Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Verification and Validation According To ISO 26262

Cargado por

최재호Título original

Derechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Verification and Validation According To ISO 26262

Cargado por

최재호Copyright:

Formatos disponibles

Verification and Validation According to ISO 26262: A Workflow to Facilitate the Development of High-Integrity Software

Mirko Conrad

The MathWorks, Inc. Natick, MA, USA mirko.conrad@mathworks.com

ABSTRACT

Model-Based Design with production code generation has been extensively utilized throughout the automotive software engineering community because of its ability to address complexity, productivity, and quality challenges. With new applications such as lane departure warning or electromechanical steering, engineers have begun to consider ModelBased Design to develop embedded software for applications that need to comply with functional safety standards such as ISO 26262. For the development of high-integrity in-vehicle software, ISO 26262 is considered state-of-the-art or generally accepted rules of technology (GART) [Fal02, Lov06]. Developers of in-vehicle software need to understand and implement the standards requirements pertaining to software development. Due to the widespread utilization of Model-Based Design to develop automotive E/E systems, it is of particular importance to set-up ISO 26262 compliant Model-Based Design processes and tool chains. This paper discusses a verification and validation workflow for developing in-vehicle software components which need to comply with ISO 26262-6 using Model-Based Design. It discusses tool support by using a Simulink family tool chain for Model-Based Design as an example.

KEYWORDS: Functional Safety, ISO 26262, Model-Based Design, Reference Workflow, Verification and Validation of

Models and Generated Code, Simulink, Embedded Coder, IEC Certification Kit

INTRODUCTION

The increasing application of embedded software in passenger cars has resulted in a staggering complexity that has proven difficult to negotiate with conventional design approaches and processes. In addition, more and more projects need to comply with functional safety standards, because modern software-based electronic control units (ECUs) control or interact with critical systems such as brakes and steering. Development approaches and processes play a decisive role in addressing the complexity, productivity, and quality challenges. Because of its ability to address these challenges, Model-Based Design has been extensively used throughout the automotive software engineering community. More recently, automotive OEMs and suppliers have begun to consider and adopt Model-Based Design for the development of embedded software for high-integrity applications that need to meet requirements of the ISO 26262 standard. ISO 26262 Road Vehicles - Functional Safety [ISO 26262] is the adaptation of IEC 61508 [IEC 61508] to comply with needs specific to the application sector of electric / electronic systems (E/E systems) within road vehicles. This adaptation applies to all activities during the safety lifecycle of systems composed of electrical, electronic, and software elements that

provide safety-related functions. ISO 26262-6 Product development: software level [ISO 26262-6] is concerned with software development, verification, and validation. Model-Based Design tools such as Simulink and Stateflow [Simulink] can be used throughout multiple phases of the software life cycle. Model-Based Design enables early simulation and testing of the functional behavior as well as automatic code generation for production systems. Production code generation within Model-Based Design has replaced manual coding in various vehicle domains and generated code is increasingly being deployed in high-integrity applications [JSB+08, FMC08]. The use of Model-Based Design for high-integrity applications requires extra consideration and rigor because additional requirements imposed by functional safety standards such as ISO 26262 have to be met. To improve quality and functional safety, models and generated code should be subjected to a combination of quality assurance measures. Further, compliance with ISO 26262 needs to be demonstrated. This paper discusses how Model-Based Design and associated verification and validation techniques can be leveraged to help develop automotive applications that comply with ISO 26262. It covers the mapping of selected ISO 26262-6 objectives onto Model-Based Design.

A WORKFLOW FOR VERIFICATION AND VALIDATION OF MODELS AND GENERATED CODE

ISO 26262 calls for application-specific verification and validation regardless of the tool chain and the development process used. When using Model-Based Design with production code generation, application-specific verification and validation needs to answer the following questions: Does the model implement its (textual) requirements? Does the object code to be deployed in the ECU implement the design embodied in the model?

To facilitate a seamless use of Model-Based Design in the context of ISO 26262, a reference workflow that describes the verification and validation activities necessary for ISO 26262-6 compliance [Cert Kit] has been developed by MathWorks and audited by the certification authority TV SD. The ISO 26262 workflow is derived from a similar reference workflow for the generic IEC 61508 standard [Con08, Con09]. Following the suggested division of the verification and validation activities for applications developed using Model-Based Design and production code generation, the workflow can be divided into the following steps (Fig 1): 1. Design Verification: Demonstrate that the model satisfies its specification and does not contain unintended functionality. 2. Code Verification: Show that the generated code matches the model and does not contain unintended functionality. Utilizing similar workflows for IEC 61508 and ISO 26262 streamlines the software development activities of companies that need to comply with different standards for different projects.

M2

M1

Model used for Production Code Generation

C2

C1

(Textual) Requirements

Executable Specification

...

C Source Code

Object Code

Modeling

Production Code Generation

Compilation / Linking

Verification,Validation, and Testing at the Model Level

Software Development Artifact / Work Product Software Development Activity

Verification, Validation, and Testing at the Code Level

Software Verification / Validation Activity

M1 M2 C1 C2

Reviews and static analyses at the model level Module and integration testing at the model level Back-to-back comparison testing between model and code Measures to prevent unintended functionality

Fig. 1: Reference workflow for application-specific verification and validation of models and generated code DESIGN VERIFICATION VERIFICATION, VALIDATION, AND TESTING AT THE MODEL LEVEL The goal of design verification is to gain confidence in the model that is being used for production code generation. Design verification takes place at the model level, before the code is generated. The design verification part comprises a combination of reviews, static analyses, and comprehensive functional testing activities at the model level [Con08, Con09]. These activities together help provide confidence that the design satisfies the associated requirements, does not contain unintended functionality and complies with defined modeling guidelines. [M1] Reviews and Static Analyses at the Model Level Model components, i.e. model subsystems considered as modules, should be reviewed. If feasible, these manual model reviews should be supported by automated static analyses of the model [Beg07]. Modeling guidelines should be used and adherence with the guidelines should be assessed. Modeling constructs that are not suited or not recommended for production code generation should not be used. In addition, modeling guidelines addressing specific ISO 26262 objectives should be employed. [M2] Module and Integration Testing at the Model Level Model components should be functionally tested using test cases systematically derived from the software requirements specification. The objective of module testing is to demonstrate that each model component performs its intended function and does not perform unintended functions. As model component testing is completed, components can be integrated. The model integration stages shall be tested in accordance with the dedicated integration tests. These tests should show that all model components interact as specified to perform their intended function and do not perform unintended functions.

A more detailed discussion on testing at the model level can be found in [CF09]. The result of the design verification process is a golden model, i.e., a validated and verified, well-formed model that implements the requirements and does not contain unintended functionality. The golden model serves as a reference for the subsequent code verification activities. CODE VERIFICATION VERIFICATION, VALIDATION, AND TESTING AT THE CODE LEVEL A combination of verification, validation, and testing activities at the code level shall demonstrate that the semantics of the golden model is being preserved during code generation, compilation, and linking. Furthermore, it needs to be shown that no unintended functionality is being introduced during code generation. [C1] Back-to-back Comparison Testing Between Model and Code The reference workflow utilizes translation testing [Con09, Con11], i.e. translation validation using systematic testing, to demonstrate numerical equivalence between the model and the generated C code. Translation testing in this context means that each model-to-code-translation (i.e. a run of the code generation tool chain) is augmented with a back-to-back testing phase (cf. ISO 26262-6, sections 9 and 10) to verify that the executable compiled from the generated C code (object code) matches the golden model. Back-to-back testing for numerical equivalence is well suited to automation, because the expected outputs for the test vectors do not have to be provided [Ald01]. Detailed discussions of back-to-back testing procedures are available in [SM05, SCD+07]. [C2] Measures to Prevent Unintended Functionality Back-to-back testing alone may not be sufficient to demonstrate the absence of unintended functionality in the generated source code. Therefore, back-to-back testing to assess numerical equivalence needs to be augmented with additional measures to demonstrate the absence of unintended functionality. This second activity in the code verification process shall demonstrate that the generated C code does not perform unintended functions, i.e., the code does not contain functionality not embodied in the model. Alternative techniques are available to achieve this objective including (a) model versus code coverage comparison and (b) traceability analysis. These techniques serve the purpose of demonstrating structural equivalence between the model and the source code. If model versus code coverage comparison is being used to show the absence of unintended functionality, model and code coverage are measured during back-to-back testing and compared against each other. Discrepancies with respect to comparable coverage metrics need to be assessed. Alternatively, a traceability analysis can be performed to demonstrate that all parts of the generated C source code can be traced back to the golden model. In this case the generated code is subjected to a limited review that exclusively focuses on traceability aspects. Non-traceable code shall be flagged and assessed. Generation of a traceability matrix to aid traceability analysis is provided in the IEC Certification Kit [Cert Kit].

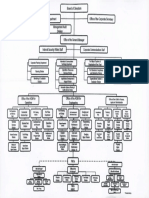

MAPPING ONTO ISO 26262-6 AND COMPLIANCE DEMONSTRATION

The design and code verification activities described in the reference workflow provide core activities to implement requirements of ISO 26262-6 when utilizing executable models and generated code as part of the software life cycle. These activities need to be augmented with additional measures to address other objectives of the ISO 26262 standard. Fig. 2 and 3 map the reference workflow and the corresponding activities in ISO 26262-6 onto each other. Fig. 2 provides a mapping between the ISO 26262-6 design phase activities and the software development artifacts from the reference workflow. Fig. 3 maps design phase verification and test phase verification activities of the standard onto their counterparts in the reference workflow.

Fig. 2: Mapping of software development artifacts and activities

Fig. 3: Mapping of software verification, validation, and testing activities

Examples for carrying out the above mentioned verification, validation and testing activities can be found in [Con11]. When using the reference workflow, compliance demonstration with the applicable requirements of ISO 26262-6 can be facilitated by Checklists that document the realization of the workflow activities and reference the work products created and Artifact management systems supporting the compilation of items for the safety case and traceability between them.

Fig. 4 illustrates the checklist-based compliance demonstration process and the management of associated artifacts with the Artifacts Explorer [CertKit].

Fig. 4: Artifact management tool and checklist-based compliance demonstration (example)

SUMMARY AND CONCLUSION

ISO 26262-6 is the main functional safety standard with respect to software development for high-integrity in-vehicle applications. It defines requirements and constraints for software development, verification and validation processes. These requirements apply to both Model-Based Design with code generation and traditional software development. However, implementing these requirements within Model-Based Design requires special consideration. To aid this process, the author discussed a reference workflow for Model-Based Design and tool considerations to address the objectives of ISO 26262-6. The proposed workflow for verification and validation of models and generated code can be viewed as instantiation of the verification and validation requirements outlined in ISO 26262-6. This instantiation exploits the advantages of production code generation as an integral part of Model-Based Design. The reference workflow can also help to meet the tool qualification requirements of ISO 26262-8 [ISO 26262-8, section 11]. In particular, it can provide the foundation for a pre-qualification of the Model-Based Design tools used in the

implementation of this workflow [CSM11, HKW+11]. Such a procedure was used for the in-context certification by TV SD of the Embedded Coder code generator and other tools for Model-Based Design. A detailed workflow description, together with a compliance demonstration template, and templates for the ISO 26262-8 tool qualification work products are made available as part of the IEC Certification Kit [Cert Kit]. The kit also contains evidence of the independent assessment carried out by TV SD (certificates and corresponding certification reports), the artifacts explorer, and the traceability matrix generation tool.

REFERENCES

[Ald01] [Beg07] [Cert Kit] [CF09] Aldrich, W.: Coverage Analysis for Model-Based Design Tools. TCS 2001. Begic, G.: Checking Modeling Standards Implementation. The MathWorks News & Notes, June 2007. IEC Certification Kit (for ISO 26262 and IEC 61508). www.mathworks.com/products/iec-61508. Conrad, M., Fey, I.: Testing Automotive Control Software. In: Navet, N., Simonot-Lion, F. (Eds): Automotive Embedded Systems Handbook, CRC Press, 2009. [Con08] Conrad, M.: Model-Based Design for IEC 61508: Towards Translation Validation of Generated Code. Proc. Workshop Automotive Software Engineering: Forschung, Lehre, Industrielle Praxis, co-located with Software Engineering 2008, Munich, February 2008. [Con09] Conrad, M.: Testing-based translation validation of generated code in the context of IEC 61508. Form. Methods Syst. Des. 35, 3 (Dec. 2009), 389-401 [Con11] Conrad, M.: Testing-Based Translation Validation of Generated Code. In: Zander, J., Schieferdecker, I., Mostermann, P. J. (Eds): Model-Based Testing for Embedded Systems (Computational Analysis, Synthesis, and Design of Dynamic Systems), CRC Press, 2011 [CSM11] Conrad, M., Sandmann, G., Munier, P.: Software Tool Qualification According to ISO 26262. SAE 2011 World Congress, Detroit, MI, USA, April 2011. SAE Techn. Paper #2011-01-1005 [Fal02] Faller, R.: The Evolution of European Safety Standards. exida.com, 2002. [FMC08] Fey, I., Mller, J., Conrad, M.: Model-Based Design for Safety-Related Applications. Proc. Convergence 2008, Detroit, MI, USA, Oct. 2008 [IEC 61508] IEC 61508 Functional Safety of Electrical/Electronic/ Programmable Electronic Safety-Related Systems. International Standard, 2nd edition, 2010. [ISO 26262] ISO 26262 Road vehicles - Functional safety. International Standard, 2011. [ISO 26262-6] ISO 26262 Road vehicles - Functional safety - Part 6: Product development: software level. International Standard, 2011. [ISO 26262-8] ISO 26262 Road vehicles - Functional safety - Part 8: Supporting processes. International Standard, 2011. [JSB+08] Jablonski, T., Schumann, H., Busse, C., Haussmann, H., Hallmann, U., Dreyer, D., Schttler, F.: Die neue elektromechanische Lenkung APA-BS. ATZelektronik 01/2008 Vol. 3 (2008) 01, pp. 3035. [Lov06] Lovric, T.: Sicherheitsanforderungen an Fahrerassistenzsysteme. 2. Sachverstndigentag (SVT 2006), Sept. 2006. [Simulink] Simulink. www.mathworks.com/products/simulink [SM05] Strmer, I.; Conrad, M.: Ein Testverfahren fr optimierende Codegeneratoren. Inform. Forsch. Entwickl. 19(4): 213-223 (2005). [SCD+07] Strmer, I.; Conrad, M.; Drr, H.; Pepper, P.: Systematic Testing of Model-Based Code Generators. IEEE Transactions on Software Engineering, Sep. 2007, pp. 622-634. [HKW+11] Hamann, R., Kriso, S., Williams, K., Klarmann, J., Sauler, J.: ISO 26262 Release Just Ahead: Remaining Problems and Proposals for Solutions. Proc. SAE World Congress 2011, Detroit, MI, USA, April 2011.

CONTACT

Dr. Mirko Conrad Development Manager - Simulink Certification and Standards; The MathWorks, Inc. Mirko.Conrad@mathworks.com

Mirko Conrad manages MathWorks certification and standards team. He oversaw the certification of Embedded Coder, Simulink Verification and Validation, and Simulink Design Verifier for usage in development processes that need to comply with IEC 61508, ISO 26262 related standards. His team develops and maintains the IEC Certification Kit.

Mirko started his professional career in the automotive industry in 1995 and joined The MathWorks in 2006. He holds a Ph.D. in engineering (Dr.-Ing.) and a M.Sc. in computer studies (Dipl.-Inform.) from Technical University Berlin, Germany. Mirko is also a visiting lecturer at Humboldt University in Berlin and Technical University Munich. His publication record includes more than 80 papers on automotive software engineering, functional safety, and Model-Based Design. He is a member of the managing team of the Special Interest Group for Automotive Software Engineering in the German Computer Society (GI-ASE) and was a member of the ISO 26262 standardization sub-working group on software.

También podría gustarte

- What Is The ISO 26262 Functional Safety Standard?: Updated Mar 5, 2019Documento8 páginasWhat Is The ISO 26262 Functional Safety Standard?: Updated Mar 5, 2019Marziyeh MoosaviAún no hay calificaciones

- Iso 26262Documento6 páginasIso 26262Ghassan Alasmar50% (2)

- Applied Sciences: Safety-Oriented System Hardware Architecture Exploration in Compliance With ISO 26262Documento29 páginasApplied Sciences: Safety-Oriented System Hardware Architecture Exploration in Compliance With ISO 26262Girish KasturiAún no hay calificaciones

- Automotive SPICE Process Reference Model: TitleDocumento47 páginasAutomotive SPICE Process Reference Model: TitleHoa LuuAún no hay calificaciones

- 4 - Ensure Freedom From Interference FFI For ASIL Applications - TASKINGDocumento19 páginas4 - Ensure Freedom From Interference FFI For ASIL Applications - TASKINGDumitru IngeauaAún no hay calificaciones

- IEC Certification Kit: Model-Based Design For ISO 26262Documento31 páginasIEC Certification Kit: Model-Based Design For ISO 26262Ícaro VianaAún no hay calificaciones

- 07.TAI Seminar WHAT Is FUNCTIONAL SAFETY BKK 25june2015 HandsoutDocumento33 páginas07.TAI Seminar WHAT Is FUNCTIONAL SAFETY BKK 25june2015 HandsoutsunithaAún no hay calificaciones

- ISO 26262-10-2012-Road Vehicles Functional Safety Guideline On ISO 26262Documento100 páginasISO 26262-10-2012-Road Vehicles Functional Safety Guideline On ISO 26262Cycy Hm100% (1)

- The UL 4600 Guidebook: What to Include in an Autonomous Vehicle Safety CaseDe EverandThe UL 4600 Guidebook: What to Include in an Autonomous Vehicle Safety CaseAún no hay calificaciones

- Session22-A-SPICE Compliance Made Easy Case Studies and Lessons LearnedDocumento49 páginasSession22-A-SPICE Compliance Made Easy Case Studies and Lessons LearnedHaissamAún no hay calificaciones

- Iso 26262 Training: Module K4 - Product Development at System LevelDocumento65 páginasIso 26262 Training: Module K4 - Product Development at System LevelPradhan HAún no hay calificaciones

- AUTOSAR and Functional Safety PDFDocumento26 páginasAUTOSAR and Functional Safety PDFbnd1uAún no hay calificaciones

- Aspice, Fusa and LeanDocumento13 páginasAspice, Fusa and LeanMarco GesslerAún no hay calificaciones

- Functional Safety Embedded Systems: Integration of in The Development Process ofDocumento34 páginasFunctional Safety Embedded Systems: Integration of in The Development Process ofAleksandar MilinkovicAún no hay calificaciones

- Experience With ISO 26262 ASIL DecompositionDocumento27 páginasExperience With ISO 26262 ASIL DecompositionSilica DorinaAún no hay calificaciones

- 05 - Lesson 3 Safety Frameworks For Self Driving - C1M3L3 - Safety - Frameworks - For - Self Driving PDFDocumento24 páginas05 - Lesson 3 Safety Frameworks For Self Driving - C1M3L3 - Safety - Frameworks - For - Self Driving PDFprogisAún no hay calificaciones

- Exposure VDA 702 062015Documento11 páginasExposure VDA 702 062015Ninja WAO2Aún no hay calificaciones

- AUTOSAR For Dummies - #10 - AUTOSAR and ISO26262 - Automotive ElectronicsDocumento5 páginasAUTOSAR For Dummies - #10 - AUTOSAR and ISO26262 - Automotive ElectronicsSameer KumthekarAún no hay calificaciones

- Automotive Functional Safety Best-Practices - ISO 26262 Standard - EmbitelDocumento5 páginasAutomotive Functional Safety Best-Practices - ISO 26262 Standard - Embitelprasanna_npAún no hay calificaciones

- UDS Protocol Implementation in Automotiv PDFDocumento6 páginasUDS Protocol Implementation in Automotiv PDFviernes06Aún no hay calificaciones

- ASIL (ISO 26262) DecompositionDocumento39 páginasASIL (ISO 26262) DecompositionMadhusudhanan RavishankarAún no hay calificaciones

- ISO 26262 Complete Self-Assessment GuideDe EverandISO 26262 Complete Self-Assessment GuideCalificación: 3 de 5 estrellas3/5 (2)

- ISO26262 and IEC61508Documento12 páginasISO26262 and IEC61508최재호100% (1)

- Iso 26262 1 2018Documento13 páginasIso 26262 1 2018Wooyoung LeeAún no hay calificaciones

- ISO 26262 Meets AUTOSAR - First Lessons Learned - : Dr. Günther HelingDocumento19 páginasISO 26262 Meets AUTOSAR - First Lessons Learned - : Dr. Günther Heling조용규Aún no hay calificaciones

- Asil DecompositionDocumento23 páginasAsil DecompositionkingsukumarAún no hay calificaciones

- Simulink Fu SaDocumento55 páginasSimulink Fu SaMarc WoutersAún no hay calificaciones

- Iso 26262Documento78 páginasIso 26262Fady Emad100% (1)

- Safety Critical Systems A Complete Guide - 2021 EditionDe EverandSafety Critical Systems A Complete Guide - 2021 EditionAún no hay calificaciones

- Dspace-Paper Hil Overview Waeltermann e 160405 PDFDocumento14 páginasDspace-Paper Hil Overview Waeltermann e 160405 PDFPranay VermaAún no hay calificaciones

- AUTomotive Open System ARchitecture A Complete Guide - 2020 EditionDe EverandAUTomotive Open System ARchitecture A Complete Guide - 2020 EditionAún no hay calificaciones

- ISO 26262 Introduction - V1.0Documento14 páginasISO 26262 Introduction - V1.0Martin BoianiAún no hay calificaciones

- FuSa standards and vehicle power electronicsDocumento21 páginasFuSa standards and vehicle power electronics204 makerAún no hay calificaciones

- Requirements of ISO 26262Documento3 páginasRequirements of ISO 26262IQPC GmbH100% (2)

- ISO26262 Product Development System LevelDocumento14 páginasISO26262 Product Development System LevelMartin BoianiAún no hay calificaciones

- Rimac Automobili Cybersecurity EngDocumento1 páginaRimac Automobili Cybersecurity EngudbarryAún no hay calificaciones

- Design of Micro Controllers For SafetyDocumento50 páginasDesign of Micro Controllers For SafetyLuca BeniniAún no hay calificaciones

- Functional SafetyDocumento8 páginasFunctional SafetyMiceasnagovAún no hay calificaciones

- D2A1 1 2 ESL Virtual Hardware SetupDocumento15 páginasD2A1 1 2 ESL Virtual Hardware SetupRaj Shekhar ReddyAún no hay calificaciones

- H Da Barth Functional Safety On MulticoreDocumento23 páginasH Da Barth Functional Safety On Multicores.b.v.seshagiri1407Aún no hay calificaciones

- ASPICE Guide KM2021 04Documento316 páginasASPICE Guide KM2021 04niketa engineerAún no hay calificaciones

- CV Resume NaderJSA En03 PDFDocumento3 páginasCV Resume NaderJSA En03 PDFazitaggAún no hay calificaciones

- Functional Safety in Automotive Electronics: Zhang Xinbo, Luo FengDocumento8 páginasFunctional Safety in Automotive Electronics: Zhang Xinbo, Luo FengVinoth kumarAún no hay calificaciones

- Emaus Vector Canoe SlidesDocumento12 páginasEmaus Vector Canoe SlidesvlsishekarAún no hay calificaciones

- Engine Control Failure Test Using HILS - Aisar RomasDocumento19 páginasEngine Control Failure Test Using HILS - Aisar RomasAisar Labibi Romas100% (1)

- Model Based TestingDocumento43 páginasModel Based Testingsandeep yadavAún no hay calificaciones

- Advanced Driver Assistance Systems (ADAS) Standard RequirementsDe EverandAdvanced Driver Assistance Systems (ADAS) Standard RequirementsAún no hay calificaciones

- Iso 26262 Dis Tutorial 2010 Final - 1 PDFDocumento160 páginasIso 26262 Dis Tutorial 2010 Final - 1 PDFashim_verma100% (1)

- 3 ISO26262 AssessmentDocumento19 páginas3 ISO26262 AssessmentOscar Alfonso Iñigo GéneraAún no hay calificaciones

- Iso26262 - Automotive BasicsDocumento10 páginasIso26262 - Automotive Basicsg_sandy_reddy2482100% (1)

- AUTOSAR and Functional SafetyDocumento26 páginasAUTOSAR and Functional Safety조용규Aún no hay calificaciones

- International Standard: Road Vehicles - Functional Safety - Product Development at The System LevelDocumento44 páginasInternational Standard: Road Vehicles - Functional Safety - Product Development at The System LevelNhat Han NguyenAún no hay calificaciones

- R4 AQUA-ASPICE-iDesigner EN v4Documento97 páginasR4 AQUA-ASPICE-iDesigner EN v4Berry Blue100% (1)

- ISO26262 Automotive safety standard overviewDocumento9 páginasISO26262 Automotive safety standard overviewJoseph Kymm100% (5)

- Whitepaper Changes IEC 61496 en IM0051633 PDFDocumento8 páginasWhitepaper Changes IEC 61496 en IM0051633 PDFjurica_2006Aún no hay calificaciones

- Oj MD Celex 32021D1813 en TXTDocumento10 páginasOj MD Celex 32021D1813 en TXT최재호Aún no hay calificaciones

- PreviewDocumento10 páginasPreview최재호Aún no hay calificaciones

- Robot Certification Guide Final 02Documento18 páginasRobot Certification Guide Final 02최재호Aún no hay calificaciones

- Reliability Data - SMALL ENCODERDocumento4 páginasReliability Data - SMALL ENCODER최재호Aún no hay calificaciones

- Whitepaper Changes IEC 61496 en IM0051633 PDFDocumento8 páginasWhitepaper Changes IEC 61496 en IM0051633 PDFjurica_2006Aún no hay calificaciones

- Whitepaper Changes IEC 61496 en IM0051633 PDFDocumento8 páginasWhitepaper Changes IEC 61496 en IM0051633 PDFjurica_2006Aún no hay calificaciones

- b10 Valdoc Irv Irvn-Sm00004Documento3 páginasb10 Valdoc Irv Irvn-Sm00004최재호Aún no hay calificaciones

- Application Note Functional Safety and Reliability 06 2021 - B10 B10d - EditedDocumento24 páginasApplication Note Functional Safety and Reliability 06 2021 - B10 B10d - Edited최재호Aún no hay calificaciones

- Hazard and Risk AssessmentDocumento99 páginasHazard and Risk Assessment최재호83% (6)

- Prosafe Rs Im32q01s10 31eDocumento27 páginasProsafe Rs Im32q01s10 31e최재호Aún no hay calificaciones

- Safety Component Guide - OmronDocumento86 páginasSafety Component Guide - Omron최재호Aún no hay calificaciones

- Functional Safety With Iec62061 and Iso13849Documento1 páginaFunctional Safety With Iec62061 and Iso13849최재호0% (1)

- 내부 소개자료 - V2.0 PDFDocumento44 páginas내부 소개자료 - V2.0 PDF최재호Aún no hay calificaciones

- 000004104Documento25 páginas000004104최재호Aún no hay calificaciones

- Development of An ISO 26262 ASIL DDocumento103 páginasDevelopment of An ISO 26262 ASIL D최재호100% (2)

- ISO26262 and IEC61508Documento12 páginasISO26262 and IEC61508최재호100% (1)

- Iso 14102 98Documento10 páginasIso 14102 98최재호Aún no hay calificaciones

- Polarion User Finland Day ISOPolarion-User-Finland-Day-ISO2626226262Documento19 páginasPolarion User Finland Day ISOPolarion-User-Finland-Day-ISO2626226262최재호Aún no hay calificaciones

- Icstt Rm449 en PDocumento17 páginasIcstt Rm449 en P최재호Aún no hay calificaciones

- Design of Micro Controllers For SafetyDocumento50 páginasDesign of Micro Controllers For SafetyLuca BeniniAún no hay calificaciones

- Chapter26 Add.1 EvaporatINTERVENTION ON GASES AND EVAPORATORSorsDocumento8 páginasChapter26 Add.1 EvaporatINTERVENTION ON GASES AND EVAPORATORSors최재호Aún no hay calificaciones

- SIS ESD Sistems For Process Industries Using IEC 61508 Unit7 SIL SelectionDocumento100 páginasSIS ESD Sistems For Process Industries Using IEC 61508 Unit7 SIL Selection최재호Aún no hay calificaciones

- Availability, Reliability, SIL: Mean Time Between Failures (MTBF)Documento4 páginasAvailability, Reliability, SIL: Mean Time Between Failures (MTBF)최재호Aún no hay calificaciones

- Functional Example No AS-FE-II-002-V10-ENDocumento93 páginasFunctional Example No AS-FE-II-002-V10-ENGrant DouglasAún no hay calificaciones

- Failure Modes and EffectFAILURE MODES AND EFFECTS ANALYSIS (FMEA) Analysis (Fmea)Documento147 páginasFailure Modes and EffectFAILURE MODES AND EFFECTS ANALYSIS (FMEA) Analysis (Fmea)최재호Aún no hay calificaciones

- Basics of Functional Safety in Process Industry (SIL ClassificationDocumento33 páginasBasics of Functional Safety in Process Industry (SIL Classification최재호Aún no hay calificaciones

- ISA-TR84.00.02-2002 - Part 3Documento72 páginasISA-TR84.00.02-2002 - Part 3Masoud MasoudiAún no hay calificaciones

- SIEMENS SIL Safety ManualDocumento30 páginasSIEMENS SIL Safety Manual최재호Aún no hay calificaciones

- Functional Safety For MachineryDocumento23 páginasFunctional Safety For Machinery최재호Aún no hay calificaciones

- PPA Organizational ChartDocumento1 páginaPPA Organizational ChartJohn Wendell Fontanilla FerrerAún no hay calificaciones

- S 4 Hana Overview - PDF CatalogueDocumento17 páginasS 4 Hana Overview - PDF CatalogueSayantani Bhattacharya0% (1)

- Fit For Growth PDFDocumento14 páginasFit For Growth PDFAnand Kumar Jha100% (1)

- Models of Service QualityDocumento12 páginasModels of Service QualityAmmy D ExtrovertAún no hay calificaciones

- Smart Mill Liners FlyerDocumento2 páginasSmart Mill Liners FlyerDaniel NovarioAún no hay calificaciones

- Business PlanDocumento8 páginasBusiness PlanmklrlclAún no hay calificaciones

- Modern Supply Chain ManagementDocumento19 páginasModern Supply Chain ManagementSrinivasa Rao Asuru100% (2)

- Quick Tip Guide: For Establishing, Sustaining, and Advancing Your PmoDocumento12 páginasQuick Tip Guide: For Establishing, Sustaining, and Advancing Your Pmosstrummer100% (1)

- Strategic Management: Participant's GuideDocumento48 páginasStrategic Management: Participant's GuideAdriana Popescu100% (1)

- Bulletin of Vacant Positions Bureau of Customs 12 05 16Documento216 páginasBulletin of Vacant Positions Bureau of Customs 12 05 16TobzMakabayanAún no hay calificaciones

- Jim Vanderbleek Resume' Time LineDocumento2 páginasJim Vanderbleek Resume' Time LineAllison TurnerAún no hay calificaciones

- HR-EssentialsDocumento29 páginasHR-EssentialsReineAún no hay calificaciones

- CH 01 (Day 01) PDFDocumento7 páginasCH 01 (Day 01) PDFAnonymous yL88JjAún no hay calificaciones

- Changes in IATF ISO 9k PlusDocumento81 páginasChanges in IATF ISO 9k PlusRoberto VeroAún no hay calificaciones

- Elite Game Lounge Business PlanDocumento39 páginasElite Game Lounge Business PlancarolAún no hay calificaciones

- SOP Formal TemplateDocumento4 páginasSOP Formal TemplateJemVivarAún no hay calificaciones

- HRM Practices at Allied BankDocumento11 páginasHRM Practices at Allied BankAhmer Khan0% (1)

- Justin Chak: EducationDocumento1 páginaJustin Chak: EducationDanishevAún no hay calificaciones

- CS8494 - SE 2marks & 16 Marks PDFDocumento39 páginasCS8494 - SE 2marks & 16 Marks PDFsathya priya0% (1)

- The Agile Manager - McKinsey PDFDocumento7 páginasThe Agile Manager - McKinsey PDFdlokAún no hay calificaciones

- Devops Study GuideDocumento41 páginasDevops Study Guideca_martin-1Aún no hay calificaciones

- Causal Analysis and Resolution ProcedureDocumento4 páginasCausal Analysis and Resolution ProcedureLuk OystAún no hay calificaciones

- The Balanced Scorecard: A Tool To Implement StrategyDocumento39 páginasThe Balanced Scorecard: A Tool To Implement StrategyAilene QuintoAún no hay calificaciones

- Inventory ERDDocumento1 páginaInventory ERDDock N DenAún no hay calificaciones

- Uitm Master Eng SyllabusDocumento7 páginasUitm Master Eng SyllabusJesse KaufmanAún no hay calificaciones

- Quality 101 - Quality Assurance Question and Answers - TrenovisionDocumento92 páginasQuality 101 - Quality Assurance Question and Answers - Trenovisionajith amigosAún no hay calificaciones

- GU 16 Transportation Pricing Strategy and To Reduce CostDocumento20 páginasGU 16 Transportation Pricing Strategy and To Reduce CostTanmayAún no hay calificaciones

- Chapter 2 Case Application (MOB)Documento11 páginasChapter 2 Case Application (MOB)TưĐồPhânVân100% (5)

- Management Accounting Techniques CompilationDocumento40 páginasManagement Accounting Techniques CompilationGracelle Mae Oraller100% (1)

- Project Report Samples For MBADocumento23 páginasProject Report Samples For MBASRIPRIYAAún no hay calificaciones