EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreCalificación: 4.5 de 5 estrellas4.5/5 (11)

- LAP Register To WLCDocumento12 páginasLAP Register To WLCAditya NugrahaAún no hay calificaciones

- Pass4sure 200-120 PDF DownloadDocumento8 páginasPass4sure 200-120 PDF DownloadEleanor19Aún no hay calificaciones

- Standing Waves Worksheet SolutionsDocumento6 páginasStanding Waves Worksheet SolutionsMaher TrabelsiAún no hay calificaciones

- HVDC Grid Feasibility StudyDocumento189 páginasHVDC Grid Feasibility StudyDeoudrafAún no hay calificaciones

- Demo-C Tfin52 67Documento5 páginasDemo-C Tfin52 67namank005Aún no hay calificaciones

- Grade CalculatorDocumento1 páginaGrade CalculatorKHENN ALDIANOAún no hay calificaciones

- Air Tool S2 A100 PDFDocumento2 páginasAir Tool S2 A100 PDFjhony andreasAún no hay calificaciones

- Chapter 1 XXXDocumento8 páginasChapter 1 XXXChristelle Mary Sabile SabanalAún no hay calificaciones

- TNK500P Taneko Industrial Generator (TNK JKT)Documento2 páginasTNK500P Taneko Industrial Generator (TNK JKT)Rizki Heru HermawanAún no hay calificaciones

- Netsys NVF-200EKIT User Guide 1.0.6Documento19 páginasNetsys NVF-200EKIT User Guide 1.0.6pkramellaAún no hay calificaciones

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDocumento3 páginasXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhAún no hay calificaciones

- Direct Stiffness Method for Truss AnalysisDocumento28 páginasDirect Stiffness Method for Truss Analysisgilberthufana446877Aún no hay calificaciones

- Vol 4 Div G ODS Part 1 of 2-Pages-18-55Documento38 páginasVol 4 Div G ODS Part 1 of 2-Pages-18-55debapriyoAún no hay calificaciones

- Introduction To CAL ProgrammingDocumento198 páginasIntroduction To CAL ProgrammingSalam Mohamed RiyadAún no hay calificaciones

- Magic Quadrant For Identity Governance and AdministrationDocumento18 páginasMagic Quadrant For Identity Governance and AdministrationmilosvblAún no hay calificaciones

- Technical Information HANSA-FLEX Hose ConnectionsDocumento75 páginasTechnical Information HANSA-FLEX Hose ConnectionshorsanicuAún no hay calificaciones

- Çimsa Eco White TDS (EN)Documento1 páginaÇimsa Eco White TDS (EN)Babu NysemereAún no hay calificaciones

- Cava v6 1x Install enDocumento29 páginasCava v6 1x Install enWael SalahAún no hay calificaciones

- SAE StandardDocumento28 páginasSAE Standardwei foo83% (6)

- Life 365 V 2 Users ManualDocumento67 páginasLife 365 V 2 Users ManualAmanda VegaAún no hay calificaciones

- Char-Lynn (Eaton) - 158-2925-001 - Motion IndustriesDocumento2 páginasChar-Lynn (Eaton) - 158-2925-001 - Motion Industriesgeovane cardosoAún no hay calificaciones

- System ConfigurationDocumento13 páginasSystem ConfigurationEdlyn Estopa BuenoAún no hay calificaciones

- Microwave Engineering - E-H Plane TeeDocumento6 páginasMicrowave Engineering - E-H Plane TeeJoker FAún no hay calificaciones

- PM IS - 12818 June2021Documento10 páginasPM IS - 12818 June2021Mahendra AhirwarAún no hay calificaciones

- Computer Aided Design Course Code: 3341904Documento7 páginasComputer Aided Design Course Code: 3341904Dhaval UpadhyayAún no hay calificaciones

- Total Internal Reflection and Critical Angle VedioDocumento16 páginasTotal Internal Reflection and Critical Angle VedioNor AzizahAún no hay calificaciones

- Lincoln FC ElectrodesDocumento44 páginasLincoln FC ElectrodeszmcgainAún no hay calificaciones

- CV Software Engineer Sarika DhingraDocumento2 páginasCV Software Engineer Sarika DhingravirenderbishnoiAún no hay calificaciones

- Distillation Is Defined As:: How Does Distillation Work?Documento35 páginasDistillation Is Defined As:: How Does Distillation Work?sankalpnambiarAún no hay calificaciones