Documentos de Académico

Documentos de Profesional

Documentos de Cultura

Downloader

Cargado por

habib_etaDerechos de autor

Formatos disponibles

Compartir este documento

Compartir o incrustar documentos

¿Le pareció útil este documento?

¿Este contenido es inapropiado?

Denunciar este documentoCopyright:

Formatos disponibles

Downloader

Cargado por

habib_etaCopyright:

Formatos disponibles

Download

Page 1 of 45

Search

Upload Browse Go Pro Login Signup

Favorite

Save

Flag

Embed

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 2 of 45

Related

More

download 866 views

download 123 views

download 127 views

download 135 views

download 124 views

Download 728 views

Download 260 views

download 142 views

Download 73 views

Download 101 views

download 388 views

Download 137 views

download 476 views

Download 525 views

DOWNLOAD 99 views

Download 220 views

Download 718 views

Download 1903 views

Download 518 views

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 3 of 45

Download 891 views

Download

Dnv os c101 design of offshore steel structures, general (lrfd method)

Download

Download

Download

Dnv os b101 metallic materials

Download

Dnv offshore codes current amendments and corrections

Download

Download

Download

Download

Download

Download

Download

Download

Download

Download

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 4 of 45

Download

Download

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 5 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 6 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 7 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 8 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 9 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 10 of 45

/16

1

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 11 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 12 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 13 of 45

Download

by Phieu Du on Jun 12, 2012

51

views

More

No comments yet

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 14 of 45

Post Comment

Subscribe to comments

Download 1. Safe Welding, Cutting, and Other Hot Work Practicesin Refineries, Gas Plants, and

Document Transcript

Petrochemical Plants API PUBLICATION 2009 SIXTH EDITION, SEPTEMBER 1995 American Petroleum Institute 1220 L Street, Northwest Washington, D.C. 20005Strategies for Todays Environmental Partnership 1 1COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 2. A P I PUBLlr2009 95 m 0 7 3 2 2 9 0 0550333 2 5 3 m STEP One of the most significant long-term trends affecting the future vitality petroleum of the industry is the publics concerns about the environment. Recognizing this trend, API member companies have developed a positive, forward looking strategy called STEP: Strategies for Todays Environmental Partnership. This program aims to address public concerns by improving industrys environmental, health, and safety performance; docu- menting performance improvements;and communicating them to the public. founda- The tion of STEP is the API Environmental Mission and Guiding Environmental Principles. API standards, by promoting the use sound engineeringand operational practices, are of an important means of implementing APIsSTEP program. API ENVIRONMENTAL MISSION AND GUIDING ENVIRONMENTAL PRINCIPLES The members of the American Petroleum Institute are dedicated tocontinuous efforts to improve the compatibility of our operations with the environment while economically developing energy resources and supplying high-quality products and services to consumers. The members recognize the importanceof efficiently meeting societys needs and our responsibility to work with the public, the government, and others to develop and to use natural resources in an environmentally sound manner while protecting health the and safety ofour employees and the public. To meet these responsibilities, API members pledge to manage our businesses according these principles: to To recognize and to respond to communityconcerns about our raw materials, products, and operations. To operate our plants and facilities and to handle our raw materials and products in a manner that protects the environment and the safety andof our employees and the health public. To make safety, health, and environmental considerationsa priority in our planning and our development of new products and processes. To advise promptly the appropriate officials, employees, customers, and the public of information on significant industry-related safety, health, environmental hazards, and and to recommend protective measures. To counsel customers, transporters, and others in the safe use, transportation, and disposal of our raw materials, products, and waste materials. To economically develop and produce natural resources and to conserve those resources by using energy efficiently. To extend knowledge by conducting or supporting research on the safety, health, and environmental effects of our raw materials, products, processes, and wastematerials. To commit to reduce overallemissions and waste generation. To work with others toresolve problems created by handling anddisposal of hazardous substances from our operations. To participate with government and others creating responsible laws, in regulations, and standards to safeguard the community, workplace, and environment. To promote these principles practices by sharing experiences and offering and assistance to others who produce, handle, use, transport, or dispose of similar raw materials, petroleum products, and wastes.COPYRIGHT American Petroleum

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 15 of 45

InstituteLicensed by Information Handling Services 3. Safe Welding, Cutting, and Other Hot Work Practices in Refineries, Gas Plants, and Petrochemical Plants Health and Environmental Affairs Department Safety and Fire Protection Group API PUBLICATION 2009 SIXTH EDITION, SEPTEMBER 1995 American Petroleum InstituteCOPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 4. ~ A P I PUBL*2009 95 0732290 0550335 02b SPECIAL NOTES 1. API PUBLICATIONS NECESSARILY ADDRESS PROBLEMS OF A GENERAL NATURE. WITH RESPECT TO PARTICULAR CIRCUMSTANCES, LOCAL, STATE, AND FEDERAL LAWS AND REGULATIONS SHOULD BE REVIEWED. 2. API IS NOT UNDERTAKING TOMEET THE DUTIES OF EMPLOYERS, MANU- FACTURERS, OR SUPPLIERS TO WARN AND PROPERLY TRAIN AND EQUIP THEIR EMPLOYEES, AND OTHERS EXPOSED, CONCERNING HEALTH AND SAFETY RISKS AND PRECAUTIONS, NOR UNDERTAIUNG THEIR OBLIGATIONS UNDER LOCAL, STATE, OR FEDERAL LAWS,. 3. INFORMATION CONCERNING SAFETY AND HEALTH RISKS AND PROPER PRECAUTIONS WITH RESPECT TO PARTICULAR MATERIALS AND CONDITIONS SHOULD BE OBTAINED FROM THE EMPLOYER, THE MANUFACTURER OR SUPPLIER OF THAT MATERIAL, ORTHE MATERIAL SAFETYDATA SHEET. 4. NOTHING CONTAINED IN ANY API PUBLICATION TO BE CONSTRUED AS IS GRANTING ANY RIGHT, BY IMPLICATION OR OTHERWISE, FORTHE MANU- FACTURE, SALE, OR USE OF ANY METHOD, APPARATUS, OR PRODUCT COVERED BY LETTERS PATENT. NEITHER SHOULD ANYTHING CONTAINED IN THE PUBLICATION BE CONSTRUED AS INSURING ANYONE AGAINST LIABILITY FOR INFRINGEMENTOF LEITERS PATENT. 5 . GENERALLY, API STANDARDS ARE REVIEWED AND REVISED, REAF- FIRMED, OR WITHDRAWN ATLEAST EVERY FIVE YEARS. SOMETIMES ONE-A TIME EXTENSION OF UP TO TWO YEARS WILL BE ADDED TOTHIS REVIEW CYCLE. THIS PUBLICATION WILL NO LONGER BE IN EFFECT FIVE YEARS AFTER ITS PUBLICATION DATEASAN OPERATIVE API STANDARD OR, WHERE AN EXTENSION HAS BEEN GRANTED, UPON REPUBLICATION. THE STATUS OF THE PUBLICATION CAN BE ASCERTAINED FROM THEAPI AUTHORING DEPARTMENT [TELEPHONE (202) 682-8000]. A CATALOG OF API PUBLICATIONS AND MATERIALS IS PUBLISHED ANNUALLY AND UPDATED QUARTERLY BY API, 1220L STREET, N.W., WASHINGTON, D.C.20005. Copyright O 1995 American Petroleum Institute iCOPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 5. FOREWORD This publication provides guidelines the protection of personnel and property when for welding, cutting or other hot work is performed in and around refineries, gas plants, or petrochemical plants. API publications may be used anyone desiring to do so. Every effort hasbeen made by by the Institute to assure the accuracy reliability of thedata containedin them; however, and the Institute makes no representation, warranty, guarantee in connection with this publi- or cation and hereby expressly disclaims any liability or responsibility for loss or damage resulting from its use or for the violationof any federal,state, or municipal regulation with which this publicationmay conflict. Suggested revisions invited and should be submitted the coordinatorof Safety and are to Fire Protection, Health and Environmental Affairs Department, American Petroleum Institute, 1220 L Street, N.W., Washington, D.C. 20005. iiiCOPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 6. A P I P U B L X 2 0 0 7 75 0732270 0550337 9T9 M CONTENTS Page SECTION 1-GENERAL 1.1 Scope......................................................................................................................... 1 1.2 Definition of Terms ................................................................................................... 1 1.3

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 16 of 45

Referenced Publications ........................................................................................... 1 1.4 Additional Reference Material ................................................................................. 2 1.5 General Precautions.................................................................................................. 2 SECTION 2-JOB ANALYSIS AND SPECIAL PRECAUTIONS 2.1 Job Analysis.............................................................................................................. 2 2.2 General ...................................................................................................................... 2 2.3 Wind .......................................................................................................................... 3 2.4 Flammable Liquids, Vapors, Solids, or Dusts........................................................... 3 2.5 Hot Work in Confined Spaces .................................................................................. 3 2.6 Fire Watch Personnel ................................................................................................ 3 2.7 Welding Machines .................................................................................................... 3 2.8 Equipment with Liners ............................................................................................. 3 SECTION 3-HOT WORK PERMITS 3.1 General ...................................................................................................................... 4 3.2 Permit Requirements ................................................................................................ 4 3.3 Extending the Permit ................................................................................................ 4 SECTION "TESTING FOR FLAMMABLE VAPOR AND OXYGEN.............................................................................. 5 SECTION 5PROTECTION OF PERSONNEL............................................ 5 SECTION W O R K ON VESSELS. EXCHANGERS. AND TANKS 6.1 Preparations .............................................................................................................. 5 6.2 Monitoring and Purging of the Atmosphere ............................................................. 6 6.3 Inspection of Internals .............................................................................................. 6 6.4 Work on Outside Surfaces ........................................................................................ 6 SECTION 7-WORK IN ....................................... BUILDINGS AND PITS 7 SECTION 8-WORK ON PIPING ...................................................................... 7 SECTION 9"OTHER WELDING WORK...................................................... 7.. VCOPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 7. Safe Welding, Cutting, and Other Hot Work Practices in Refineries, Gas Plants, and Petrochemical Plants SECTION I-GENERAL 1.1 Scope 1.2.4.2 Threshold limit values (TLVS)~ recommended are This publication provides guidelines for safe practices exposure limits published annually the American Confer- by when welding, cutting or other hot work is performed in ence of Governmental Industrial Hygienists in the booklet refineries, gas plants, or petrochemical plants. Threshold Limit Values and Biological Exposure Indices. The latest edition should consulted. be 1.2 Definition of Terms 1.2.5 A confined space is an enclosure with known or Terms usedin this publication are defined 1.2.1 through in potential hazards and restrictedmeans of entrance and exit, 1.2.6. See 1.3 for publication data. is not normally occupied by people, and is usually not well 1.2.1 A competent person means one who is capable of ventilated. Examples of confined spaces in the petroleum identifying existing and predictable hazards in the surround- industry include the following: process vessels and related ings or working conditions which are unsanitary, hazardous, equipment (vessel tower skirts and flare stacks), boilers, or dangerous to personnel, and who has authorization to take storage tanks, tank cars and trucks, vaults, large-diameter prompt corrective measures to eliminate them. [This defini- piping, and under certain circumstances, spaces located tion is from OSHA, 29 Code of Federal Regulations (CFR) below ground level, such pits (See OSHA definition from as 1926.32.1 29 CFR 1910.146). 1.2.2 The lowerflammable limit (LFL) is the minimum 1.2.6 Hot work is an operation that can produce spark or a concentration of a vapor in air (or other oxidant) below flame or other sourceof ignition having sufficient energy to which propagation of flame does not occur on contact with cause ignition, where the potential for flammable vapors, an ignition source. The lower flammable limit is usually gases, or dust exists. Hot work includes such things as arc, expressed as a volume percentage of the vapor in air. [This gas and cad welding, chipping,flaming,grinding,gas definition is based on the definitions of flammable (explo- cutting, sandblasting, and soldering. sive) limits given in NFPA 325M.I 1.3 Referenced Publications 1.2.3 The upperflammable limit (UFL) is the maximum The latest editions of the following publications are refer- concentration

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 17 of 45

of a vapor in air (or other oxidant) above enced in this publication: which propagation of flame does not occur on contact with an ignition source. The upper flammable limit is usually ACGIH2 expressed as a volume percentage of the vapor in air. [This Threshold Limit Values and Biological Exposure Indices definition is based on the definitions of flammable (explo- ANSI3 sive) limits given in NFPA 325M.I 249.1 Safety in Welding and Cutting Note: In popular terms, a mixtureabove the UFL is too rich to bum and API one below the LFL is too lean to bum. Std 590 Steel Line Blanks 1.2.4 An exposure limit is a measure of the maximum Publ 570 Piping Inspection Code Inspection, Repail; airborne concentration limits for toxic substances to which Alteration, and Re-Ratingof ln-Service workers may be exposed without protection (for example, Piping Systems respirators). Exposure limits are usually expressed in parts Std 2015 Cleaning Petroleum Storage Tanks per million or milligrams per cubic meter. Material Safety RP 220 Procedures for Welding or Hot Tapping on 1 Data Sheets (MSDSs) from the manufacturer or supplier of Equipment in Service the material should list exposure limits as established by Publ 2202 Dismantling and Disposing of Steel From OSHA or other organizations (See 1.2.4.1 and 1.2.4.2). Tanks WhichHaveContainedLeaded 1.2.4.1 Permissible exposurelimits (PELS)are federal Gasoline regulations set by the Occupational Safety and Health lTLVs is a registered trademark of the American Conference of Govern- Administration, US.Department of Labor, and found at 29 mental Industrial Hygienists. Code of FederalRegulations 1910.1000, and in the *American Conference of Governmental Industrial Hygienists, 6500 Glenway Avenue, Building D-7, Cincinnati, Ohio 452114438, substance-specificstandards which follow. Thelatest 3America.n National Standards Institute, 1430 Broadway, New York, New editions should be consulted. York 10018. 1COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 8. A P I PUBLa2009 95 W 0732290 0550339 77L m 2 API PUBLICATION 2009 Pub1 22 17A Guidelines f o r Work in Inert Confined 1.4 Additional ReferenceMaterial Space in the Petroleum Industry The latest editions of the following are related reference BMUSDI4 materials: Flammability Characteristics o Combustible Gases and f API Vapors, Bulletin 627 Std 2610 Design,Operation, Construction, Mainte- NFPA5 nance, and Inspection o Terminal and Tank f 10 Portable Fire Extinguishers Facilities 325M Fire Hazard Properties of Flammable NFPA 30 Flammable and Combustible Liquids Code Liquids, Gases, and Volatile Solids 5 1B Cutting and Welding Processes OSHA6 29 Code of Federal Regulations, Sections: 1.5 General Precautions 1910.119 Process Safety Management of Highly Gas and electric cutting and welding operations are impor- Hazardous Chemicals tant adjuncts to petroleum operations and require a high 1910.146 Permit-Required Confined Spaces degree of skill. Personnel engaged these operations should in 1910.147 The Control of Hazardous Energy have a thorough understanding of the duties they are to perform and the potential hazards to guard against. These (Lockouflagout) personnel shall be qualified and properly instructed to ensure 1910.251 Welding, Cutting, and Brazing that safe work procedures are followed. In all welding and 1910.1000 Air Contaminants cutting operations, the welder andother personnel related to 1926.32 Definitions the job shall be briefed on the health and safety aspects of 1926.350 Gas Welding and Cutting their specific jobs before any work is started, so that they 1926.354 Welding, Cutting, and Heating in Way of will follow safe work practices and facility procedures, Preservative Coatings including emergency response. SECTION 2 4 O B ANALYSIS AND SPECIAL PRECAUTIONS 2.1 Job Analysis conducted. Normally, the work area should be hydrocarbon vapor and gas free. Under permit conditions, however, hot Permits should be used to authorize and control all hot work may be performed on equipment in service with hydro- work. To determine the appropriate safeguards and required carbon vaporsor gases present, provided that hot workis (a) persona protective a be performed in an oxygen deficient atmosphere, such as in an made Of the potentia hazards and the perations to be inerted space, or (b) hydrocarbon vapors or gases are Performed Prior to This can be controlled so as to remain within predetermined percent of a Part Of the perrmit Procedure. Some Of the factors that the LFL, or (c) the

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 18 of 45

equipment is in a well-ventilated area, be considered in the pre-job safety planning are and Precautions have been taken to ensure there is no accu- described in 2.2 through 2.5. mulation of hydrocarbon vapors or flammable gases to or create an explosive atmosphere major fire hazard. In addi- 2.2 General tion, precautions should be taken to prevent burn-through Precautions shall be taken prevent uncontrolled ignition to (see API RP 2201). of flammable or combustible materials. With proper proce- Before weldingor cutting is performed above or near oily dures, restricting access to the work area, issuance and surfaces, the area should be flushed with water, steam posting ofdetailed permits as appropriate, and adherence to cleaned, or covered with cleandirt or sand, or other precau- site-specific safe work conditions, hot work can be safely tions should be taken. Holes the ground or cracks in pave- in ment should be similarly flushed or covered. All sewer 4Bureau of Mines, U.S. Department of the Interior, Ffammabilify Charac- manholes and catch basins in the vicinity of the work area teristics of Combustible Gases and Vapors by Michael G . Zebetakis, should be covered to prevent hydrocarbon vapors or gases Bulletin 627. 1965, is available through the Bureau of Mines, Washington, D.C. from exiting the sewer or drain and reaching an area of hot 5National Fire Protection Association, Batterymarch Park, Quincy, work, or to prevent sparks from getting into the sewer. If a Massachusetts 02269-9990. catch basinis equipped witha trap, the basin may be contin- Qccupational Safety and Health Administration,U.S. Department of Labor. The Code of Federal Regulations (CFR) is available from the US.Govern- uously flushed with water.If sewer manholes or drains are ment Printing Office, Washington, D.C. 20402. covered in preparation for hot work, the covers must beCOPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 9. S F WELDING, AE CUlTING, AND OTHER HOTWORK PRACTICES IN REFINERIES, PLANTS, AND PETROCHEMICAL PLANTS GAS 3 or at removed when the work has been completed the end of tended oxygenlacetylene hose attached to a torch in a the day or shift (if the work is notcompleted) and replaced confined space could increase oxygen or flammable gas when work startsagain. If wood scaffolding or other concentrations as a result of a leak. combustibles are in use, appropriate precautions should be c. Care should be taken to ensure that exhaust fumes from taken to protect them against ignition. internal combustion engines, such as welding machines, generators, or vehicles, do not contaminate confined spaces. 2.3 Wind If airsupplied or self-contained breathing apparatus Hot work should not be permitted in areas into which (SCBA) for respiratory protection is not required, precauflammablevaporscould be blown, forexample, from tions must be taken ensure that the atmosphere will at all to leaking process piping or equipment in adjacent areas or in times meet the following conditions when personnel are the event of a pressure-relief valve discharging into the present: atmosphere. Wind can carry sparksand embers from the also a. An oxygen content, by volume, of at least 19.5 percent hot work into adjoining process areas and ignite any vapors and no more than23.5 percent. leaking from flanges, valve packings, sewer catch basins, b. Concentrationsof toxic vaporsand gases below theestab- vents, gauging hatches, and so forth (see 2.6). lished exposure limit (see 1.2.4 and Section 8). 2.4 FlammableLiquids,Vapors,Solids, 2.6, Fire WatchPersonnel or Dusts Properly trained and equipped fire watch personnel shall Hot work should not be permitted while adjacent equip- be required whenever hot work is performed in locations ment thatcontains flammable liquid, vapor, solids, or dust is where flammable vapors or gas may be present, where fire being opened, disassembled, steamed, ventilated, or flushed might develop from combustible liquids or Class A (as of sediment without considering how such actions might defined in NFPA 10) materials, or when special conditions affect the hot work,or visa versa. Attention shouldbe given may warrant the use of fire watch personnel. The person todrums or otherportablecontainers which contain assigned to a fire watch shall have no other duties that would flammable or combustible materials. Hot work performed in distract from the primary safety function. One should areas where tanks are receiving flammable liquids or gases consider having fire watcher personnel wear special vests or should be continuously monitored to ensure that the atmo- clothing so that they can be

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 19 of 45

easily recognized. sphere is safe. In areas where hot work is approved, opera- Fire watch personnel shall have theappropriate fire extin- tors mustnot release flammable liquids or vapor until the hot guishing equipment readily available and shall be trained in work has stopped. the equipments use. They shallfamiliar with facilities for be sounding an alarm in the eventof a fire. They shall watch for 2.5 Hot Work in Confined Spaces fires in all exposed areas, try to extinguish them only when If hot work requires entry into a confined space, the obviously within the capacity the equipment available, or of permit system should address both the hazardsof entry and otherwisesound the alarm. completion After of of doing hot work in a confined space. Also, OSHA-permit weldingkutting, the fire watch shallbe maintained until the required confined-space procedures may apply (see API area hasbeen inspected and found be free of fires or smol- to Pub1 2217A and OSHA, CFR 1910.146).With the excep- 29 dering materials. tion of inert spaces, the concentration of flammable vapors present must always be less than 10 percent of the LFL, 2.7 Welding Machines regardless of the type of respiratory protection required in Welding machines can be an ignition source and must be order to permit entry. Note the following: treated as such. Care must be taken to ensure that welding a. Special precautions must taken in the event that oxygen be machines and leads are properly grounded to avoid stray levelsincreaseabove23.5percent,asthisaffects the currents, and that the welding machine and the grounding flammable limits of any materials present, and the LFL will free connection are located an area of flammable vapors or in be lowered. gases. Welding machines shouldbe inspected before use to b. Provisions should also be made to ensure that adequate ensure that there are no frayed or broken wires, all connec- ventilation is provided to each welder and that cutting or tions are tight, and the machinefunctions properly. Welding welding operations inside a confined space do not create a leads should be protected from chaffing when passing hazard to personnel (see OSHA, 29 CFR 1910.252 and through openings, across access ways, and so forth.- ANSI 249.1). For example, burning could deplete the 2.8 EquipmentWithLiners- oxygen in a confined space, and welding or cutting exotic metals or surfaces which are galvanized or lead contami- Careful inspections must be performed and special nated couldcreate a toxic atmosphere. Also, leaving an unatprecautions taken on any vessels, tanks, piping, or otherCOPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 10. A P I PUBLa2009 95 0732290 0550343 32T m 4 API PUBLICATION 2009 equipment which is lined and which could have void layers. This includes tanks with double bottoms, fiber- spaces (for example, vessels with stainless steel liners) to glasslined tanks, double-walled tanks and piping, and the ensure that no product or vapors are trapped between the like. SECTION 3-HOT WORK PERMITS General 3.1 person issuing the permit and the permit recipient (who in A written hot work permit system should be used to control some instances may a contract worker). be all hot work within units usedprocess or store flammable to or k. The time and date the permit was issued. combustible materials. Authorization of those hot work If hot work is to be performed in a confined space, the permits should be vested the personnel in charge of oper- in confined space permit should supplemented or combined be ating such process or storage equipment. Operations personnel with a hot work permit. should immediately notify workers engaged in hot work if Once the safe work procedures and permit requirements actual or imminent changesin conditions (for example, a and conditions have beendetermined, and before thepermit release of material frompressure-relief valve) may endanger is issued, a careful analysis and inspection shall be made, a their safetyso that the hot work be stopped at once. can including oxygen and flammable vapor tests, to determine that unconfined flammable vapors or gases or combustible 3.2Permit Requirements materials are not present the work area or equipment and in Except in areas specifically designated as safe for hot that no reasonable probability exists of any such material work, suchas maintenance welding shops or outlying fabrientering the area while hot work is performed. The autho- cating areas, a permit shall be obtained before starting any rizing individual, who must a competent person, be may then work that can involve a source of ignition. (Equipment such issue a permit for the work to proceed. If several work as vessels and piping should be gas free and cleared of

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 20 of 45

toxic groups are involved in the work process, the permit system substances and liquid hydrocarbons before being brought should ensure adequate communication. A copy of the into weld shops or the designated safe areas.) Each permit permit shall be kept on site until the work is completed. for hot work should state precautions necessary for the OSHA standards (29 CFR 1910.147) addressspecific specific job. The permit shall be in writing and should requirements for written procedures associated with locking include the following information and conditions: out and tagging out equipment and other energy sources. The permit processshouldindicate who isresponsible for a. The equipment to be worked on and the location of work. inspecting the work site,conductinggastesting,and b. The type of work to be performed (for example, cutting, approving the permit allowing hot work to proceed. welding, grinding). c.Theprotectiveequipment and protective measures CAUTION: The fact that a permit has been issued for the required, including rescue equipment for work in confined performance of certain work in no way relieves those doing spaces. the work of their responsibilities the safe execution of the for d. Standby fire protection equipment and/or personnel assigned taskin accordance with the permit requirements. If required. any unsafecondition arises, work should be stopped and the e. The permits expiration date and time. condition reported immediately. f. The aredequipment required to be tested with an oxygen and combustible gas detector and, if required, tested for 3.3Extending the Permit toxics, plus the test results. When it is necessary to continue the work beyond the g. Whether continuous monitoring is required. designated time, the authorizing individual on each h. Any special precautions which are necessary to complete succeeding dayor shift shall ensure that conditions are satis- the job safely, including conditions for stopping work. factory for work to continue and may then reissue the permit; I. Indication that affected personnel have been notified. if conditions have changed, it may be necessary to issue a j. Signatures of authorized individuals, that is, at least the new permit or amend the existing permit.COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 11. A P I PUBLU2009 95 0 7 3 2 2 9 0 0550342 266 SAFE WELDING, CUlTING, AND OTHER HOT WORK PRACTICES IN REFINERIES, PLANTS, AND GAS PETROCHEMICAL PLANTS 5 SECTION &TESTING FOR FLAMMABLE VAPOR AND OXYGEN A competent person using appropriate combustible-gas an unit shutdowns.Such oils that may be heated during the hot detector should perform tests to determine flammable vapor work process constitute a hazard and must be removed concentrations before hot work is started. The combustible before cutting or welding isstarted. Detector tests should be gas detector mustbe properly maintained, adjusted, cali- and conducted only after steaming operationshave been brated. The surroundingarea and equipment andcontainers completed so that steam vapors will longer affect detector no that might contain flammable vapors must be thoroughly results. Nitrogen, argon, hot gases may affect some types and checked, evenif such equipment has been steamed, flushed, of combustible-gas instruments, possibly resultinginaccu- in or otherwise cleaned. Most hydrocarbon vaporsare heavier rate readings. Anytime a tank, vessel, or piping has been than air. Gas testing should include all low points such as purged with or has contained an inert gas (for example, sumps, drains, liquids boots, and so on, and all confined nitrogen, argon), or anytime the possibility exists for an areas, such as floating roof pontoons on aboveground oxygenenriched or oxygen-deficient atmosphere above or storage tanks, piping, vessels, and the like. Long runs of below the amount requiredby the instrument manufacturer piping should be tested at multiple locations. to give a correct reading-an oxygen reading must be taken A combustible-gas detector may not detect the presence of using a properly maintained and adjusted oxygen meter oils with flash points substantially above ambient tempera- before the flammable vapor test. Consult the instrument tures, suchas those sometimes found in catalyst beds during manufacturers literature for further information. SECTION 5-PROTECTION OF PERSONNEL Appropriate steps must be taken during hot work opera- sible Exposure Limits andor Threshold Limit Values, should tions to protect personnel from potential and actual safety be implemented as appropriate.Note: A flammable vapor or and health hazards such the following: as gas

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 21 of 45

concentration less than 10 percent LFL provides no a. Skin burns from sparks, slag, and thelike. assurance that exposures certain materialswill be less than to b. Ultraviolet light rays fromelectric welding. their PELs(for example, benzene, lead, total hydrocarbons). c. Welding fumes. toxicity of welding fumes depends on The Specialized monitoring and testing for these types of mate- their composition and concentration. The composition and rials are required if possibilities for exposures abovethe quantity of fumes are determined by the materials being PELs exist. welded, the composition of the rods and any coatings or e. Flying particles during chipping and slag removal. paints, the process being used, and circumstances of use. the f. Oxygen deficiency in poorly ventilated spaces. Toxic fumes are generated from welding on metals that are g. Setting combustible materials, oil-soaked insulation or coated withor contain alloys of lead, zinc, cadmium, beryl- workers outer clothing on fire from sparks or slag. lium, chromium, and certain other metals. Some paints may f. Accumulation of flammable vapor or gas. produce toxic fumes when heated. The potential health g. Oxygen or gas from welding equipment leaking into effects vary in type andseverity depending on many factors, confined spaces. and someeffects can be extremelyserious. h. Oxygen content rising unsafe levels in inerted confined to d. Other toxic substances. Atmospheric testing and moni- spaces. toring, along with personal protective equipment or other i. Toxic preservatives which should be stripped away (see means to keep personnel exposures below OSHA Permis- OSHA 29 CFR 1926.354). SECTION &WORK ON VESSELS, EXCHANGERS, AND TANKS 6.1 Preparations connected to the space, or by other approved means. A connection is considered properly blinded when correct the A confined-space entry permit, indicating the require- blind, gaskets, andb o l t s are properly installed to ensure that ments and conditions for entry, shall be issued before any no leakage occurs. The open ends of connecting piping- work is done inside a confined space. Before any work is should be properly blinded, and the vessel should be thor- done inside a vessel, exchanger,or tank, thespace should be oughly cleaned (unlessinerted). [Additional s p i a l precau-- completely isolated from energy and Potential energy tions are necessary the vessel has nonmetallic liner, has an if a sources by blinding, blankingand/or disconnecting alllines internal coating, has been used in leaded gasoline service or orCOPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 12. A P I PUBL*W2009 95 m 0732290 0550343 LT2 m 6 API PUBLICATION 2009 other toxic material service (see API Std 2015 and Pub1 the vessel need not be gas freed if one of the following 2202).] Energized equipment should locked and/or tagged be procedures is employed: out. The vessel should be gas freed, tested for oxygen, then a. In a vessel thatis partly filled with liquid, welding may be tested for combustible gas and/or toxics (unless inerted). done 3 feet or more below level of the liquid if adequate the Appropriate written procedures should be developed and precautions have been taken toprevent burning through the used when conducting such operations. tank or vessel wall. Welding should not be conducted on a partly filled vessel which is double walled and/or which has 6.2 Monitoring and Purging of the an internal lining such as glass, plastic, or alloy until inspec- Atmosphere tion and analysis are made to determine how to perform the Periodic combustible gas and oxygen retests, or contin- work safely. (Important:see API RP 2201, which describes uous monitoring, may be required while hot work is precautions and procedures for hot tapping and welding on a proceeding. If the detector registers an excess or lack of pressurized vessel. Also, see Sections 7 and 8 herein.) oxygen or the presence of vapors in excess of that allowed b. Welding may bepermitted if chemical analysis or other by the permit, work should be stopped immediately, andthe reliable evidence indicates that the petroleum-products source of vapor or oxygen should be located and controlled vessel contains an atmosphere incapable of being ignited (see API Std 2015). because it is too rich or too lean or is non-combustible or For situations where the work in a vessel that has previ- nonreactive and thatadequate precautions have been taken ously beenpronounced gas free is delayed or suspended, the to prevent burning through the vessel wall. permit systemshall specify the lengthof time beyond which Note: If steam is used as a means of displacing oxygen, every part of the detector tests must be repeated. vessel shallbe

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 22 of 45

heated by the steam a temperature of at least to 77C (170T) Before entry and during work, the atmosphere inside the so that the oxygen concentration is reducedto a point at which no ignitable mixture c n be formed. In addition, when steam-inerting, pockets of oxygen a vessel (if notinerted) should be continuously purged-using or vapors maybe present. Visible discharge steam from an opening is insuf- of an appropriate air exchanger-if natural ventilation is inad- ficient evidence that the atmosphere within is not explosive. dioxide, If carbon equate. nitrogen, or another inert gas is used as the displacing medium, it shall be introduced so that the atmosphere in all parts of the vessel is completely displaced. (Carbon dioxide should be introduced using a fixed-pipe system 6.3 Inspection of lnternals electrically bondedto the container to avoid a buildup static electricity or of An inspection should be made to ensure that oil, residue, a staticchargedcloud). The relative weight of the compared with that gas of air must be taken into account. Steam or inertgas shall not be emitted from vapor, and other flammable and combustible materials have vessels or piping inthe vicinity of hot work. The effectiveness of the purging been removed or protected from ignition by sparks or must be determined by chemical analysis. Even if the oxygen content has pyrophoric iron sulfide. This includes areas such as bubble- been reduced to less than 10 percent by volume, it is not to assume that safe the vesseldoes not contain an ignitable mixture example, hydrogens and (for cap trays, weirs, internal pans, vapor seals, double bottoms, carbon monoxides limiting oxygen index less than 10 percent). For more is pontoons, linings, under floors, or roof drain piping. If any precise data, US. Bureau of Mines Bulletin 627 should be consulted. An ordi- doubt exists about the cleanliness of internal equipment, the nary combustible-gas detector can identify the flammable characteristics only of acombustible-gadairmixture. Such a detector cannot accurately measure equipment should removed, be cleaned, or suitably combustible-gadinert-gas mixtures if the oxygen content is below certain protected. levels. Check the manufacturers recommendationsfor proper operation of these detectors under such conditions. 6.4 Work on Outside Surfaces Hot work shall not be performed on one vessel or piece of When hot work is limited to the outside surface of an equipment within a unit while other parts of the same unit empty vessel that has been isolated and gas freed, internal are in operation unless it is determined that no unconfined surfaces in the vicinity ofthe hot work which could become flammable or combustible material is present in the work heated should be cleaned of anyoil, wax, or pyrophoric iron area and that no reasonable probability exists of any such sulfide deposits, prior to starting hot work. In all cases where material entering the area while hot work is being done. hot work is being done on the outside surface of a vessel, Precautions could include isolating the vessel or equipment adequate provisions, such as venting, should be made to from the remaining Units, covering common drains, and/or protect against overpressure due to thermal expansion of the keeping a steady flow of water any adjacent leaks, flows, on contents. or drips that couldresult in flammable vapors. If welding is to be done on the outsidesurface of a vessel, Hot work shall not be performed on vessels under and if thearea is otherwise safe for the useof an openflame, vacuum, unless anengineering evaluation is performed.COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 13. ~ A P I PUBLX2009 95 m 0732290 0550344 039 m CUTTING, OTHER WORKPRACTICESREFINERIES, PLANTS, PETROCHEMICAL WELDING, SAFE AND HOT IN GAS AND PLANTS 7 SECTION 7-WORK IN BUILDINGS AND PITS Precautions should be taken when hot work to be done is gases or vapors are eliminated and appropriate toxic gas in buildings such as compressor rooms, manifold and pump and/or combustible-gas tests show that the area is safe for houses, pits, receiving houses, and blending and container hot work.Air movers, approved for service in hazardous filling rooms while any equipment within these areas or locations, may be used to assist in ventilation. Confined buildings is in operation. If hot work is done within build- space permit and work requirements shall followed if safe be ings or pits, the equipment to be worked onshall be isolated applicable. Any combustible materials shall be protected or and freed from gas and oil. If necessary, other equipment moved to another area if there is any chance of heat transfer shall be depressurized. The

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 23 of 45

area shall be ventilated until or contact withsparks or hot slag. SECTION &-WORK ON PIPING The need to free piping of flammable gases or liquids strict precautions both in preparation and in execution to should be determined the same basis for vessels. The on used avoid burning through the pipe wall. These precautions presence of flammable vapor can be established with a prop include determining that (a) the area is safe for an open erly calibrated combustible-gas detector. Periodicretests or flame, (b) the pipe wall is sound and sufficiently thick, (c) continuousmonitoring may be necessary as the work there isa minimum flowfor heat dissipation, where required, proceeds. hazardous Other materials example, (for and (d) the methods, tools, and equipment are safe and combustible liquids, corrosives, or toxics) may be present proper. Please note, however, that providing necessary tech- which could be harmful to personnel performing the work. nical information and recommended procedures for welding Appropriate precautions must taken to monitor exposures be on equipment in service is beyond thescope of this publica- and to protect personnel. RP tion (see API 2201 for more information on this subject). or An important precaution before welding cutting piping API Pub1570 contains information on repairs, alterations, is to properly isolate the piping, (for example, blinding, and rrating of in-service pipingsystems. disconnecting, or double blocking and bleeding). The type of Preservative coatings another are important issue isolation used will depend on the contents, pressure, or involving welding, cutting, and heating pipes and other piping configuration.A single valvemay be used, depending surfaces. OSHA describes the precautions that should be on conditions und i f isolation is not required (for example, taken for preservative coatings in 29 CFR 1926.354. The welding on inert gas piping, water lines, units outservice, of standard requires that when welding, cutting, or heating a and so on). However, under the confined space standard (29 surface witha preservative coating, a test shall be madeby a CFR 1910.146), a single closed valve is not approved as a competent personto determine the coatings flammability if means of isolation underOSHA. In addition, adequate provi- the flammabilityis not already known. Further, OSHA states sions, such as venting, should be made to protect against that when coatings are determined to be highly flammable, overpressure due to thermal expansion of the contents. The they shall be stripped from the areato be heated in order to actual determination that a pipe is safe, is a step-by-step prevent ignition. In enclosed spaces, all surfaces covered procedure that must followed closely prior to issuing be a hot with toxic preservatives shall be stripped of all toxic coatings work permit. for a distance of at least 4 inches from the of heatappli- area Piping that has contained compressed air from a lubri- cation, or the employees shall be protected air line respi- by cated compressor may have an internal filmof oil. Welding rators. Also, the preservative coatings shall be removed a should not begin until theoil film has been removed or the sufficient distance from the area to be heated to ensure that pipe inerted. the temperature of the unstripped metal will not be appre- Under certain conditions, it may be necessary to weld on ciably raised. Artificial cooling of the metalsurrounding the or hot tap a pipe while theline is in operation. This work can heating area may used to limit the size of the area required be be performed safely provided that qualified personnel take to be cleaned. SECTION 9 4 T H E R WELDING WORK It is an accepted practice to repair certain leaks (such as on while the unit remains operation. Such repairs are accom- in the Catalystsection of Fluid CatalyticCracking Unit plished by welding on patch platesandor using a prefabri(FCCU)) on hydrocarbon lines, vessels, other equipment and cated enclosure.COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 14. 8 API PUBLICATION 2009 Small leaks can be safely repaired when proper precau- Factors to consider regarding the on-stream repair deci- tions are taken. Larger leaks may require more elaborate sionprocess and precautions to be taken includethe procedures, suchas the use of nitrogen to flush or liquids gas following: away from the leak through a line to a discharge location a. Compliance with company policy and permit procedures. remote from the point of welding. exact techniquesvary The b. Needs for oxygen and gas tests. considerably as there are many considerations involved, c. Monitoring for toxic materials. including the size and location of the leak, piping

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 24 of 45

contents, d. Size and locationof the leak. the configuration of the equipment, operating pressures, and e. Location, length, and depth of the crack. so forth. f. Whether the crack is in the parent metal, weld, heat- It is essential that whatever repair procedures are used, affected zone, or all three. appropriate precautions are taken to ensure the safety of all g. Metal thickness. personnel involved, and that written procedures exist or are h. Size and proximityof weld or heat-affected zone. developed priorto performing such operations. briefing to A i. Amount of possible thinning due to corrosion or erosion. review the procedures should occur prior to the start of the j. Needs for inerting. job, and a hot work permit issued consistent with OSHA k. Nature of PWHT requirements, if any. requirements, for example, 29 CFR 1910.119. Important: See API RP 2201 for more information.COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 15. A P I PUBL*2009 95 m 0732290 0550347 848 m 1-0832&9/95-1 M ( l E) COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services 16. A P I P U B L X 2 0 0 9 95 m 0732290 0550351 279 m American Petroleum Institute 1220 L Street. Northwest Order No. K20096COPYRIGHT American Petroleum InstituteLicensed by Information Handling Services

Search

Connect on LinkedIn Follow us on Twitter Find us on Facebook Find us on Google+ Learn About Us About Careers Our Blog Press Contact us Help & Support Using SlideShare SlideShare 101 Terms of Use Privacy Policy Copyright & DMCA Community Guidelines SlideShare on mobile Pro & more Go PRO New Business Solutions Advertise on SlideShare Developers & API Developers Section Developers Group Engineering Blog Blog Widgets 2013 SlideShare Inc. All rights reserved. RSS Feed ENGLISH English Franais Deutsch

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 25 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 26 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 27 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 28 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 29 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 30 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 31 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 32 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 33 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 34 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 35 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 36 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 37 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 38 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 39 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 40 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 41 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 42 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 43 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 44 of 45

/16

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

Download

Page 45 of 45

http://www.slideshare.net/ctvb90/download-13289299

22/01/2013

También podría gustarte

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryCalificación: 3.5 de 5 estrellas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Calificación: 4.5 de 5 estrellas4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe EverandGrit: The Power of Passion and PerseveranceCalificación: 4 de 5 estrellas4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe EverandNever Split the Difference: Negotiating As If Your Life Depended On ItCalificación: 4.5 de 5 estrellas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe EverandThe Little Book of Hygge: Danish Secrets to Happy LivingCalificación: 3.5 de 5 estrellas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaCalificación: 4.5 de 5 estrellas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeCalificación: 4 de 5 estrellas4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDe EverandRise of ISIS: A Threat We Can't IgnoreCalificación: 3.5 de 5 estrellas3.5/5 (137)

- Her Body and Other Parties: StoriesDe EverandHer Body and Other Parties: StoriesCalificación: 4 de 5 estrellas4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreCalificación: 4 de 5 estrellas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyCalificación: 3.5 de 5 estrellas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersCalificación: 4.5 de 5 estrellas4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe EverandShoe Dog: A Memoir by the Creator of NikeCalificación: 4.5 de 5 estrellas4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe EverandThe Emperor of All Maladies: A Biography of CancerCalificación: 4.5 de 5 estrellas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe EverandTeam of Rivals: The Political Genius of Abraham LincolnCalificación: 4.5 de 5 estrellas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceCalificación: 4 de 5 estrellas4/5 (895)

- The Perks of Being a WallflowerDe EverandThe Perks of Being a WallflowerCalificación: 4.5 de 5 estrellas4.5/5 (2104)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureCalificación: 4.5 de 5 estrellas4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe EverandOn Fire: The (Burning) Case for a Green New DealCalificación: 4 de 5 estrellas4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Calificación: 4 de 5 estrellas4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe EverandThe Unwinding: An Inner History of the New AmericaCalificación: 4 de 5 estrellas4/5 (45)

- Material Safety Data Sheet: Diesel Fuel No. 2Documento9 páginasMaterial Safety Data Sheet: Diesel Fuel No. 2bunker44Aún no hay calificaciones

- CBC - Hairdressing NC II - Amended 04-13-2011Documento96 páginasCBC - Hairdressing NC II - Amended 04-13-2011krizv_2813100% (2)

- Production of Silica Gel From Rice HuskFULLDocumento82 páginasProduction of Silica Gel From Rice HuskFULLNez Ardenio50% (2)

- MSDS Benzene PDFDocumento6 páginasMSDS Benzene PDFPiyu SyahputraAún no hay calificaciones

- ISO 7243 (Heat Stress)Documento12 páginasISO 7243 (Heat Stress)ch_ahmedfouad3431100% (1)

- 16 Point Msds Format As Per ISO-DIS11014 PDFDocumento8 páginas16 Point Msds Format As Per ISO-DIS11014 PDFAntony JebarajAún no hay calificaciones

- Spray Paint MsdsDocumento4 páginasSpray Paint MsdsHillary RyanAún no hay calificaciones

- ABBREVATIONDocumento5 páginasABBREVATIONAsad AwanAún no hay calificaciones

- 856 Neutral OA Flux (10-10)Documento10 páginas856 Neutral OA Flux (10-10)irish634Aún no hay calificaciones

- Gunk Heavy Duty Gel Engine DegreaserDocumento11 páginasGunk Heavy Duty Gel Engine DegreaserYoutube For EducationAún no hay calificaciones

- Thermaline 4700 Alu MSDSDocumento10 páginasThermaline 4700 Alu MSDSTATIANAAún no hay calificaciones

- Exemestane Tablets - MSDS PDFDocumento10 páginasExemestane Tablets - MSDS PDFMostofa RubalAún no hay calificaciones

- Maleic Anhydride MSDS: Section 1: Chemical Product and Company IdentificationDocumento6 páginasMaleic Anhydride MSDS: Section 1: Chemical Product and Company IdentificationFábio BrancoAún no hay calificaciones

- MsdsDocumento6 páginasMsdsRizki Adwitiyo 'Dito'Aún no hay calificaciones

- 141 MsdsDocumento14 páginas141 Msdsivan_kenzo1290Aún no hay calificaciones

- Material Safety Data Sheet: Section I. Material IdentificationDocumento2 páginasMaterial Safety Data Sheet: Section I. Material IdentificationtamAún no hay calificaciones

- MSDS - AgNO3Documento6 páginasMSDS - AgNO3Fischer01Aún no hay calificaciones

- Safety Data Sheet: GraniteDocumento8 páginasSafety Data Sheet: GraniteAzuan MABKAún no hay calificaciones

- Safety Data Sheet: Liquid Fire Starting FluidDocumento10 páginasSafety Data Sheet: Liquid Fire Starting FluidPubcrawlAún no hay calificaciones

- Mil STD 1472eDocumento209 páginasMil STD 1472ebarreto104Aún no hay calificaciones

- Material Safety Data Sheet: AcetoneDocumento6 páginasMaterial Safety Data Sheet: AcetonefructoraAún no hay calificaciones

- MsdsDocumento7 páginasMsdsLorenzo L. BastosAún no hay calificaciones

- Dose Response PDFDocumento6 páginasDose Response PDFjohnrey_lidresAún no hay calificaciones

- DIETHYL ETHER Nios Lcss IcscDocumento9 páginasDIETHYL ETHER Nios Lcss IcscdwiAún no hay calificaciones

- Pom Tenac-C 3510Documento11 páginasPom Tenac-C 3510Medio AmbienteAún no hay calificaciones

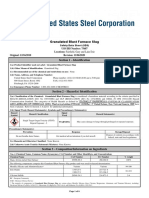

- Granulated Blast Furnace Slag SDSDocumento6 páginasGranulated Blast Furnace Slag SDSBa Nguyễn VănAún no hay calificaciones

- Solvente Mutual ChevronDocumento12 páginasSolvente Mutual Chevronjcamacho95Aún no hay calificaciones

- Unsw Ume m2 Environcontam NotesDocumento106 páginasUnsw Ume m2 Environcontam Noteskrainajacka100% (1)

- Sika® Watertight Concrete Powder: Safety Data SheetDocumento10 páginasSika® Watertight Concrete Powder: Safety Data Sheet4919404Aún no hay calificaciones

- Somatropin For Injection: Section 1 - Chemical Product and CompanyDocumento8 páginasSomatropin For Injection: Section 1 - Chemical Product and CompanyRima Puspita RahayuAún no hay calificaciones